Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81 results about "Dissolution precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dissolution and Precipitation. The process of dissolution occurs when a solute is placed in contact with a solvent and dissolves to form a solution. If solvent is removed from a solution, by a process such as evaporation, eventually the solute will be found to separate from the remaining solution.

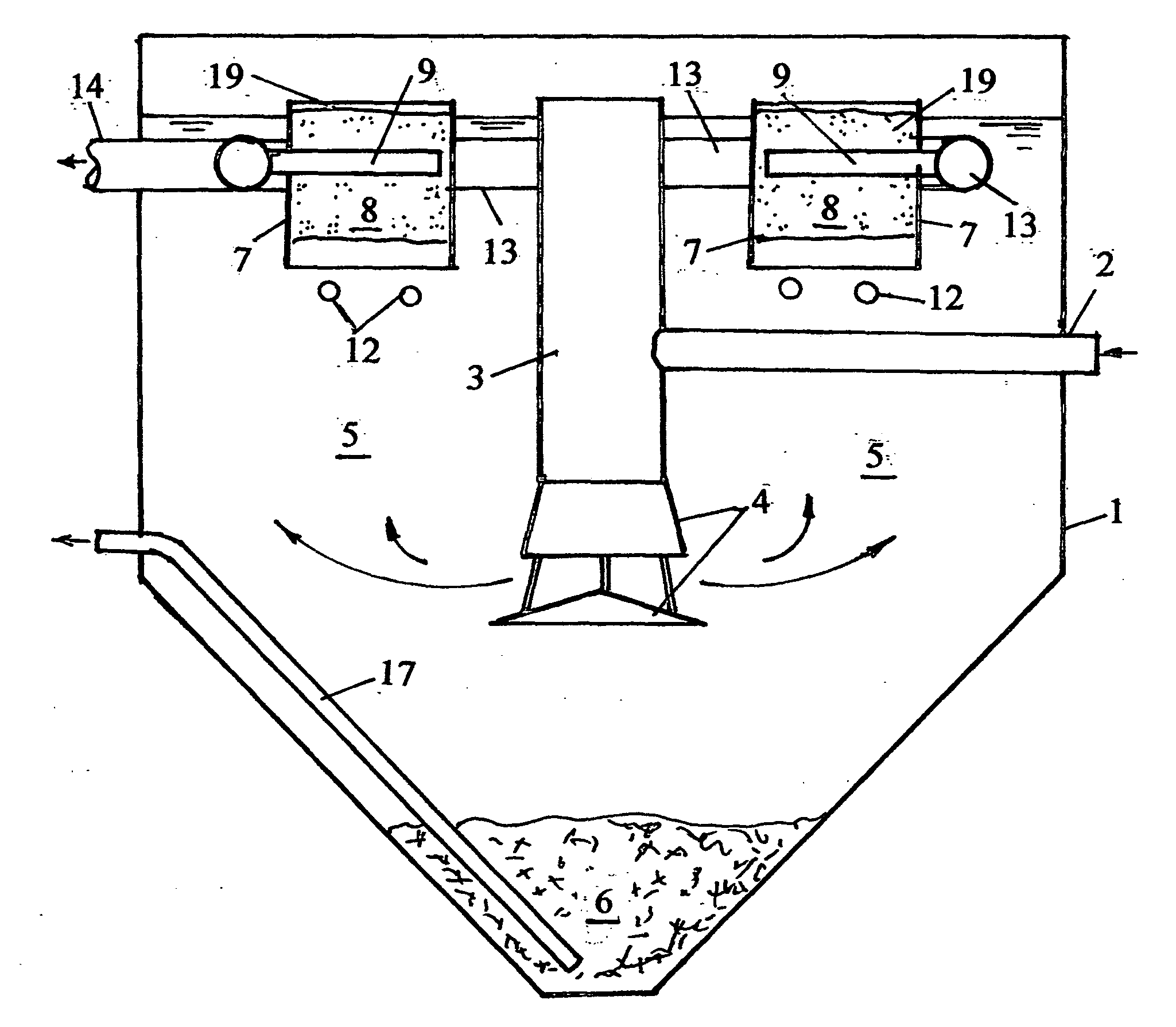

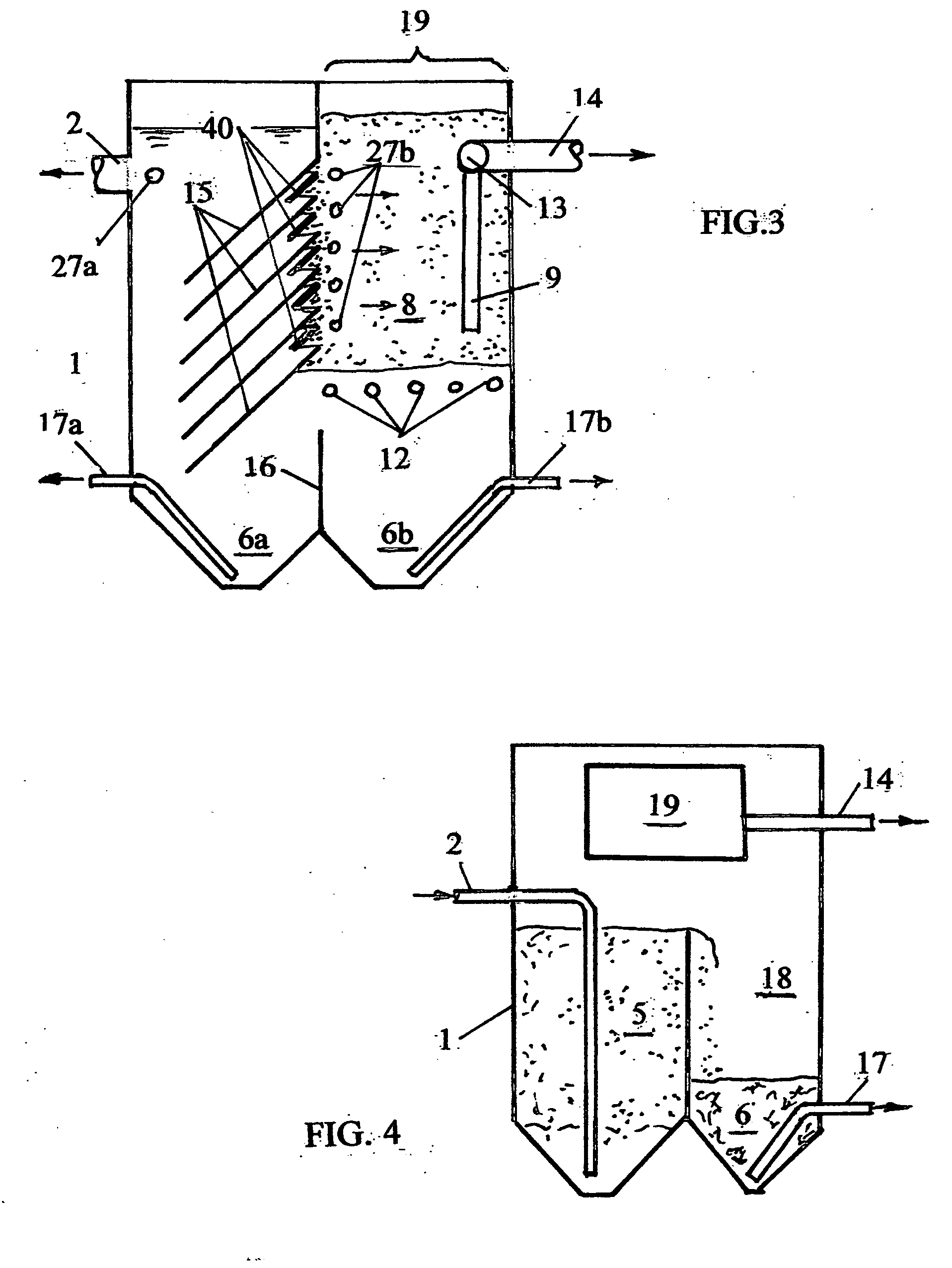

Combined gravity separation-filtration for conducting treatment processes in solid-liquid systems

InactiveUS20100133196A1Convenient to accommodateLower cost of capitalWaste water treatment from animal husbandryTreatment involving filtrationIon exchangeLiquid system

This is a method and apparatus for combined gravity separation-filtration for conducting physical, physical-chemical, chemical, and biological processes in solid-liquid systems; including but not limited to separation of dispersed solids from liquids, separation of alkalinity from the liquid stream, chemical acid-base interactions, chemical oxidation-reduction, chemical dissolution-precipitation, physical chemical adsorption, ion exchange, mass transfer in any combinations of multiple liquid-solid-gas phases, biological oxidation-reductions, biological growth, and combinations of these processes; gravity separation steps can be conducted in rectangular horizontal unidirectional flow clarifiers, rectangular or circular radial flow clarifiers, rectangular or circular vertical flow clarifiers, lamella clarifiers, suspended sludge blanket clarifiers, fluidized bed separators, and combinations thereof, wherein the filtration step is disposed in the upper portion of the combined process or side-by-side with clarification step; filtration steps are conducted in single or multiple attachment media filters, including particulate filter media either heavier than liquid or floating; liquid filtered through the attachment media is collected by holed pipes, screens, or membranes. Reagents can be introduced before the gravity separation and / or before filtration steps. This method and apparatus can be used for municipal and industrial water purification and wastewater treatment for removal of a broad range of admixtures including BOD / COD, suspended solids, nitrogen and phosphorus, organics imparting color, salts of hardness, heavy metals, and other constituents of admixture.

Owner:KHUDENKO BORIS MIKHAIL

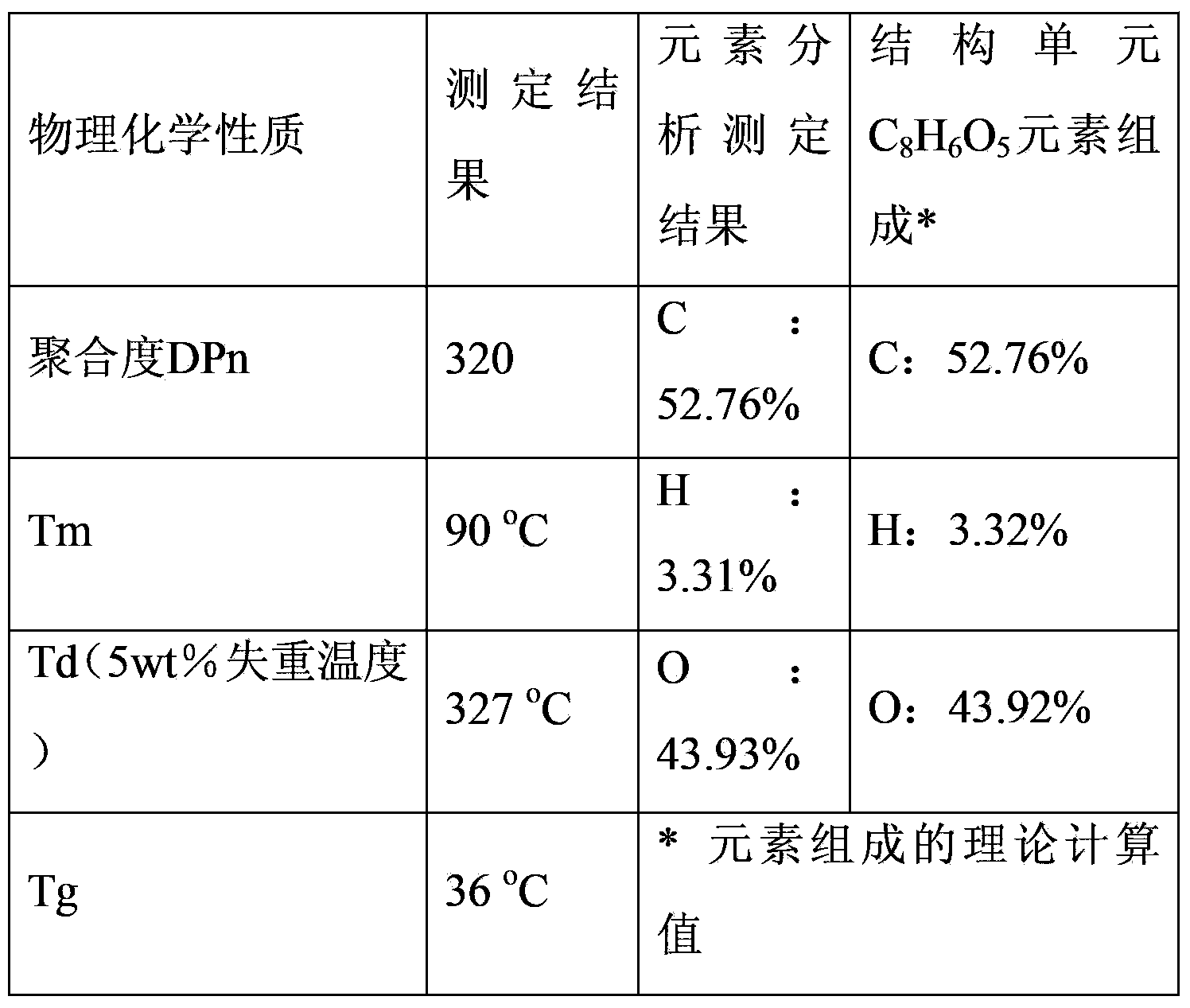

Preparation method of nylon micro powder for selective laser sintering

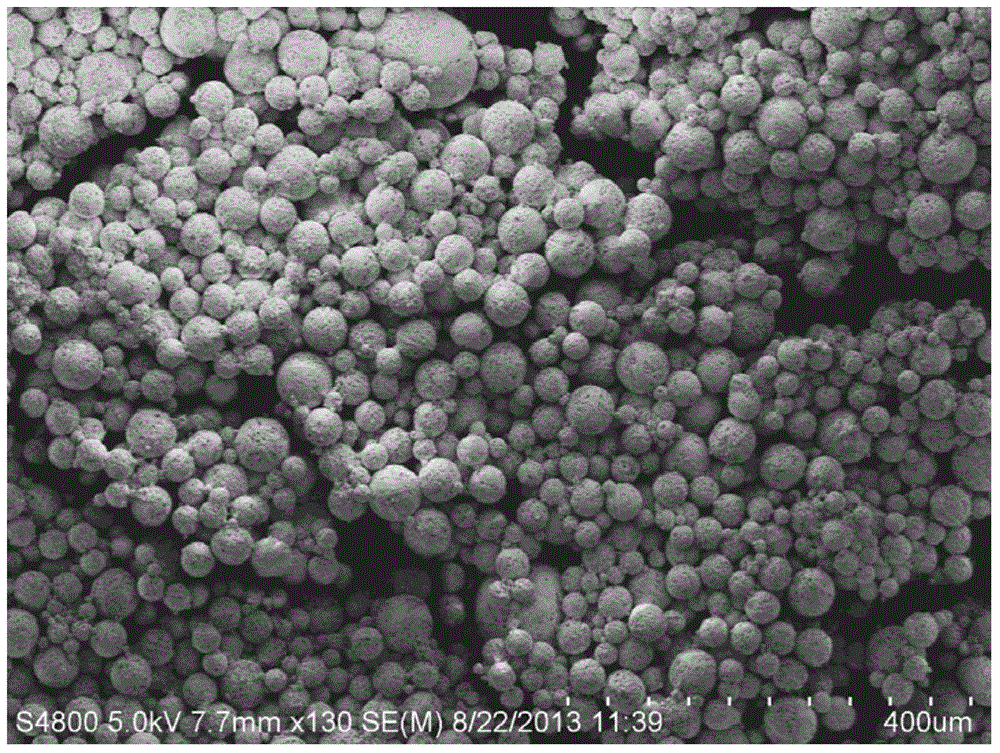

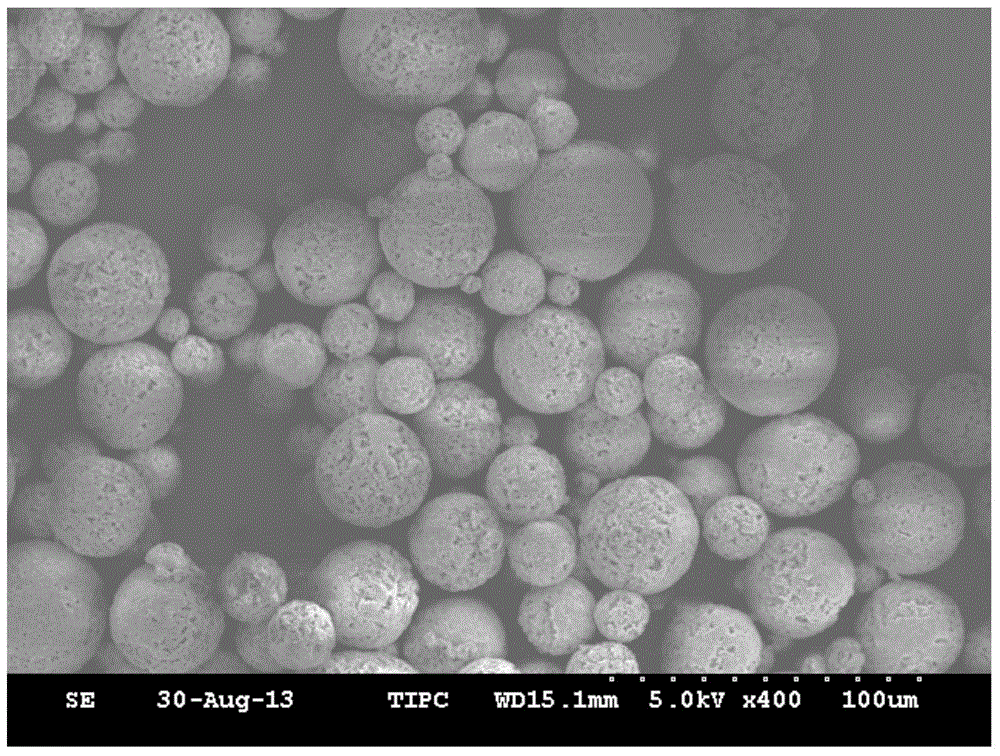

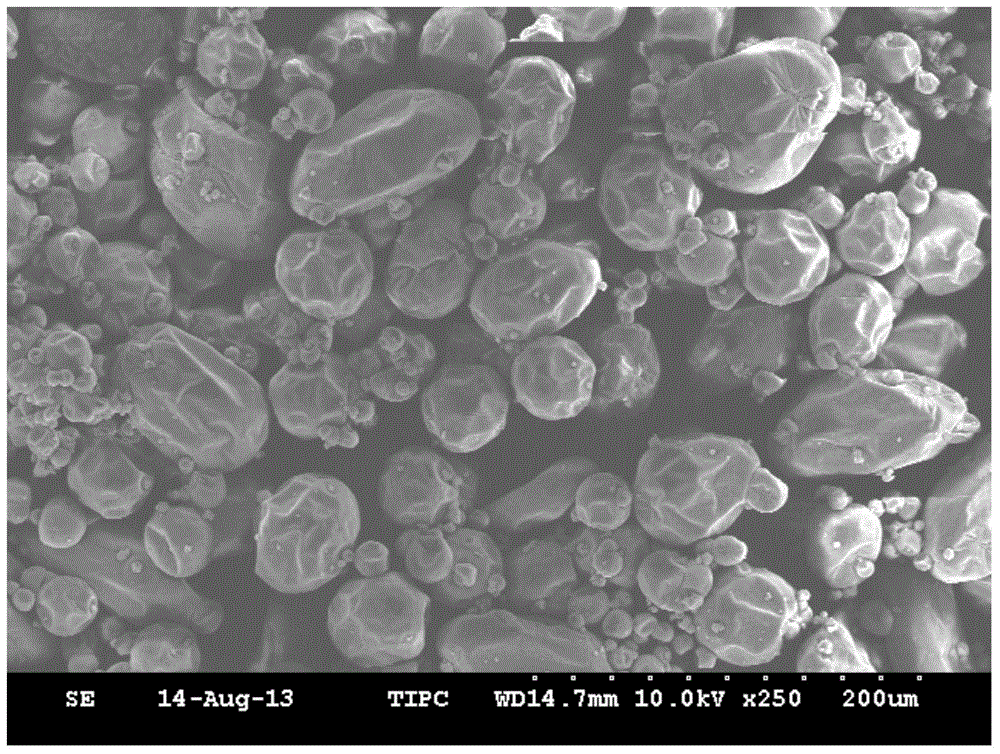

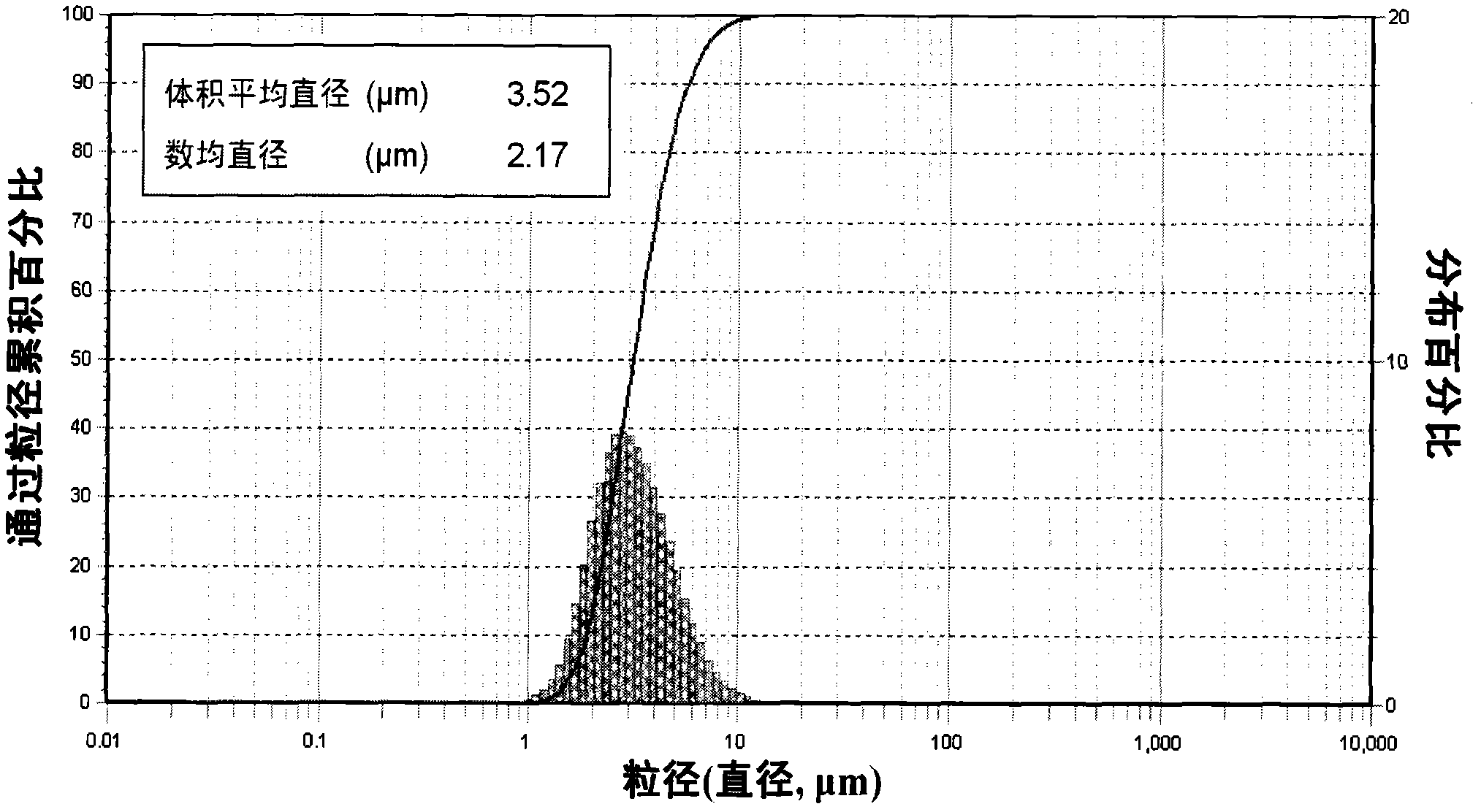

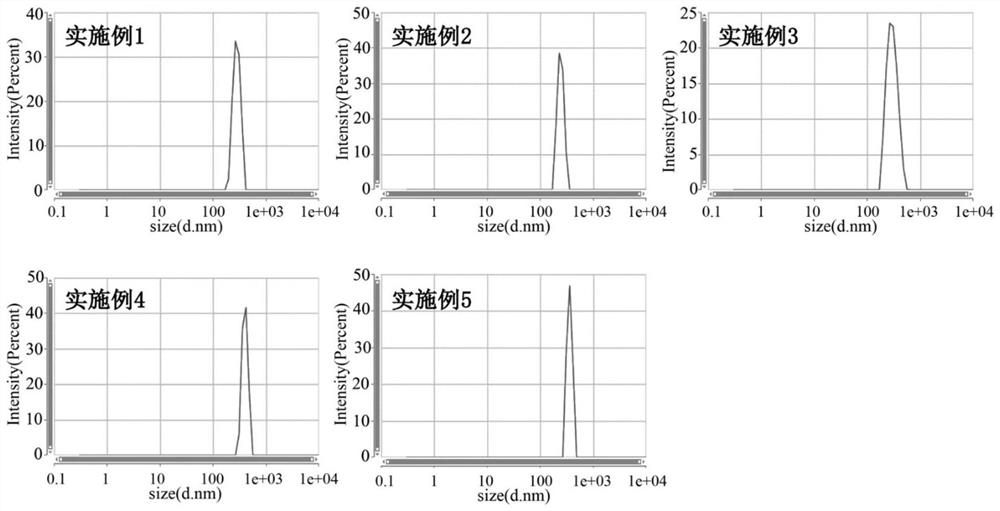

The present invention discloses a preparation method of nylon micro powder for selective laser sintering, the method is as follows: in the manner of dissolution-precipitation, first a dispersant is introduced into a polymer good solvent system, a poor solvent is added for precipitating of a polymer, and by use of the interaction of the dispersant and polymer chains in the system and particle stability protective effect, well dispersed polymer microspheres can be obtained. A used solvent and the used dispersant both can be recycled, compared with the prior art, no high-temperature high-pressure equipment is used, the process is simple, and the preparation method is cost-effective, environmentally-friendly and easy to implement. According to the method, the nylon powder for selective laser sintering with excellent physical and chemical properties can be obtained, the nylon powder has good particle shape and liquidity, larger sintering window, and better heat resistance and thermal stability, and can meet the needs of SLS parts in the aerospace, automotive, medical equipment, electronic equipment, machinery mold, art work and other fields.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

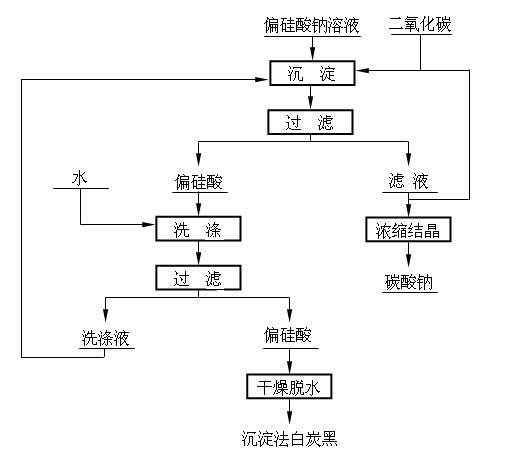

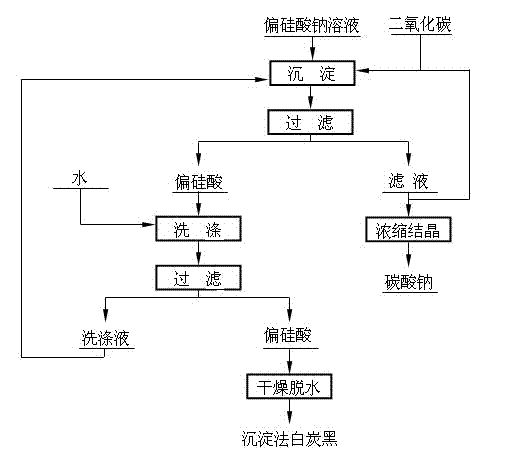

Process for preparing precipitated white carbon black by adopting carbon dioxide for decomposition

The invention relates to a process for preparing precipitated white carbon black by adopting carbon dioxide for decomposition. The process comprises the following steps: introducing the precipitator carbon dioxide into industrial sodium metasilicate solution with the pH value of 12.5-13.5 to react, stopping introducing the carbon dioxide when the pH value of the solution is 8.5-9.0, filtering the reactant to obtain metasilicic acid filter residues and filtrate containing sodium carbonate; adding water to metasilicic acid according to the liquid solid mass ratio of 6:1, stirring and washing the mixture, filtering the mixture and then washing entrained sodium carbonate solution, and drying the product to obtain the precipitated white carbon black; and returning one half of the filtrate containing sodium carbonate to the sodium metasilicate solution to be dissolved again to precipitate the metasilicic acid and concentrating and crystallizing the other half of the filtrate to obtain sodium carbonate product. The process has the following advantages: the carbon dioxide is adopted to replace the acid to precipitate the metasilicic acid in the sodium metasilicate solution, thus solving the filtering performance of the precipitate metasilicic acid in the traditional precipitation process; meanwhile, the liquid after precipitation is ensured to be the sodium carbonate solution with high additional value, thus completely eliminating discharge of waste water in the precipitation process; and besides, carbon is utilized.

Owner:KUNMING METALLURGY INST

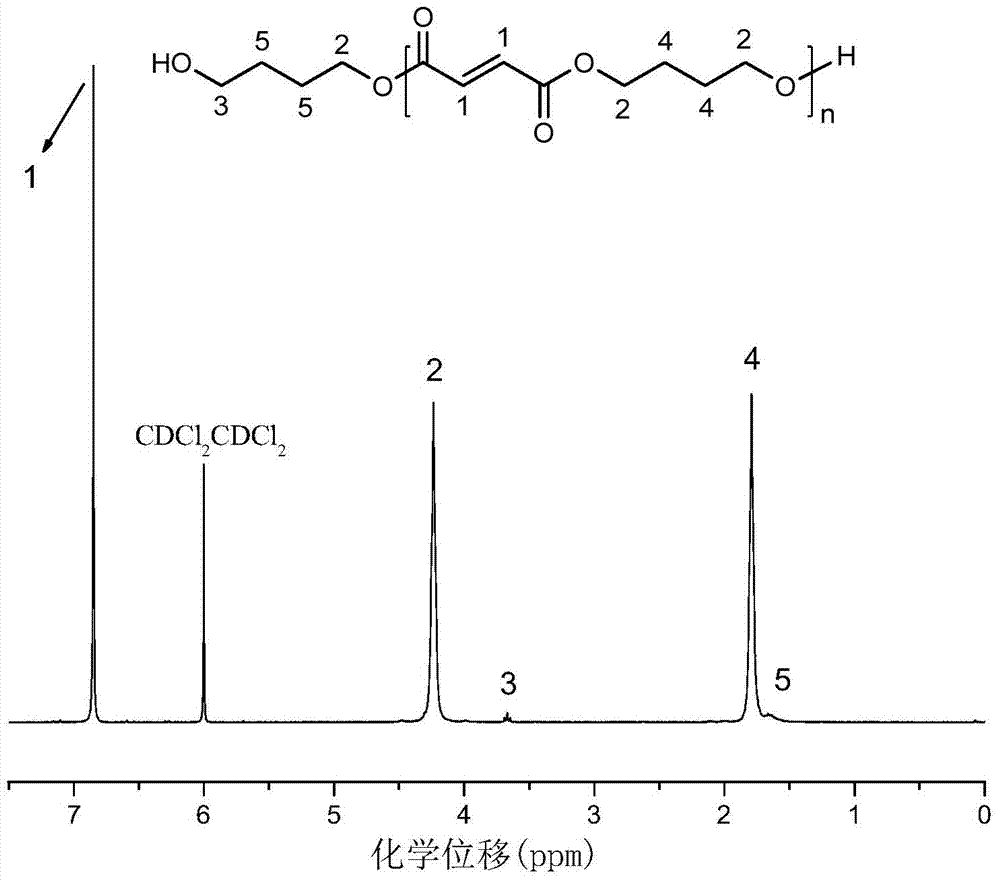

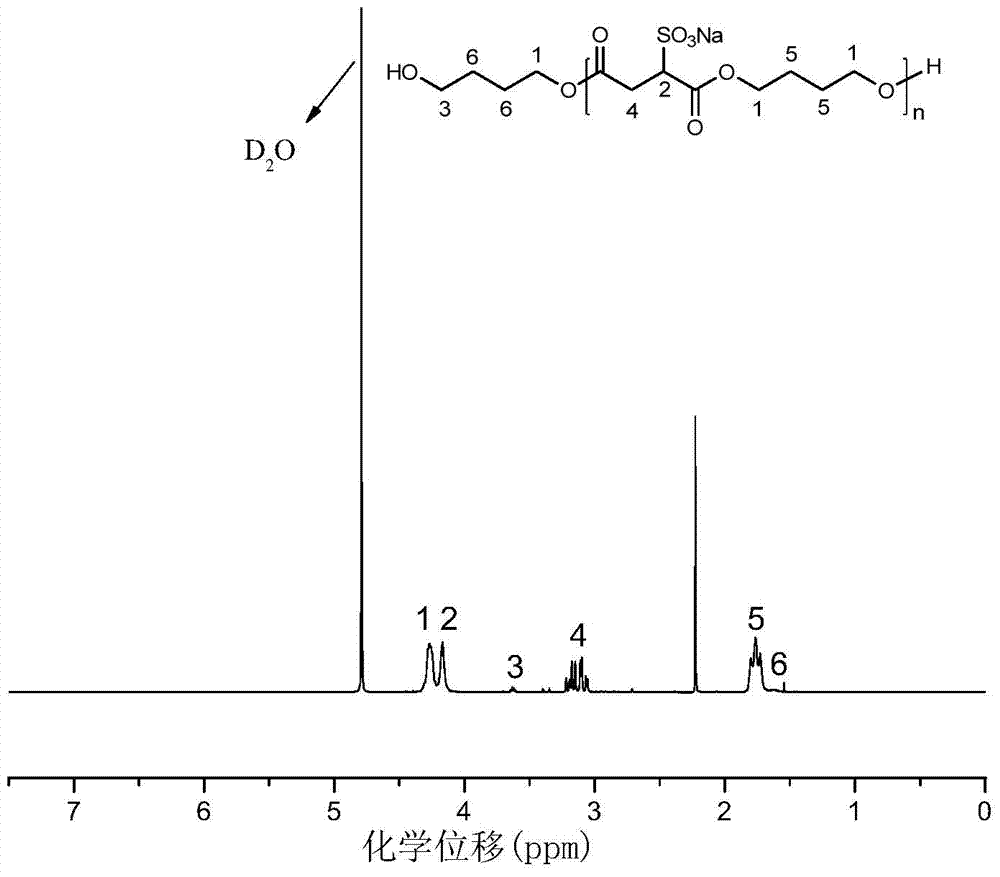

Sulfonate-anion-functionalized biodegradable polyester and preparation method thereof

InactiveCN103936975ASimple preparation processEasy to operateBulk chemical productionIon contentDouble bond

The invention relates to a biodegradable polyester, particularly a sulfonate-anion-functionalized biodegradable polyester and a preparation method thereof. The preparation method comprises the following steps: carrying out addition reaction on a double-bond-containing biodegradable polyester or copolyester thereof and a sodium bisulfite water solution in an organic solvent at 0-200 DEG C; and purifying the product of the addition reaction by dissolution-precipitation or supercritical carbon dioxide extraction, and carrying out vacuum drying to obtain the sulfonate-anion-functionalized biodegradable polyester discloses as the following general formula. The preparation technique of the sulfonate-anion-functionalized biodegradable polyester is convenient and easy to operate, and has the advantage of mild reaction conditions and high efficiency; the unsaturated C=C double bond can be sulfonated by the sodium bisulfite; and the ion content of the obtained product is controllable.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing high-hydrophobic polyester

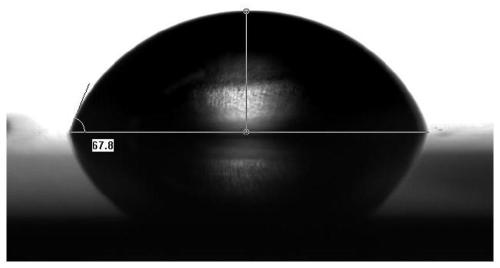

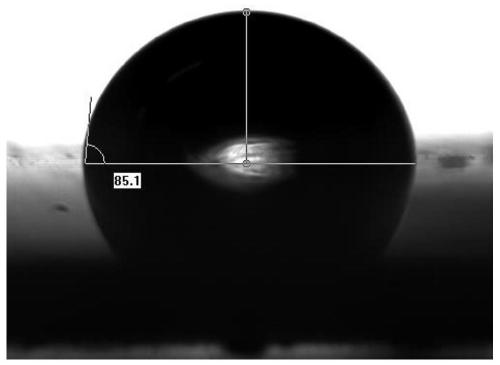

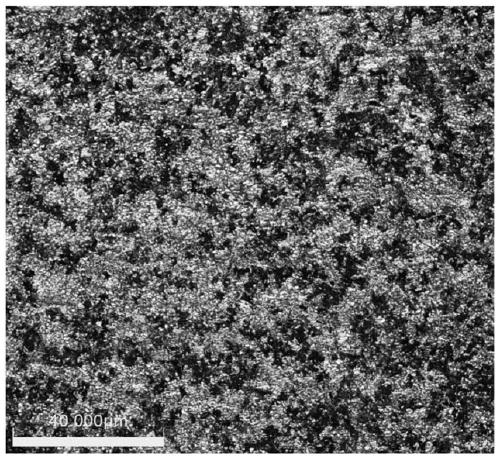

ActiveCN102115543AImprove hydrophobicityEasy to cleanMaterial nanotechnologyFibre typesPolyesterDissolution precipitation

The invention relates to polyester and a preparation method thereof, in particular to a method for preparing high-hydrophobic polyester, and the prepared high-hydrophobic polyester with a lotus leave-like micro / nano hierarchical composite structure. A dissolution-precipitation method is adopted for preparing the high-hydrophobic polyester, and comprises the following steps of: putting polyester into a good solvent for dissolution at the temperature of between 0 and 80DEG C; after the polyester is dissolved for 1 to 300 seconds, taking a part of dissolved polyester sample out, and putting intoa poor solvent; and drying the treated polyester sample to obtain the high-hydrophobic polyester product. In the method for preparing the high-hydrophobic polyester, by strong effects of the good solvent and the poor solvent on a substrate material, the surface of the substrate material is dissolved and crystals are separated out, so that the lotus leave-like micro / nano hierarchical composite structure is formed, the hydrophobic property is good and the contact angle is 118 to 155 degrees.

Owner:CHINESE TEXTILE ACAD

Preparation method of polylactic acid particles

The invention discloses a preparation method of polylactic acid particles. The method mainly comprises the following steps: dissolving polylactic acid and a water-soluble polymer in a solvent at 80-140 DEG C, cooling to 0-80 DEG C, carrying out solid-liquid separation with a precipitant, and drying to obtain the polylactic acid particles. The method is convenient to operate and mild in conditions, can prepare the polylactic acid particles with different porosity by the aid of the water-soluble polymer through a simple dissolution-precipitation process, and is especially suitable for industrial production. The obtained polylactic acid particles can be widely used in the fields of cosmetic substrates, catalyzed sorption, drug release, biological stents and the like.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

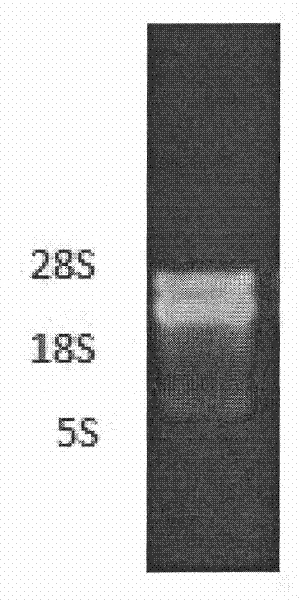

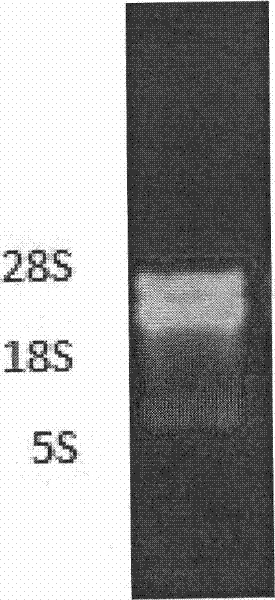

Method for extracting total RNA from leechee

The invention discloses a method for extracting total RNA from leechee, which comprises: grinding a leechee leaf sample treated by liquid nitrogen, and extracting with acetone under vacuum; adding RNA extraction solution into a plant material, which is subjected to vacuum extraction, for extraction, centrifuging, precipitating supernate with LiCl, centrifuging and collecting precipitate; washing and precipitating by using LiCl solution, centrifuging and discarding the supernate; and precipitating, drying, dissolving in diethyl pyrocarbonate (DEPC) sterilizing solution, precipitating and storing at 80 DEG C below zero for later use. Compared with the conventional extraction method, the method is simple in operation, low in extraction cost and high in repeatability and adaptability, can acquire high-quality and high-concentration RNA, and lays a foundation for further molecular biological research. Meanwhile, the method can also be used for extracting total RNA from the plant tissues of other species rich in polysaccharide and polyphenol substances.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

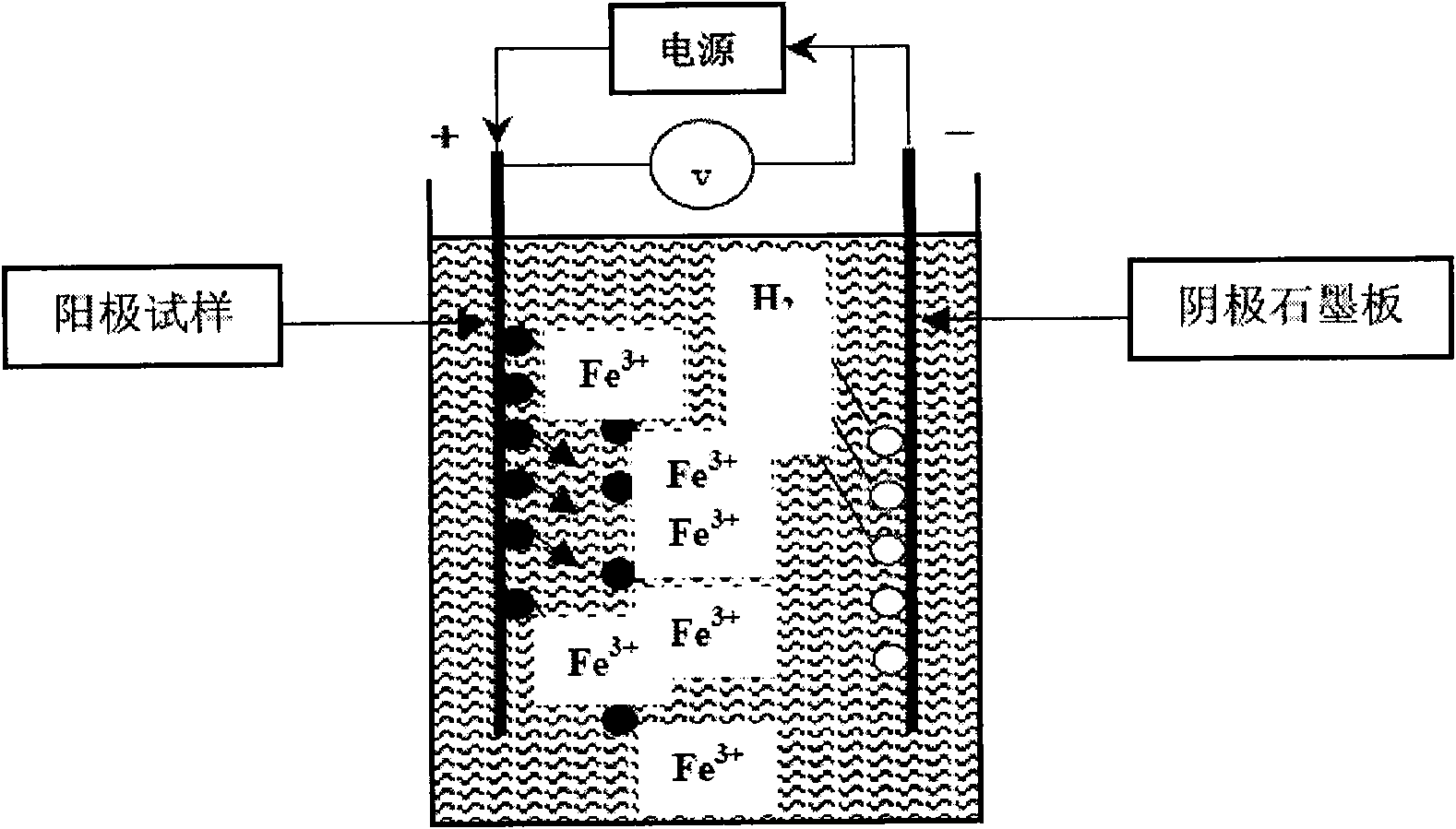

Method adopting neutral salt electrolyte to electrolytically extract tiny impurities from steel

InactiveCN101556225AIntact ingredientsIntact shapeMaterial analysis using wave/particle radiationPreparing sample for investigationWater bathsElectrolysis

The invention relates to a method adopting neutral salt electrolyte to electrolytically extract tiny impurities from steel and belongs to the research approach field of physics of metals. The method comprises the detailed steps of: mixing sodium citrate, sodium chloride, ferrous sulfate and ammonium chloride according to a certain proportion so as to be taken as a neutral electrolyte; adopting ammonium chloride solution to react with non-solute in water bath after electrolysis; repeatedly dissolving precipitate till the precipitation mass is stable; and obtaining the final product, namely, the required impurities. By adopting the neutral salt electrolyte for electrolysis, the method can obtain the micron-level and nanometer-level tiny impurities which have complete appearance and distinct components by observation with a scanning electron microscope.

Owner:UNIV OF SCI & TECH BEIJING

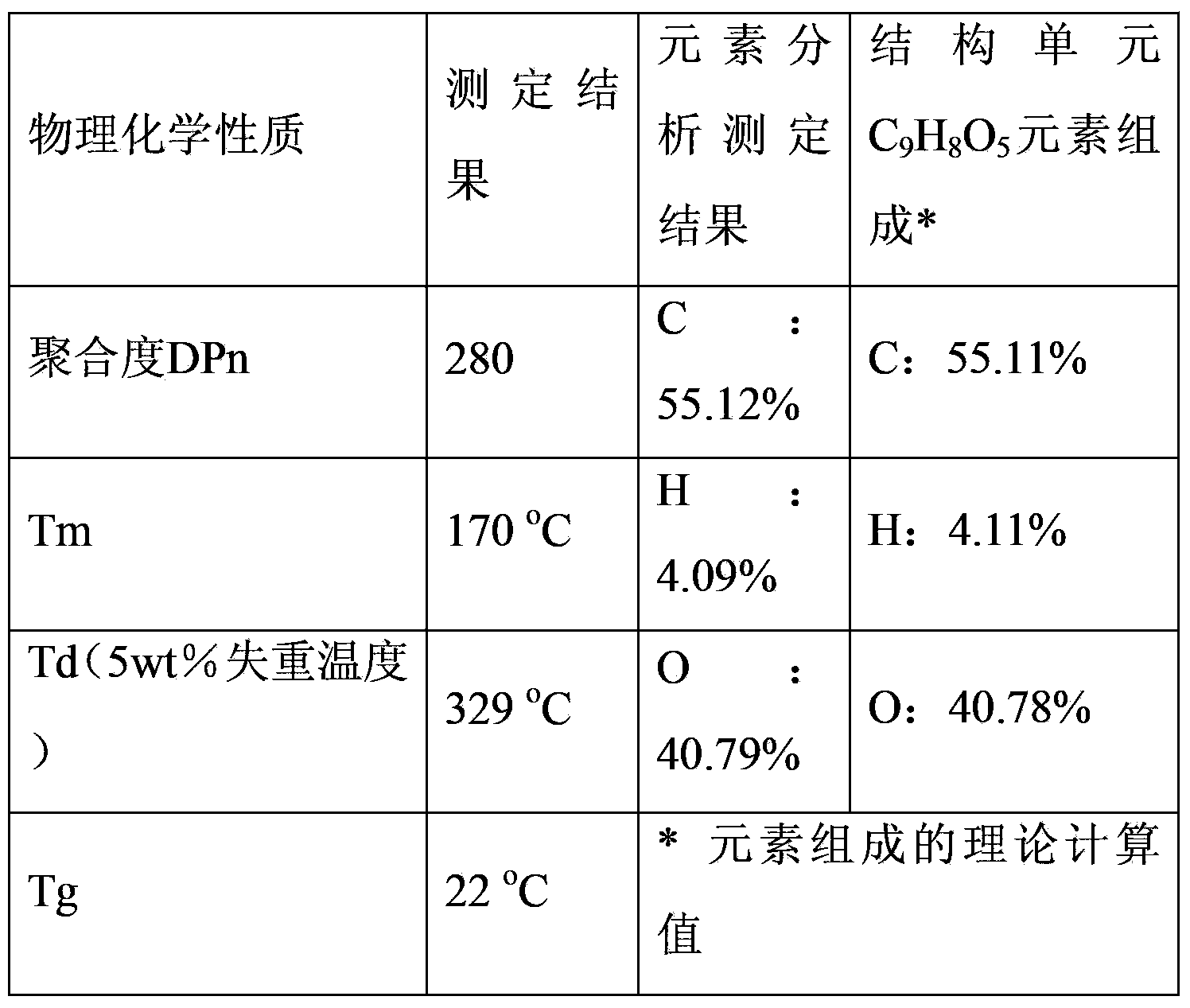

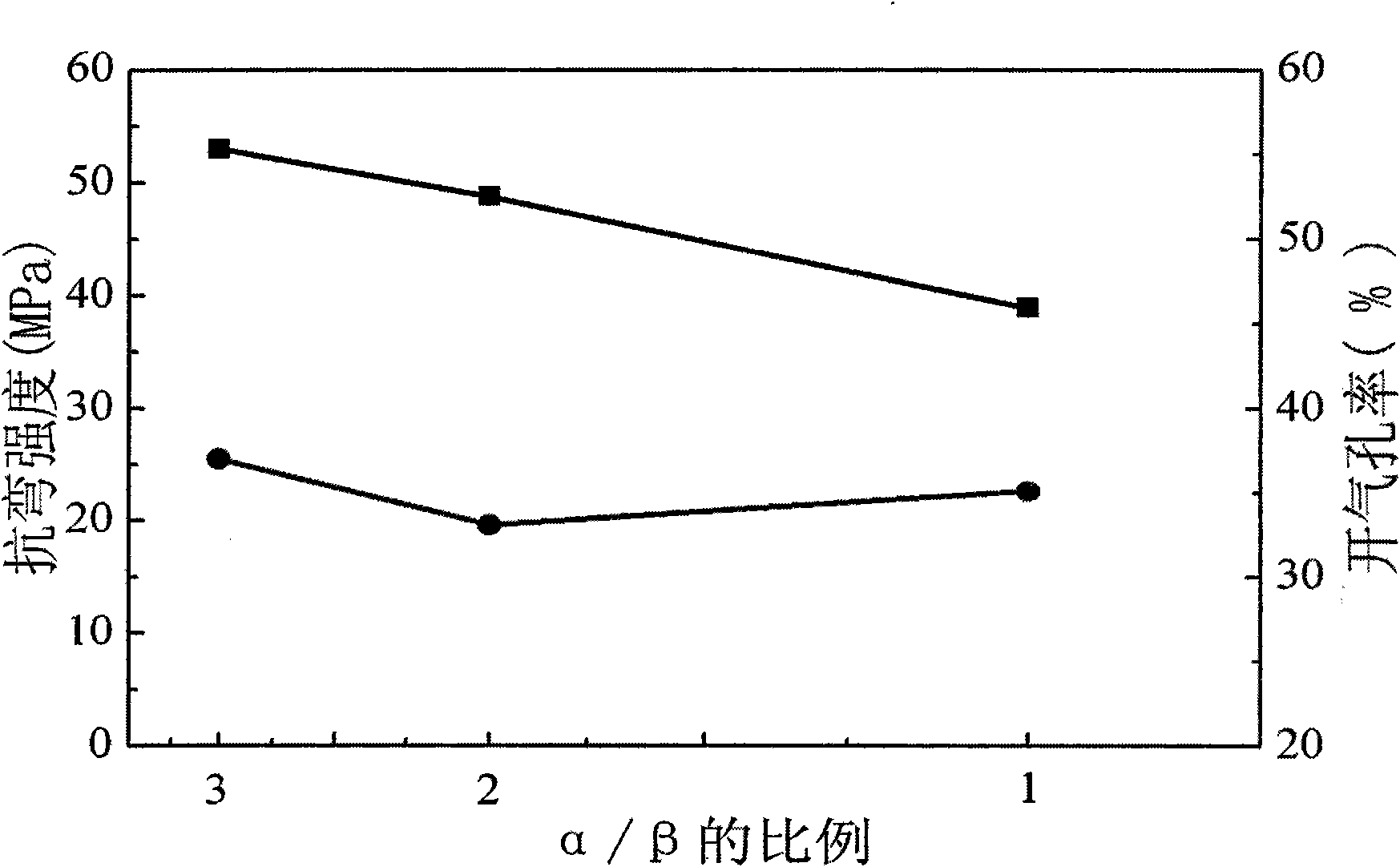

Polyamide porous microspheres and preparation method thereof

The invention discloses polyamide porous microspheres and a preparation method thereof. The preparation method comprises the preparation steps: heating and dissolving polyamide into a good solvent of the polyamide by a dissolution-precipitation mode; adding a poor solvent of the polyamide, which contains a dispersing agent PVP, and performing precipitation and aftertreatment to obtain the polyamide porous microspheres with high dispersibility. The preparation method does not need high-temperature high-pressure equipment, and the process is simple, convenient, economic, effective, environment-friendly and easy to implement. The used solvents are low in boiling point and insusceptible to remain, and the solvents and the dispersing agent can be recycled. The polyamide porous microspheres prepared with the method is narrow in size distribution, and fine particles with small particle size can be obtained; furthermore, the particle size can be adjusted along with the change of the preparation conditions such as the ratio of the good solvent to the poor solvent and the PVP content.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

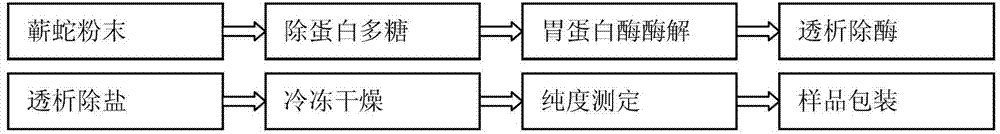

Method for extracting collagen type II by taking agkistrodon as raw material

InactiveCN103088096AHigh purityEasy to operatePeptide preparation methodsFermentationHydrolysateDissolution precipitation

The invention provides a method for extracting collagen type II by taking agkistrodon as a raw material. The method comprises the following steps of: removing protein polysaccharide from agkistrodon powder by a mixed guanidine hydrochloride-Tris-HCl solution; collecting precipitates after the polysaccharide is removed; dissolving the precipitates with an acetic acid solution; releasing the collagen type II from the solution by pepsase enzymolysis; centrifuging enzymatic hydrolysate to obtain supernatant, and salting out the supernatant to fully precipitate the collagen type II; centrifuging and collecting the precipitated collagen type II, and dissolving the precipitated collagen type II with the acetic acid solution again, and dialyzing the dissolved solution to remove the pepsase and other impure proteins; dissolving the collagen type II in a dialysis bag by the acetic acid solution again, and dialyzing the collagen type II to remove salt ions; and freezing the dialyzed liquid in the bag at a low temperature, and drying the liquid in vacuum to obtain the collagen type II of the agkistrodon. The method provided by the invention mainly has the beneficial effects that the operation is simple, and the purity of the obtained collage type II is high.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

Method for preparing high-purity vanadium pentoxide by purifying ammonium metavanadate

InactiveCN112209441AHigh purityAvoid handling difficultiesVanadium oxidesCellulosePhysical chemistry

The invention belongs to the technical field of metallurgy, and particularly relates to a method for preparing high-purity vanadium pentoxide by purifying ammonium metavanadate. Aiming at the problemsof complex process, over-high cost and the like of an existing ammonium metavanadate purification method, the invention provides a method for preparing high-purity vanadium pentoxide by purifying ammonium metavanadate, which comprises the following steps of: a, dissolving ammonium metavanadate in an alkali; b, heating and boiling the solution, adding lignocellulose, conducting stirring and reacting for 1-2 hours, conducting standing and precipitating for 12-24 hours, and conducting filtering; c, adding the filtrate into sulfuric acid, conducting heating to boil, conducting stirring for reaction for 10-30 minutes, conducting filtering, and washing a filter cake; d, heating the filter cake to 60-80 DEG C, adding ammonia water to dissolve the filter cake, quenching the solution at 5-25 DEG C, separating out white crystals, and conducting washing to obtain high-purity ammonium metavanadate; and e, calcining ammonium metavanadate to obtain high-purity vanadium pentoxide. According to the method, the ammonium metavanadate and the vanadium pentoxide which are high in purity can be prepared through alkali dissolution precipitation and hydrolysis precipitation, the technological process issimple, and the cost is low.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Biomass based polyester preparation method

A biomass based polyester preparation method is as follows: biomass based monomer 2, 5-dihydroxy methyl furan and a dibasic acid are used as raw materials for esterification prepolymerization for reaction for 0.5-10h in the presence of a catalyst at 90-300 DEG C under the protection of nitrogen; ester exchange condensation is performed at 150-350 DEG C under the condition of 1-10mmHg vacuum, and the reaction is performed for 0.1-15h; a dissolution-precipitation method is used for purification and removing of impurities and unreacted monomers and oligomers to obtain the biomass based polyester product. The biomass based polyester product prepared by the preparation method is high in yield, easy in product separation, and environmental friendly, and has good application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Multilayer high-frequency printed circuit board copper foil surface coarsening solution and using method thereof

ActiveCN110241422AImprove processing efficiencyReduce roughnessInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentPhosphoric acidCopper foil

The invention provides a multilayer high-frequency printed circuit board copper foil surface coarsening solution and a coarsening method thereof, and belongs to the technical field of printed circuit manufacturing. The copper foil coarsening solution comprises the components of hydrogen peroxide, sulfuric acid, phosphoric acid, a copper coordination agent, a corrosion inhibitor and the like, wherein the phosphoric acid, the copper coordination agent and the corrosion inhibitor form a reaction adjusting system, the oxidation reduction and the dissolution precipitation are skillfully fused together by adding a reaction regulator, and a layer of substance benzotriazole with strong affinity with resin is generated on the surface of the treated copper foil, so that organic consideration of surface coarsening and interlayer binding force of the copper foil is realized. Due to the fact that the copper reaction activity of the phosphoric acid system is low, air plasma activation is added before coarsening of the surface of the copper foil, high-activity particles such as electrons, positive ions, neutral particles and the like existing in the air plasma are utilized to activate copper, and then the treatment efficiency is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for producing porous ceramic materials by adopting low-temperature hydrothermal method

InactiveCN101570436ANo reduction in dielectric propertiesDoes not cause oxidationCeramicwareSilica particleNon oxide ceramics

The invention discloses a method for producing porous ceramic materials by adopting the low-temperature hydrothermal method. The method utilizes the hydrothermal reaction to immerse a ceramic formed body in silicon dioxide sol; according to the dissolution-precipitation mechanism, part of silicon dioxide particles can be precipitated on the surfaces of ceramic grains to play a bonding role, thereby producing the porous ceramic materials. The hydrothermal temperature in the preparation method is lower and can not cause the oxidation of non-oxide ceramics during the sintering process.

Owner:BEIHANG UNIV

Method for preparing crystalline silicon by direct electrolysis in ionic liquid at low temperature

InactiveCN104746130APolycrystalline material growthFrom normal temperature solutionsElectrolysisSemiconductor materials

The invention discloses a method for preparing crystalline silicon by direct electrolysis in an ionic liquid at low temperature, used for solving the existing problem that low temperature cannot be compatible with a crystalline structure in a process of preparing silicon by virtue of an electro-deposition method. The method is characterized in that cubic crystalline silicon can be successfully prepared within a low-temperature range from 90-120 DEG C by taking a low-temperature ionic liquid as an electrolytic solution and liquid metal and alloy thereof as a negative electrode on the basis of the characteristics of the ionic liquid which is low in melting point and not easy to volatilize as well as the dissolution-precipitation balance of silicon in a liquid metal electrode. The method disclosed by the invention has the following characteristics: low operation temperature, stable ionic liquid system, and simple and easy processing steps; the method is subjected to constant-current and constant-voltage control and easy for continuous production, and the method can significantly reduce energy consumption and cost in silicon production. The method disclosed by the invention has a good application prospect in the preparation of a semiconductor material.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

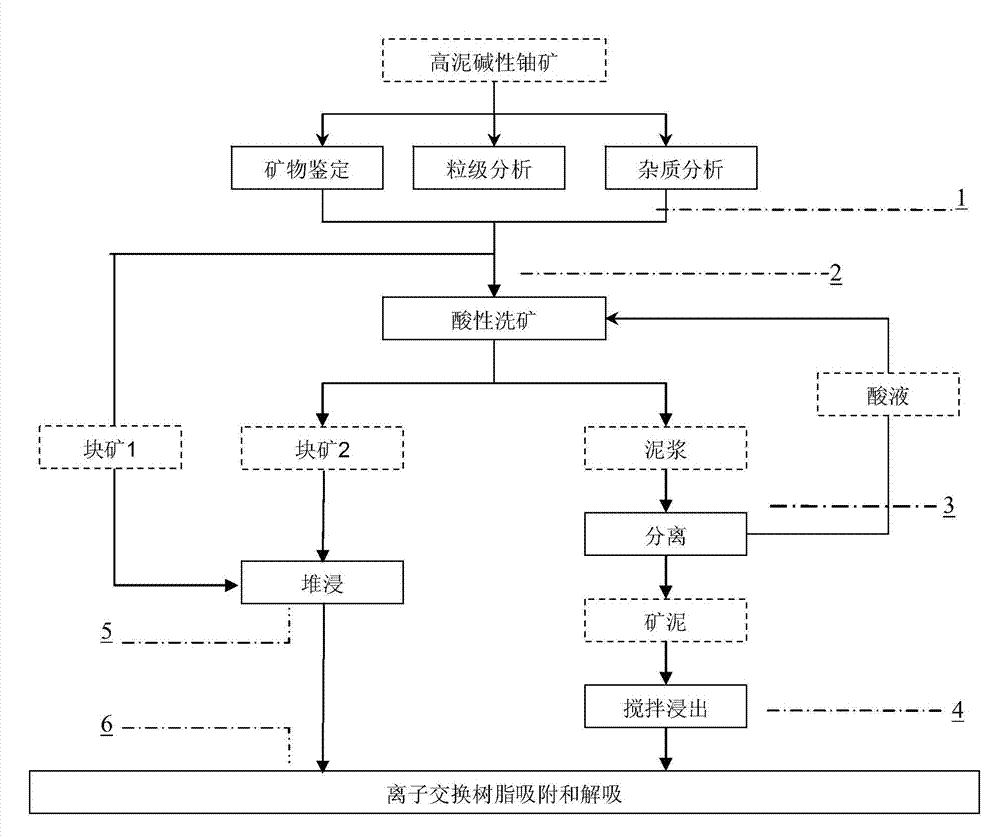

Acid ore washing biological leaching process used for high mud alkaline uranium ore

An acid ore washing biological leaching process used for high mud alkaline uranium ore comprises the following main steps: after crushing and screening of raw ore, sending + 30 mm particle grade ore into a heap field for heap construction, and performing acid ore washing treatment on-30mm particle grade ore. Sulfuric acid is added into a washing solution, then part of basic gangue is removed by ore washing, the washing solution is separated and precipitated, and an acid solution can be recycled. After processing by the acid ore washing system, + 0.074mm particle grade sand ore is sent to the heap field for heap construction, and-0.074mm particle grade sand ore enter the intensive agitation leaching process. An agitation leaching solution and a heap leaching solution are merged, and enter ion exchange resin adsorption desorption process, and finally a qualified enriched uranium product is obtained. According to the process, in the ore washing process, the part of basic gangue easy to dissolve is removed by neutralization, the problems of poor heap leaching permeability, low uranium leaching rate and the like caused by existence of mud ore and dissolution precipitation of the basic gangue can be solved, the uranium recovery rate is improved, high mud alkaline uranium ore mineral resources can be comprehensively utilized, and greater economic benefits can be obtained.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Preparation method and application of amphiphilic photoelectric active branched macromolecules

InactiveCN104650288AOptimal Control StructureEasy to operateCoatingsMaterial electrochemical variablesDispersion stabilityFiltration

A preparation method of amphiphilic photoelectric active branched macromolecules belongs to the field of macromolecular polymerization. The preparation method comprises the following steps: (1) under normal pressure condition, 7-(4-vinyl benzyloxy)-4-methylcoumarin, N-(4-vinyl benzyl)-9H-carbazole, 4-vinyl benzyl mercaptan, maleic anhydride, a radical initiator and a solvent are placed in a 250ml four-neck flask; (2) nitrogen is introduced into the container in the step (1) for 30 min, sealed stirring is carried out to fully dissolve the nitrogen, solution temperature rises to 65-70 DEG C and a thermostatic reaction is carried out for 24h; and (3) after the reaction, the solution obtained from the step (2) is precipitated in a precipitating agent and undergoes suction filtration, and a solid obtained after filtration undergoes dissolution, precipitation and suction filtration repeatedly for 3 times, and the solid obtained finally undergoes vacuum drying to constant weight. According to the invention, polymerization conditions are mild, and the preparation method is simple to operate. The polymer obtained can be used to remarkably raise dispersion stability of carbon nano-tube in an aqueous solvent.

Owner:JIANGNAN UNIV

Method for deeply purifying phosphorous and fluorine co-existing wastewater

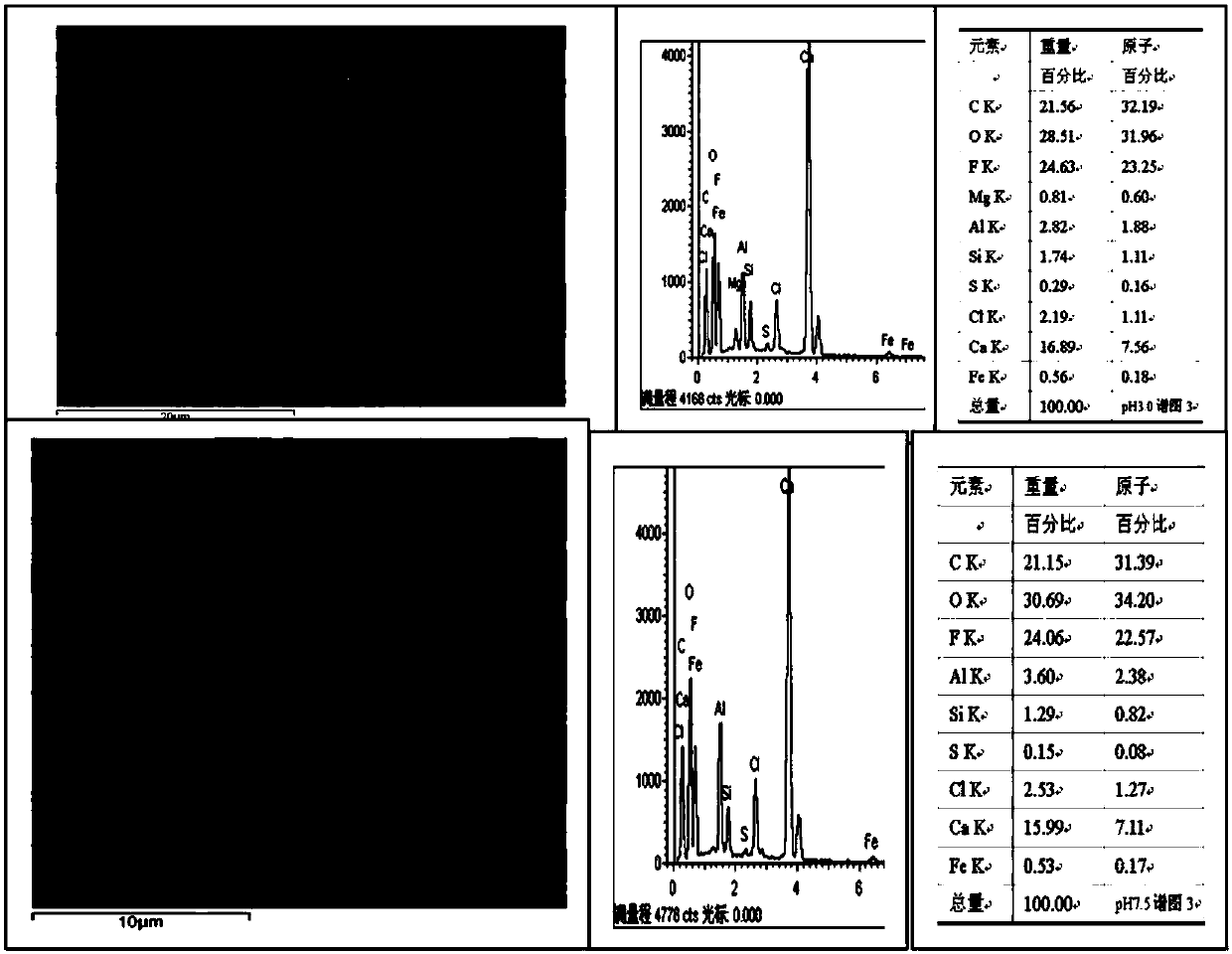

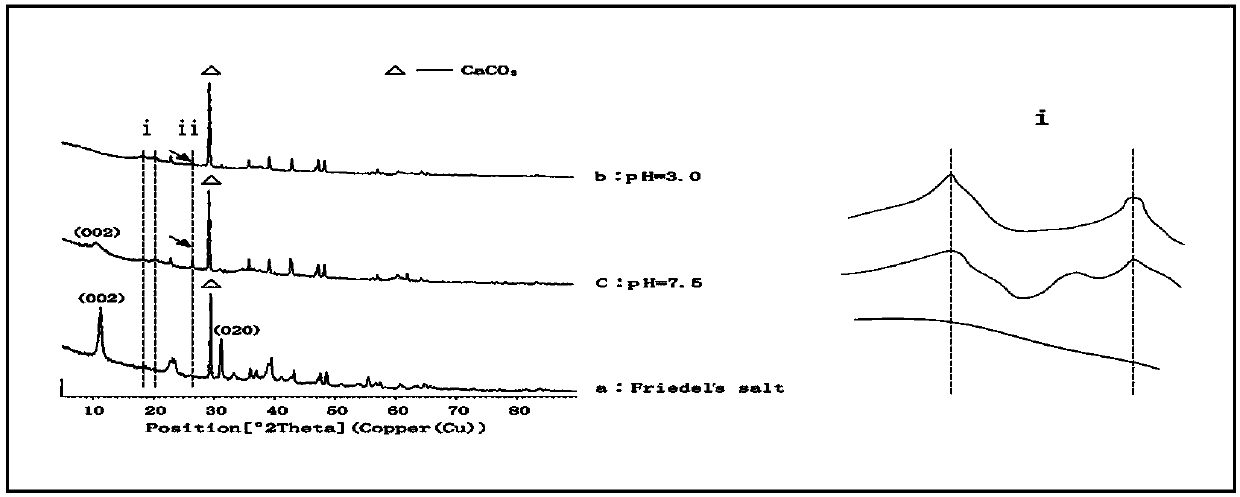

The invention discloses a method for deeply purifying phosphorous and fluorine co-existing wastewater. The method comprises the following steps: controlling removal of fluorine in polluted water by adopting Friedal salt dissolution-precipitation and ionic exchange reaction; controlling removal of phosphorous in the polluted water by adopting chemical precipitation of calcium ions and complex precipitation of a Fe-Al-Ca phosphate removing agent; completing the Friedal salt dissolution-precipitation, ionic exchange reaction, chemical precipitation of calcium ions and complex precipitation of theFe-Al-Ca phosphate removing agent under the condition of the same pH value variation in the same reactor so as to realize synchronous performance of multiple phosphorous-removing and defluorination reactions. According to the method, the technology of using Friedal salt as an absorbent for controlling fluorine removal and the technology of synchronously removing phosphorous and fluorine with Fe-Al-Ca phosphate removing agent and lime milk to control phosphorous absorption are adopted for the first time, so that synchronous performance of multiple phosphorous removing and defluorination reactions under the condition of same pH value variation in the same reactor can be realized.

Owner:GUIZHOU UNIV

Method for recovering germanium from germanium-containing material

InactiveCN106337139ASolve processing problemsReduce manufacturing costAlkali metal silicatesGermanium dioxideSoluble glassDissolution precipitation

The invention discloses a method for recovering germanium from a germanium-containing material. According to the method, a resin adsorption principle is adopted in the germanium separation process so as to thoroughly adsorb germanium into resin and let silicon enter a solvent in the form of sodium silicate. Therefore, germanium is separated thoroughly, recovery rate of germanium reaches about 95%, and the problem that lots of germanium is brought into silica precipitate in the silicon precipitation process of electrolyte produced by the electrolyte separation method of germanium is avoided. After resin adsorption, part of water is evaporated from a sodium silicate solution and then the product can be used as a soluble glass product for sale. Thus, sewage treatment problem is avoided, and production cost is reduced. Defects of a hydrofluoric acid method for processing a germanium-containing material, such as high production cost, severe equipment corrosion and environmental pollution, are eliminated; and the problem of low recovery rate in an alkali dissolution precipitation method is avoided. By the method of the invention, equipment corrosion, environmental pollution and other problems are not caused in the germanium-containing waste material dissolving process.

Owner:王朋

Method for fractional precipitation and purification of casein

ActiveCN113461795AReduce typesHigh component recoveryPeptide preparation methodsAnimals/human peptidesFractional PrecipitationAlcohol ethyl

The invention belongs to the field of separation and extraction of casein. The method comprises the steps: separating alpha-, beta-and k-casein by a simple and feasible ethanol separation, isoelectric precipitation and low-temperature cooling method; weighing a certain mass of casein, adding a certain volume of an ethanol solution, fully dissolving, centrifuging for 20 minutes, taking supernate, and carrying out rotary evaporation on the supernate to obtain a k-casein component; dissolving the obtained precipitate in water at the temperature of 20 DEG C, adjusting the pH value to 7.0, cooling for 2-6 hours at the temperature of 0-4 DEG C, adjusting the pH value to 3.5-5.5, centrifuging for 20 minutes to obtain alpha-casein precipitate, and repeatedly dissolving and precipitating to obtain high-purity alpha-casein; heating the supernatant to room temperature, adjusting the pH value to 3.5-5.5, and performing centrifuging to obtain the beta-casein component.

Owner:湖北百特威生物科技有限公司

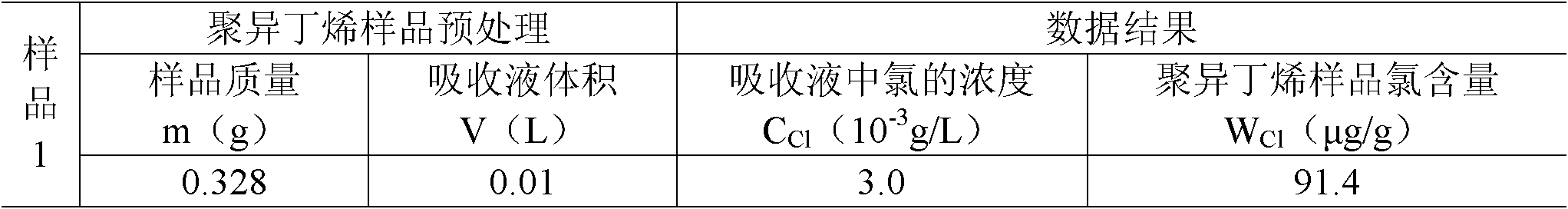

Detection method of free chlorine ions in polyisobutylene

The invention discloses a detection method of free chlorine ions in polyisobutylene, which is also applicable to the detection of other polyolefin free chlorine ions, and adopts a dissolution-precipitation method to separate and extract the free chlorine ions in the polyisobutylene and measures the chlorine ion content in the absorption liquid though the chlorine ion quantitative analysis method as the ion chromatography. The technical scheme is simple and reliable to operate, requires no special device, is particularly applicable to the detection of the free chlorine ions in the polyisobutylene, and has high detection accuracy. The detection method of the free chlorine ions in the polyisobutylene adopting the ion chromatography with the detection lower limit being ppb level is convenient and reliable.

Owner:SHANDONG UNIV

Porous polylactic acid particles and preparation method thereof

The invention discloses porous polylactic acid particles and a preparation method thereof. The preparation method comprises the following steps: dissolving polylactic acid and an inducer in a high boiling solvent, carrying out solid-liquid separation with a precipitating agent, and drying to obtain the porous polylactic acid particles, wherein the high boiling solvent has higher boiling point than the precipitating agent, and the polylactic acid is polylactic acid of which the 1.2%<=D-lactic acid mass content or 1.2%<=L-lactic acid mass content is less than 11%. The method disclosed by the invention is convenient to operate, has the advantage of mild conditions, and can be used for preparing the porous polylactic acid particles with uniform particle size distribution by using a simple dissolution-precipitation process.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Enrichment separation extraction method of rare earth element in pulverized fuel ash

InactiveCN107523695AIncrease contentEasy to operateProcess efficiency improvementRare-earth elementDissolution precipitation

The invention discloses an enrichment separation extraction method of a rare earth element in pulverized fuel ash. The method comprises following steps: the pulverized fuel ash is ground to the grain size below 200 meshes, the pulverized fuel ash is weighed and is placed in a round-bottom boiling flask, hydrochloric acid with the volume fraction being 50% is added for mixing, heating and stirring are carried out, and medium speed filter paper is used for filtering; an NaOH solution is added into filtrate, and after the reaction is finished, filtering and separate deposition are carried out; hydrochloric acid is used for dissolution precipitation, and then, an oxalic acid acetone solution is added and is heated to be boiled; ammonium hydroxide is used for adjusting the pH value of the solution to 2.0, then, water is added for dilution, and heat preservation is carried out for 1h; filtering after cooling is carried out, an oxalic acid solution is used for repeated washing, precipitation is placed in a muffle furnace to be fired for 30 min, and after firing, the matter is rare earth oxide mixed crude extract. The industrious solid rubbish pulverized fuel ash is used, the waste is turned into wealth, the beneficial effects of being easy and convenient to operate, high in extract rate and high in content of crude extract rare earth element, and the method is suitable for application and popularization.

Owner:ANHUI UNIVERSITY

Micron-sized MOF-303 and preparation method thereof

The invention belongs to the technical field of new materials, and particularly relates to micron-sized MOF-303 and a preparation method thereof. The preparation method comprises the following steps: (1) mixing 3,5-pyrazoledicarboxylic acid with deionized water and a NaOH solution, and conducting heating to obtain a mixed solution a; (2) mixing an Al source with the mixed solution a, and conducting dissolving and precipitating to obtain a mixed solution b; and (3) growing the mixed solution b at a certain temperature. In the step (3), the growth is divided into the following stages: in a first stage, growth is conducted in a temperature not less than 95 DEG C and not larger than 105 DEG C; in a second stage, growth is conducted in a temperature not less than 85 DEG C and less than 95 DEG C; in a third stage, growth is conducted at a temperature no less than 75 DEG C and less than 85 DEG C; and in a fourth stage, growth is conducted in a temperature not less than 65 DEG C and less than 75 DEG C. The prepared MOF-303 material belongs to a micron-scale flaky MOF-303 material, is uniform in size and regular in shape, can be better applied to adsorption of gas and pollutants (such as various metal ions) and a Lewis acid catalyst, and can be used as a high-efficiency water absorbent and an industrial drying agent.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Polyester self-nucleating agent as well as preparation method and application thereof

The invention discloses a polyester self-nucleating agent as well as a preparation method and application thereof. A dissolution-precipitation method is adopted. The preparation method comprises the following steps: firstly dissolving polyethylene dicarboxylate resin in a phenol / tetrachloroethane mixed solvent, chloroform, dichloromethane, tetrachloroethane, xylene, benzene, nitrobenzene, dioxane, o-chlorophenol, m-cresol or a decahydronaphthalene solvent, then precipitating out in acetone and converting an ethylene glycol structure unit in a polyester resin molecular chain into easy-to-crystallize Kink conformation through amorphous gauche conformation to obtain the polyester self-nucleating agent. The polyester self-nucleating agent is Kink conformation-based polyester resin, has rapid crystallization capacity, can be directly taken as a self-nucleating agent for the polyester resin, can also be blended with the polyester resin to form crystallization master batches firstly and then be taken as the self-nucleating agent for the polyester resin, is endowed with the rapid crystallization ability and cannot result in the reduction of molecular weight. The preparation method is simple and feasible, and facilitates industrialized application.

Owner:ZHEJIANG UNIV

Purification method of plant exosome

PendingCN114540271AHigh purityGuaranteed contentCell dissociation methodsPlant cellsBiotechnologyPlant cell

The invention belongs to the technical field of exosome separation, discloses a purification method of plant exosomes, and aims to overcome the technical problems of insufficient exosome activity, small separation and extraction amount and low purity in the existing method. The purification method of the plant exosome comprises the following steps: collecting plant cell disruption liquid, and centrifugally collecting supernate; adding a precipitation solution into the supernate to obtain a mixed solution; centrifuging the mixed solution, discarding the supernatant, collecting the precipitate, and adding PBS to completely dissolve the precipitate so as to obtain a dissolved solution; and carrying out gel filtration chromatography separation on the dissolved solution to obtain the exosome. According to the method, separation and purification of large-scale and high-purity exosomes are achieved through combination of PEG8000 precipitation and gel filtration chromatography, the content, purity and biological activity of the exosomes can be guaranteed at the same time, and the separated exosomes are high in yield and purity; the method is high in efficiency, simple to operate and easy for large-scale production.

Owner:广州远想医学生物技术有限公司

Process for preparing precipitated white carbon black by adopting carbon dioxide for decomposition

ActiveCN102040225BEliminate emissionsSolve filterabilitySilicaSodium metasilicateEnvironmental engineering

The invention relates to a process for preparing precipitated white carbon black by adopting carbon dioxide for decomposition. The process comprises the following steps: introducing the precipitator carbon dioxide into industrial sodium metasilicate solution with the pH value of 12.5-13.5 to react, stopping introducing the carbon dioxide when the pH value of the solution is 8.5-9.0, filtering thereactant to obtain metasilicic acid filter residues and filtrate containing sodium carbonate; adding water to metasilicic acid according to the liquid solid mass ratio of 6:1, stirring and washing the mixture, filtering the mixture and then washing entrained sodium carbonate solution, and drying the product to obtain the precipitated white carbon black; and returning one half of the filtrate containing sodium carbonate to the sodium metasilicate solution to be dissolved again to precipitate the metasilicic acid and concentrating and crystallizing the other half of the filtrate to obtain sodium carbonate product. The process has the following advantages: the carbon dioxide is adopted to replace the acid to precipitate the metasilicic acid in the sodium metasilicate solution, thus solving the filtering performance of the precipitate metasilicic acid in the traditional precipitation process; meanwhile, the liquid after precipitation is ensured to be the sodium carbonate solution with high additional value, thus completely eliminating discharge of waste water in the precipitation process; and besides, carbon is utilized.

Owner:KUNMING METALLURGY INST

Hydrophobic pore-blocking ingredient emulsion and preparation method thereof

ActiveCN110255962AReduce precipitationAvoid the problem of air bubble freezingIsooctyl acrylateDissolution precipitation

The invention relates to a hydrophobic pore-blocking ingredient emulsion and a preparation method thereof, wherein the raw materials mainly comprise hardening oil, an emulsifier, ammonia water, an antifoaming agent methyl high-oxygen-content silicone oil-isooctyl acrylate adduct, and water. According to the present invention, the ammoniation temperature is below a triple point temperature of 60-70 DEG C, wherein the long-chain fatty acid can be directly aminated to form a long-chain fatty acid salt emulsion without dissolution precipitation at the temperature; the methyl high-oxygen-content silicone oil-isooctyl acrylate adduct is used as the antifoaming agent so as to reduce the precipitation of long-chain fatty acid salts, eliminate a large number of bubbles present in the system, and avoid the problem of emulsion solidification due to bubbles; and the hydrophobic pore-blocking ingredient emulsion has low viscosity, can be preserved for a long time at high temperature and low temperature, and can significantly reduce the water absorption rate and the electric flux of concrete and improve the service life of concrete at a certain adding amount.

Owner:WUHAN UNIV OF TECH

Method for detecting beta-receptor agonists in pig urine

The invention belongs to the field of analytical chemistry, and particularly relates to a method for detecting beta-receptor agonists in pig urine. According to the method for detecting beta-receptor agonists in pig urine, a pig urine sample is diluted through acetonitrile containing ammonia water and centrifuged after being evenly mixed with anhydrous sodium sulfate and sodium chloride, supernatant liquor is taken and extracted through a scattered solid phase, extracted liquid is subjected to high-speed centrifugal separation to precipitate, precipitate is dissolved in a methanol-0.1% formic acid aqueous solution, a microporous membrane is used for filtration, a liquid chromatogram-tandem mass spectrum is used for measuring, and an internal standard method is adopted for quantification. According to the method, the scattered solid phase is used for extraction, impurities are adsorbed, the sample is purified, but the beta-receptor agonists in the pig urine sample are not adsorbed, 26 beta-receptor agonists can be detected at a time, and flux is high. Meanwhile, scattered solid phase extraction one-step purification is adopted, the complex steps of leaching and eluting are avoided, operation is easy, an extraction agent is low in price, cost is lower than that of an existing solid phase extraction column purification method, the quantity of organic reagents in use is small, and the health of experimenters can be protected easily.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Well washing method for in-situ leaching uranium mining

PendingCN111878039AIncrease the pumping volumeRestore permeabilityCleaning apparatusDrilling compositionPhysical chemistryEngineering

The invention provides a well washing method for in-situ leaching uranium mining, and belongs to the technical field of in-situ leaching uranium mining. The method comprises the steps that a packer islowered into a uranium deposit production well to the upper surface of a filter; water is injected into the packer for pressurization, and setting of the packer is achieved; a chemical well washing agent is injected into an ore bed through the packer, wherein the chemical well washing agent and the ore bed are subjected to a mud cake dissolution reaction; and after the mud cake is subjected to the dissolution reaction, the packer is unsealed, the packer is lifted to the ground surface, then the uranium deposit production well is subjected to water pumping, and well washing is completed when the pH value of obtained pumped well washing water is 6.5-7.5. An ore bed is sealed through the packer, then the chemical well washing agent is directionally injected into the ore bed under the actionof pressure, dilution of a solution in the well to the chemical well washing agent is reduced, precipitates are fully dissolved through the chemical well washing agent, the permeability of the ore bedis recovered, the liquid pumping amount of the production well is increased, and then the well washing effect is improved.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com