Rutile crystal form titanium oxide having hierarchical structure, and preparation method and use thereof

A hierarchical structure, titanium oxide technology, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of violent reaction, thick and short nano branches, compressed specific surface area, etc. The effect of increased surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The concrete steps of preparation are:

[0032] Step 1, firstly mix hydrated titanyl sulfate, ethanol, glycerin and deionized water according to the molar ratio of 1:16:15:15 and then stir for 1 hour to obtain a mixed solution. Then the mixed solution was placed in a closed state, and reacted at a temperature of 140° C. for 38 hours to obtain a reaction mixture.

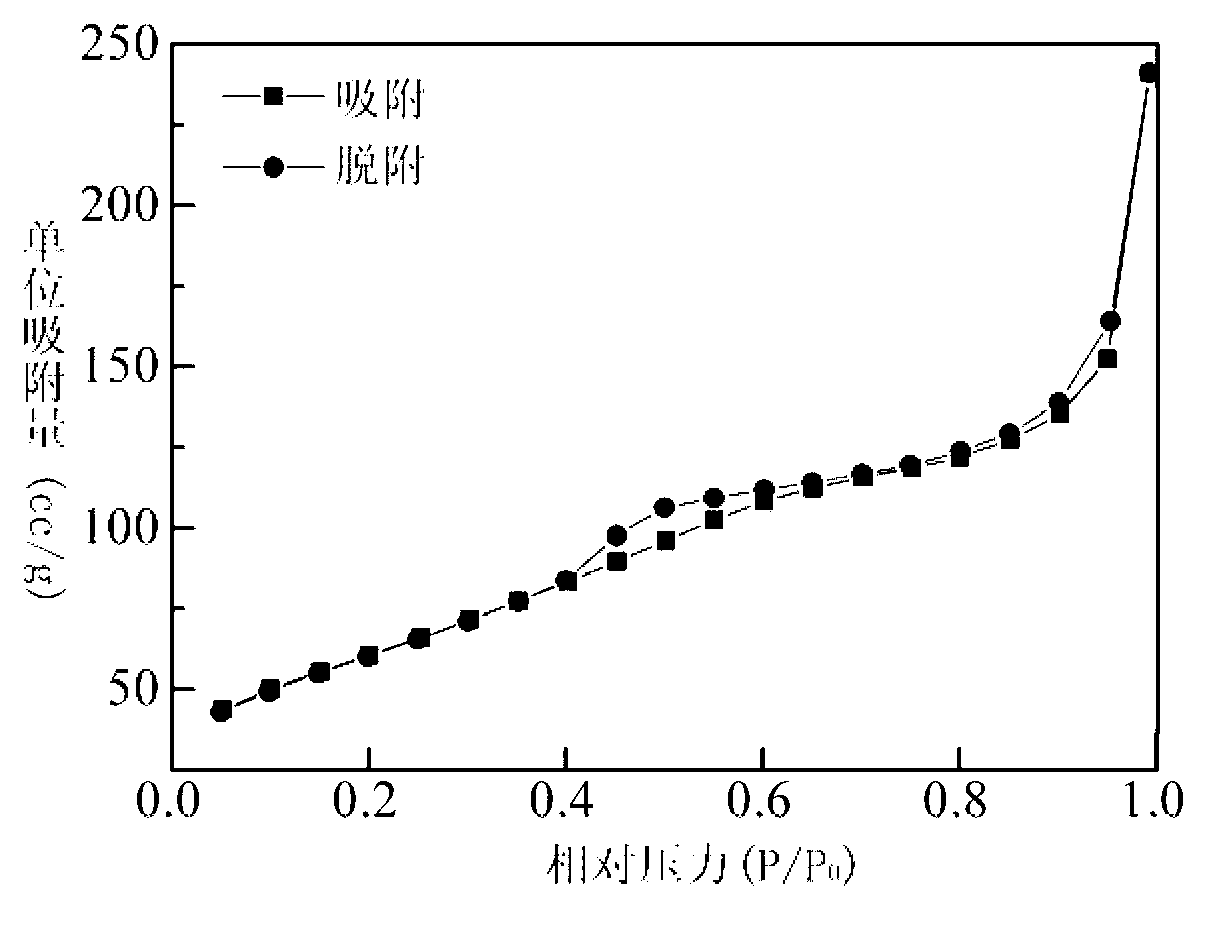

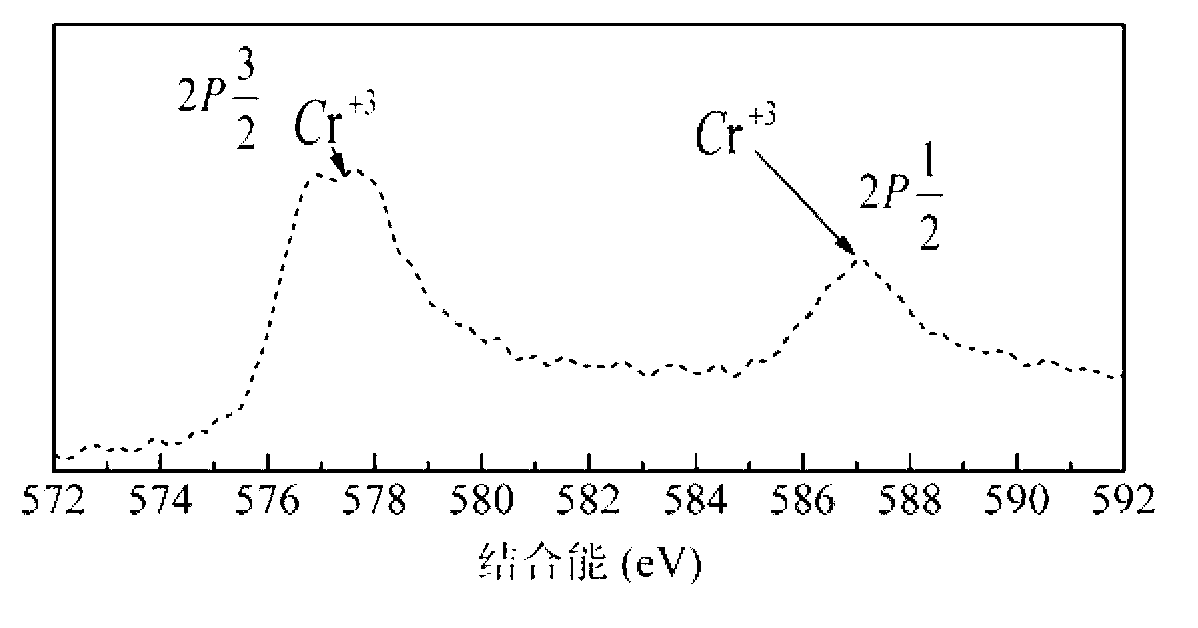

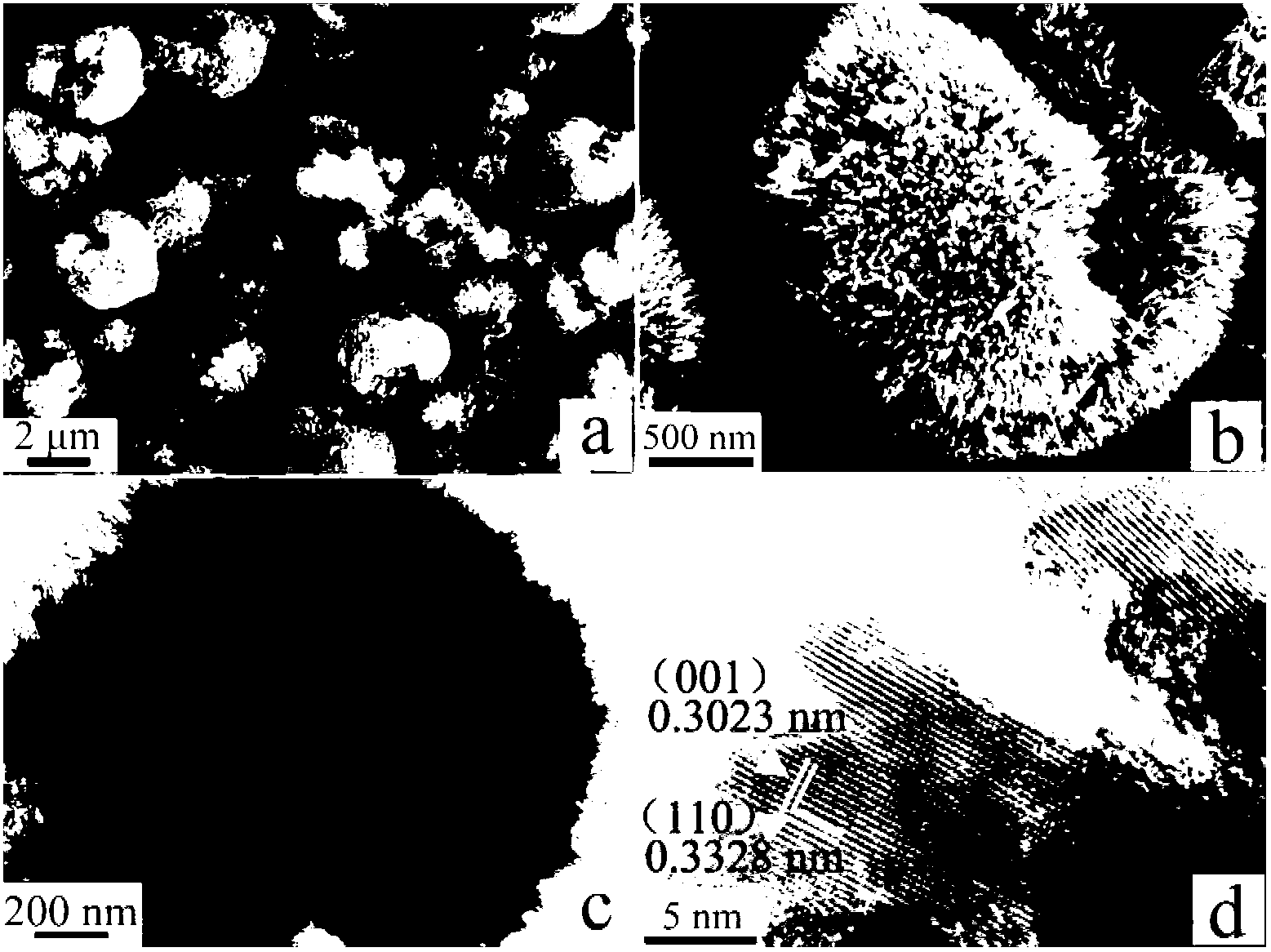

[0033] In step 2, wait for the reaction mixture to cool naturally to room temperature, then remove the upper liquid of the reaction mixture, and then wash the obtained precipitate with industrial alcohol for 3 times. Afterwards, it was dried at 75°C for 2 hours to obtain a figure 1 shown, and as figure 2 and image 3 The hierarchical structure shown in the curve in the rutile crystal form of TiO.

Embodiment 2

[0035] The concrete steps of preparation are:

[0036] Step 1: first mix hydrated titanyl sulfate, ethanol, glycerin and deionized water according to a molar ratio of 1:18.5:14:16, and then stir for 1.3 hours to obtain a mixed solution. Then the mixed solution was placed in a sealed state, and reacted at a temperature of 145° C. for 36 hours to obtain a reaction mixture.

[0037] In step 2, wait for the reaction mixture to cool naturally to room temperature, then remove the upper liquid of the reaction mixture, and then wash the obtained precipitate with industrial alcohol for 3 times. Afterwards, it was dried at 78°C for 1.8h to obtain a figure 1 shown, and as figure 2 and image 3 The hierarchical structure shown in the curve in the rutile crystal form of TiO.

Embodiment 3

[0039] The concrete steps of preparation are:

[0040] Step 1: first mix hydrated titanyl sulfate, ethanol, glycerin and deionized water according to a molar ratio of 1:21:12.5:17.5, and then stir for 1.5 hours to obtain a mixed solution. Then the mixed solution was placed in a closed state, and reacted at a temperature of 150° C. for 34 hours to obtain a reaction mixture.

[0041] In step 2, wait for the reaction mixture to cool naturally to room temperature, then remove the upper liquid of the reaction mixture, and then wash the obtained precipitate with industrial alcohol for 4 times. After that, it was dried at 80°C for 1.5h to obtain the following figure 1 shown, and as figure 2 and image 3 The hierarchical structure shown in the curve in the rutile crystal form of TiO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com