Two-component water-based matte clear finish paint and preparation method thereof

A two-component, water-based technology, used in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of water-based topcoats such as difficult to quickly dry, poor durability, and low adhesion, and achieve excellent chemical resistance. , good adhesion, good anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

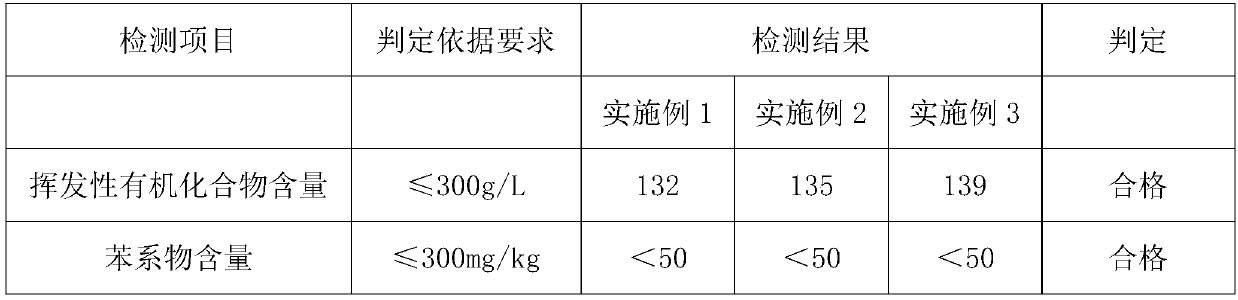

Examples

Embodiment 1

[0024] A two-component water-based matte clear topcoat,

[0025] The base includes the following components by weight:

[0026] Lacper-4700 emulsion 76 parts g, Lacper-4220 dispersion 4g, dipropylene glycol methyl ether 2g, dipropylene glycol butyl ether 2g, RM-8W rheology modifier 0.5g, TEGO-825 defoamer 0.2g, TEGO- 825 defoamer 0.2g, TEGO-245 wetting agent 0.2g, RM-2020 leveling agent 0.6g, TEGO-482 leveling agent 0.2g, W-212 matte paste 4g, ME-95535 water-based wax emulsion 4g, Aminomethylpropanol 0.1g, deionized water 6g.

[0027] The curing agent is composed of 75g of isocyanate, 12g of dipropylene glycol methyl ether, 12g of dipropylene glycol butyl ether and 1g of water remover.

[0028] Production process:

[0029] a. Preparation of base material: Weigh each component according to the formula, add deionized water into the dispersion kettle, add Lacper-4700 emulsion, Lacper-4220 dispersion, dipropylene glycol methyl ether, and dipropylene glycol in the dispersion ket...

Embodiment 2

[0033] A two-component water-based matte varnish, the base comprises the following components by weight:

[0034] Lacper-4700 emulsion 78g, Lacper-4220 dispersion 4g, dipropylene glycol methyl ether 2g, dipropylene glycol butyl ether 2g, RM-8W rheology modifier 0.5g, TEGO-825 defoamer 0.2g, TEGO-825 defoamer Agent 0.2g, TEGO-245 wetting agent 0.2g, RM-2020 leveling agent 0.6g, TEGO-482 leveling agent 0.2g, W-212 matte paste 4g, ME-95535 water-based wax emulsion 4g, aminomethyl Propanol 0.1g, deionized water 4g.

[0035] The curing agent is composed of 75g of isocyanate, 12g of dipropylene glycol methyl ether, 12g of dipropylene glycol butyl ether and 1g of water remover.

[0036] Production process:

[0037] a. Preparation of base material: Weigh each component according to the formula, add deionized water into the dispersion kettle, add Lacper-4700 emulsion, Lacper-4220 dispersion, dipropylene glycol methyl ether, and dipropylene glycol in the dispersion kettle in turn But...

Embodiment 3

[0041] A two-component water-based matte varnish, the base comprises the following components by weight:

[0042] 80 parts of Lacper-4700 emulsion, 4 parts of Lacper-4220 dispersion, 2g of dipropylene glycol methyl ether, 2g of dipropylene glycol butyl ether, 0.5 parts of RM-8W rheology modifier, 0.2g of TEGO-825 defoamer, TEGO -825 defoamer 0.2g, TEGO-245 wetting agent 0.2 parts, RM-2020 leveling agent 0.6g, TEGO-482 leveling agent 0.2g, W-212 matte paste 4 parts, ME-95535 water-based wax emulsion 4 parts, 0.1 part of aminomethyl propanol, 2 parts of deionized water.

[0043] The curing agent is composed of 75g of isocyanate, 12g of dipropylene glycol methyl ether, 12g of dipropylene glycol butyl ether and 1g of water remover.

[0044] Production process:

[0045]a. Preparation of base material: Weigh each component according to the formula, add deionized water into the dispersion kettle, add Lacper-4700 emulsion, Lacper-4220 dispersion, dipropylene glycol methyl ether, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com