Acrylic acid water-based paint and preparation method thereof

A technology of acrylic water-based and acrylic emulsion, applied in the direction of coating, etc., can solve the problems of poor wear resistance and water resistance, unsatisfactory physical and chemical properties, etc., and achieve good emulsion stability, good storage stability and workability, good The effect of film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

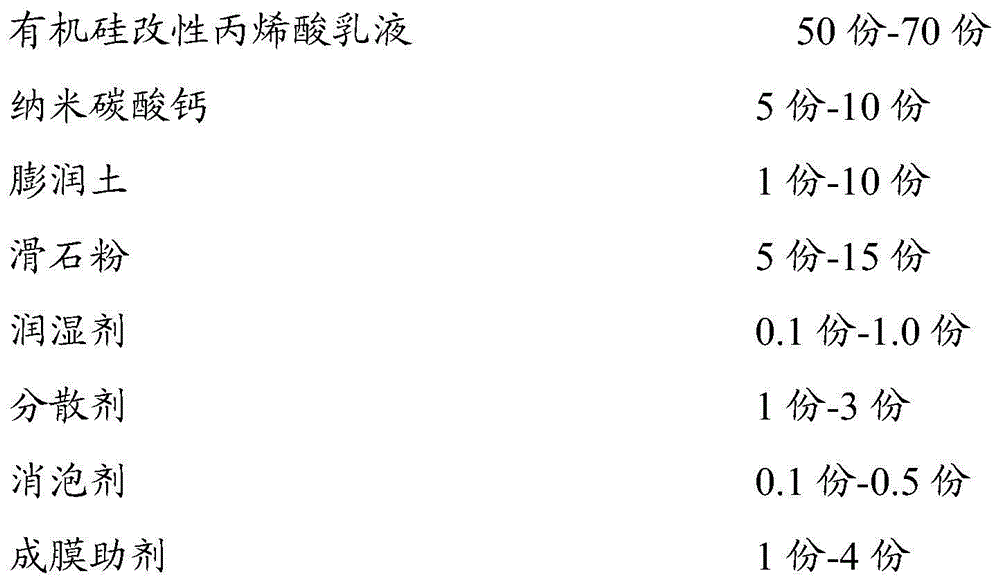

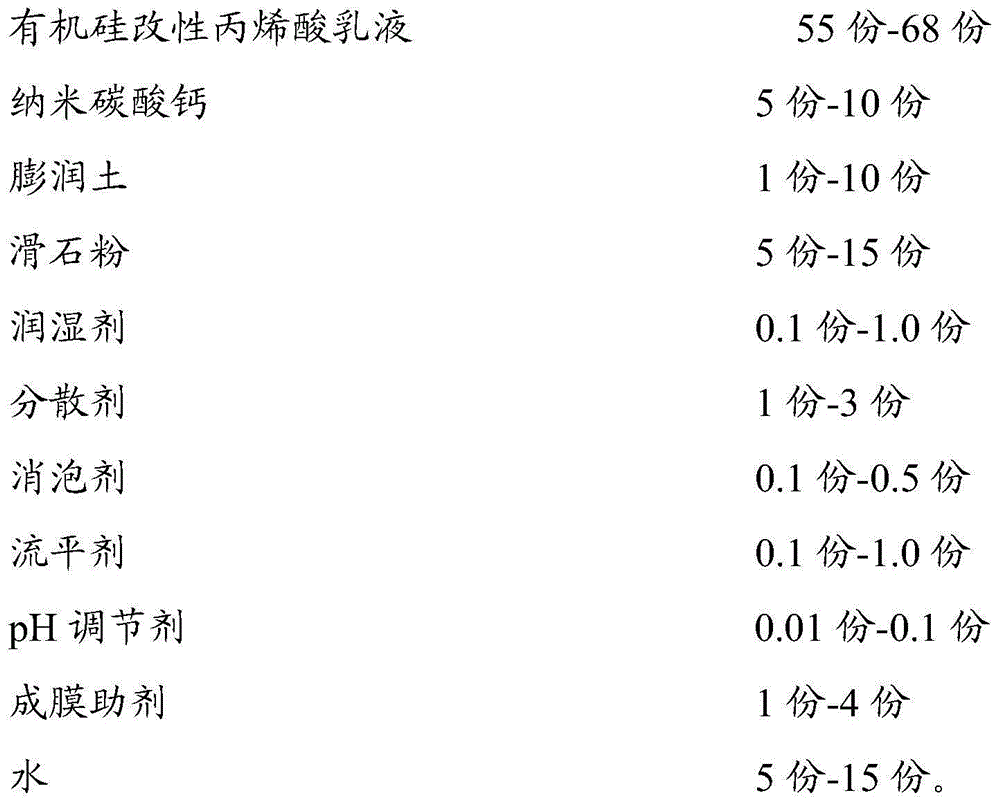

[0044] The acrylic water-based paint of the present invention comprises the following components by weight:

[0045]

[0046]

[0047] The method for preparing the above-mentioned acrylic water-based paint using this formula is as follows: according to the content of each component in the above-mentioned formula, water, nano-calcium carbonate, bentonite, talcum powder, wetting agent, dispersant and defoamer are added to the high-speed dispersion tank, Stir and disperse at high speed to obtain a slurry; add silicone-modified acrylic emulsion and film-forming aids to the slurry, stir and disperse to obtain a semi-finished product, add a pH regulator to adjust the pH value to 7-8; pass the semi-finished product through 200 mesh yarn Filter through a net to obtain acrylic water-based paint.

[0048] Wherein, the preparation method of silicone-modified acrylic emulsion is: add persulfate as initiator in acrylate (hard monomer) and acrylic acid (soft monomer), optimize the rat...

Embodiment 2

[0052]Different from Example 1, the acrylic water-based paint of the present invention includes the following components by weight:

[0053]

[0054]

[0055] Among them, the film-forming aid is composed of 70% tripropylene glycol methyl ether and 30% DALPAD H.

[0056] In this embodiment, the wetting agent is the polyether-modified organosilicon compound of Germany BYK; the dispersant adopts 5040; the defoamer is the organic silicon defoamer of Germany BYK; Disodium hydrogen phosphate is used; the particle size of nano-calcium carbonate is 30nm; the particle size of bentonite is 300 mesh; the particle size of talcum powder is 700 mesh.

Embodiment 3

[0058] Different from Example 1, the acrylic water-based paint of the present invention includes the following components by weight:

[0059]

[0060] The film-forming aid is compounded by dipropylene glycol n-butyl ether and dipropylene glycol methyl ether in a ratio of 1:1.

[0061] In this embodiment, the wetting agent is K12; the dispersant is the polyacrylate dispersant of German BK Baker Gilini Company; the defoamer is polyether defoamer; 95pH regulator; nano calcium carbonate particle size is 50nm; bentonite particle size is 300 mesh; talcum powder particle size is 800 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com