Sulfonate-anion-functionalized biodegradable polyester and preparation method thereof

A technology for biodegrading polyester and sulfonate anions, applied in the production of bulk chemicals, etc., can solve the problems of low reactivity of sulfonated monomers, high price, difficulty in preparing high molecular weight polyester, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

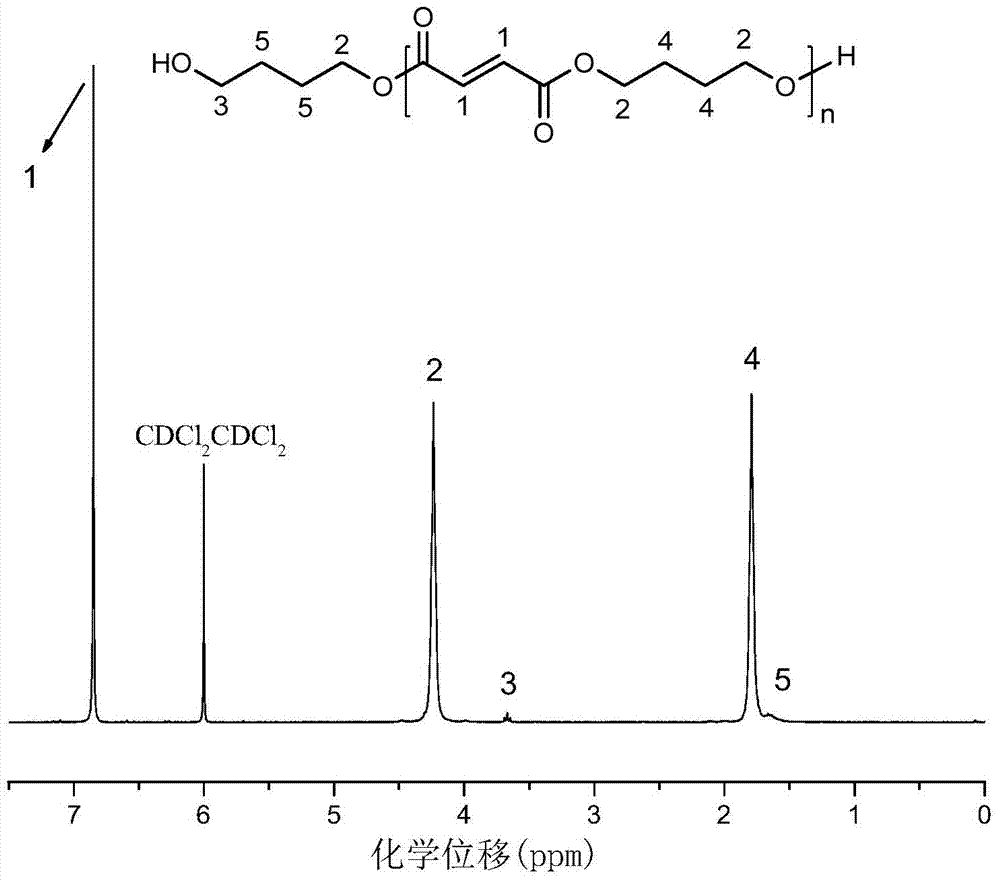

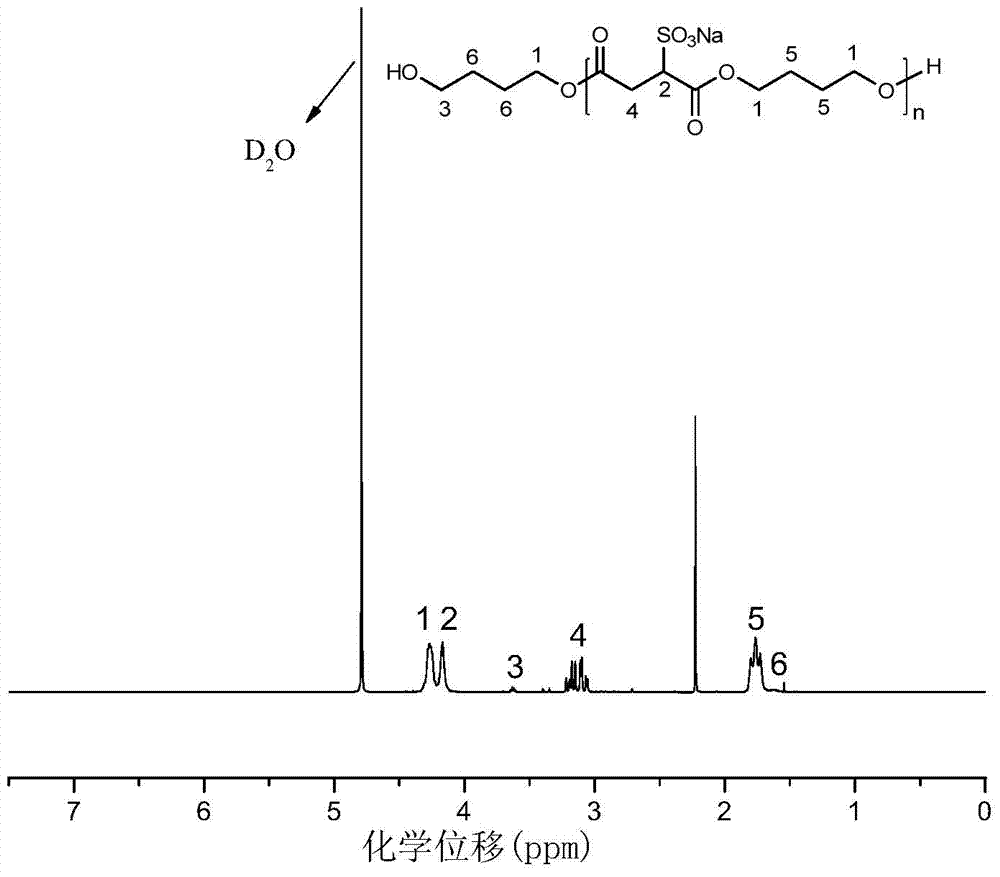

[0047] Embodiment 1, prepare the polybutylene fumarate of sulfonate anion functionalization

[0048] 1) prepare polybutylene fumarate homopolymer

[0049] At normal temperature and pressure, add fumaric acid and 1,4-butanediol with a molar ratio of 1:1.25 into a four-necked flask replaced with high-purity nitrogen; control the temperature of the system at 150°C, and stir the reaction with nitrogen gas until the water output reaches 95% of the theoretical water output; then add the catalyst tetraisopropyl titanate 0.0005g / 1g polybutylene fumarate homopolymer under the protection of nitrogen atmosphere, and stir rapidly to make it disperse evenly; The pressure of the system was slowly reduced to 50Pa, and the polycondensation reaction was carried out at 200°C for 5 hours to obtain a polybutylene fumarate homopolymer with a number average molecular weight of 30,000g / mol and a molecular weight distribution of 2.32. and attribution as figure 1 shown;

[0050] 2) Preparation of p...

Embodiment 2

[0052] Embodiment 2, preparation of sulfonate anion functionalized biodegradable polyester

[0053] 1) prepare polyethylene glycol maleate homopolymer

[0054] Under normal temperature and normal pressure, add maleic acid and ethylene glycol with a molar ratio of 1:2.5 into a four-necked flask replaced by high-purity nitrogen; control the temperature of the system at 160°C, and stir the reaction with nitrogen until the water output reaches 95% of the theoretical water output; then add the catalyst tetrabutyl titanate 0.0005g / 1g polyethylene maleate homopolymer under the protection of nitrogen atmosphere, stir rapidly to disperse it evenly; then slowly reduce the system pressure to 5Pa, polycondensation reaction at 220°C for 3 hours to obtain a homopolymer of polyethylene glycol maleate with a number average molecular weight of 88,600g / mol and a molecular weight distribution of 2.51;

[0055] 2) Preparation of sulfonate anion functionalized polyethylene glycol maleate

[0056...

Embodiment 3

[0057] Example 3, preparation of sulfonate anion functionalized biodegradable polyester

[0058] 1) prepare polydecanediol maleate homopolymer

[0059] Add maleic anhydride and 1,10-decanediol with a molar ratio of 1:2 to a four-necked flask replaced with high-purity nitrogen at normal temperature and pressure; control the temperature of the system at 200°C, and stir the reaction to The water output reaches 95% of the theoretical water output; then add the catalyst tetrabutyl titanate 0.0005g / 1g polydecanediol maleate homopolymer under the protection of nitrogen atmosphere, and stir rapidly to make it disperse evenly; after that, the system pressure Slowly lowered to 100Pa, polycondensation reaction at 230°C for 4 hours to obtain a polydecanediol maleate homopolymer with a number average molecular weight of 500,000g / mol and a molecular weight distribution of 2.11;

[0060] 2) Preparation of sulfonate anion functionalized polydecanediol maleate

[0061] Take 5g of the polydec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com