High-temperature-resistant heat-dissipating graphene-carbon nanotube coating and preparation method thereof

A technology of graphene carbon and heat-dissipating coatings, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problems of unsatisfactory heat dissipation effects of heat-dissipating coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

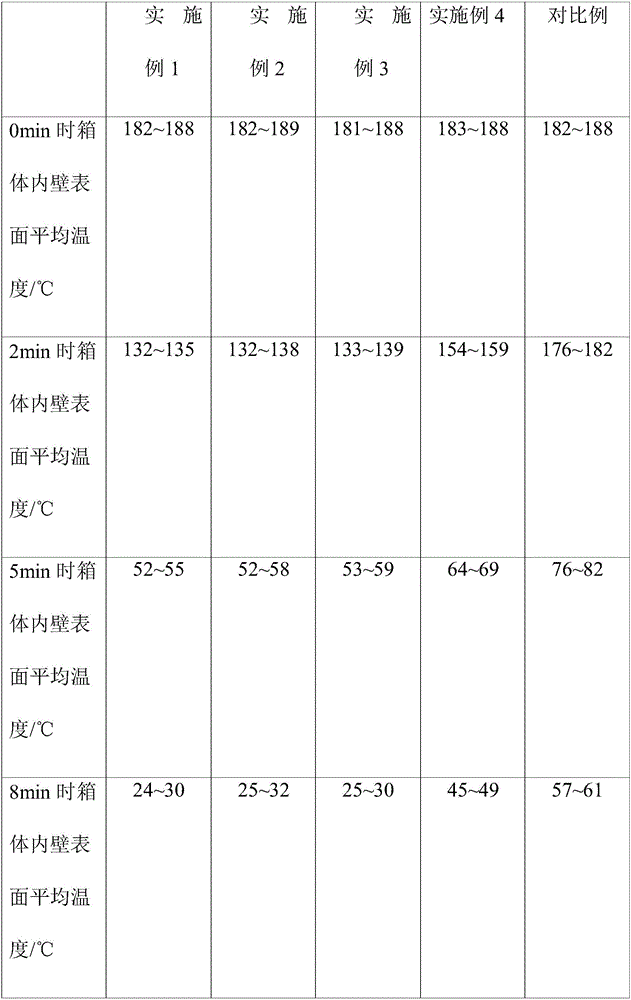

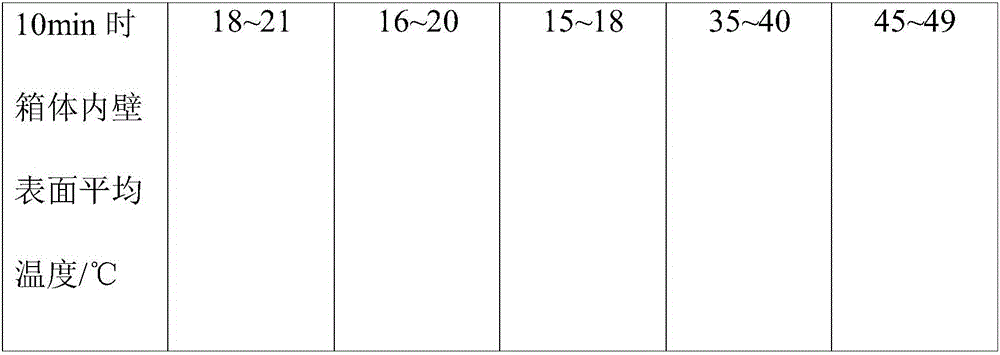

Examples

Embodiment 1

[0028] A graphene carbon nanotube high-temperature heat dissipation coating, comprising the following components in parts by weight: 30 parts of graphene carbon nanotube composite slurry, water-based fluorocarbon resin or fluorocarbon resin emulsion: 28 parts, water: 15 parts, Defoamer: 0.1 part, leveling agent: 0.1 part, thickener: 0.1 part, dipropylene glycol methyl ether 2 parts.

[0029] The graphene-carbon nanotube composite slurry includes 1.5% carbon nanotubes, graphene: 2.5%, defoamer: 0.1%, wetting agent: 0.3%, and the rest is water.

[0030] A preparation method of graphene carbon nanotube high temperature heat dissipation coating, comprising the following steps:

[0031] 1) Put graphene and carbon nanotubes into water, add wetting agent to moisten; add defoamer, grind, and grind to fineness ≤ 30um;

[0032] 2), magnetic field induction;

[0033] 3), put the slurry into a certain amount of water, and add a defoamer;

[0034] 4), slowly add water-based fluorocarbon...

Embodiment 2

[0038] A graphene carbon nanotube high-temperature heat dissipation coating, comprising the following components in parts by weight: 40 parts of graphene carbon nanotube composite slurry, water-based fluorocarbon resin or fluorocarbon resin emulsion: 45 parts, water: 30 parts, Defoamer: 0.3 parts, leveling agent: 0.3 parts, thickener: 0.3 parts, dipropylene glycol methyl ether 5 parts.

[0039] The graphene-carbon nanotube composite slurry includes 3% carbon nanotubes, graphene: 1%, defoamer: 0.3%, wetting agent: 0.1%, and the rest is water.

[0040] The preparation method of the graphene carbon nanotube high-temperature heat dissipation coating of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0042] A graphene carbon nanotube high-temperature heat dissipation coating, comprising the following components in parts by weight: 36 parts of graphene carbon nanotube composite slurry, water-based fluorocarbon resin or fluorocarbon resin emulsion: 36 parts, water: 22 parts, Defoamer: 0.2 parts, leveling agent: 0.2 parts, thickener: 0.2 parts, dipropylene glycol methyl ether 4 parts.

[0043] The graphene-carbon nanotube composite slurry includes 2% carbon nanotubes, graphene: 1.5%, defoamer: 0.2%, wetting agent: 0.2%, and the rest is water.

[0044] The preparation method of the graphene carbon nanotube high-temperature heat dissipation coating of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com