Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

235 results about "Dipropylene glycol methyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

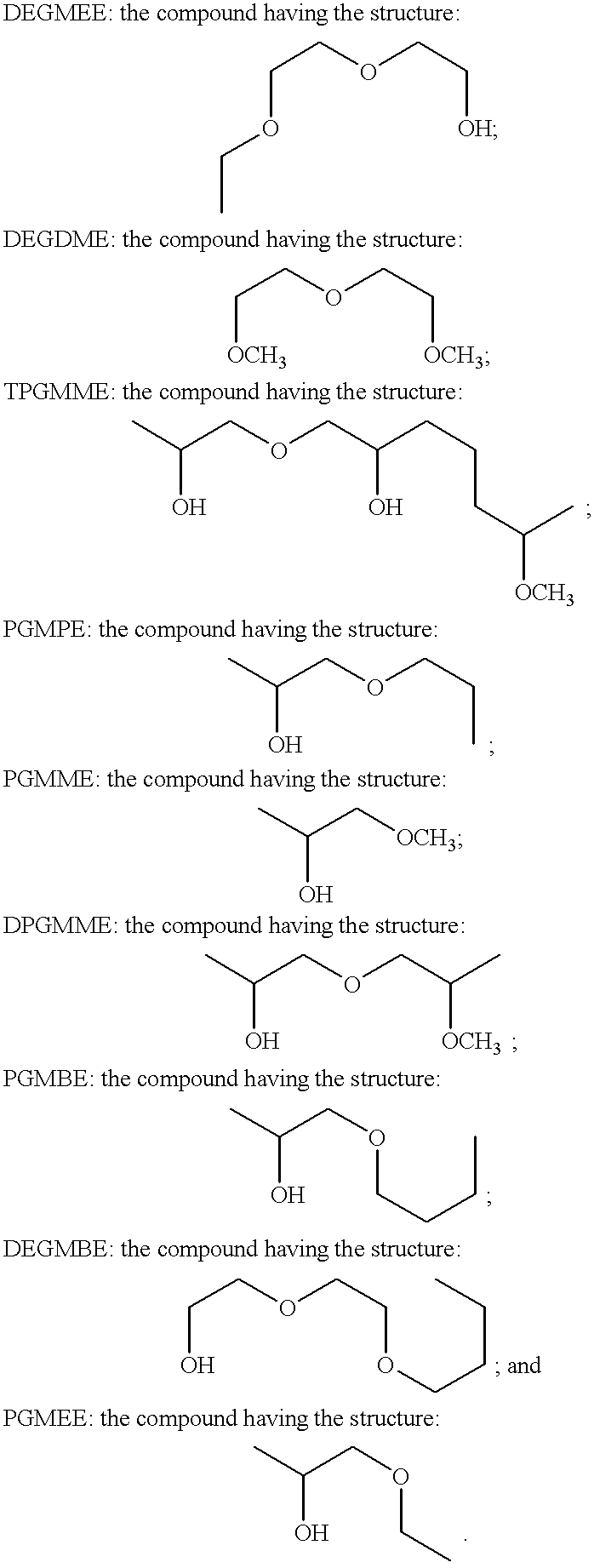

Inventor

Dipropylene glycol methyl ether (DPGME) is one of the most commonly used propylene glycol ethers in industry and is discussed in a recently published NEG/NIOSH document. (Ref. 5.1) DPGME is a collective term describing a mixture of structural isomers.

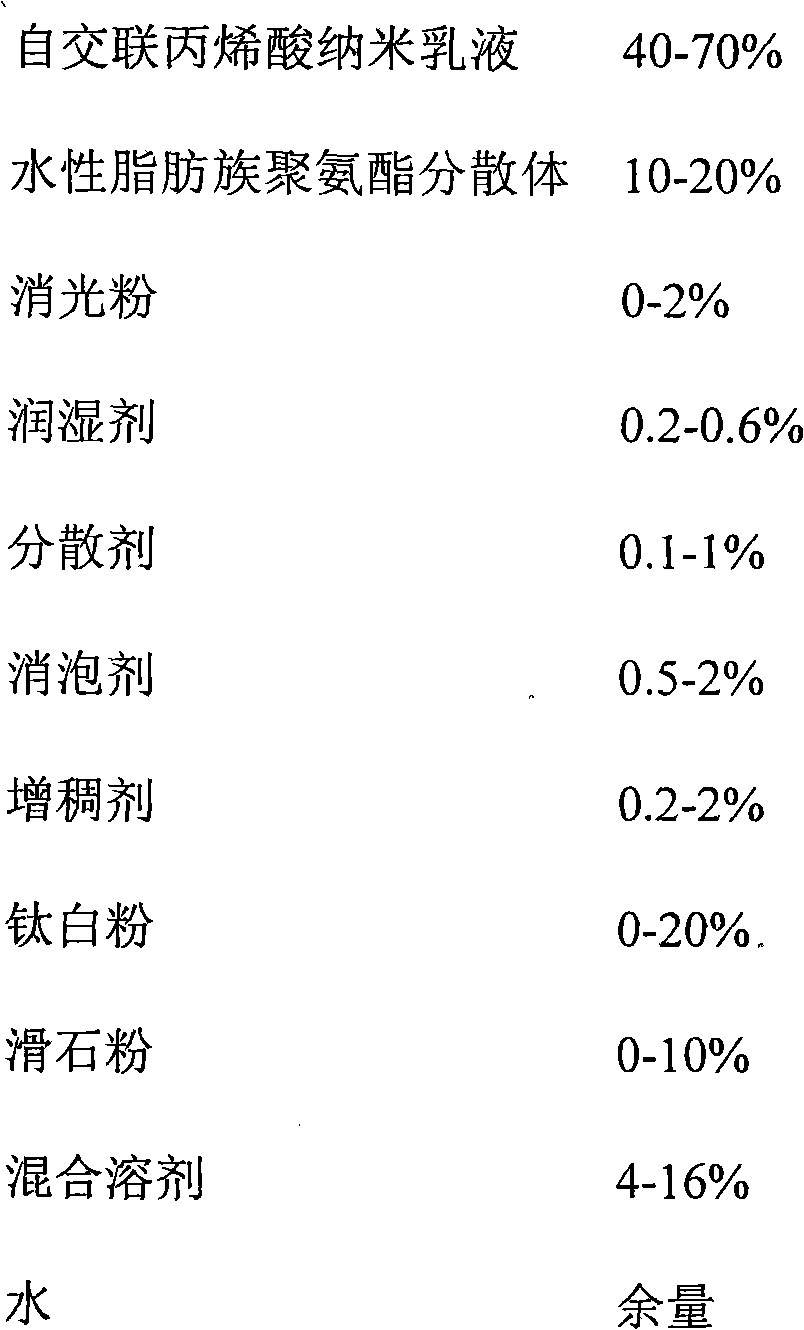

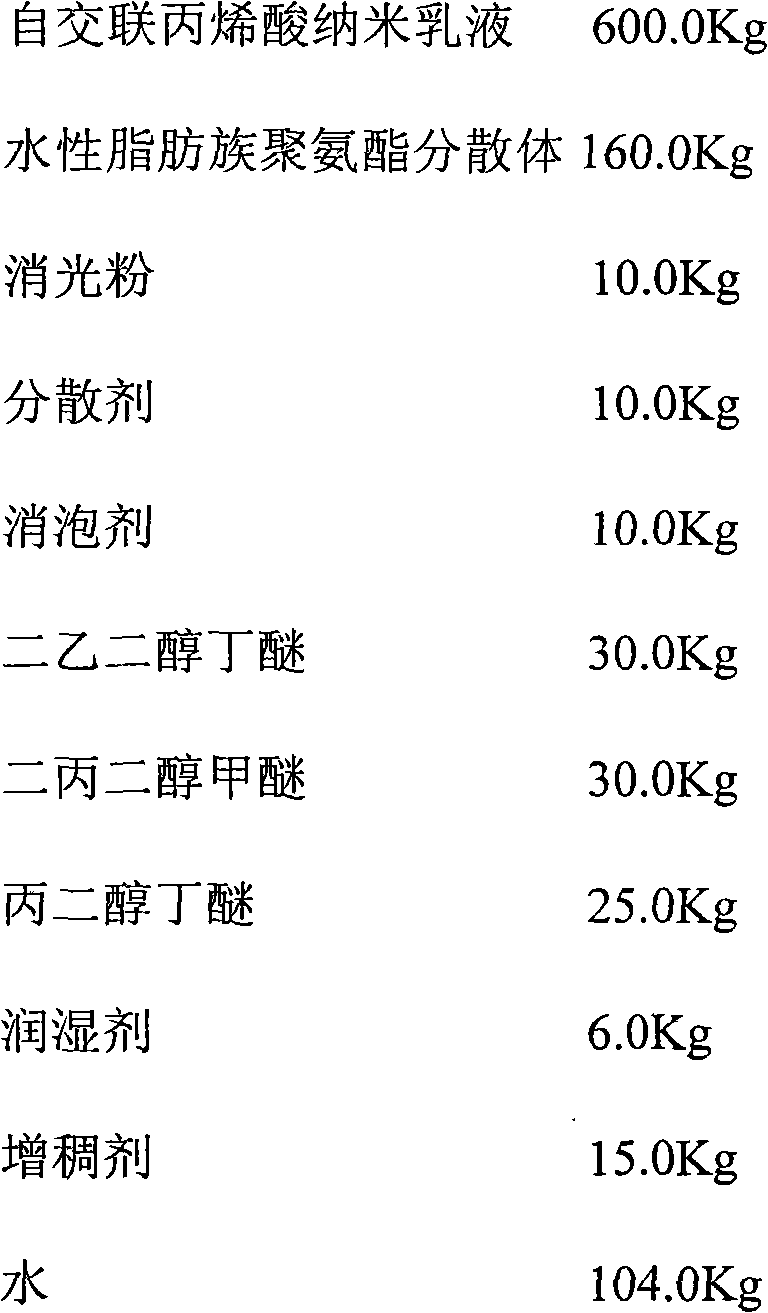

Environmentally-friendly high-performance water-based woodware paint and using method thereof

ActiveCN102051096AGood weather resistanceGood quick dryingPolyurea/polyurethane coatingsDiethylene glycol monobutyl etherWater based

The invention discloses an environmentally-friendly high-performance water-based woodware paint and a using method thereof. The environmentally-friendly high-performance water-based woodware paint comprises 40 to 70 weight percent of self-crosslinking acrylic nano-emulsion and 10 to 20 weight percent of water-based aliphatic polyurethane dispersion. The water-based woodware paint is mainly prepared from the self-crosslinking acrylic emulsion with high triglyceride (Tg) content and weather resistance, so that a paint film has high quick-drying property, chemical resistance and weather resistance, and economy; the self-crosslinking acrylic emulsion is compounded with castor oil modified aliphatic polyurethane dispersion, so that the paint film has high adhesion, hardness, fullness, weather resistance, dry heat resistance and block resistance; and diethylene glycol monobutyl ether is matched with dipropylene glycol methyl ether and propylene glycol monobutyl ether, so that the film forming property of the paint film is ensured, and high drying property is achieved.

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

Water-based woodenware matte varnish

InactiveCN101186773AGood chemical resistanceImprove grinding effectLiquid surface applicatorsCoatingsWater basedCross-link

The invention discloses matte transparent finish paint for the surface of wooden ware which is used for family decorates and furniture production. The formula and mixture ratio are that self-cross linking acrylic resin is 75-85, polysiloxane antifoaming agent is 0.3-0.6, organic silicon flatting and slipping agent is 0.3-0.6, polyether modified wetting agent is 0.3-0.5, macromolecular dispersant is 0.3-0.5, silica matting agent is 1.5-3, Dipropylene Glycol Methyl Ether is 5-8, propyleneglycol monobutyl ether is 5-8, polyurethane associated rheological additives are 1-3, and water is 4-6. The invention is characterized by 1, good chemical resistance, 2, excellent blocking resistance, 3, good sanding ability, 4, high hardness, 5, good waterproof property, 6, excellent fullness and hand feeling.

Owner:GUANGDONG SANVO CHEM IND TECH

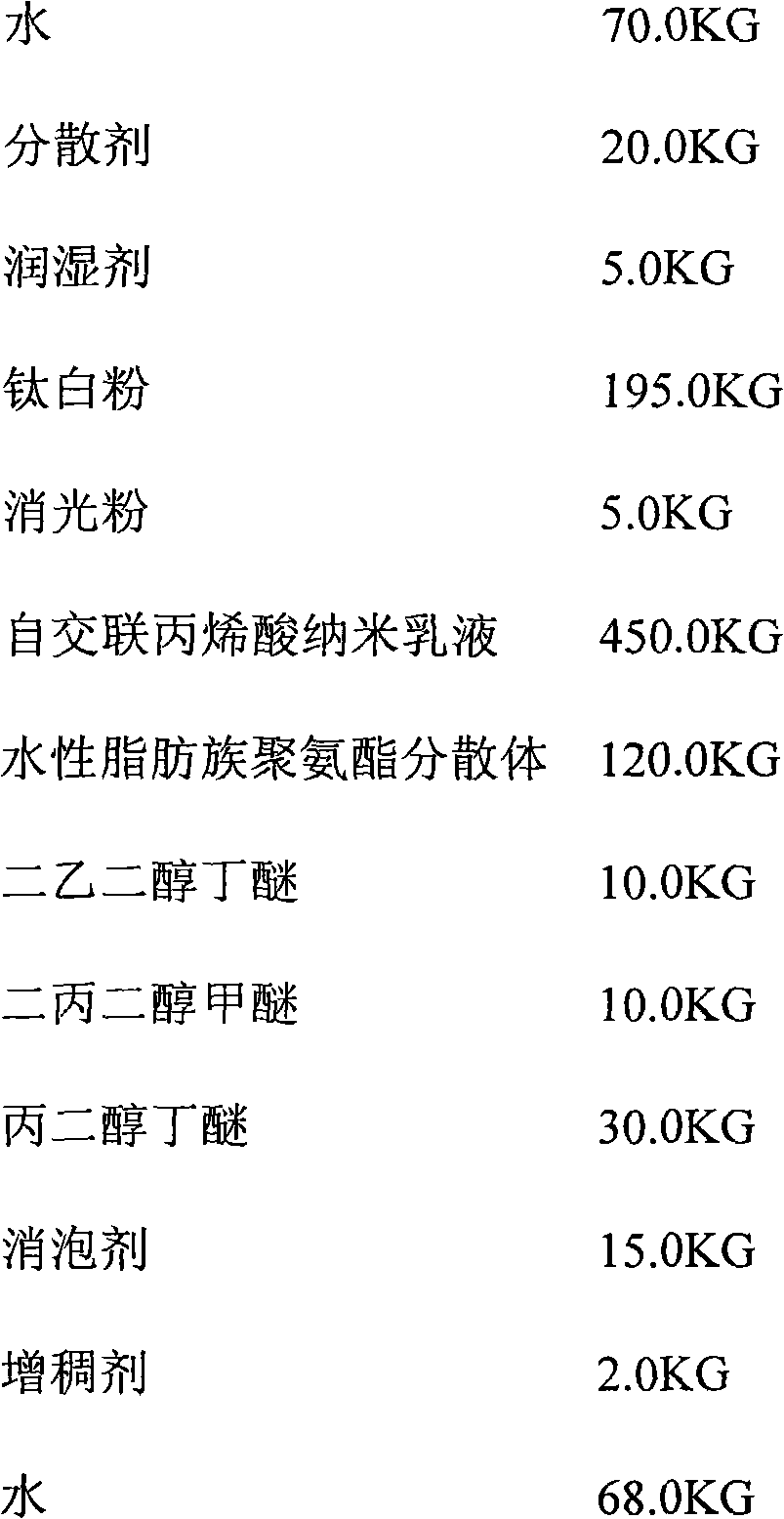

White waterborne wood base coat for medium density fiberboard and preparation technology thereof

Owner:ZHEJIANG FEIDA ZHONGKE FINE CHEM

Zinc base liquid composite heat stabilizer and preparation method of zinc base liquid composite heat stabilizer

The invention discloses a zinc base liquid composite heat stabilizer and a preparation method of the zinc base liquid composite heat stabilizer. The heat stabilizer is formed by the following raw materials according to mass ratio: 40-60 parts of barium fatty acid, 10-18 parts of zinc fatty acid, 10-35 parts of phosphite ester, 2-7 parts of beta-diketone, 1-10 parts of anti oxidizers and 10-20 parts of solvent, wherein barium in the barium fatty acid accounts for 10-15 percent in mass fraction, zinc in the zinc fatty acid accounts for 8-12 percent in mass fraction, and one of diethylene glycolmonobutylether, butyl cellosolve, dipropylene glycol methyl ether, tripropylene glycol methyl ether, white oil or coal oil is used as the solvent; the zinc base liquid composite heat stabilizer can effectively delay zinc burning phenomenon in a system, the PVC (polyvinyl chloride) thermal stabilization is improved, auxiliaries and PVC resin selected in the system have more approximate refractive indexes, a prepared PVC product has good transparent performance and good anti-precipitation property.

Owner:ZHEJIANG HIMPTON NEW MATERIAL

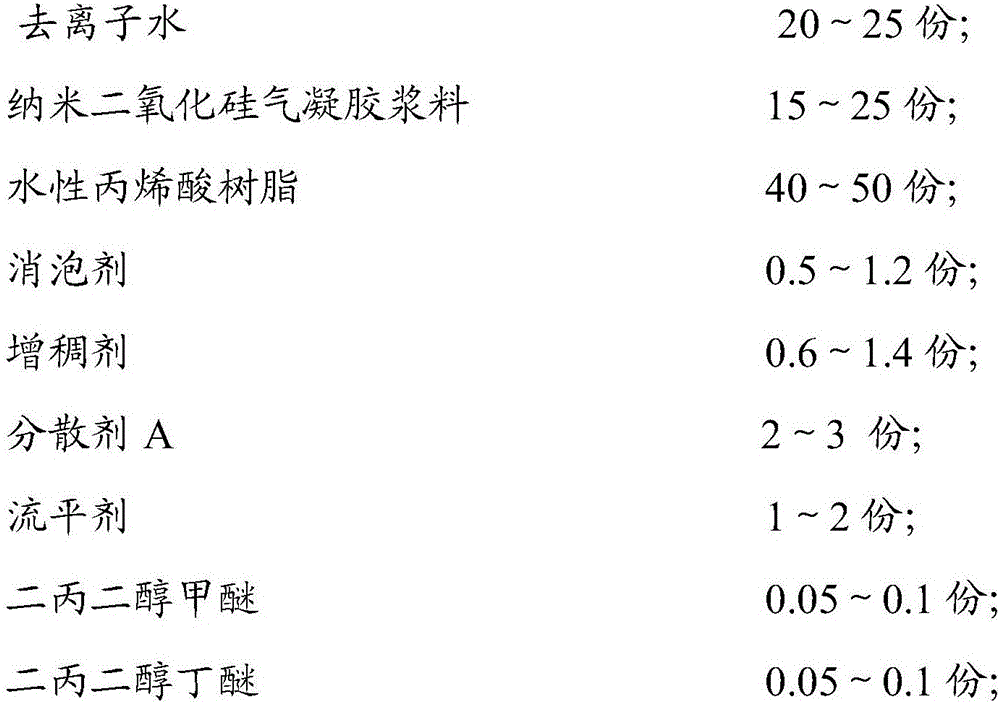

Nano transparent heat-insulating coating and preparation method thereof

ActiveCN105694629AEliminate the problem of easy agglomeration and difficult dispersionLow costCoatingsWater basedAcrylic resin

The invention discloses a nano transparent heat-insulating coating and a preparation method thereof. The nano transparent heat-insulating coating comprises raw materials in parts by weight as follows: 20-25 parts of deionized water, 15-25 parts of nano-silica aerogel slurry, 40-50 parts of water-based acrylic resin, 0.5-1.2 parts of a defoaming agent, 0.6-1.4 parts of a thickening agent, 2-3 parts of a dispersing agent A, 1-2 parts of a leveling agent, 0.05-0.1 parts of dipropylene glycol methyl ether and 0.05-0.1 parts of dipropylene glycol monobutyl ether. The single nano-silica aerogel slurry with excellent performance is added to the nano transparent heat-insulating coating and modified with the optimized dispersing agent, the problems that the nano transparent heat-insulating coating is prone to agglomeration and is difficult to disperse are solved, the ideal nano transparent heat-insulating coating is prepared through optimization of the other raw materials, ratio, processing steps, parameters and the like, the cost is saved, and the construction technology is simplified.

Owner:GUANGZHOU BAIYUN CHEM IND

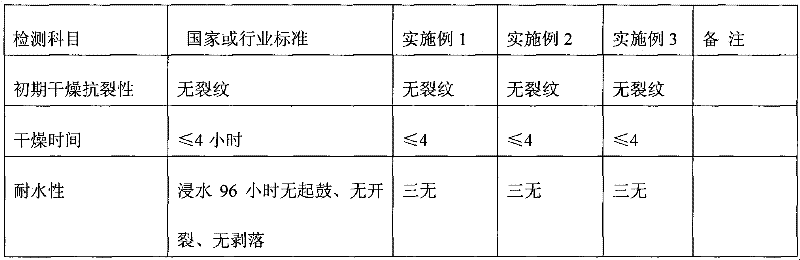

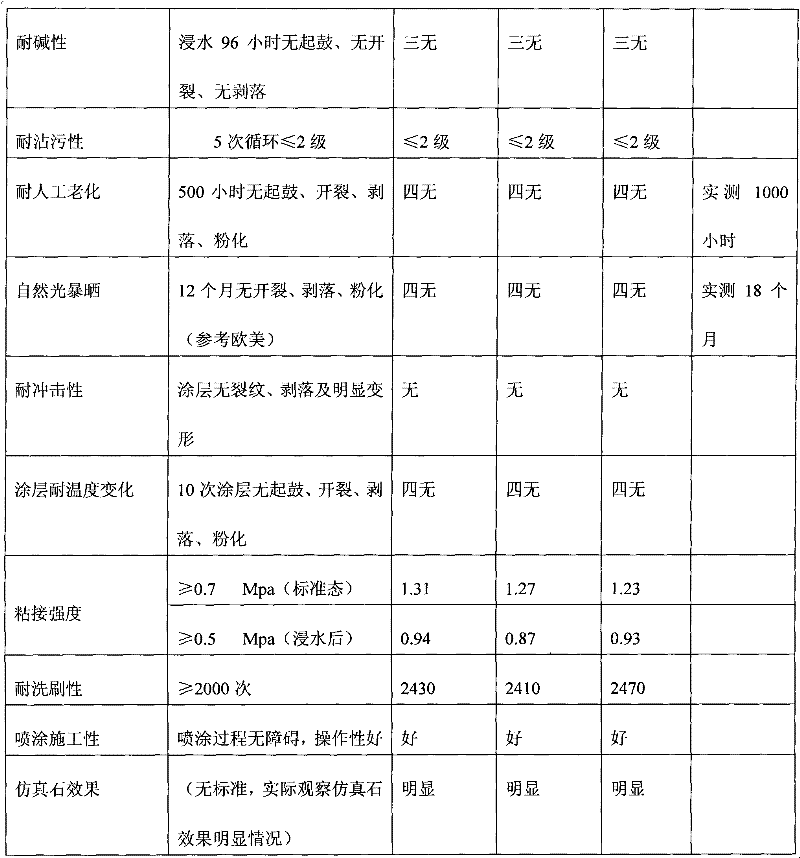

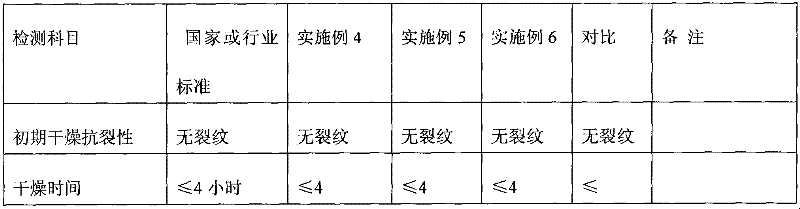

Sand textured two-component plaster mortar composition

The invention provides a sand textured two-component plaster mortar composition. The composition consists of the following components in parts by weight: 20 to 30 parts of white cement, 40 to 60 parts of silicon carbide, 0.5 to 1.5 parts of gelatin powder, 0.1 to 0.3 part of xanthan gum, 0.1 to 0.2 part of cellulose ether, 3 to 7 parts of lithopone, 1.5 to 3 parts of fire retardant, 0.1 to 0.5 part of sodium tripolyphosphate, 0.1 to 0.5 part of hardening agent, 0.1 to 0.3 part of defoaming agent, 40 to 50 parts of modified polyurethane emulsion, and 1 to 3 parts of dipropylene glycol methyl ether. A filmed polyurethane adhesive film has hydrophobic nature better than an adhesive film copolymerized from pure acrylic acid, styrene-acrylate or vinyl acetate, so that the mortar spraying effect is excellent, and the effect of simulating stones rivals that of stones; and the composition has good effects in adhesive strength, water resistance, stain resistance, light and weather resistance.

Owner:苏州盛泽科技创业园发展有限公司

American type water-based coating finish paint and preparation method thereof

InactiveCN102408826AImprove adhesionGood chemical resistancePolyurea/polyurethane coatingsPolymer scienceAziridine

The invention provides an American type water-based coating finish paint and a preparation method thereof. The finish paint comprises the following components in mass percent: 5-25% of self-crosslinking acrylic emulsion, 30-50% of polyurethane modified acrylic emulsion, 5-30% of polyurethane dispersion emulsion, 0.05-0.1% of macromolecular segmented copolymer solution containing pigment affinity groups, 0.1-0.3% of polysiloxane mixture, 0.2-0.5% of organic silicon flatting agent, 0.05-0.2% of primary amine multifunctional additives, 0.5-2% of silica matting powder, 1-4% of dipropylene glycol methyl ether, 3-5% of dipropylene glycol butyl ether, 5-10% of deionized water, 2-4% of polyethylene wax water-based dispersion, 0.2-0.4% of polyether siloxane copolymer emulsion, 0.1-0.3% of non-ionic special polyurethane polymer, 0.1-0.3% of polysiloxane-polyether copolymer and 0.3-3% of one or two of silane coupling agent and aziridine. The finish paint provided by the invention is used for solid wood substrates, is environment-friendly and has excellent performance, and the adhesive force, glossiness and hardness of the finish paint can meet the operating requirements of indoor decoration of wooden furniture.

Owner:KUSN WANSHENG CHEM

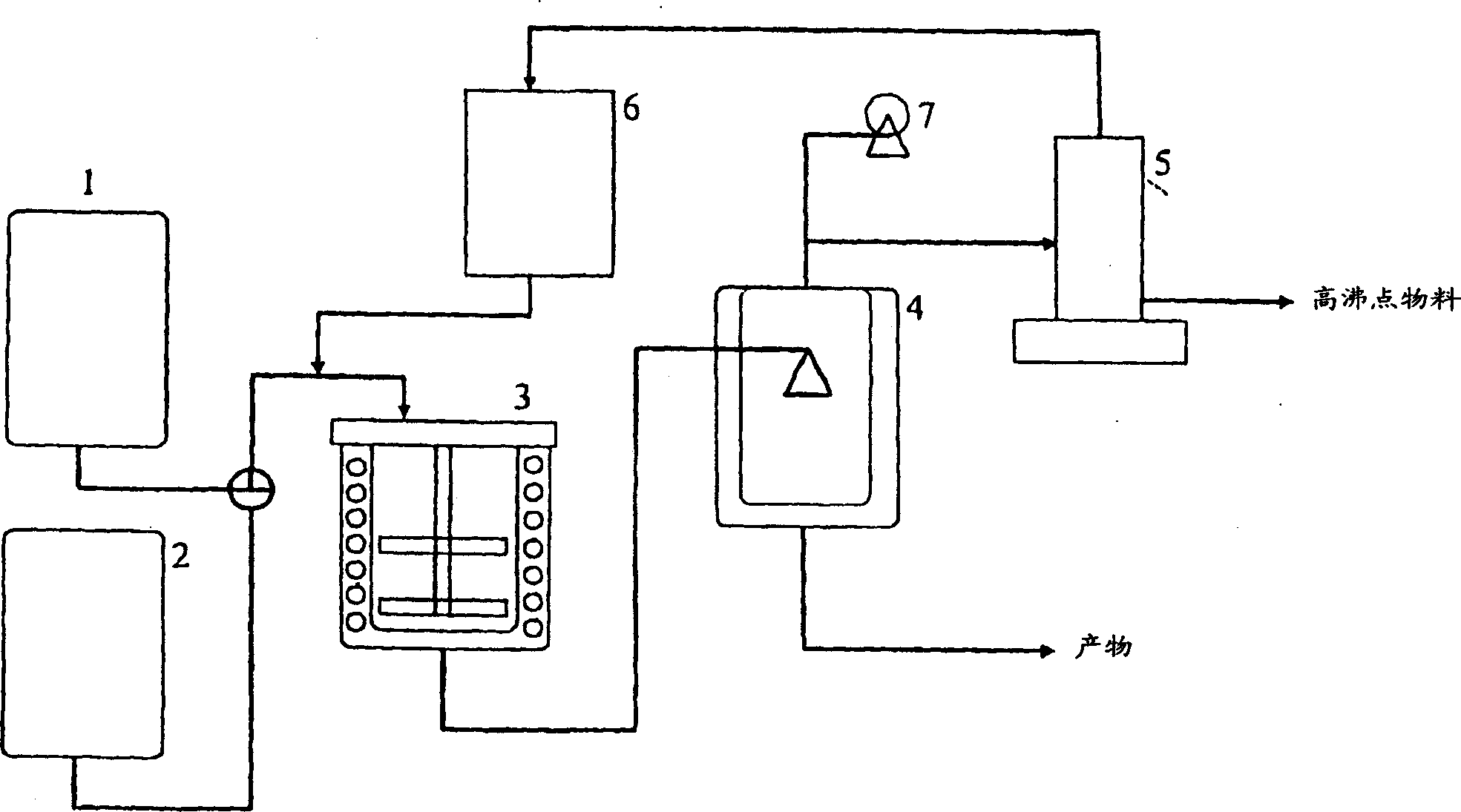

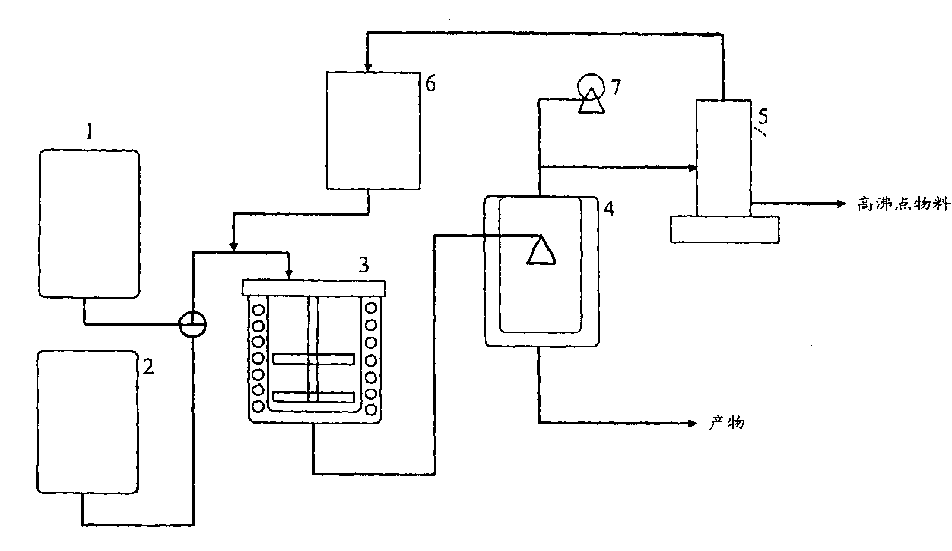

Process for preparing water-soluble styrenelacrylic resins by continuous bulk polymerization

The invention relates to a bulk polymerization process for preparing water-soluble styrene / acrylic resins, in which styrene and acryl monomers are polymerized in a solvent mixture of dipropylene glycol methyl ether and water in a temperature-controllable reactor equipped externally with an oil jacket containing a cooling coil therein and the resulting polymers are deprived of volatile contents in a falling-strand type devolatilizer. The water-soluble styrene / acrylic resins take industrial advantages over conventional resins because the resins, if polymerized at lower temperatures, show lower molecular weights, narrower molecular weight distributions, higher acid values and lower volatile content.

Owner:HANWHA CHEMICAL CORPORATION

Single phase aqueous surfactant-free nontoxic air freshening composition and wick-containing air freshening device using said composition

Described is a single phase aqueous surfactant-free nontoxic air freshening composition containing 30-70% water, 5-20% of a fragrance, at least 60% of the components of which has a C log10P<=2.5 and 30-60 weight percent of a mixture of two glycol ether components:(i) dipropylene glycol methyl ether; and(ii) propylene glycol propyl ether or propylene glycol butyl ether.Also described is an air freshener device comprising a vessel for the aforementioned composition, an emanating surface and a wick for supplying the composition to the emanating surface.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

High-temperature-resistant heat-dissipating graphene-carbon nanotube coating and preparation method thereof

InactiveCN106700756AOvercome the defect of unsatisfactory heat dissipation effectFireproof paintsAnti-corrosive paintsLow speedCarbon nanotube

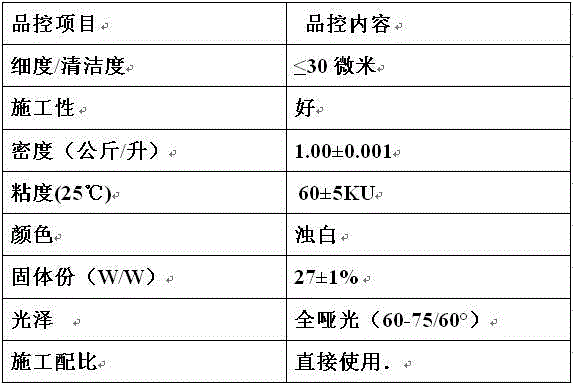

The invention discloses high-temperature-resistant heat-dissipating graphene-carbon nanotube coating. The high-temperature-resistant heat-dissipating graphene-carbon nanotube coating comprises the following components in parts by weight: 30-40 parts of a graphene-carbon nanotube composite slurry, 28-45 parts of waterborne fluorocarbon resin or a fluorocarbon resin emulsion, 15-30 parts of water, 0.1-0.3 part of a defoaming agent, 0.1-0.3 part of a leveling agent, 0.1-0.3 part of a thickening agent and 2-5 parts of dipropylene glycol methyl ether. A preparation method of the high-temperature-resistant heat-dissipating graphene-carbon nanotube coating comprises the following steps: grinding the graphene-carbon nanotube composite slurry till the fineness is lower than or equal to 30 microns; then performing magnetic field induction; then sequentially adding water, the defoaming agent, the waterborne fluorocarbon resin or fluorocarbon resin emulsion, the leveling agent, the thickening agent and the dipropylene glycol methyl ether, and stirring at a low speed. By improving the orientation of the tube diameter of carbon nanotubes and then by doping a proper amount of graphene through chemical means, the heat conductivity and the heat emission of the carbon nanotubes and the graphene are further improved, so that the heat-dissipating effect is more ideal; in addition, by replacing a film-forming base material with the waterborne fluorocarbon resin or fluorocarbon resin emulsion with better weather resistance and high temperature resistance, the application field of the heat-dissipating coating is widened.

Owner:苏州碳丰石墨烯科技有限公司

Acrylic acid water-based paint and preparation method thereof

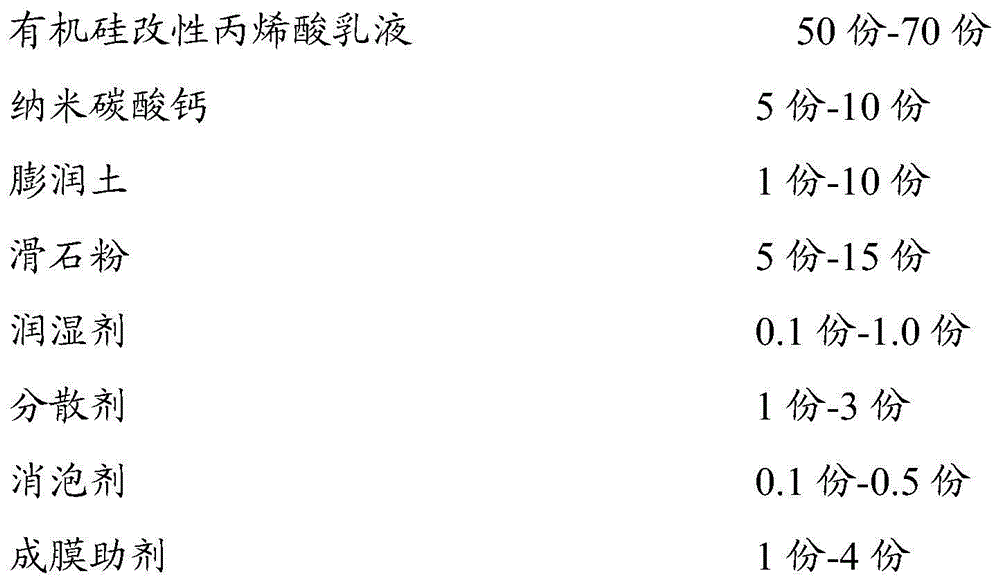

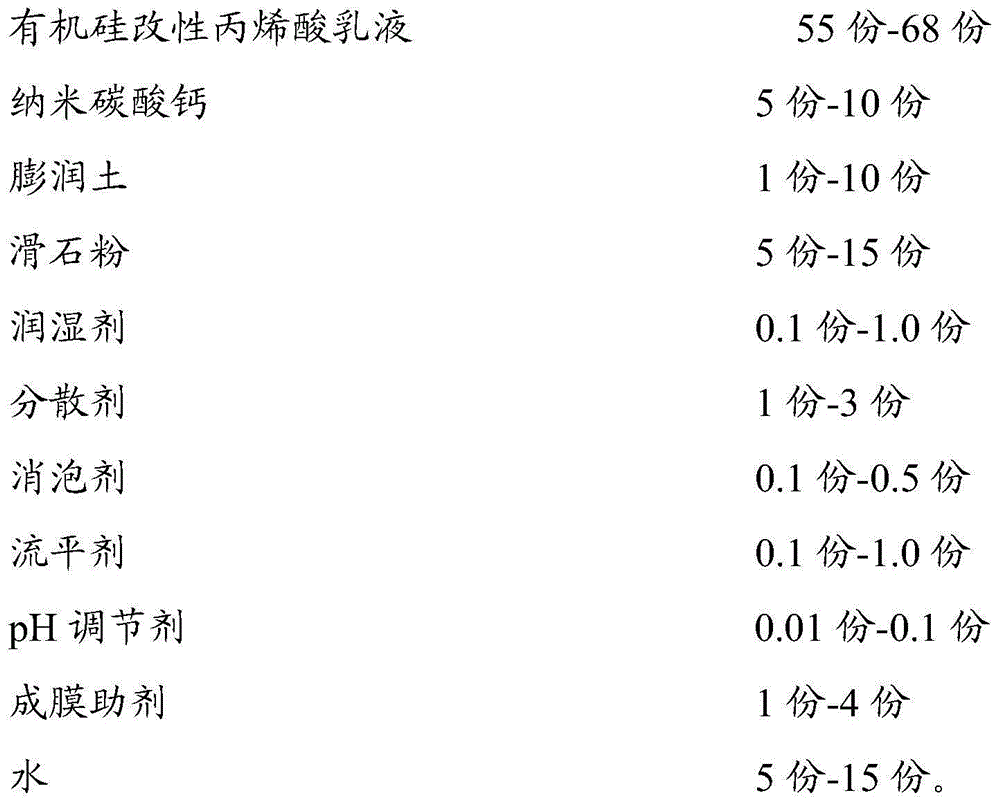

The invention relates to an acrylic acid water-based paint comprising the following components in parts by weight: 50-70 parts of organic modified acrylic acid emulsion, 5-10 parts of nano calcium carbonate, 1-10 parts of bentonite, 5-15 parts of talcum powder, 0.1-1.0 part of a wetting agent, 1-3 parts of a dispersing agent, 0.1-0.5 part of a defoaming agent, 1-4 parts of a coalescing agent and 1-25 parts of water, wherein the coalescing agent is compounded of dipropylene glycol n-butyl ether and dipropylene glycol methyl ether at a molar ratio of 1:(1-3). The acrylic acid water-based paint has good abrasive resistance, water resistance, resistance to soiling and scratch resistance, high hardness and excellent physical and chemical property.

Owner:广东朗法博涂装新材料科技有限公司

Alcohol-free fountain solution for printing and preparation method thereof

InactiveCN103722928AReduce surface tensionImprove wettabilityPrinting pre-treatmentAlcohol freeSodium metasilicate

The invention discloses an alcohol-free fountain solution for printing and a preparation method thereof. The alcohol-free fountain solution is composed of, by weight, 2-4% of apricot glue, 4-6% of dipropylene glycol methyl ether, 3-5% of sodium metasilicate, 0.5-1% of octadecyl dimethyl benzyl ammonium chloride, 1-3% of cocamidopropyl betaine, 0.5-1% of lauryl dimethyl amine oxide, 1.5-2.5% of lanolin alcohol polyoxyethylene ether, 2-4% of triethanolamine phosphate, 1.5-2.5% of liquid citric acid, 1-2% of zinc nitrate and the rest water. The alcohol-free fountain solution is free of adding of any alcohol, completely free of containing of VOC substances, completely environment friendly and harmless to human body, has the advantages of low surface tension, good wettability and stable chemical performance, is an ideal fountain solution for a high-speed multicolor offset press, can remarkably improve printing effect and quality, is simple in preparation process and low in production cost, and has important economic and social benefit.

Owner:青岛中科菲力工程技术研发有限公司

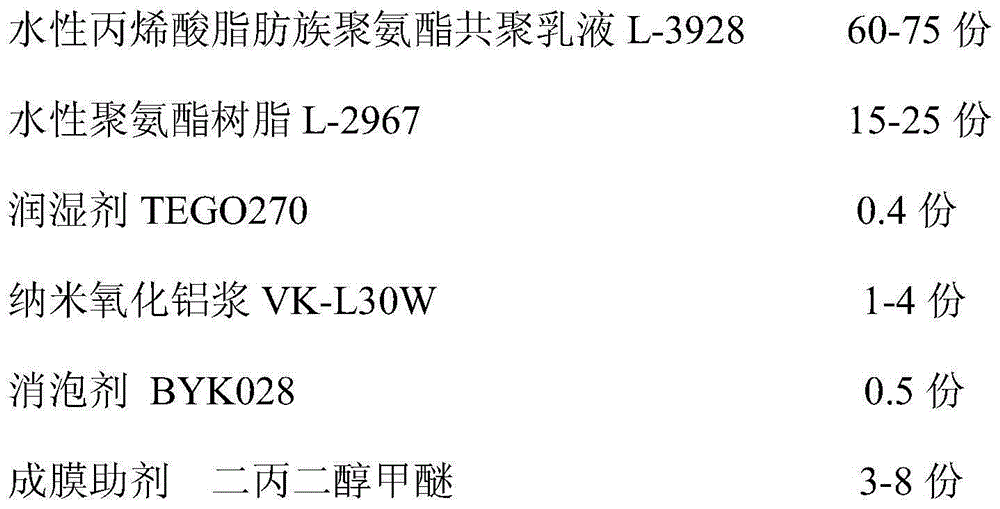

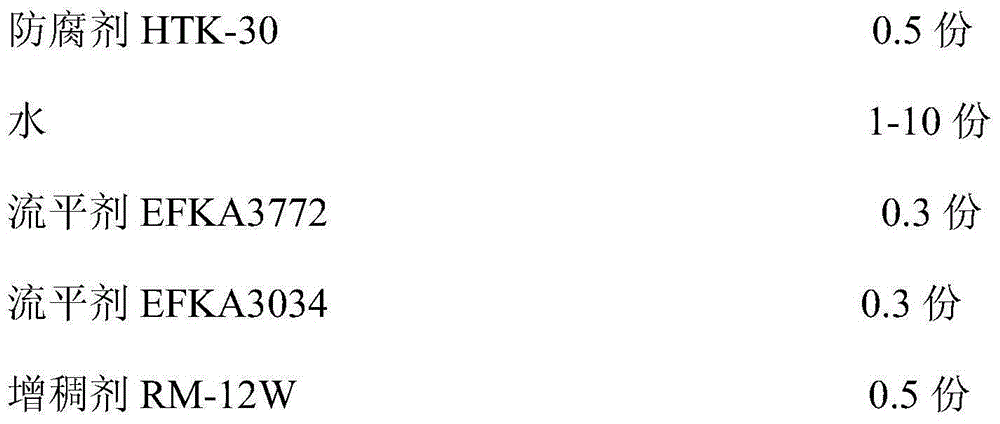

High hardness and high wear resistance waterborne wood paint and preparation method thereof

InactiveCN104987818AHigh hardnessImprove wear resistancePolyurea/polyurethane coatingsEmulsionNano al2o3

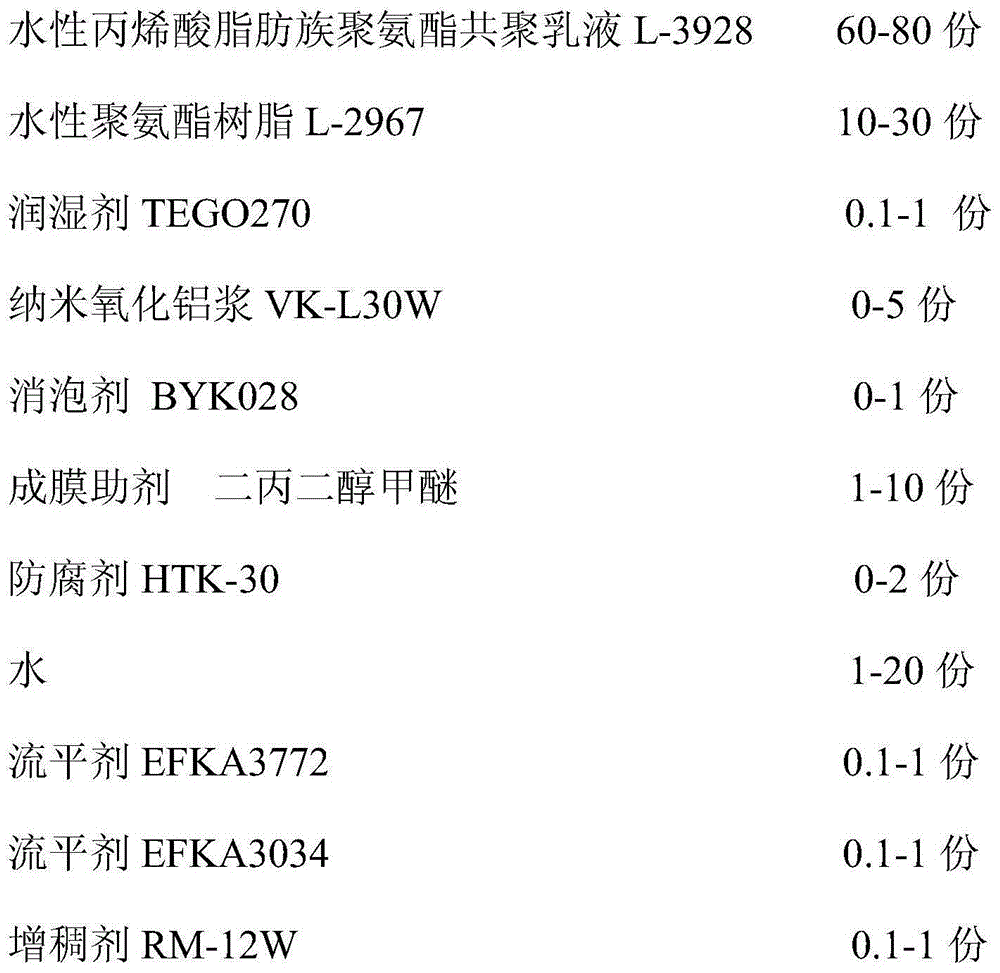

The invention discloses a high hardness and high wear resistance waterborne wood paint and a preparation method thereof. The high hardness and high wear resistance waterborne wood paint is composed of the following components by weight: 60-80 parts of a waterborne acrylic aliphatic polyurethane copolymerization emulsion L-3928; 10-30 parts of waterborne polyurethane resin L-2967; 0.1-1 part of a wetting agent TEGO270; 0-5 parts of a nano-alumina slurry VK-L30W; 0-1 part of a defoaming agent BYK028; 1-10 parts of a film-forming assistant dipropylene glycol methyl ether; 0-2 parts of a preservative HTK-30; 1-20 parts of water; 0.1-1 part of a leveling agent EFKA3772; 0.1-1 part of a leveling agent EFKA3034; and 0.1-1 part of a thickener RM-12W. The product provided by the invention has high hardness and good wear resistance, and the hardness can be greatly improved without changing the luster. By adopting the two-component leveling agents, the handfeel and fullness of the product are improved.

Owner:GUANGDONG VALSPAR CHEM IND

Environment-friendly alcohol-free fountain solution for offset printing and preparing method thereof

InactiveCN104960354AMeet high viscosity requirementsControl and prevent pollutionPrinting pre-treatmentEthylenediamineBetaine

The invention discloses an environment-friendly alcohol-free fountain solution for offset printing and a preparing method thereof. The solution is prepared from, by weight, 4-7 parts of lauryl polyoxyethylene, 6-8 parts of coconut diethanolamide, 3-5 parts of petroleum sodium sulfonate, 4-6 parts of potassium pyrophosphate, 10-14 parts of trisodium citrate, 8-10 parts of Arabic gum, 4-5 parts of dodecyl polyglucoside, 2-4 parts of hydroxyethyl ethylenediamine, 7 parts of dimethyl dodecyl amine oxide, 2-3 parts of di-o-tolyl-thiourea, 1-2 parts of sodium carboxymethylcellulose, 0.6-0.8 part of methylisothiazolinone, 4-5 parts of Turkey red oil, 0.8-1.2 parts of ethylene diamine tetraacetic acid tetrasodium, 0.6-0.8 part of tea saponin, 3-5 parts of dipropylene glycol methyl ether, 3-4 parts of dodecyl betaine type phosphate, 2-3 parts of sodium hexametaphosphate, and 120-140 parts of deionized water. According to the fountain solution, alcohol of any kinds is not added, no volatile harmful substance is contained, environment friendliness is realized completely, no harm can be done to the human body, a quite strong microorganism killing effect can be realized, microbial pollution of the fountain solution can be controlled and prevented, metal parts can be prevented from being corroded, and a printing plate and a printing machine are prevented from being damaged by early water.

Owner:李子健

Water-borne silk-screen suede printing ink and preparation method thereof

The invention provides water-borne silk-screen suede printing ink and a preparation method thereof. The printing ink is prepared by mixing and uniformly mixing the following materials in percentage by weight (based on the total weight of the materials): 80%-83.5% of water-borne polyurethane, 2%-4% of water-borne adhesion promoting resin, 0.2%-0.3% of water-borne defoamer, 6%-8.5% of dipropylene glycol methyl ether, 1%-2% of thickener, 1.5%-2.5% of flatting agent, 5%-6% of elastic touch powder, and 0.5%-0.7% of wax powder. The water-borne silk-screen suede printing ink provided by the invention does not need V-lamp drying, and has the advantages of being more fine and smooth, strong in touch, high in thickness, outstanding in soft feeling, and the like, in comparison with the existing silk-screen printing ink such as dull-polish silk-screen printing ink, snowflake silk-screen printing ink, and the like.

Owner:HUBEI ZHONGXIN JINGHUA COLOR PRINTING

Conductive paste for internal electrode of laminated ceramic capacitor

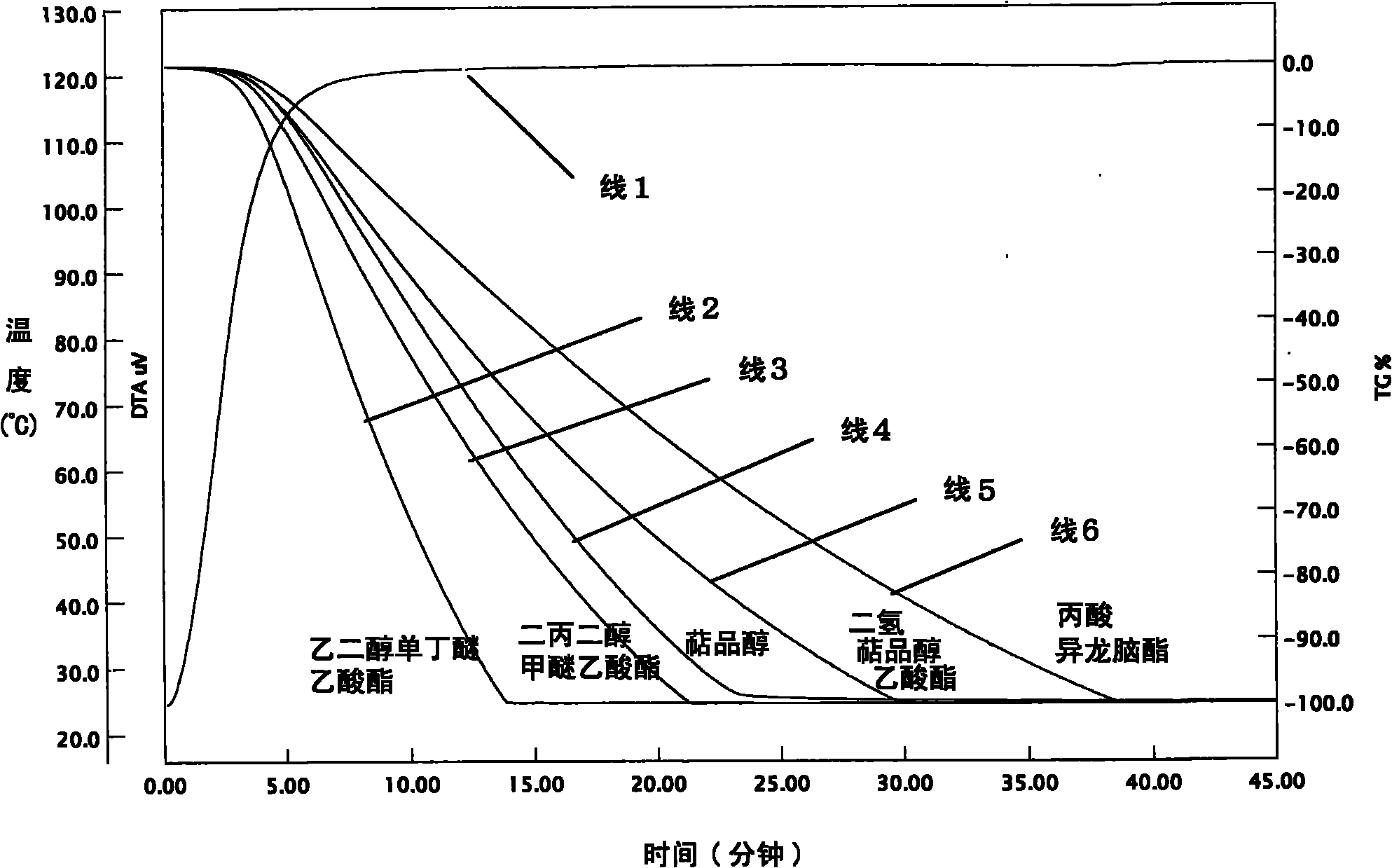

ActiveCN102169755AEliminate corrosionKeep dryFixed capacitor electrodesNon-conductive material with dispersed conductive materialConductive pasteOrganic solvent

The invention provides a conductive paste for an internal electrode of a laminated ceramic capacitor. Even if a green slice of the laminated ceramic capacitor is as thin as 2-5mum, the green slice can eliminate the slice corrosion caused by the conductive paste, has better dryness, and can effectively inhibit troubles caused by the slice corrosion. The conductive paste for the internal electrode of the laminated ceramic capacitor is used for printing on a green slice of a dielectric medium containing polyvinyl butyral resin and comprises conductive powder (A), organic resin (B) and an organic solvent (C), wherein the organic solvent (C) comprises at least one solvent selected from ethylene glycol butyl ether acetate and dipropylene glycol methyl ether acetate. The invention also provides the conductive paste for the internal electrode of the laminated ceramic capacitor, which comprises a mixed solvent of at least one solvent selected from dihydroterpineol acetate, isobornyl propanoate, isobornyl butyrate and isobornyl isobutyrate in the organic solvent.

Owner:SUMITOMO METAL MINING CO LTD

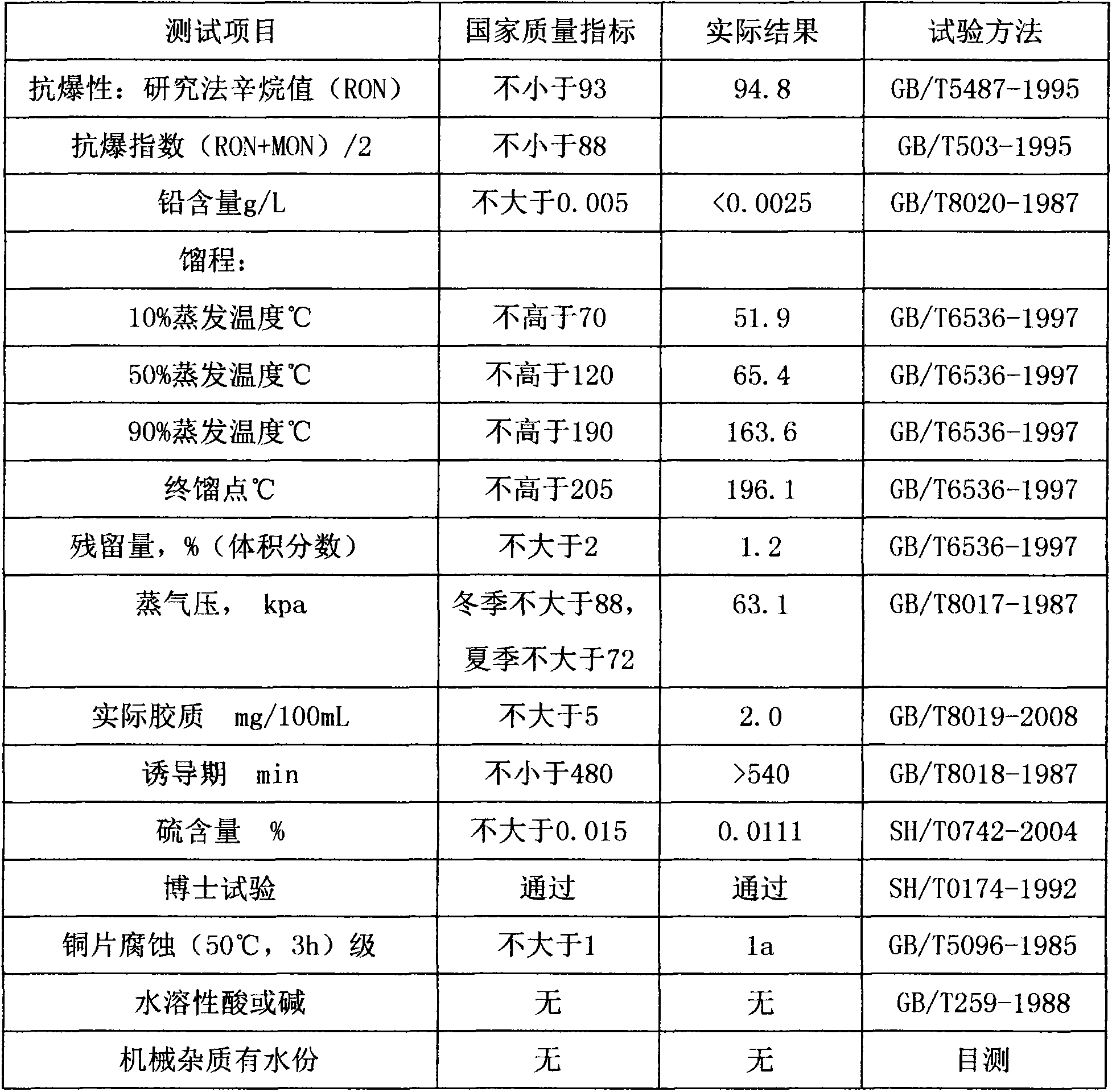

Methanol gasoline for vehicle and preparation method thereof

InactiveCN104004551AImprove combustion characteristicsIncrease profitLiquid carbonaceous fuelsAlternative fuelsTert butyl

The invention discloses methanol gasoline for a vehicle and a preparation method thereof. The methanol gasoline is prepared from the following raw materials in parts by weight: 60-70 parts of methanol, 15-25 parts of 90# gasoline, 10-15 parts of dipropylene glycol methyl ether acetate, 5-10 parts of tert amyl methyl ether, 5-10 parts of dimethyl carbonate, 4-8 parts of diethylene glycol dimethyl ether, 3-6 parts of 2,2-dimethoxypropane, 1-2 parts of ferrocene, 0.5-1.5 parts of methyl cyclopentadiene tricarbonyl manganese, 0.8-1.4 parts of 2,5-di-tert-butyl hydroquinone, 0.4-0.8 part of glycerol monolaurate, 0.5-1 part of sodium petroleum sulfonate, 0.3-0.6 part of N-Polyoxyethylated-N-tallow-alkylamine, 5-10 parts of wood tar, 3-6 parts of isopropanol, 2.5-4.5 parts of fish meal, 2-3 parts of bone meal, 1-2 parts of stearic acid and 0.5-1 part of urotropine. The methanol gasoline disclosed by the invention is favorable in combustion characteristic, high in utilization ratio, favorable in anti-detonating quality, low in corrosivity, high in safety and reliability, energy-saving and environment-friendly, can be used instead of any of 90#, 93#, 97# and 98# gasoline for a vehicle, is novel environment-friendly alternative fuel, and can reduce pollutant emission and carbon emission; and the combustion emission of the methanol gasoline meets the standards in Europe and America. The methanol gasoline has excellent economic benefits and far-reaching social benefits.

Owner:BEIJING DAMING QIAOHUA ENERGY SCI & TECH

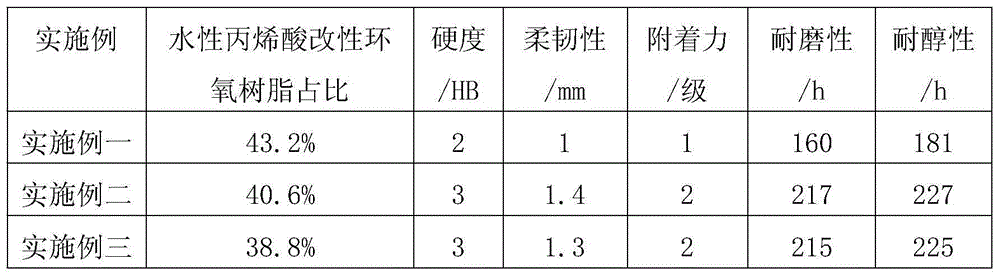

Environment-friendly water-borne acrylic-modified epoxy baking varnish

The invention relates to environment-friendly water-borne acrylic-modified epoxy baking varnish. The backing varnish consists of the following components in parts by weight: 15-18 parts of dipropylene glycol methyl ether, 0.5-0.7 part of isopropanol, 6-8 parts of amino resin, 42-44 parts of water-borne acrylic-modified epoxy resin, 0.6-1.1 parts of dispersant, 0.2-0.5 part of defoaming agent, 0.45-0.55 part of flatting agent, 0.35-0.45 part of PH regulator, 30-36 parts of white slurry, 2-4 parts of deionized water and 0.1-0.2 part of thickening agent. The environment-friendly water-borne acrylic-modified epoxy baking varnish has the advantages of high modulus, high strength, high toughness, excellent wear resistance and alcohol resistance and the like, so that the performances of the baking varnish are changed; in addition, the prepared environment-friendly water-borne acrylic-modified epoxy baking varnish does not contain any heavy metals harmful to a human body and the environment and is innocuous and harmless; the body health of people is protected, and meanwhile, the surrounding environment is protected from being polluted.

Owner:ANQING LIANTAI ELECTRONICS TECH

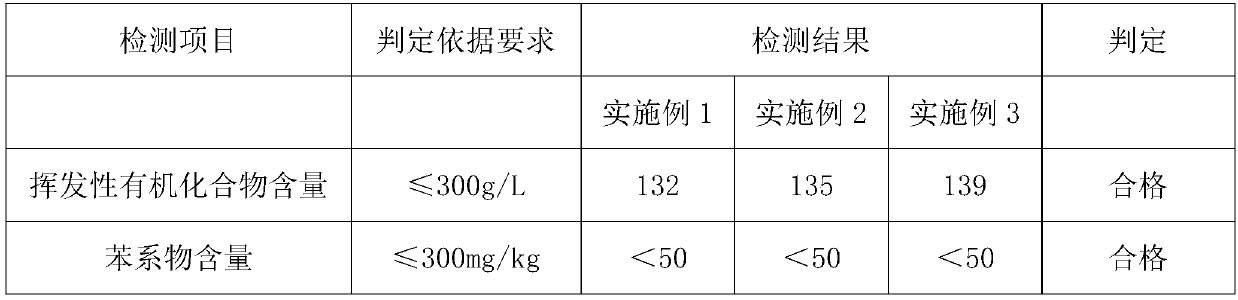

Two-component water-based matte clear finish paint and preparation method thereof

InactiveCN109554041AFast dryingStrong resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedSlurry

The invention discloses two-component water-based matte clear finish paint. The finish paint comprises a substrate and a curing agent, wherein the substrate comprises the following components: in parts by weight, 75-82 parts of a water-based acrylic emulsion, 3-8 parts of a polyurethane dispersion, 1-3 parts of dipropylene glycol methyl ether, 1-3 parts of dipropylene glycol butyl ether, 0.4-0.6 part of a modified rheological agent, 0.2-0.5 part of an antifoaming agent, 0.1-0.3 part of a substrate wetting agent, 0.5-1 part of a leveling agent, 3-5 parts of waterborne matte slurry, 3-5 parts ofa waterborne wax emulsion, 0.05-0.2 part of aminomethylpropanol and 2-8 parts of ionized water, and the curing agent is composed of 75% of isocyanate, 12% of dipropylene glycol methyl ether, 12% of dipropylene glycol butyl ether and 1% of a water removal agent. The two-component water-based matte clear finish paint has the characteristics of quick drying, good adhesion, good abrasion resistance,high transparency and a fine smooth paint layer surface, and the content of volatile organic compounds in the finish paint is less than 150 g / L, and detection results of harmful substances are lower than limits of the harmful substances.

Owner:广东新格新材料股份有限公司

Waterproof corrosion-resistant photocuring paint

InactiveCN104987790AImprove anti-corrosion performanceImprove waterproof and anti-corrosion performanceAnti-corrosive paintsPolyurea/polyurethane coatingsAntioxidantAluminium hydroxide

The invention discloses waterproof corrosion-resistant photocuring paint. The paint comprises, by weight, 15-40 parts of acrylic emulsion, 3-10 parts of polyurethane, 0.5-5 parts of rosin modified phenolic resin, 0.5-2 parts of triethoxyisobutylsilane, 0.5-1.7 parts of carboxymethylcellulose, 0.6-0.9 parts of hydroxypropyl methyl cellulose, 1-4 parts of dipropylene glycol methyl ether, 2-4 parts of potassium chromate, 4-6 parts of aluminium hydroxide, 2-6 parts of preservatives, 1-4 parts of barium sulfate, 2-5 parts of antioxidants, 6-14 parts of photoinitiators, 3-6 parts of defoaming agents, 2-7 parts of a molybdenum compound, 2-6 parts of sodium sulfate and 16-23 parts of water. The photocuring paint has the advantages of being short in curing time, low in curing temperature and low in volatile component, and meanwhile the coating is good in waterproof performance and corrosion resistance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Water-based paint with long opening time and preparation method thereof

The invention discloses water-based paint with long opening time and a preparation method thereof. The water-based paint with long opening time mainly comprises diethanol amine, sodium methylate, sunflower seed oil, phosphoric acid, dimethylolpropionic acid, N-methyl pyrrolidone, 1,4-cyclohexane dimethanol, methoxy polyethylene glycol, toluene diisocynate, dipropylene glycol methyl ether, dimethylethanolamine, surface active agents, borax decahydrate, 12.5% of ammonium persulfate solution, wetting agents, methyl methacrylate, butyl acrylate, acrylic acid, 12.5% of ammonia water, titanium dioxide and deionized water. The preparation method comprises firstly preparing an isocyanate base polyurethane prepolymer and an acrylic acid polymer according to a formula, and then mixing the isocyanate base polyurethane prepolymer and the acrylic acid polymer. The water-based paint with low volatile organic compound (VOC) content, no toxicity and long opening time and wet-edge time can be obtained, leveling of emulsion surface, exhaust of air bubbles in a coating and directional arrangement of dispersing objects in the coating can be facilitated, and the good film-forming effect can be achieved.

Owner:湖南福湘涂料股份有限公司

Water-soluble ink for printing metal and ceramic products

The invention discloses a water-soluble ink for printing a metal product, a ceramic product and a product made of a metal and ceramic composite material, as well as a method for obtaining a product made of a required material by plasticizing, unsticking and sintering a molding product printed by the ink. The ink comprises components in mass ratio as follows: 30%-70% of material components, 1%-9% of high polymer material components and 69%-21% of water, wherein the material components include metal, alloy, ceramic and the like, and the high polymer material components include one or more of caprolactam, 2-pyrrolidone, polytrimethylene terephthalate, polybutylene terephthalate, poly(ethylene glycol) diacrylate, dipropylene glycol methyl ether acetate, phthalic anhydride, phthalimide, polyacrylamide, polyacrylic polymethacrylic acid and copolymer thereof, polyvinyl alcohol, polyethylene glycol, polyoxyethylene, polyvinyl pyrrolidone, polymaleic anhydride, KEPS resin, poly dimethyl diallyl ammonium chloride, water-soluble cellulose, single-stranded polyurethane and the like.

Owner:JIANGSU TIANYI ULTRA FINE METAL POWDER

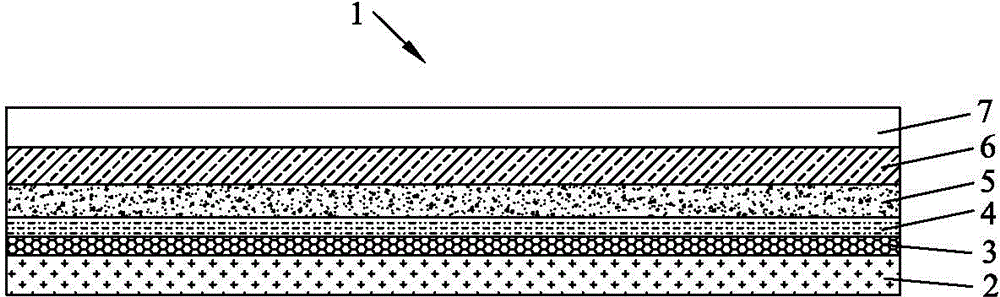

Decorative pattern transfer paper adapting to various special environments and transfer method thereof

The invention relates to the technical field of decorative pattern transfer, in particular to a decorative pattern transfer paper adapting to various special environments and a transfer method thereof. The transfer paper comprises a backing paper, a hydrosol layer, a gloss oil bottom layer, a white bottom ink layer, a decorative pattern layer and a protective gloss oil layer in sequence, wherein the gloss oil bottom layer, the white bottom ink layer and the protective gloss oil layer are all prepared by bi-component ink; and the gloss oil bottom layer consists of 22-28% of cellulose acetate butyrate, 24-32% of hydroxy acrylic resin, 14-20.5% of HDI polyisocyanate, 19-39.5% of dipropylene glycol methyl ether, and 0.5-1.0% of methyl polysiloxane. The transfer paper effectively enhances the fineness and the durability of decorative patterns decorated on products, and can be widely applied to the surface decoration under various special environments of alloy, glass and ceramic due to excellent adhesive force, high gloss, high hardness, strong solvent resistance, high-temperature resistance and water boiling resistance.

Owner:广州市彩能印刷有限公司

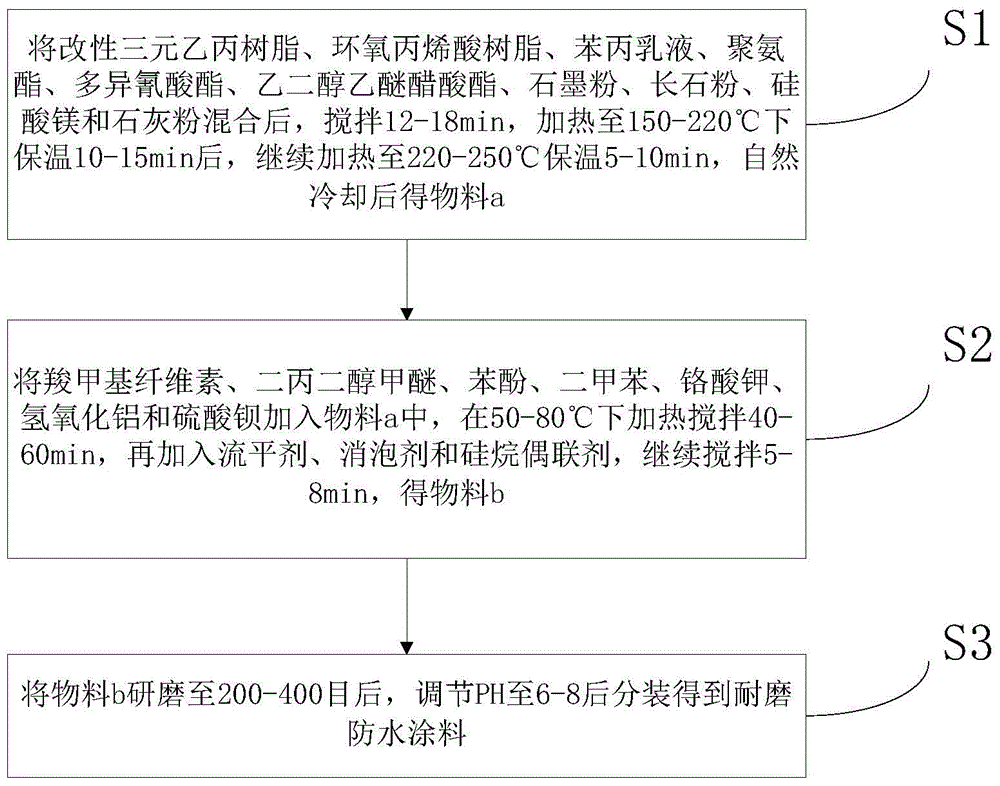

Abrasion-resistant waterproof coating for building outer wall and method for preparing the same

InactiveCN104946029AExtended service lifeLow costPolyurea/polyurethane coatingsAcrylic resinAluminium hydroxide

The invention discloses an abrasion-resistant waterproof coating for a building outer wall. The abrasion-resistant waterproof coating comprises, by weight parts, 60-80 parts of modified EPDM resin, 30-60 parts of epoxy acrylic resin, 20-40 parts of styrene-acrylic emulsion, 10-30 parts of polyurethane, 5-15 parts of polyisocyanate, 2-8 parts of ethylene glycol monoethyl ether acetate, 3-8 parts of graphite powder, 2-6 parts of feldspar powder, 1-5 parts of magnesium silicate, 2-6 parts of phenol, 3-5 parts of carboxymethyl cellulose, 2-5 parts of hydroxypropyl methylcellulose, 3-7 parts of dipropylene glycol methyl ether, 2-8 parts of phenol, 3-7 parts of xylene, 2-6 parts of potassium chromate, 1-3 parts of aluminum hydroxide, 2-4 parts of barium sulfate, 1-3 parts of flatting agent, 2-6 parts of defoamer and 1-5 parts of silane coupling agent. The invention further discloses a method for preparing the abrasion-resistant waterproof coating for the building outer wall. The abrasion-resistant waterproof coating for the building outer wall is excellent in abrasion resistance, good in waterproof performance, long in service life and low in cost.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Transparent primer for splint water-based woodware and preparation method thereof

InactiveCN101993653AFast dryingImprove grinding effectPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention discloses a transparent primer for splint water-based woodware and a preparation method thereof. The preparation method comprises the following steps of: adding 75 to 82 parts of polyurethane modified acrylic resin into a dispersing cylinder; adjusting the pH value of the polyurethane modified acrylic resin to 8.0 to 8.5 with stirring; adding 0.3 to 0.5 part of thickener; adding 0.3to 0.5 part of defoamer, 0.3 to 0.6 part of wetting agent and 0.3 to 0.6 part of flatting agent into the mixed materials in turn and then stirring uniformly; adding a mixture of 2 to 4 parts of propylene glycol phenyl ether, 2 to 4 parts of dipropylene glycol methyl ether and 5 to 10 parts of dimethylformamide into the stirred solution; adding 5 to 8 parts of water-based zinc pulp into the mixed solution; and finally regulating viscosity by using 0.5 to 0.8 part of thickener, discharging the obtained product and packaging the product. The transparent primer has high adhesion which can reach 0grade, has a high drying speed and a high rubbing property and can be directly coated on a release agent-containing splint without surface washing, so that work time and washing cost are effectively saved, and environmental pollution can be avoided.

Owner:ZHEJIANG FEIDA ZHONGKE FINE CHEM

High-hardness and high-wear-resistance acrylate water-based paint

The present invention discloses a high-hardness and high-wear-resistance acrylate water-based paint, which comprises a component A and a component B. The component A comprises the following raw materials: aqueous acrylate emulsion, alkyd resin, polyhydroxy unsaturated polyester resin, phenolic resin, nitrocellulose, silane coupling agent KH-560 modified nano-silicon dioxide, calcium carbonate whisker, talc, dipropylene glycol methyl ether, dipropylene glycol butyl ether, anti-settling agent, wetting agent and anti-foaming agent. The component B comprises the following raw materials: fully-methoxylated melamine resin, 3, 5-dimethyl-2-aminobenzoic acid, flatting agent and de-ionized water. The high-hardness and high-wear-resistance acrylate water-based paint is high in hardness, good in wear resistance, excellent in water resistance and heat resistance, and long in service life.

Owner:ANHUI JINDUN PAINT

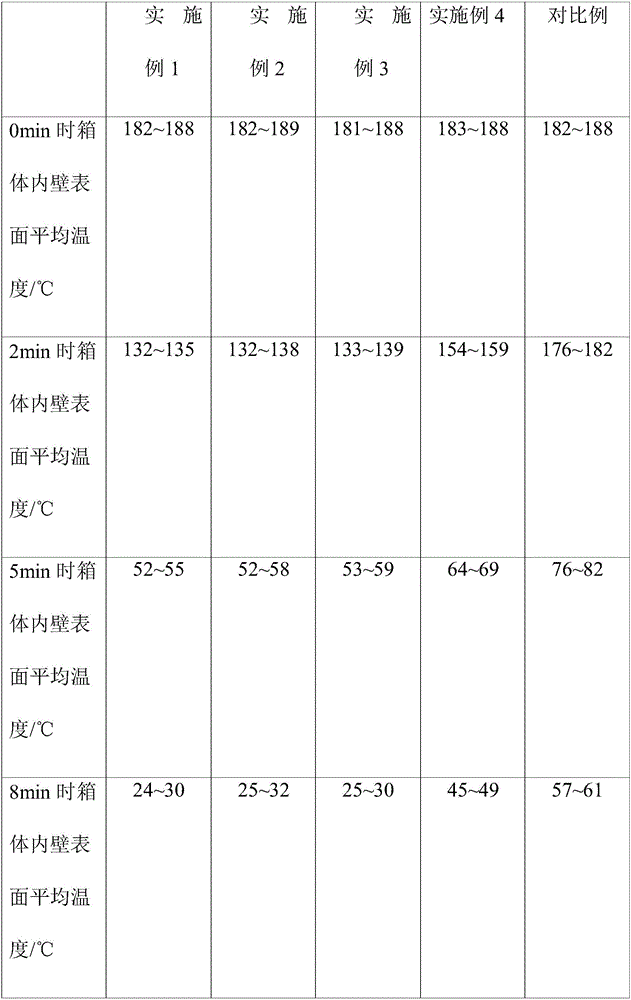

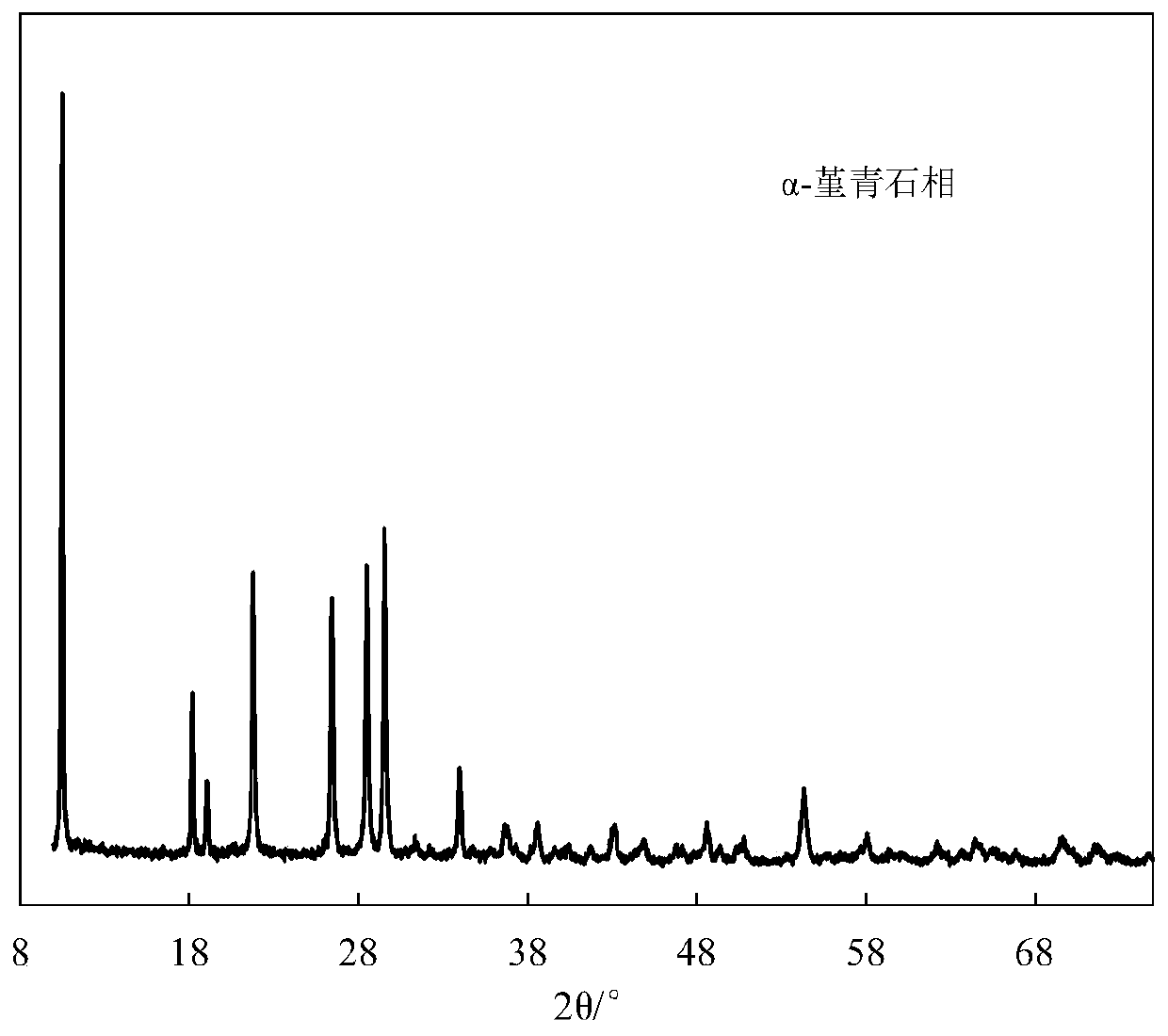

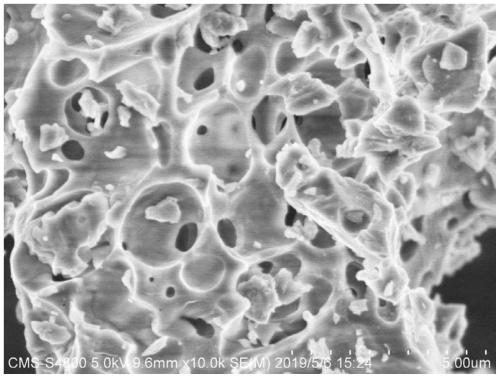

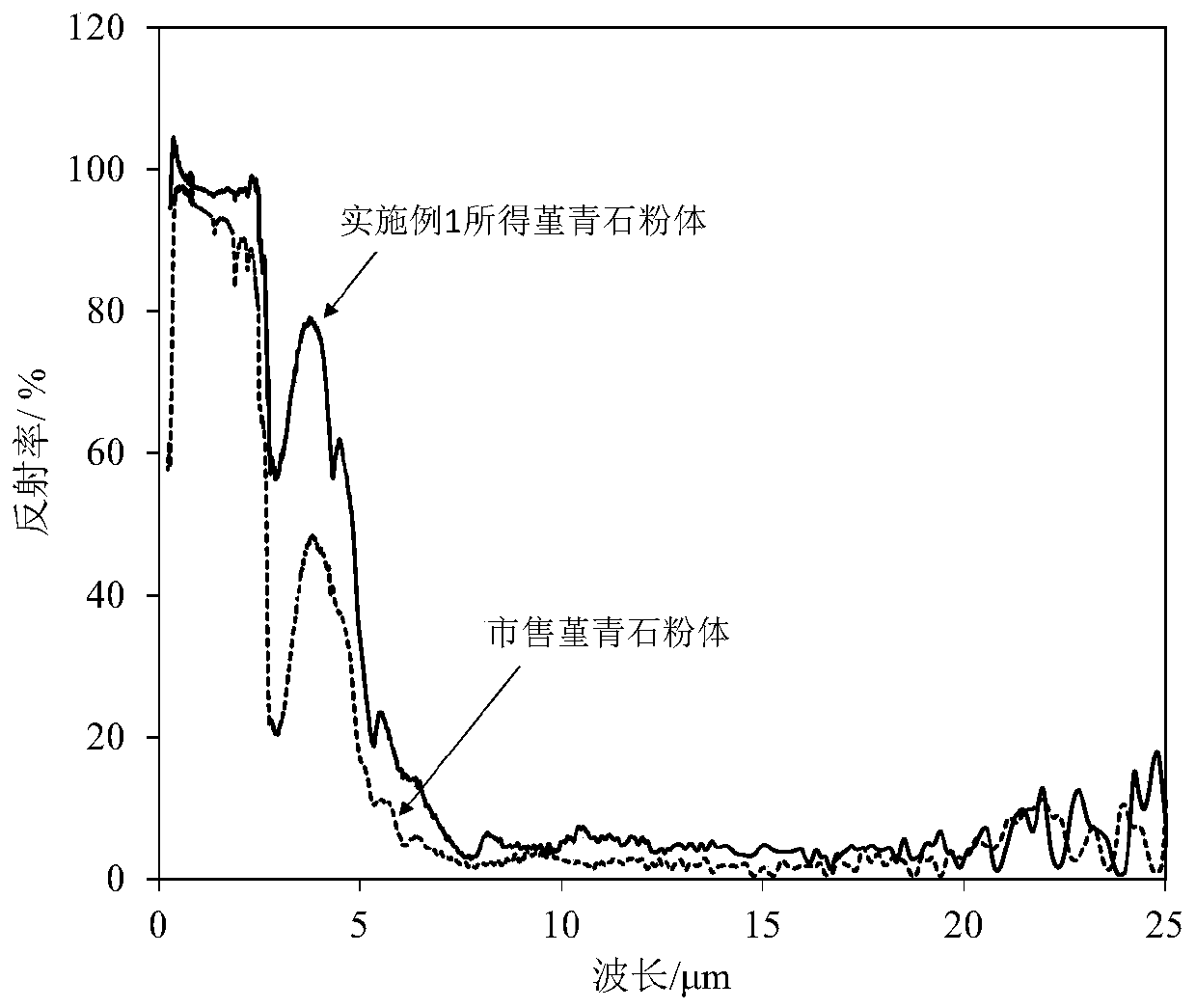

Radiation refrigeration coating and preparation method and application thereof

ActiveCN111303709AIncrease surface tensionReduce surface tensionAluminium silicatesReflecting/signal paintsAcrylic resinEthylic acid

The invention discloses a radiation refrigeration coating as well as a preparation method and application thereof. The radiation refrigeration coating is prepared from the following raw material components in percentage by mass: 4%-8% of porous cordierite, 10%-18% of titanium dioxide, 22%-35% of acrylic resin, 0.5%-1.5% of a silane coupling agent, 0.1%-1% of a coalescing agent, 0.1%-1% of a leveling agent, 0.1%-1% of a dispersing agent, 0.2%-1% of an antifoaming agent, 0.1%-2% of a thickener, 0.1%-2% of an anti-flash rust agent and the balance of dipropylene glycol methyl ether acetate, and the radiation refrigeration coating is prepared by mixing the raw materials. The radiation refrigeration coating disclosed by the invention has high sunlight reflectivity and high selectivity and radiance in an atmospheric window, the preparation method has the advantages of simplicity, feasibility, low cost and the like, and meanwhile, a radiation refrigeration coating layer prepared from the coating can realize all-weather refrigeration, has a good refrigeration effect, and has very high use value and application prospect.

Owner:NAT UNIV OF DEFENSE TECH

Stone back mesh glue

The invention relates to stone back mesh glue which is prepared from the following steps of: heating up 450-470 parts by weight of pure water to 90 DEG C and adding the heated pure water into a reaction kettle; adding 110-120 parts by weight of protective colloid FRC (Fire Resistant Viscose Fiber) 678 into the reaction kettle; adding 180-200 parts by weight of methyl methacrylate MMA, 180-200 parts by weight of acrylic acid-2-ethyl hexyl ester 2EHA (Ethylhexyl Acrylate), 3.0-5.0 parts by weight of dipropylene glycol methyl ether (DPM), 2.0-4.0 parts by weight of ammonium persulphate APS, 0.3-1.0 part by weight of ammonia water, 2.0-4.0 parts by weight of preservative GXL, and 0.20-0.95 part by weight of wetting agent X-405 into a single slot for uniformly mixing and stirring. The invention provides the stone back mesh glue which is capable of greatly lowering the pollution to environment, reducing the occurrence of safety accidents and free of damages to the body of a worker.

Owner:河北霖江木业有限公司

Fast-Drying Ink Composition

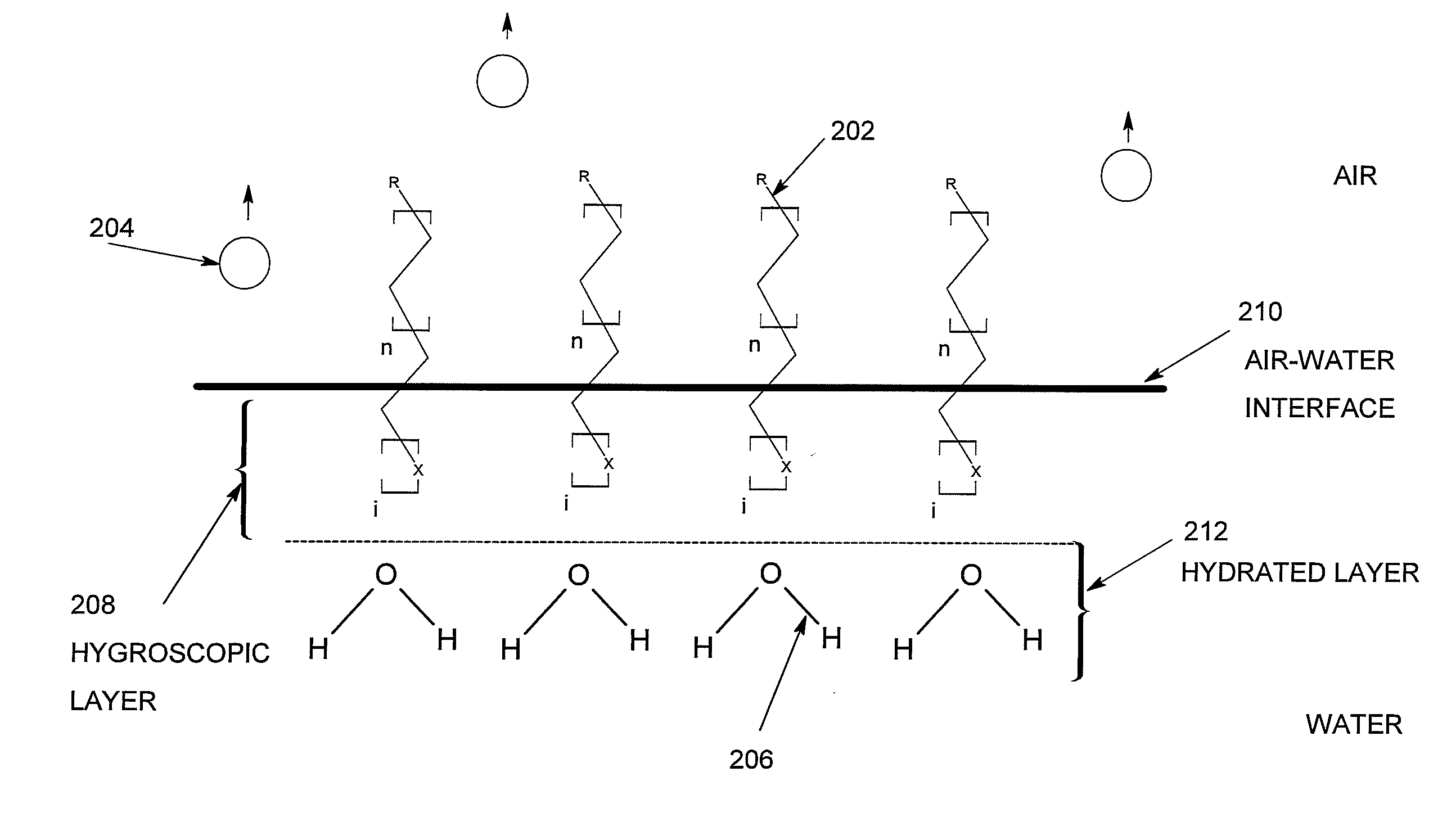

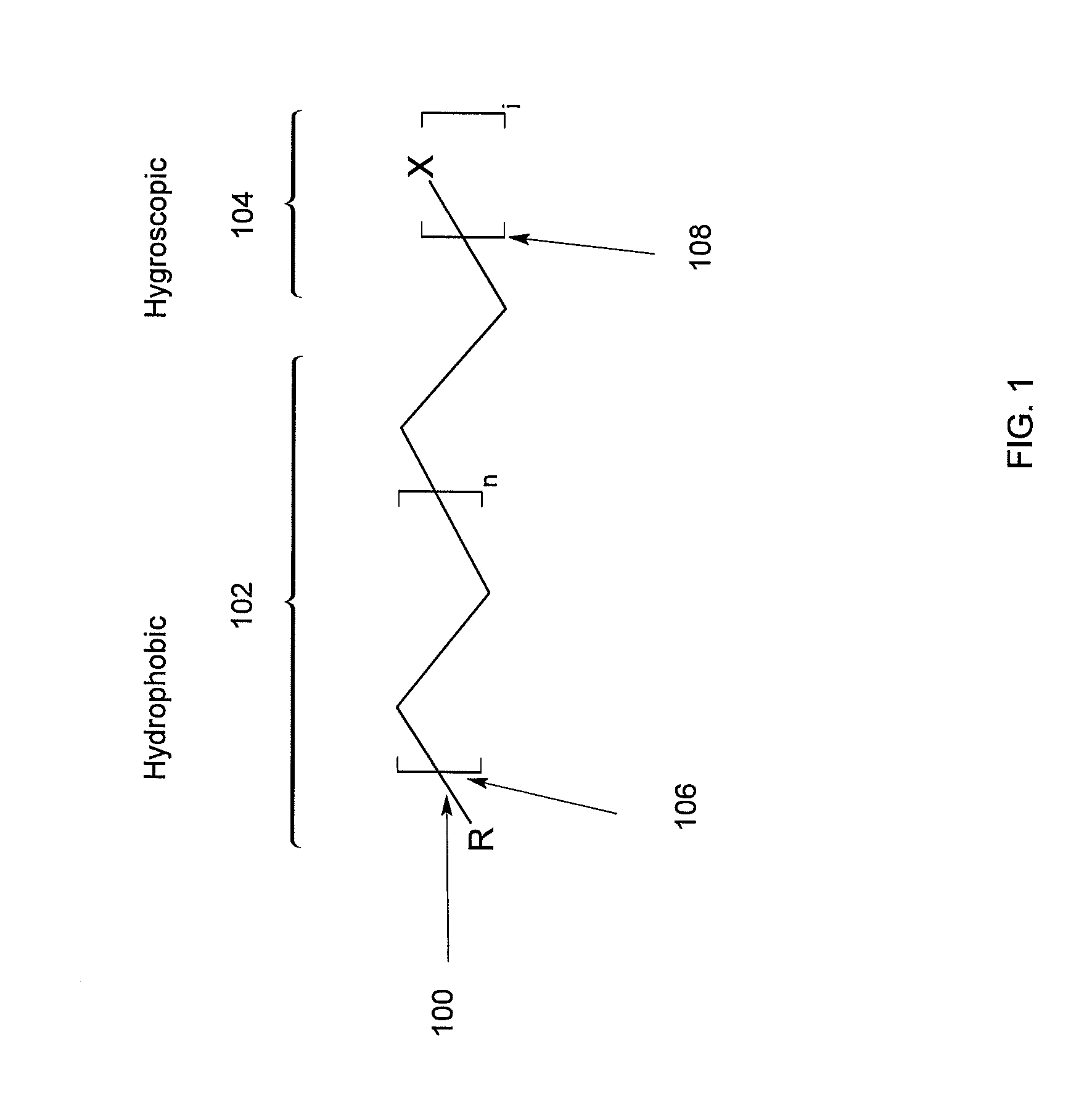

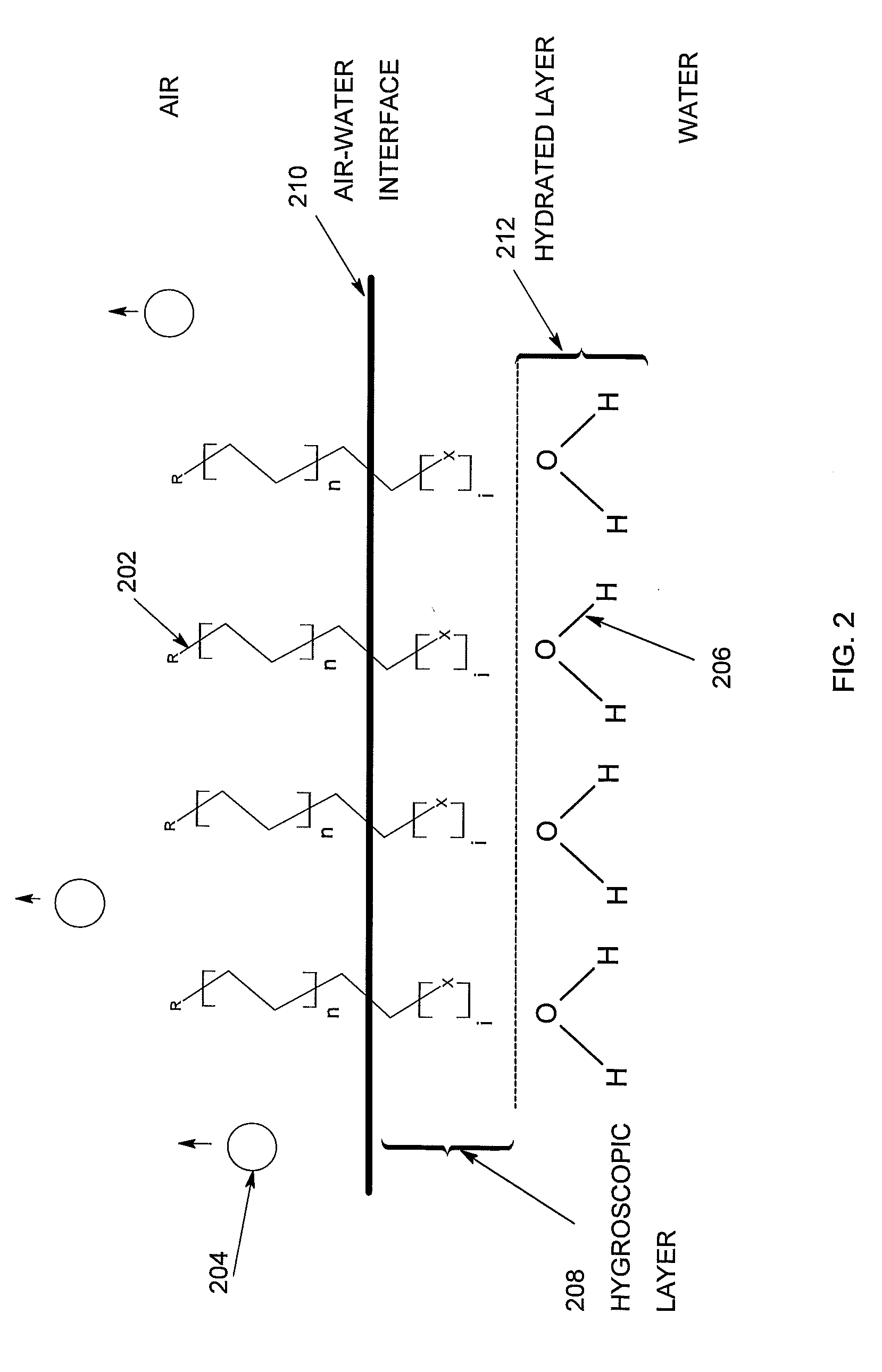

A fast-drying ink composition comprising water, a fast-drying solvent mixture including a hydrophilic co-solvent having low enthalpy of evaporation, a surface-active humectant, and a colorant. The hydrophilic co-solvent may be selected from the group consisting of propylene glycol n-propyl ether, tripropylene glycol methyl ether, and dipropylene glycol methyl ether. The surface-active humectant may comprise a hydrophobic end having a repeating unit “n” ranging from 1 to 36 and selected from the group consisting of alkane-based (CH2)n, fluoro-based (CF2)n, and silicone-based (SiO)n, and a hygroscopic end having a repeating unit “i” ranging from 2 to 8 and selected from the group consisting of a hydroxyl group, an amine group, a carboxyl group and an ester group.

Owner:BUI LOC +4

Full matt aqueous paint for wood surface, and production process thereof

InactiveCN105255334AIncrease costPolyurea/polyurethane coatingsPolyurethane dispersionPROPYLENE GLYCOL BUTYL ETHER

The present invention discloses a full matt aqueous paint for wood surface, and a production process thereof, wherein the components comprise, by weight, 20.7 parts of pure water, 50 parts of an aqueous polyurethane dispersion, 15 parts of an acrylic ester emulsion, 3 parts of dipropylene glycol butyl ether, 2.5 parts of dipropylene glycol methyl ether, 0.5 part of a PA30 dispersant, 0.43 part of a BYK defoamer, 0.1 part of a BYK wetting agent, 2.6 parts of matting powder, 0.26 part of a leveling agent, 0.1 part of RM-2020 nonionic polyurethane, 0.1 part of RM-8W nonionic polyurethane, and 4.78 parts of 95% ethanol. According to the present invention, the aqueous polyurethane dispersion and the acrylic ester emulsion are adopted as the main raw materials, the full matt aqueous paint is suitable for the wood surface paint and the plastic, the full matt varnish is formed after the film forming, and the product developed through the formula has the great cost advantage compared with the current practical aqueous paint on the market.

Owner:开平市开物化工建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com