Chromic oxide-titanium oxide based high-temperature and high-emissivity coating and preparation method thereof

A high-emissivity, titanium oxide technology, applied in coating, metal material coating process, fusion spraying, etc., can solve problems such as shedding, coating cracking, complex workpieces, etc., and the emissivity will not decay, improve Bonding force, effect of relieving thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

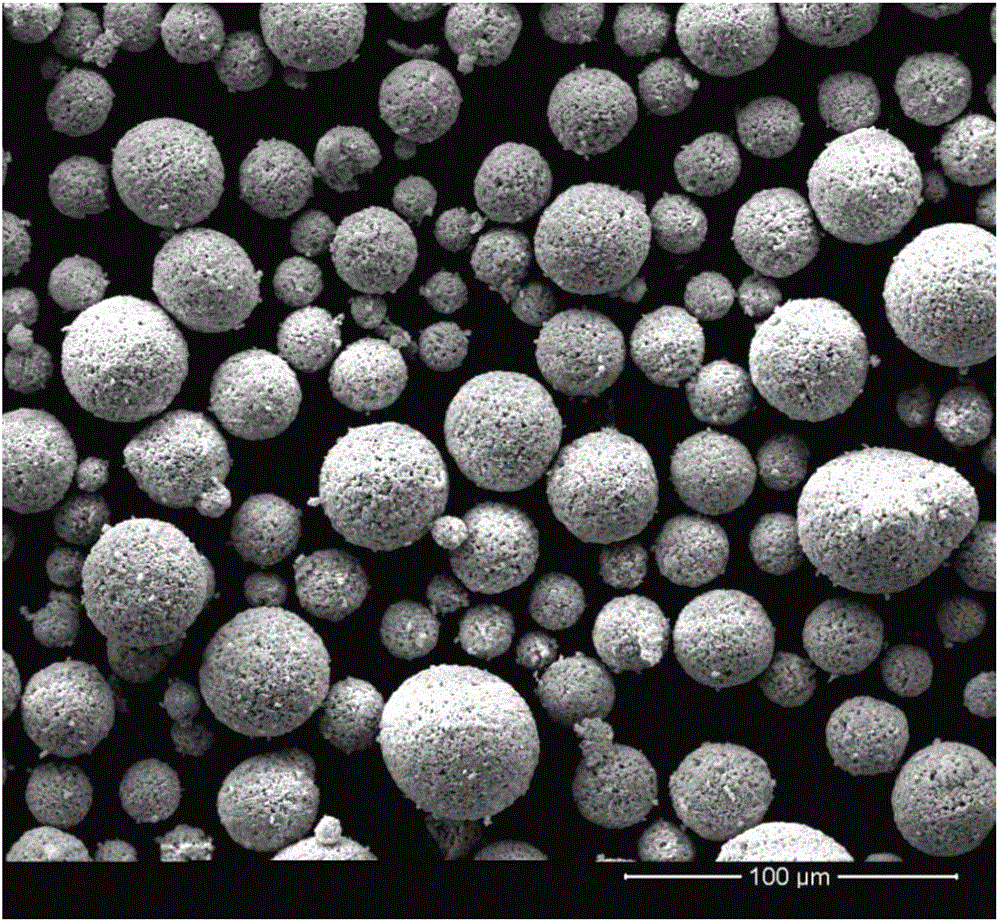

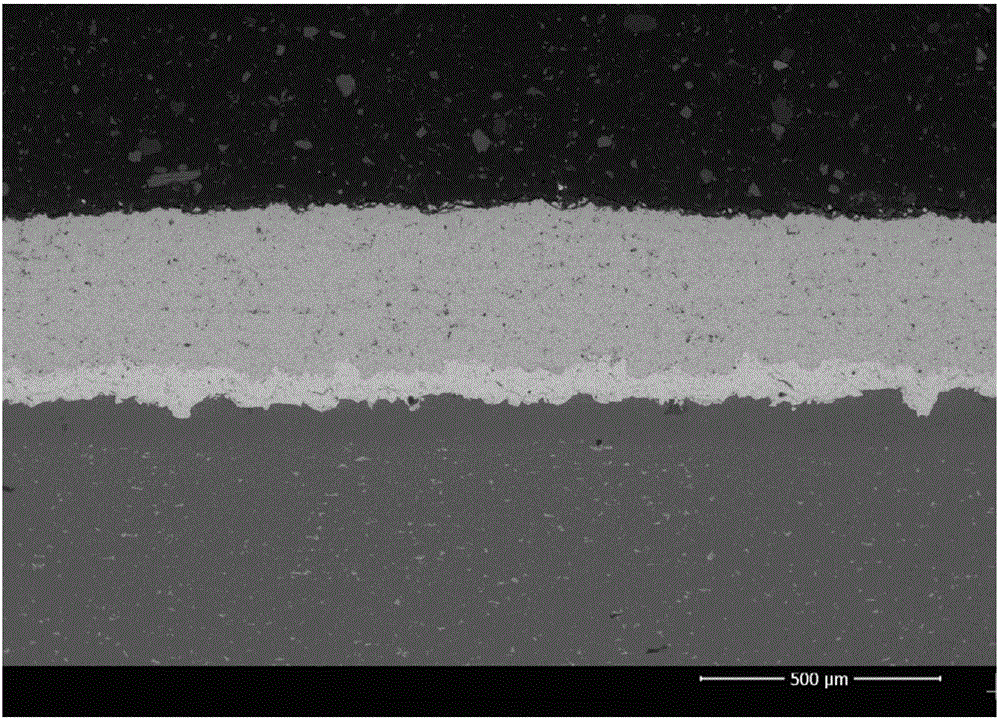

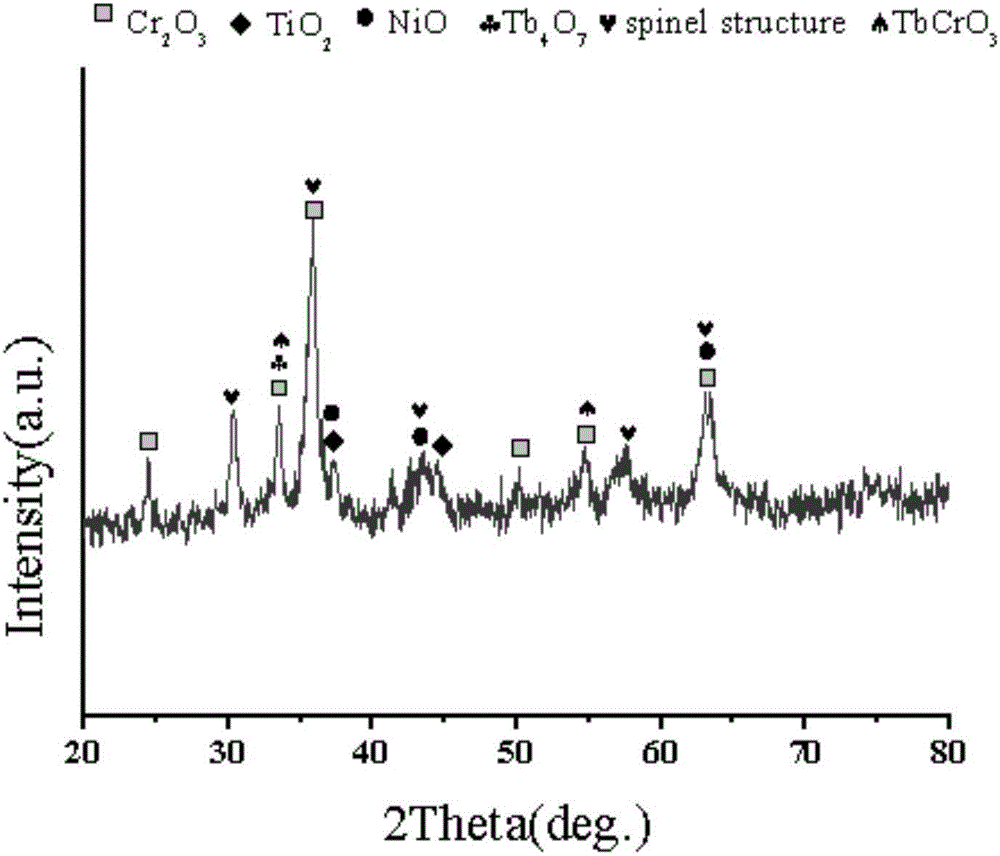

[0038] Step 1: Add Cr 2 o 3 Powder, TiO 2 Powder and NiO powder are mixed according to a certain ratio, and then the rare earth oxide Tb is added 4 o 7 powder for doping modification;

[0039] The Cr 2 o 3 、TiO 2 , NiO mass ratio is 65:30:5; said rare earth oxide Tb 4 o 7 with Cr 2 o 3 、TiO 2 , The total mass ratio of NiO mixed powder is 5:95;

[0040] The Cr 2 o 3 、TiO 2 , NiO primary particle size is 1 ~ 5μm; the Tb 4 o 7 The original particle size is 5-10μm;

[0041] Step 2: Obtain the mixed material in step 1, add absolute ethanol to obtain a mixed solution, add a binder to the mixed solution, prepare a slurry and ball mill it;

[0042] The quality of the absolute ethanol is 1.5 times of the quality of the mixture; the binder is 3% of the quality of the mixture;

[0043] The binder is a mixture of polystyrene and polyvinyl alcohol, and the mass ratio of polystyrene and polyvinyl alcohol is 30:70;

[0044] The ball milling time is 24 hours; the ball mill...

Embodiment 2

[0058] Step 1: Add Cr 2 o 3 Powder, TiO 2 Powder and NiO powder are mixed according to a certain ratio, and then the rare earth oxide Pr 6 o 11 powder for doping modification;

[0059] The Cr 2 o 3 、TiO 2 , NiO mass ratio is 50:40:10; said rare earth oxide Pr 6 o 11 with Cr 2 o 3 、TiO 2 , The mass ratio of NiO mixed powder is 10:90;

[0060] The Cr 2 o 3 、TiO 2 , NiO primary particle size is 1 ~ 5μm; the Pr 6 o 11 The original particle size is 5-10μm;

[0061] Step 2: Obtain the mixed material in step 1, add absolute ethanol to obtain a mixed solution, add a binder to the mixed solution, prepare a slurry and ball mill it;

[0062] The quality of the absolute ethanol is 1.0 times of the quality of the mixture; the binder is 5% of the quality of the mixture;

[0063] The binder is a mixture of polystyrene and polyvinyl alcohol, and the mass ratio of polystyrene and polyvinyl alcohol is 40:60;

[0064] The ball milling time is 32 hours; the ball milling speed ...

Embodiment 3

[0077] Step 1: Add Cr 2 o 3 Powder, TiO 2 Powder and NiO powder are mixed according to a certain ratio, and then the rare earth oxide La 2 o 3 powder for doping modification;

[0078] The Cr 2 o 3 、TiO 2 , NiO mass ratio is 60:30:10; said rare earth oxide La 2 o 3 with Cr 2 o 3 、TiO 2 , The mass ratio of NiO mixed powder is 5:95;

[0079] The Cr 2 o 3 、TiO 2 , NiO primary particle size is 1 ~ 5μm; said La 2 o 3 The original particle size is 5-10μm;

[0080] Step 2: Obtain the mixed material in step 1, add absolute ethanol to obtain a mixed solution, add a binder to the mixed solution, prepare a slurry and ball mill it;

[0081] The quality of the absolute ethanol is 1.5 times of the quality of the mixture; the binder is 4% of the quality of the mixture;

[0082] The binder is a mixture of polystyrene and polyvinyl alcohol, and the mass ratio of polystyrene and polyvinyl alcohol is 45:55;

[0083] The ball milling time is 38 hours; the ball milling speed is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Fluidity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com