Honeycomb structure

A honeycomb structure and honeycomb technology, applied in household appliances, clay products, applications, etc., can solve problems such as deactivation, and achieve excellent effects of NOx purification rate and thermal durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

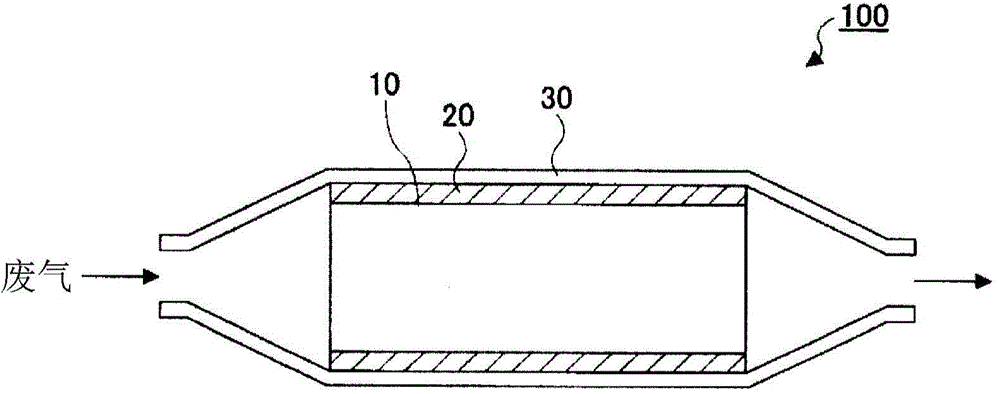

Image

Examples

Embodiment 1

[0131] 3910 mass parts of titanium dioxide, 210 mass parts of ammonium metavanadate as vanadium raw material, 670 mass parts of ammonium metatungstate (50% solution) as tungsten raw material, 300 mass parts of alumina binder, 170 mass parts of wollastonite fiber 300 parts by mass of methylcellulose as a forming aid, 80 parts by mass of sorbitan trioleate as a forming lubricant, 150 parts by mass of diethanolamine as a pH regulator, and 1750 parts by mass of ion-exchanged water Mixing to prepare raw material paste 1. The molar ratio (W / V) of vanadium atoms in the vanadium raw material to tungsten atoms in the tungsten raw material was 0.8.

[0132] Next, the raw material paste 1 was extruded using an extrusion molding machine to produce a rectangular prism-shaped honeycomb formed body. Then, using a batch microwave dryer, the honeycomb formed body was dried under a drying pressure of 86.7kPa for 6 minutes, then the honeycomb formed body was put into a gas circulation furnace, ...

Embodiment 2

[0138] A honeycomb structure 10' was produced in the same manner as in Example 1, except that the oxygen concentration in the mixed gas introduced during firing was 40% (nitrogen concentration: 60%).

Embodiment 3

[0140] 170 parts by mass of ammonium metavanadate was added to an 8% diethanolamine aqueous solution prepared from 150 parts by mass of diethanolamine and 1750 parts by mass of ion-exchanged water, and heated to 100°C to obtain a premixed solution for dissolution. Next, 670 parts by mass of ammonium metatungstate (50% solution) as a tungsten raw material and 80 parts by mass of sorbitan trioleate as a molding lubricant were added to prepare a solution raw material.

[0141] Next, after mixing 3950 parts by mass of titanium dioxide, 300 parts by mass of alumina binder, 170 parts by mass of wollastonite fiber, and 300 parts by mass of methyl cellulose as a forming aid, the above-mentioned pre-mixed liquid was added and mixed. Refining to prepare raw material paste 2. The molar ratio (W / V) of vanadium atoms in the vanadium raw material to tungsten atoms in the tungsten raw material was 0.80.

[0142] Next, using the raw material paste 2, a honeycomb structure 10' was produced in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com