Full matt aqueous paint for wood surface, and production process thereof

A water-based paint, full matte technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of difficult to achieve matte effect, high cost of consumers, etc., to achieve the effect of high cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

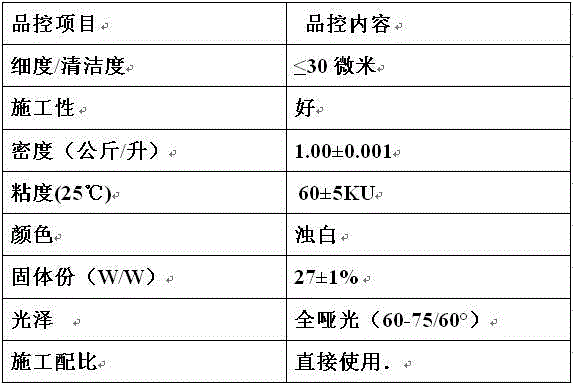

Image

Examples

Embodiment Construction

[0021] A kind of all-matte water-based paint applied to the surface of woodware of the present invention, the weight fraction of each component is: 20.7 parts of pure water, 50 parts of water-based polyurethane dispersions, 15 parts of acrylic ester emulsions, 3 parts of dipropylene glycol butyl ether, two 2.5 parts of propylene glycol methyl ether, 0.5 parts of PA30 dispersant, 0.43 parts of BYK defoamer, 0.1 part of BYK wetting agent, 2.6 parts of matting powder, 0.26 parts of leveling agent, 0.1 part of RM-2020 non-ionic polyurethane, RM-8W non-ionic 0.1 parts of ionic polyurethane, 4.78 parts of 95% ethanol.

[0022] Further, the water-based polyurethane dispersion adopts Huajinsi R4188.

[0023] Further, Huajinsi HD1902 is used as the acrylate emulsion.

[0024] Further, the dipropylene glycol butyl ether adopts American Dow Chemical DPnB.

[0025] Further, the dipropylene glycol butyl ether adopts American Dow Chemical DPM.

[0026] Further, the matting powder adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com