Photothermal directional control elastic superhydrophobic surface liquid drop migration device and using method thereof

A super-hydrophobic surface and droplet technology, applied in the field of microfluidics, can solve problems such as lack of research, and achieve the effects of simple manufacturing process, low control cost, and easy integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

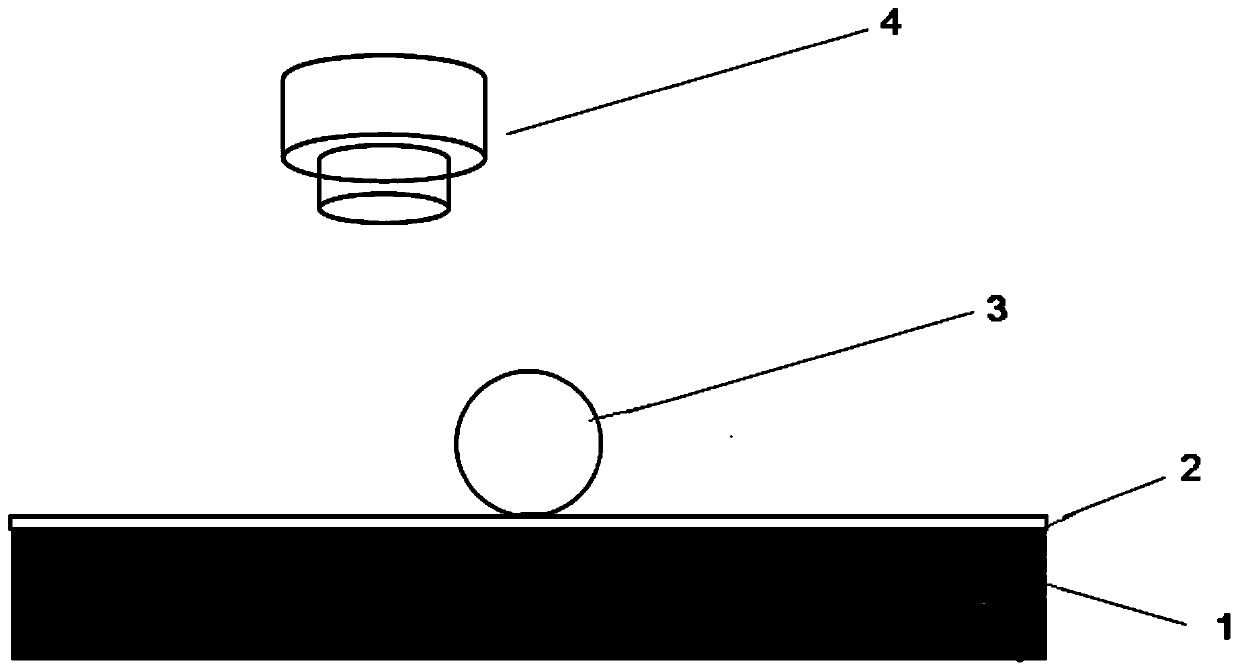

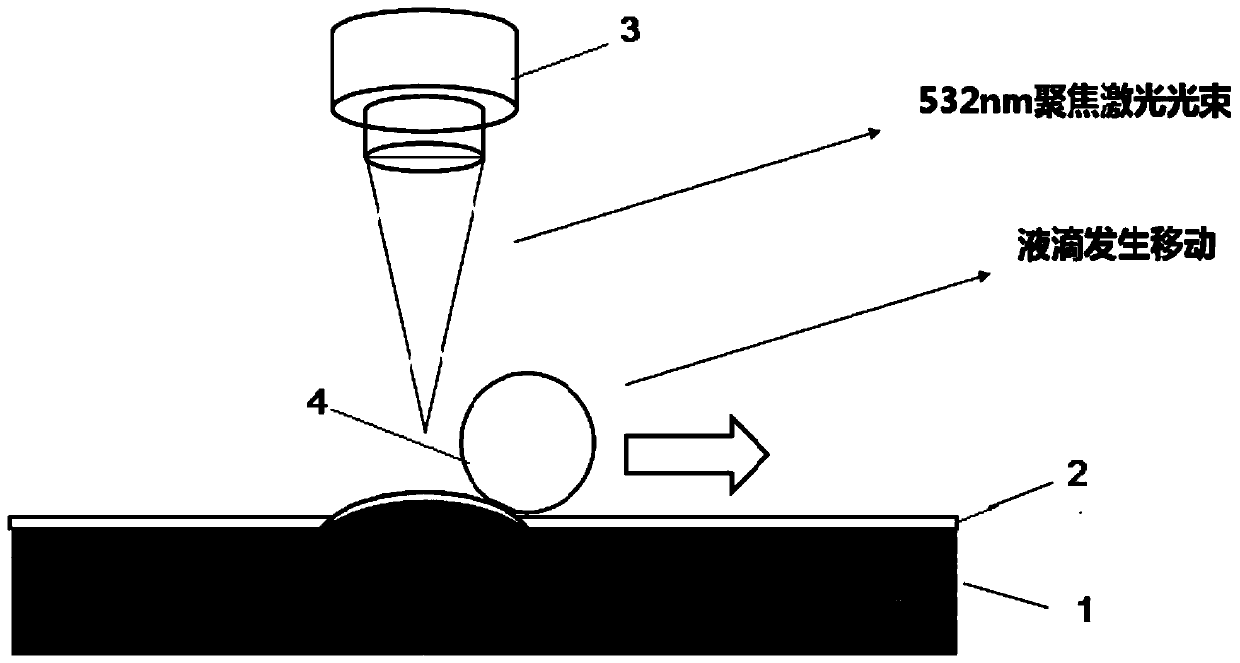

[0022] see figure 1 and figure 2 , Embodiment 1: A light-thermal directional control elastic superhydrophobic surface droplet migration device, including a substrate 1; the substrate 1 is mixed and solidified by polydimethylsiloxane PDMS and endothermic material titanium dioxide powder The base 1 can also be formed by mixing and solidifying polydimethylsiloxane PDMS and endothermic material ferric oxide powder; or by mixing polydimethylsiloxane PDMS with other endothermic materials and solidified. The surface of the substrate 1 is engraved or sprayed with a transparent super-hydrophobic layer 2 , and a 532nm green laser 3 is arranged above the transparent super-hydrophobic layer 2 .

[0023] In a specific embodiment, the substrate 1 is formed by mixing polydimethylsiloxane and heat-absorbing material titanium dioxide powder or ferric iron tetroxide powder in a ratio of 100:3 to 100:13 and solidified. Specifically, polydimethylsiloxane: curing agent: heat-absorbing material...

Embodiment 2

[0024] see figure 1 and figure 2 , Embodiment 2. The use method of photothermal directional control elastic superhydrophobic surface droplet migration device, this method comprises the following steps:

[0025] A. Pour polydimethylsiloxane into a mold with regular shape, add curing agent and heat-absorbing material titanium dioxide powder, stir evenly and let it stand for about 20 minutes to remove the air bubbles, then place the mold on Heat on a heating plate at a temperature of 100° C.±10° C. for 15-20 minutes to cure, and obtain a substrate 1 .

[0026] B. A transparent superhydrophobic layer 2 is formed on the surface of the substrate 1 by template engraving or transparent superhydrophobic paint spraying method.

[0027] C. Setting a 532nm green laser 3 above the transparent superhydrophobic layer 2 .

[0028] D. Turn on the laser 3, the dititanium oxide in the substrate 1 performs light-to-heat conversion and transfers the heat to the polydimethylsiloxane PDMS, and t...

Embodiment 3

[0030] Embodiment 3: The method for using the liquid droplet migration device on the elastic superhydrophobic surface controlled by photothermal orientation, the method comprises the following steps:

[0031] A. Pour polydimethylsiloxane into a mold with regular shape, add curing agent and endothermic material ferric oxide powder, stir evenly and let it stand for 20 minutes to remove the air bubbles, then place the mold at temperature Heating on a heating plate at 100° C.±10° C. for 15-20 minutes for curing to obtain a substrate 1 .

[0032] B. A transparent superhydrophobic layer 2 is formed on the surface of the substrate 1 by template engraving or transparent superhydrophobic paint spraying method.

[0033] C. Setting a 532nm green laser 3 above the transparent superhydrophobic layer 2 .

[0034] D. Turn on the laser 3, the ferroferric oxide in the substrate 1 performs light-to-heat conversion and transfers heat to polydimethylsiloxane PDMS, and the polydimethylsiloxane PD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com