Method for rapidly detecting oxygen vacancy in titanium oxide

A technology of titanium oxide and oxygen vacancies, which is applied in the direction of chemiluminescence/bioluminescence, and analysis by making materials undergo chemical reactions, can solve the problems of high cost, long time consumption, and high requirements, and achieve short reaction time, simple equipment, and methods easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

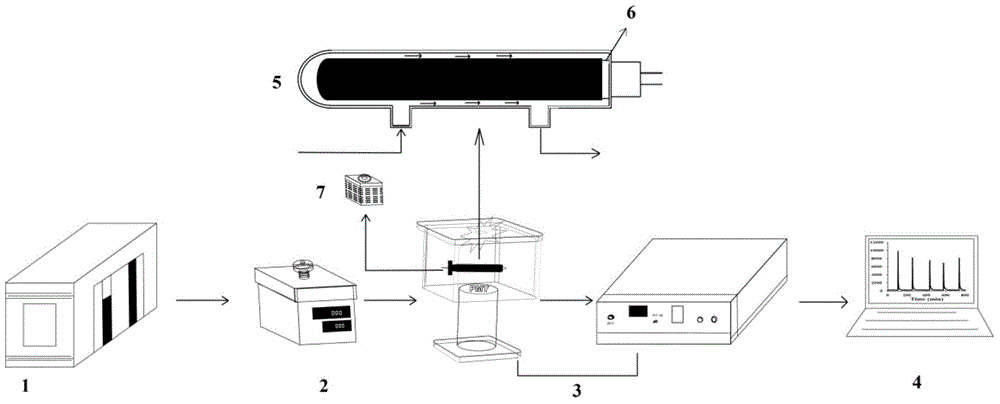

[0021] use figure 1 The experimental setup.

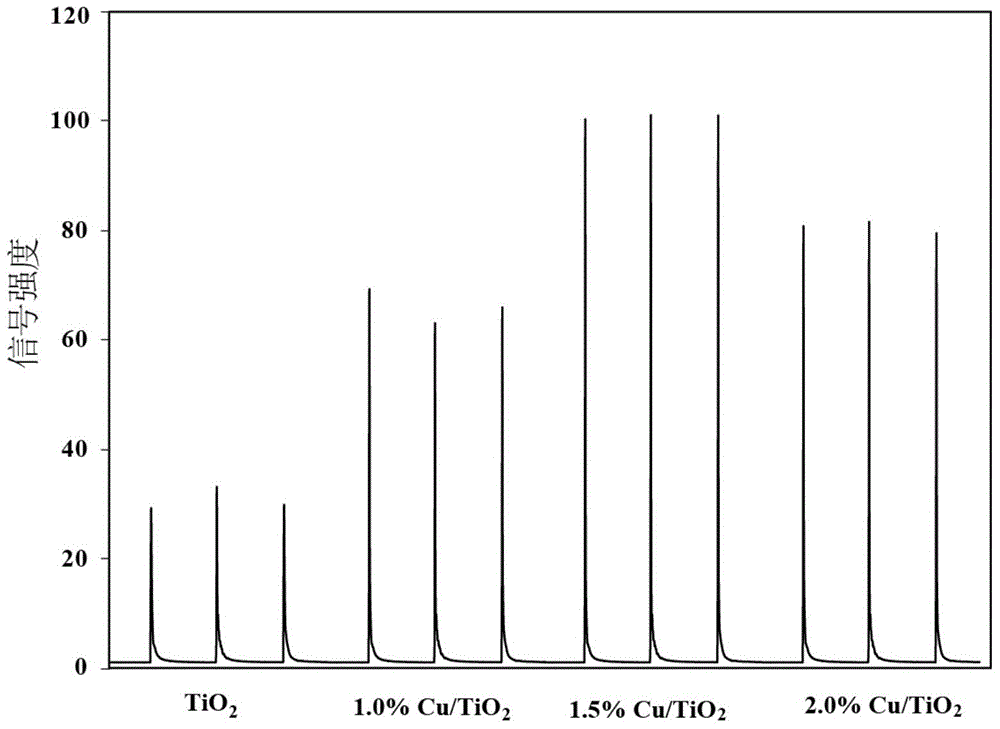

[0022] A. Take undoped TiO 2 and 1.0%, 1.5%, 2.0% Cu-doped TiO 2 Add the powder into deionized water and stir evenly to make a 0.50g / mL slurry; apply it on the ceramic rod with a thickness of about 0.50mm, insert the ceramic rod into the quartz tube, apply a voltage of 105V to the ceramic rod, and then Use the air treated with silica gel and activated carbon in the air pump as the carrier gas for the reaction to ventilate for 30 minutes, and the gas flow rate is 250mL / min. When the temperature of the ceramic rod reaches 170°C, start the heating device of the vaporization chamber until the temperature of the vaporization chamber is 170°C. ℃. Ensure the stable operation of the chemiluminescence analyzer.

[0023] B. Inject 25 μL of 0.1mol / L ether solution into the vaporization chamber, and the air from the air pump is loaded into the quartz tube and Cu / TiO on the ceramic rod 2 The surface reacts with the oxygen chemisorbed on th...

Embodiment 2

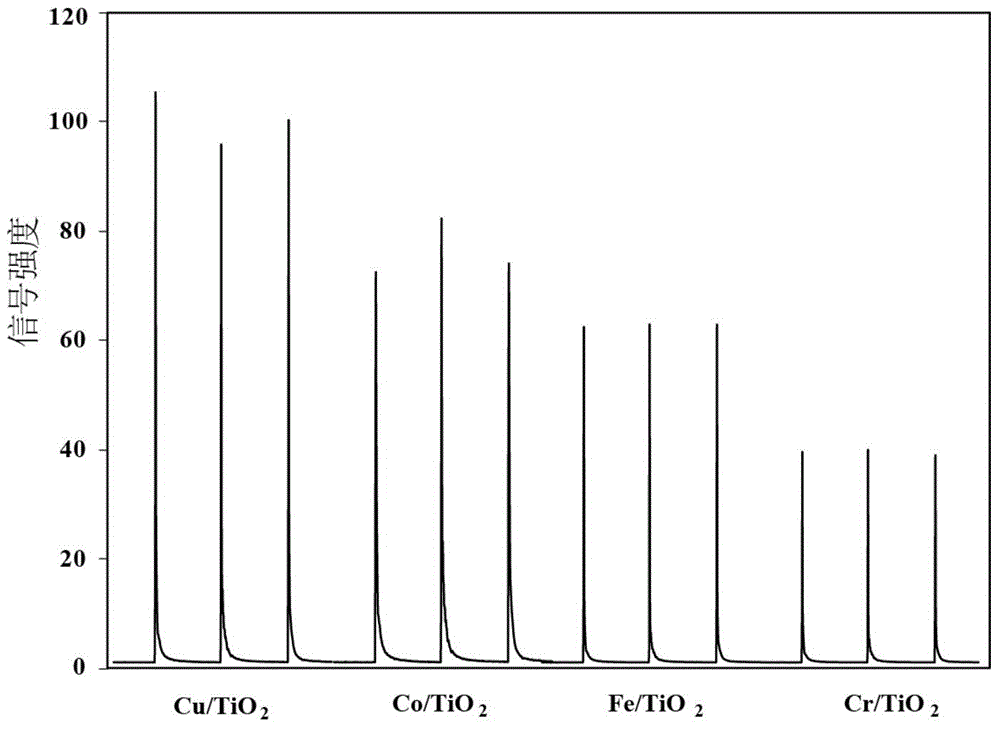

[0034] TiO doped with Cu, Co, Fe, Cr four metal ions with a mass fraction of 1.0% 2 . Other steps are with embodiment 1, test result sees image 3 , the strength of the chemiluminescent signal is: Cu / TiO 2 >Co / TiO 2 >Fe / TiO 2 >Cr / TiO 2 .

Embodiment 3

[0036] With the undoped TiO in embodiment 1 2 The powders were calcined at 250°C, 300°C, 350°C, and 400°C for 2 hours under a hydrogen atmosphere, and the obtained samples were designated as H-250, H-300, H-350, and H-400. Other steps are with embodiment 1, test result sees Figure 4 , the strength of the chemiluminescent signal is: H-400>H-350>H-300>H-250.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com