High hardness and high wear resistance waterborne wood paint and preparation method thereof

A technology of water-based wood paint and high wear resistance, which is applied in the field of coatings, can solve the problems of water-based wood paint hardness and wear resistance, poor solvent type, and poor fullness, and achieve good fullness, increased hardness, and high hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

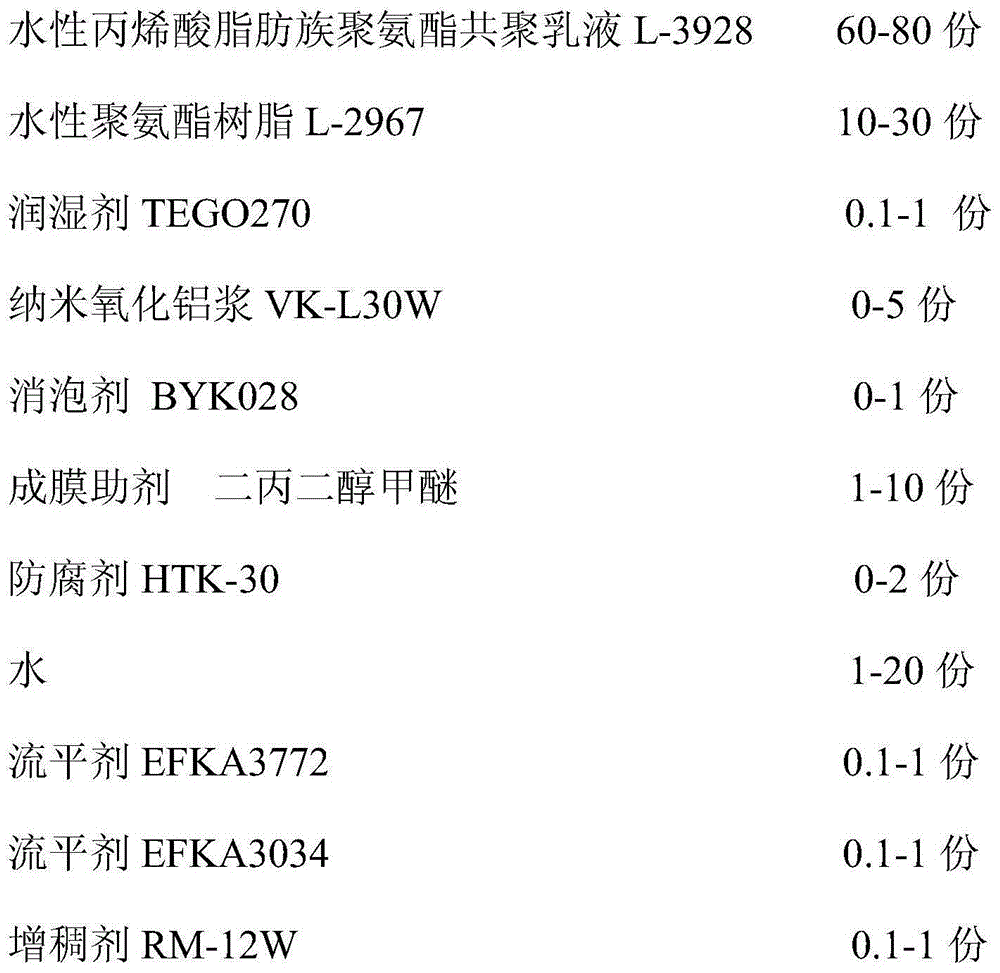

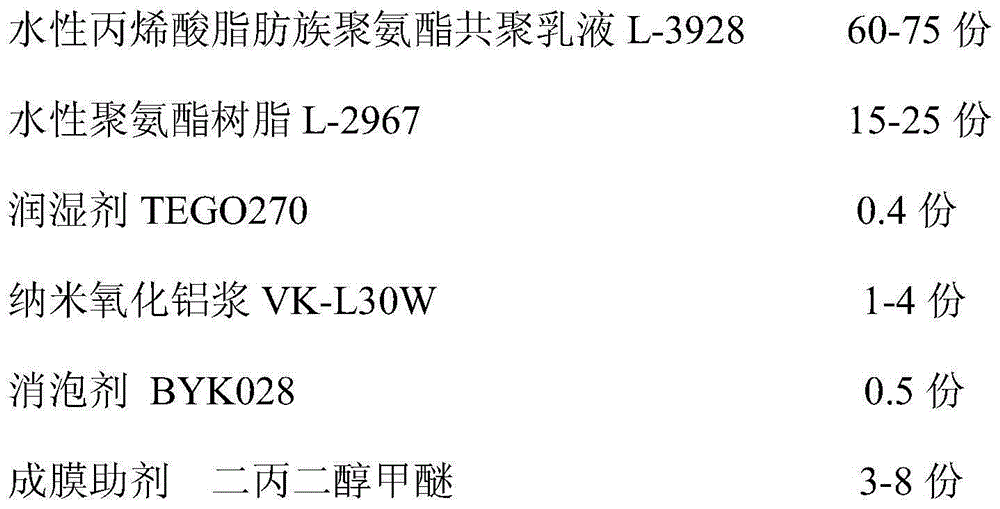

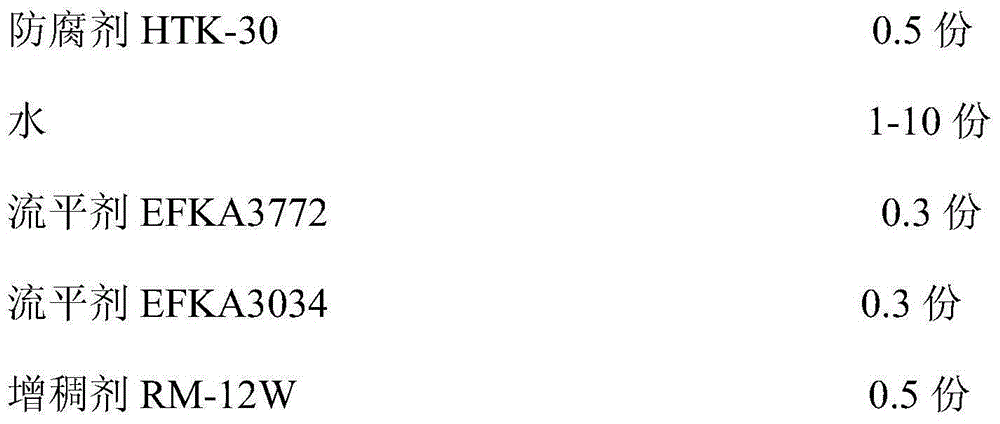

[0052] Equipped with 100kg of water-based wood lacquer of the present invention, it is formulated by the following components in weight ratio:

[0053] Put 71.5kg of water-based acrylic aliphatic polyurethane copolymer emulsion, 15kg of water-based polyurethane resin, and 0.4kg of wetting agent into the dispersion tank; then add 1kg of nano-alumina slurry, 0.5kg of defoamer, 7kg of film-forming aids, and 0.5 kg, water 3kg, leveling agent EFKA3772 0.3kg, leveling agent EFKA3034 0.3kg, thickener 0.5kg, disperse at 800 rpm for 5 minutes to form a uniform solution, filter, pack, and store.

Embodiment example 2

[0055] Equipped with 100kg of water-based wood lacquer of the present invention, it is formulated by the following components in weight ratio:

[0056] Put 66.5kg of water-based acrylic aliphatic polyurethane copolymer emulsion, 18kg of water-based polyurethane resin, and 0.4kg of wetting agent into the dispersion tank; then add 2kg of nano-alumina slurry, 0.5kg of defoamer, 6kg of film-forming aid, and 0.5 kg, water 5kg, leveling agent EFKA3772 0.3kg, leveling agent EFKA3034 0.3kg, thickener 0.5kg, disperse at 800 rpm for 5 minutes to form a uniform solution, filter, pack, and store.

Embodiment example 3

[0058] Equipped with 100kg of water-based wood lacquer of the present invention, it is formulated by the following components in weight ratio:

[0059]Put 62.5kg of water-based acrylic aliphatic polyurethane copolymer emulsion, 20kg of water-based polyurethane resin, and 0.4kg of wetting agent into the dispersion tank; then add 3kg of nano-alumina slurry, 0.5kg of defoamer, 5kg of kg, water 7kg, leveling agent EFKA3772 0.3kg, leveling agent EFKA3034 0.3kg, thickener 0.5kg, disperse at 800 rpm for 5 minutes to form a uniform solution, filter, pack, and store.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com