Radiation refrigeration coating and preparation method and application thereof

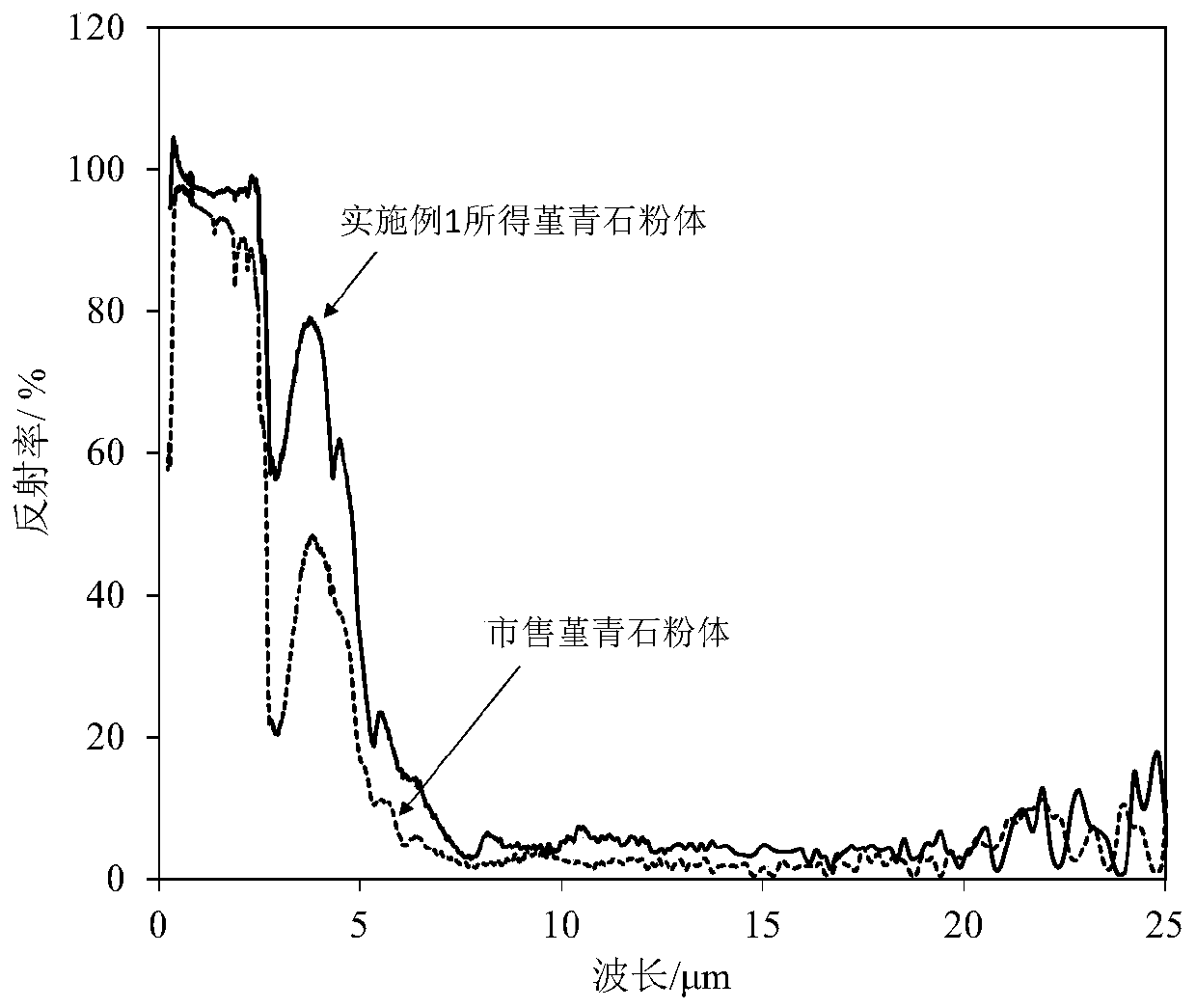

A radiation refrigeration and coating technology, applied in the direction of reflection/signal coating, coating, silicate, etc., can solve the solar reflection ability of cordierite powder, weak infrared radiation heat dissipation ability in the window, and lack of options In order to achieve the effects of widening the construction temperature range, preventing settlement and condensation, and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A kind of radiant cooling paint, comprises the following raw material components according to mass percentage:

[0053]

[0054]

[0055] In the present embodiment, silane coupling agent is Z6040, Dow Corning; Film-forming aid is Loxanol @ CA 5308, BASF; leveling agent is BYK-3700, Germany BYK; dispersant is Efka @ FA 4654AN, BASF; defoamer is TEGO @ Foamex810, Evonik; thickener is Rheovis @ PE 1331, BASF; anti-flash rust agent is Efka @ MI 6613, BASF.

[0056] A preparation method of the radiant refrigeration coating in the above-mentioned embodiment 1 of the present invention, comprising the following steps:

[0057] (1) Pour porous cordierite, titanium dioxide, dipropylene glycol methyl ether acetate, silane coupling agent, film-forming aid, leveling agent, dispersant, defoamer, thickener, anti-flash rust agent into a beaker , sonicated for 30 minutes, and stirred by a high-speed shearer for 30 minutes to mix them uniformly to obtain a filler / dipropylene g...

Embodiment 2

[0085] A radiation cooling coating, which is basically the same as the radiation cooling coating in Example 1, the only difference is that the preparation method of porous cordierite is different.

[0086] In Example 2, the preparation method of the porous cordierite used is basically the same as the preparation method of the porous cordierite in Example 1, the only difference being: in step S2 of the preparation method of Example 2, pH=3; in step S3, The temperature of the second step of calcination is 1200°C.

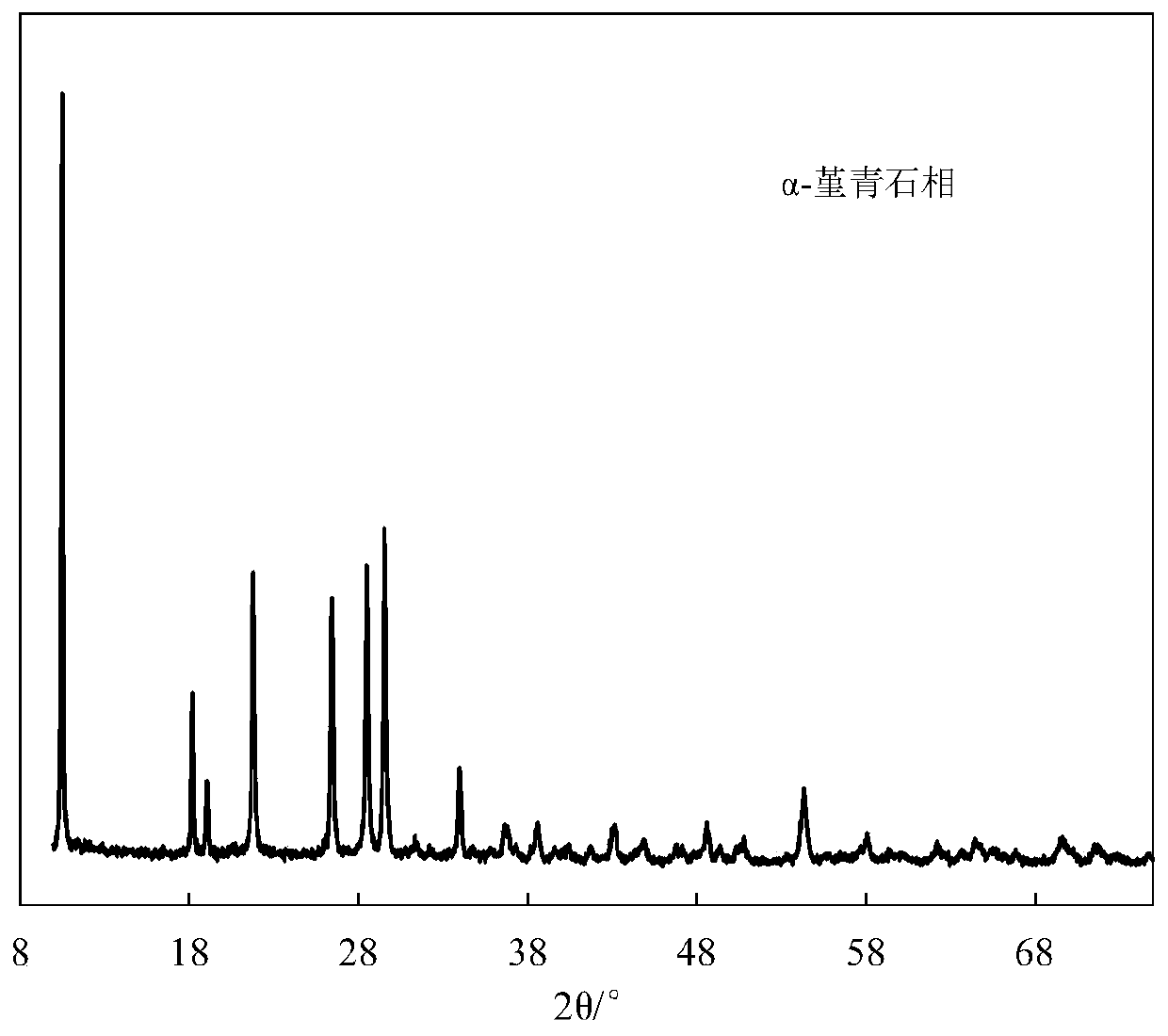

[0087] Figure 11 It is the XRD spectrum of the porous cordierite powder prepared in Example 2 of the present invention. Such as Figure 11 As shown, it shows that the gel obtained at pH = 3 can also obtain pure α-cordierite phase after calcination at 1200°C for 2 hours.

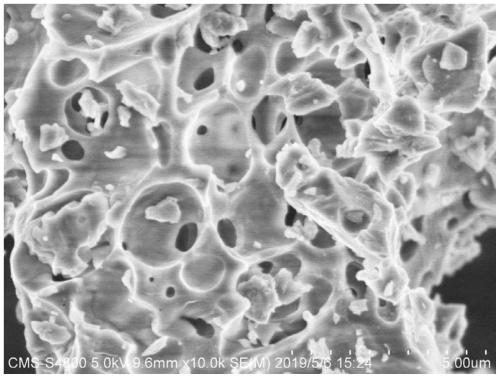

[0088] Figure 12 It is the SEM image of the porous cordierite powder prepared in Example 2 of the present invention. Such as Figure 12 As shown, it can be seen that the product still has a p...

Embodiment 3

[0092] A radiation cooling coating, which is basically the same as the radiation cooling coating in Example 1, the only difference is that the preparation method of porous cordierite is different.

[0093] In Example 3, the preparation method of the porous cordierite used is basically the same as the preparation method of the porous cordierite in Example 2, the only difference being that in the step S2 of the preparation method of Example 3, the sol was placed at 50° C. 60h to get a gel.

[0094] The heat insulation test results show that the coated panel obtained in Example 3 can achieve an absolute cooling effect (daytime) of 6.2°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com