Multilayer high-frequency printed circuit board copper foil surface coarsening solution and using method thereof

A printed circuit board, surface roughening technology, applied in the direction of printed circuit, printed circuit manufacturing, printed circuit secondary processing, etc., can solve the problem that it is difficult to take into account the interlayer bonding force and high-frequency signal integrity of multilayer boards at the same time , to achieve excellent technical effects, improve processing efficiency, and reduce investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

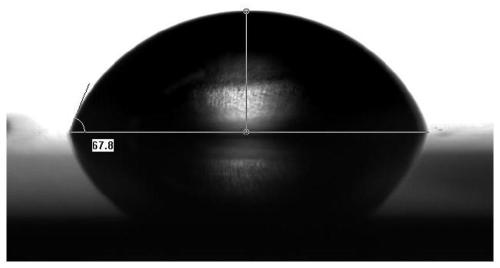

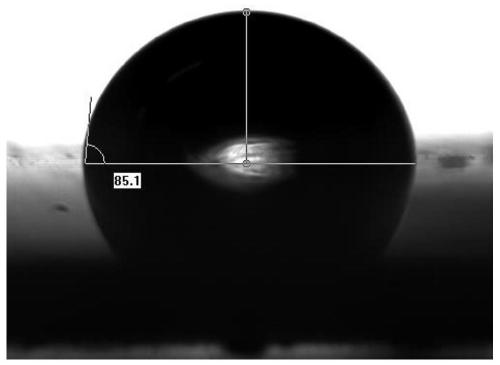

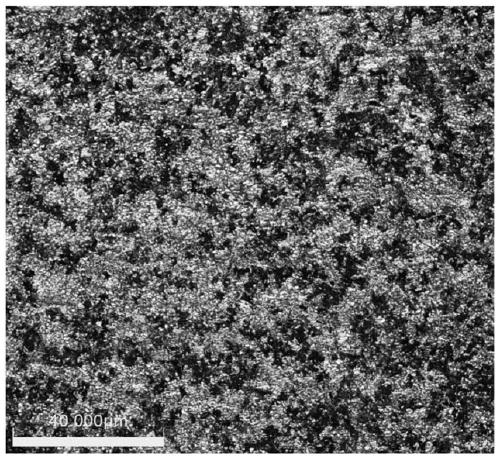

[0030] In this embodiment, M6G copper foil for high-frequency and high-speed printed circuit board manufacturing is selected. The thickness of the copper layer is 35 μm, and it is cut into a size of 40 mm×40 mm with a cutter.

[0031] A kind of surface roughening liquid of copper foil of multi-layer high-frequency printed circuit board, preparation steps are as follows:

[0032] First add a certain amount of deionized water, slowly add 75 grams of 98% concentrated sulfuric acid into the deionized water, stir while adding, and after the mixed solution is cooled, add 65 grams of 85% phosphoric acid, 45 grams of 30% hydrogen peroxide, and 8 grams of ethyl alcohol in sequence. Disodium diamine tetraacetate, 2 grams of benzotriazole, and 6 grams of polyethylene glycol were finally adjusted to 1000 ml with water to obtain the roughening solution required in this embodiment.

[0033] A method for roughening the copper foil surface of a multilayer high-frequency printed circuit board,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com