Decorative pattern transfer paper adapting to various special environments and transfer method thereof

A technology of transfer printing paper and pattern layer, which is applied in the direction of decorative art, technology for producing decorative surface effects, applications, etc., can solve the problems of thick dots, hidden dangers, and insufficient fineness of silk screen patterns, etc. Focus on the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

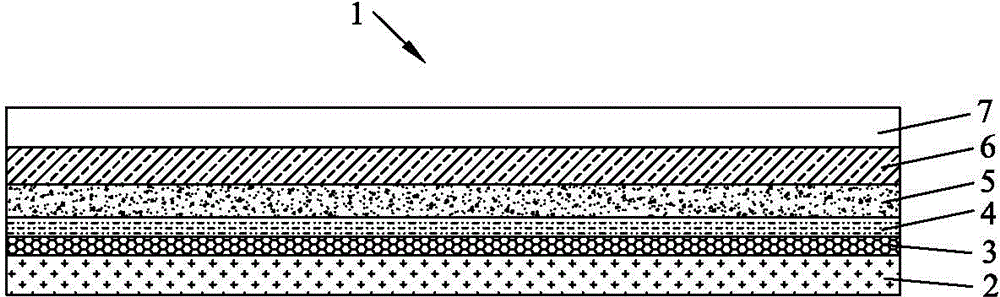

[0081] The transfer printing method of the decorative pattern transfer paper adapted to various special environments of the present embodiment, especially a kind of transfer printing method of a color pattern for printing or product exterior decoration, it comprises the following steps:

[0082] 1) Making transfer paper 1, including the following steps;

[0083] a, screen printing a varnish bottom layer 4 on the backing paper 2 that is provided with a layer of hydrosol layer 3 in advance;

[0084] The hydrosol layer 3 is formed by mixing components of 5% arabic resin or starch, 94.5% water, and 0.5% modified siloxane by mass percentage;

[0085] Varnish base layer 4 is composed of 22% cellulose acetate butyrate, 24% hydroxyacrylic resin, 19.5% HDI polyisocyanate, 33.5% dipropylene glycol methyl ether, and 1.0% polymethylsiloxane by mass percentage. made by mixing

[0086] B, screen printing a white ink layer 5 on the varnish bottom layer 4, the white ink layer 5 mass percent...

Embodiment 2

[0094] The transfer printing method of the decorative pattern transfer paper adapted to various special environments of the present embodiment, especially a kind of transfer printing method of a color pattern for printing or product exterior decoration, it comprises the following steps:

[0095] 1) Making transfer paper 1, including the following steps;

[0096] a, screen printing a varnish bottom layer 4 on the backing paper 2 that is provided with a layer of hydrosol layer 3 in advance;

[0097] The hydrosol layer 3 is formed by mixing the components of 15% arabic resin or starch, 84% water, and 1.0% modified siloxane by mass percentage;

[0098] Varnish base layer 4 is composed of 28% cellulose acetate butyrate, 32% hydroxyacrylic resin, 14% HDI polyisocyanate, 25% dipropylene glycol methyl ether, and 1.0% polymethylsiloxane by mass percentage. made by mixing

[0099] B, screen printing a white ink layer 5 on the varnish bottom layer 4, the white ink layer 5 mass percent ...

Embodiment 3

[0107] The transfer printing method of the decorative pattern transfer paper adapted to various special environments of the present embodiment, especially a kind of transfer printing method of a color pattern for printing or product exterior decoration, it comprises the following steps:

[0108] 1) Making transfer paper 1, including the following steps;

[0109] a, screen printing a varnish bottom layer 4 on the backing paper 2 that is provided with a layer of hydrosol layer 3 in advance;

[0110] The hydrosol layer 3 is formed by mixing the components of 11% Arabic resin or starch, 88% water, and 1.0% modified siloxane by mass percentage;

[0111] Varnish base layer 4 is composed of 24% cellulose acetate butyrate, 28% hydroxyacrylic resin, 17.2% HDI polyisocyanate, 30% dipropylene glycol methyl ether, and 0.8% polymethylsiloxane made by mixing

[0112] B, screen printing a white ink layer 5 on the varnish bottom layer 4, the white ink layer 5 mass percent is 16% cellulose a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com