Ag-embedding titanium oxide-bamboo charcoal composite powder and preparation method thereof

A technology of silver-loaded titanium dioxide and composite powder is applied in the fields of botanical equipment and methods, chemicals for biological control, animal repellents, etc. The effect of low cost, simple reaction process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Porous bamboo charcoal pretreatment: choose 450 mesh bamboo charcoal, first boil the bamboo charcoal with deionized water for 30 minutes, then wash and filter with deionized water, repeat this 3 times, remove the dust and surface residues in the bamboo charcoal, keep the temperature at 105°C Dry in a drying oven for later use.

[0036] Disperse 2.5g of silver-loaded titanium dioxide in deionized water. In the silver-loaded titanium dioxide, the mass ratio of silver to titanium dioxide is 2:100. Under an ultrasonic disperser, it is ultrasonically treated at a frequency of 20kHz for 2 hours to form a suspension. Heat to boiling in the bath pot, then add 50g of spare bamboo charcoal, continue to heat and boil, and stir vigorously for 2 hours, then take it out and put it in a constant temperature drying oven for drying at 105°C, and finally put the bamboo charcoal powder loaded with silver-loaded titanium dioxide into the high-temperature furnace Anaerobic calcination at 45...

Embodiment 2

[0040] Porous bamboo charcoal pretreatment: choose 450 mesh bamboo charcoal, first boil the bamboo charcoal with deionized water for 30 minutes, then wash and filter with deionized water, repeat this 3 times, remove the dust and surface residues in the bamboo charcoal, keep the temperature at 105°C Dry in a drying oven for later use.

[0041] Disperse 1.5g of silver-loaded titanium dioxide in deionized water. In the silver-loaded titanium dioxide, the mass ratio of silver to titanium dioxide is 3:100. Under an ultrasonic disperser, the frequency of 20kHz is ultrasonically treated for 2 hours to form a suspension. Heat to boiling in the bath pot, then add 50g of spare bamboo charcoal, continue to heat and boil, and stir vigorously for 2 hours, then take it out and put it in a constant temperature drying oven for drying at 105°C, and finally put the bamboo charcoal powder loaded with silver-loaded titanium dioxide into the high-temperature furnace Anaerobic calcination at 450°C fo...

Embodiment 3

[0043] Porous bamboo charcoal pretreatment: choose 300-mesh bamboo charcoal, boil it in deionized water for 20 minutes, take it out, wash it, filter it, repeat twice, and then dry it in a constant temperature drying oven at 105°C for later use.

[0044] Disperse 0.5g of silver-loaded titanium dioxide in deionized water. In the silver-loaded titanium dioxide, the mass ratio of silver to titanium dioxide is 3:100. Ultrasonic treatment at a frequency of 15kHz for 3h forms a suspension under an ultrasonic disperser, and the suspension is placed in an oil bath Heat the pot to boiling, then add 50g of spare bamboo charcoal, continue to heat and boil, stir vigorously, react for 1 hour, then take it out and put it in a constant temperature drying oven to dry at 105°C to obtain a coarse powder; then put the coarse powder into a high-temperature furnace Anaerobic calcination at 400°C for 3 hours to obtain silver-loaded titanium dioxide-bamboo charcoal composite powder.

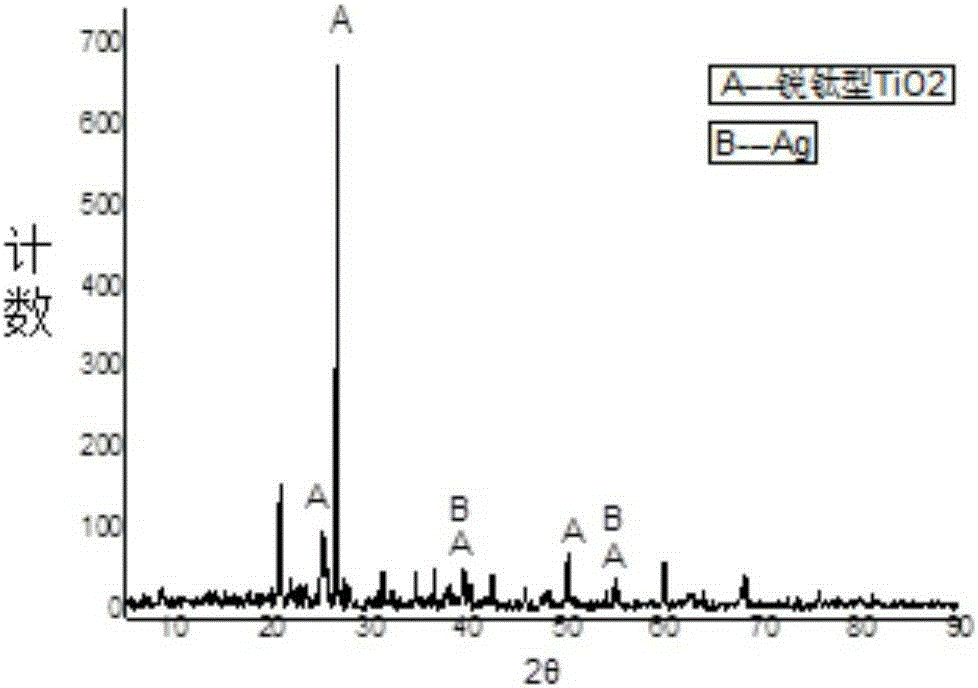

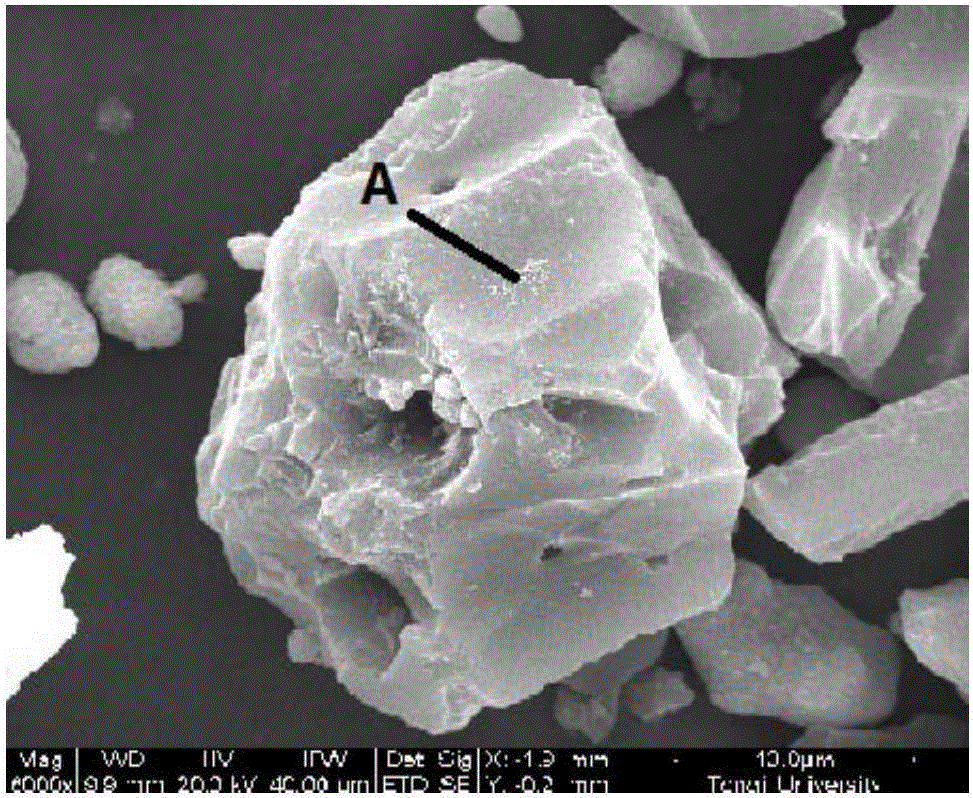

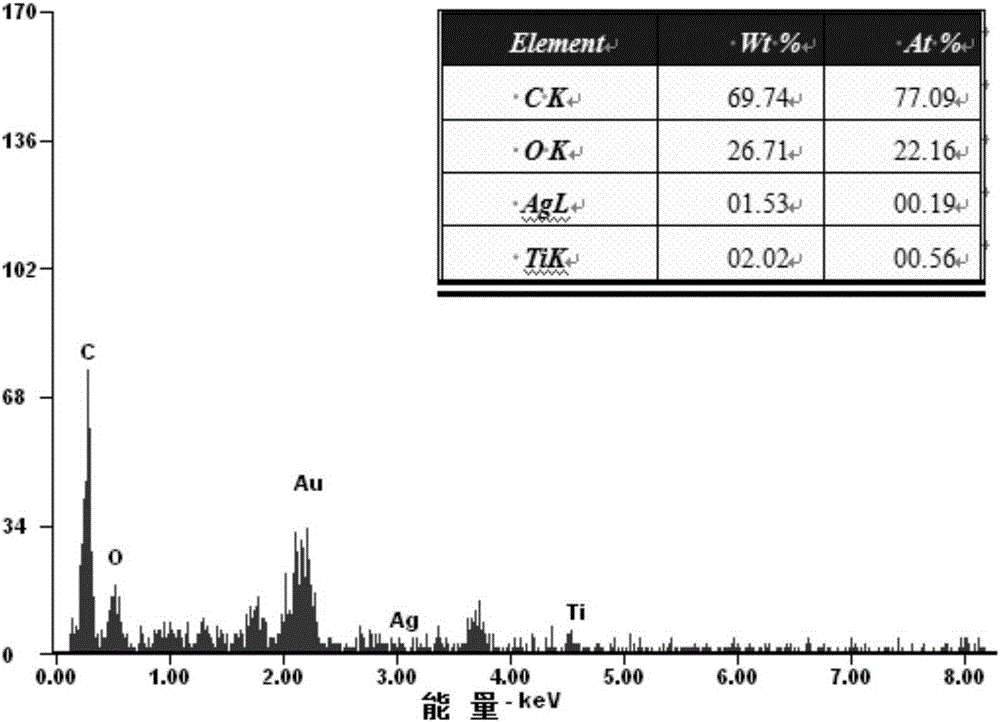

[0045] Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com