Conductive paste for internal electrode of laminated ceramic capacitor

A technology of ceramic capacitors and internal electrodes, which is applied to fixed capacitor electrodes, components of fixed capacitors, conductive materials dispersed in non-conductive inorganic materials, etc. The effect of eliminating chip corrosion and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

[0099] (manufacturing of organic media)

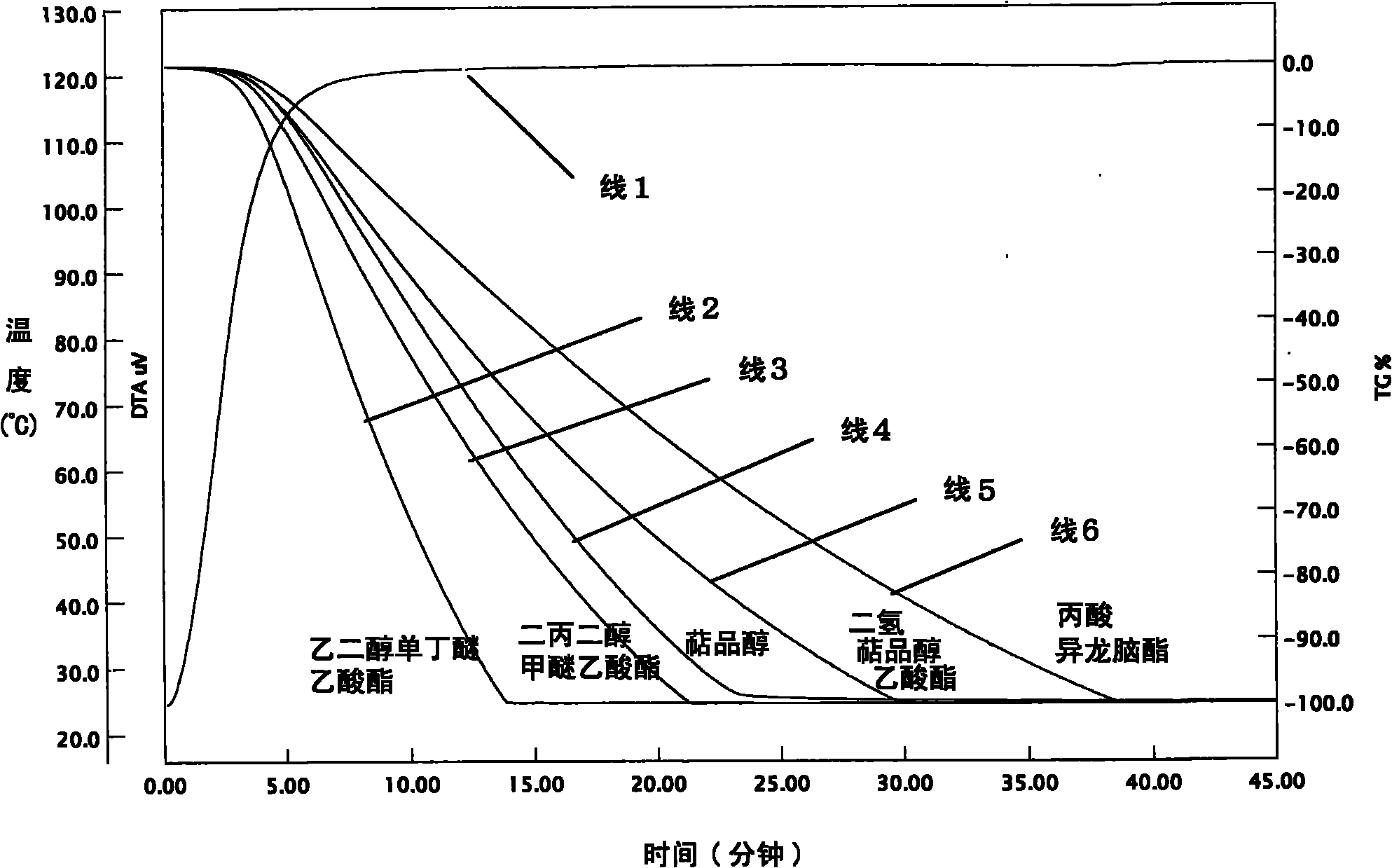

[0100] Using ethylene glycol monobutyl ether acetate or dipropylene glycol methyl ether acetate shown in Table 1 as an organic solvent, ethyl cellulose resin was dissolved therein to prepare an organic medium used in the paste for internal electrodes.

[0101] Each solvent was heated to a temperature of 60° C. with a heater, stirred with a stirring paddle, and ethyl cellulose resin was slowly added to dissolve, thereby obtaining an organic medium. In order to confirm that the resin is completely dissolved, a part of the dissolved material is taken out, and it is confirmed that there is no residue of the resin on the specimen.

[0102] The content of ethyl cellulose was 15 parts by weight relative to 100 parts by weight of all solvents. As ethyl cellulose, grades STD-45 and STD-300 manufactured by Dow Chemical Co. were mixed and used, and the mixing ratio of the two was adjusted so as to have a predetermined viscosity to prepare an org...

Embodiment 3~10

[0115] (Examples 3-10) (Comparative Examples 9-10)

[0116] As the first solvent, ethylene glycol monobutyl ether acetate was used, and as the second solvent, dihydroterpineol acetate, isobornyl propionate, isobornyl butyrate, and isobornel isobutyrate were used. Brain esters were mixed in various ratios to prepare mixed solvents, and conductive pastes were prepared in the same manner as in Examples 1 and 2 (Examples 3-10).

[0117] In addition, using ethylene glycol monobutyl ether acetate as the first solvent and terpineol as the second solvent, conductive pastes were also prepared in the same manner (Comparative Examples 9 to 10).

[0118] Table 2 shows the evaluation results of the dryness, sheet corrosion, and sheet peeling tests of the conductive pastes prepared using various mixed solvents.

[0119] Table 2

[0120]

first solvent

second solvent

solvent

weight ratio

60℃-1min

piece

corrosion

...

Embodiment 11~18

[0126] (Examples 11-18) (Comparative Examples 11-12)

[0127] As the first solvent, dipropylene glycol methyl ether acetate was used, and as the second solvent, dihydroterpineol acetate, isobornyl propionate, isobornyl butyrate, and isobornyl isobutyrate were used , mixed in various ratios to prepare mixed solvents, and similarly to Examples 1 and 2 to prepare conductive pastes (Examples 11-18).

[0128] In addition, using dipropylene glycol methyl ether acetate as the first solvent and terpineol as the second solvent, conductive pastes were also prepared in the same manner (Comparative Examples 11 to 12).

[0129] Table 3 shows the evaluation results of the dryness, sheet corrosion, and sheet peeling tests of the conductive pastes prepared using various mixed solvents.

[0130] table 3

[0131]

first solvent

second solvent

solvent weight

Proportion

60℃-1min

dryness

piece

corrosion

peel off

te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com