Titanium sesquioxide and preparation process and application thereof

A technology of titanium dioxide and preparation process, applied in the direction of titanium oxide/hydroxide, low-value oxide of titanium, etc., can solve the problems of high consumption of raw material hydrogen, long reaction time, high raw material cost, and reach a large market Prospect and application value, low requirements for production equipment and production environment, and the effect of shortening the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation technology of titanium dioxide of the present invention comprises the following steps:

[0030] a. Mix titanium dioxide and silicon powder according to the weight ratio of 1:0.25 to 0.5, and shape them to obtain molding materials; wherein, titanium dioxide and silicon powder are preferably high-purity titanium dioxide and high-purity silicon powder, and are preferably in a weight ratio of 1:0.25~ 0.4 mixing, more preferably mixing at a weight ratio of 1:0.3; making the mixed powder into a molding material can increase the reaction contact area between silicon powder and titanium dioxide and improve the reaction kinetics conditions;

[0031] b. Evenly cover the surface of the molding material obtained in step a with silicon powder, heat it to 1400-1500°C in an air atmosphere, keep it warm for 5-25 minutes, cool, and ball mill to obtain a reduced product; the role of the silicon powder covering is to insulate The effect of air prevents the product from bei...

Embodiment 1

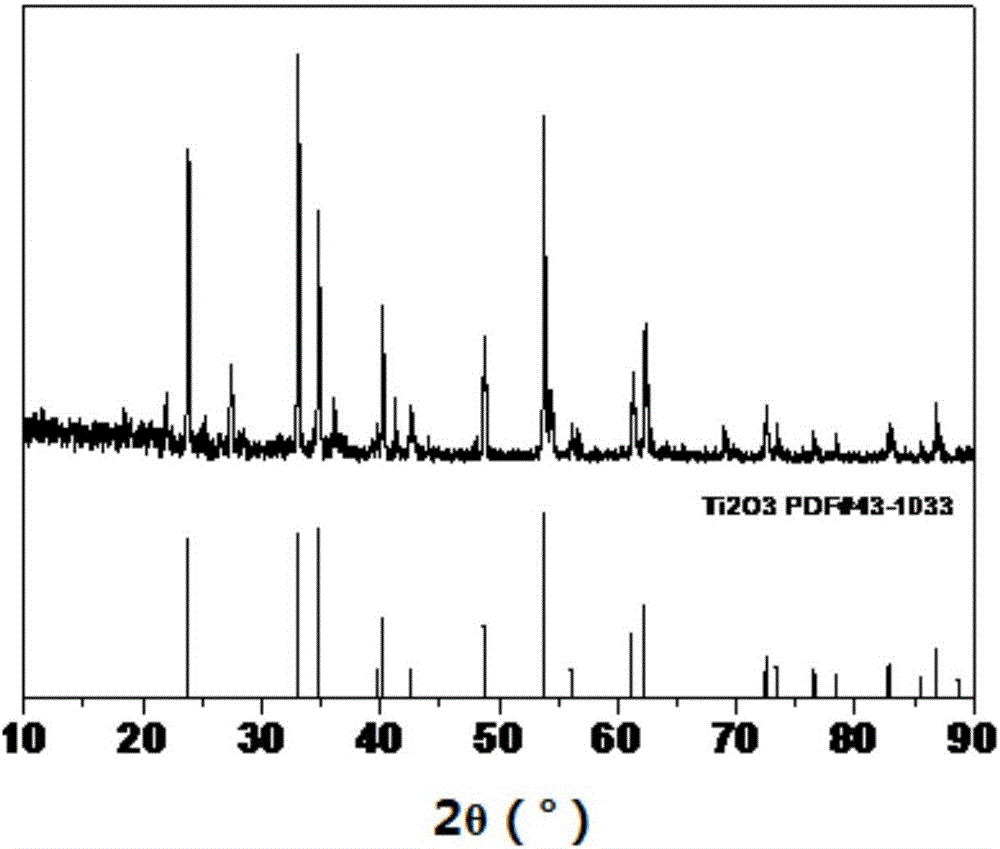

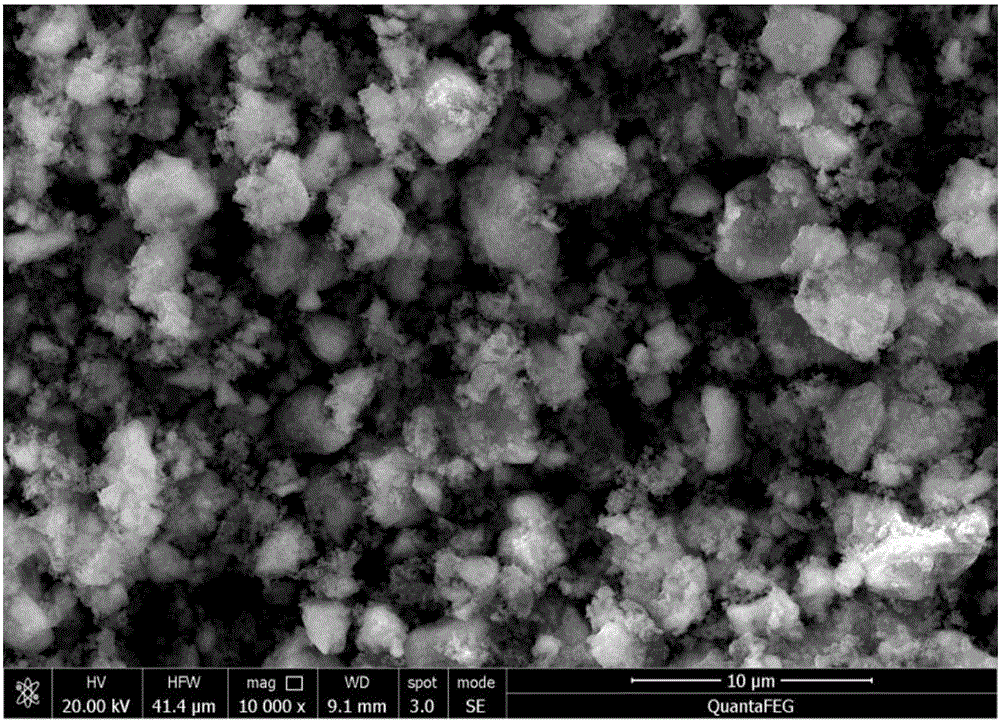

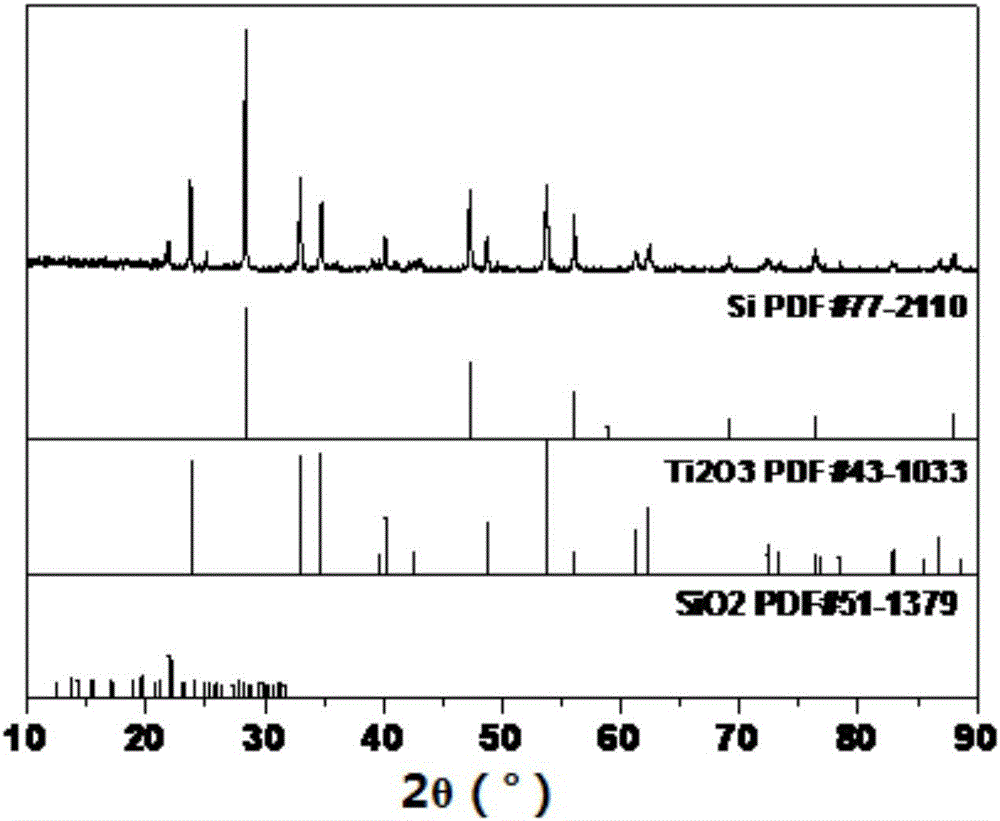

[0046] Take 100g TiO 2 , 25g silicon powder (TiO 2 The particle size of silicon powder and silicon powder are all less than 10 μm, and the impurity content is all less than 1wt%), mix uniformly and press into a block, put the mixture block into a crucible, and evenly cover the surface of the material with silicon powder (silicon powder thickness 0.5cm), Then put it into a high-temperature furnace, and reduce it at a reduction temperature of 1450°C for 20 minutes in an air atmosphere. After the reduction time is reached, quickly take out the crucible and pour the material into graphite powder for protection, cool to room temperature, and ball mill the reduction product. The obtained intermediate product is silicon-silicon dioxide-titanium trioxide composite material; alkali leaching is carried out on the material after ball milling with sodium hydroxide, the leaching temperature is 90°C, the leaching time is 120min, the solid-liquid ratio is 1:9g / mL, hydrogen The concentration...

Embodiment 2

[0050] Take 100g TiO 2 , 40g silicon powder (TiO 2 The particle size of silicon powder and silicon powder are all less than 10 μm, and the impurity content is all less than 1wt%), mix uniformly and press into a block, put the mixture block into a crucible, and evenly cover the surface of the material with silicon powder (silicon powder thickness 0.5cm), Then put it into a high-temperature furnace, and reduce it at a reduction temperature of 1430°C for 25 minutes in an air atmosphere. After the reduction time is reached, quickly take out the crucible and pour the material into graphite powder for protection, cool to room temperature, and ball mill the reduction product. The obtained intermediate product is silicon-silicon dioxide-titanium trioxide composite material; alkali leaching is carried out on the material after ball milling with sodium hydroxide, the leaching temperature is 80°C, the leaching time is 80min, the solid-liquid ratio is 1:10g / mL, hydrogen The concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com