Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58 results about "ACETONE/ALCOHOL" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The main active ingredient in most nail polish removers, acetone is a solvent. It is able to dissolve other substances, including plastic. It is usually made with isopropyl alcohol, but it is different because its acetone properties makes it a solvent.

Process of preparing rich acetone alcohol biological oil by biomass microwave catalytic pyrolysis

InactiveCN100999676AHighly selective generationImprove use valueOrganic chemistryLiquid hydrocarbon mixture productionCatalytic pyrolysisLiquid product

The microwave catalytic biomass cracking process for preparing biological oil with rich acetone alcohol features using sodium carbonate as catalyst, silicon carbide as microwave absorbing medium, microwave source as heat source for cracking biomass, and ice water mixture for cooling volatile component to obtain biological oil with rich acetone alcohol. By means of the unique temperature effect of microwave in biomass particle and the unique catalyzing effect of sodium carbonate in cracking biomass, the present invention realizes the creation of acetone alcohol in high selectivity. The present invention can obtain liquid product with acetone alcohol content of 30-55 % and raise the utilization value of acetone alcohol greatly. The present invention uses cheap and facile material and catalyst and has greatly shortened reaction period.

Owner:ANHUI UNIV OF SCI & TECH

Method for preparing 1,3 propylene glycol by using glycerol method

InactiveCN101003462AHigh purityGood choiceOrganic compound preparationHydroxy compound preparationHydrogenGlycerol

This invention discloses a method for preparing 1, 3-propylene glycol from glycerol. The method has such advantages as high catalytic activity, mild reaction conditions, high product selectivity, high product purity, simple process. The method comprises: (1) adding 95% glycerol and 30% oxydol into a round bottom flask, setting condensing tube and drying tube, heating to 100 deg.C under stirring, and reacting for 1-3 h to obtain acetone alcohol; (2) adding acetone alcohol into a pressure reaction kettle loaded with transition oxometalate catalyst, introducing hydrogen for 4-6 h at 100-200 deg.C and 10 MPa, reacting, and rectifying to obtain 1,3-propylene glycol.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

Method for preparing granulating auxiliary agent for processing plastic

InactiveCN101235162ADepressed maximum melting pointGood dispersionGranulation by material expressionAdjuvantRoom temperature

The invention relates to a preparation method of granulating agent for plastic processing, in particular to a preparation method of granulating anti-oxidant for metaformaldehyde processing. The granulating agent is composed of anti-oxidant, common stabilizer, acid absorber and lubricant. The preparation method comprises mixing the powder agents aforementioned uniformly, using acetone alcohol and water as adjuvants, adding at least one adjuvant into the uniform powder agent, using twin-screw extruder to extrude and granulate at room temperature, drying to obtain granulating agent. The agent has high rigidity and non dust generation in carriage and transmission. The granulating agent has significant alloying effect, which can be used in metaformaldehyde resin to obtain lower yellow index, higher thermal decomposition temperature, higher product thermal stability and better application effect than the metaformaldehyde resin applied with powder agent.

Owner:SICHUAN UNIV

Hardware electroplating finishing coating

The invention discloses a hardware electroplating finishing coating which is prepared from the following raw materials in percentage by weight: 50-60% of acrylate resin, 10-15% of isobutyl etherified amino resin, 3-7% of high imino methylated amino resin, 5-8% of epoxy resin, 15-20% of diluter, 1-2% of di-tert-butyl peroxide and 0.1-0.2% of diacetone alcohol. The hardware electroplating finishing coating can be cured at high temperature and low temperature; when the finishing coating is cured at low temperature, the coating film has the advantages of superhigh adhesive force, high hardness, high gloss, high resistance, wear resistance and the like; and the technique for producing the hardware electroplating finishing coating is simple and low in cost.

Owner:柳州市五环水暖器材经营部(微型企业)

Method of producing lower alcohols from glycerol

ActiveUS20090105509A1High yieldHigh purityOther chemical processesOrganic compound preparationGlycerol DerivativesAlcohol

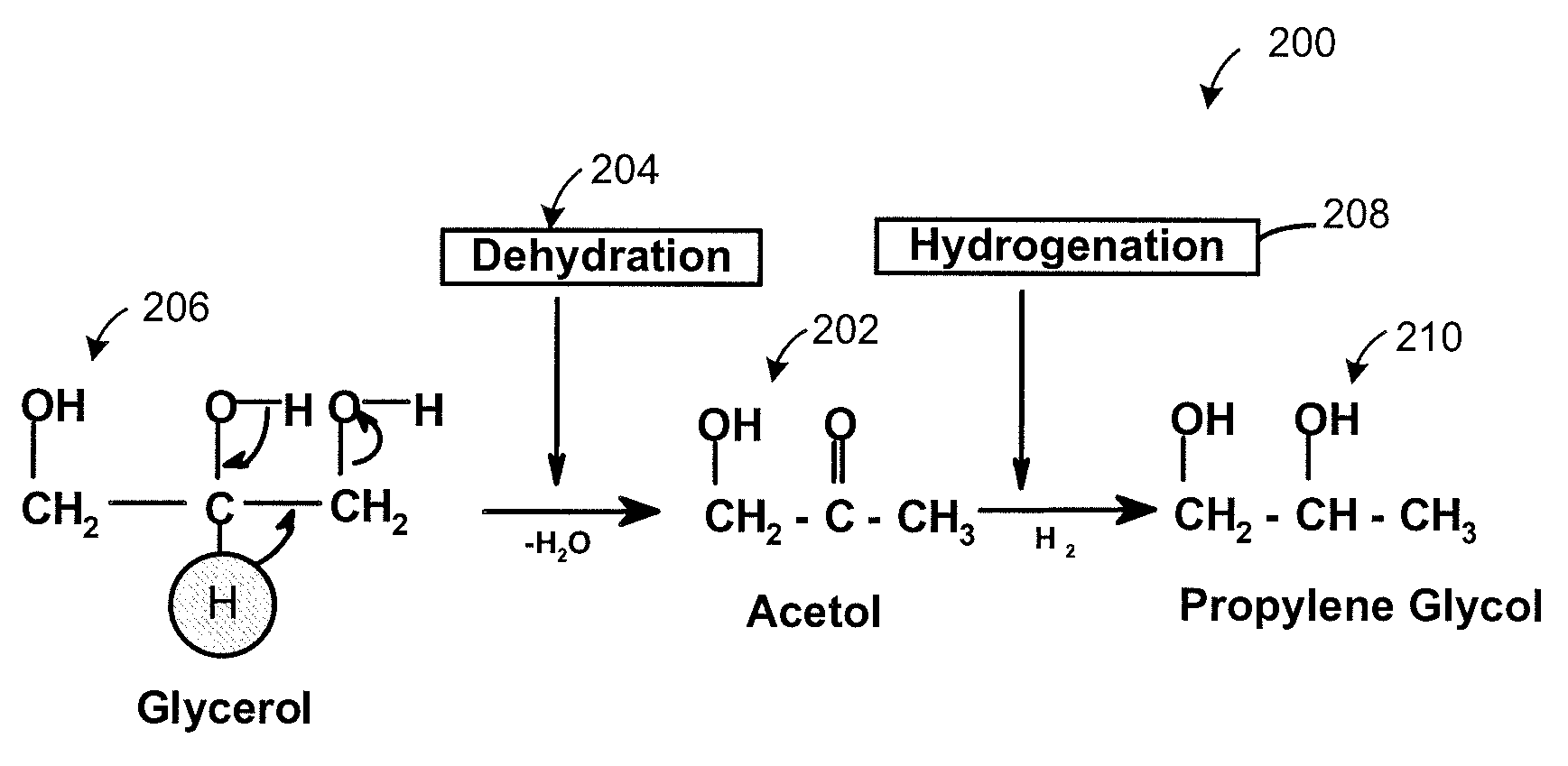

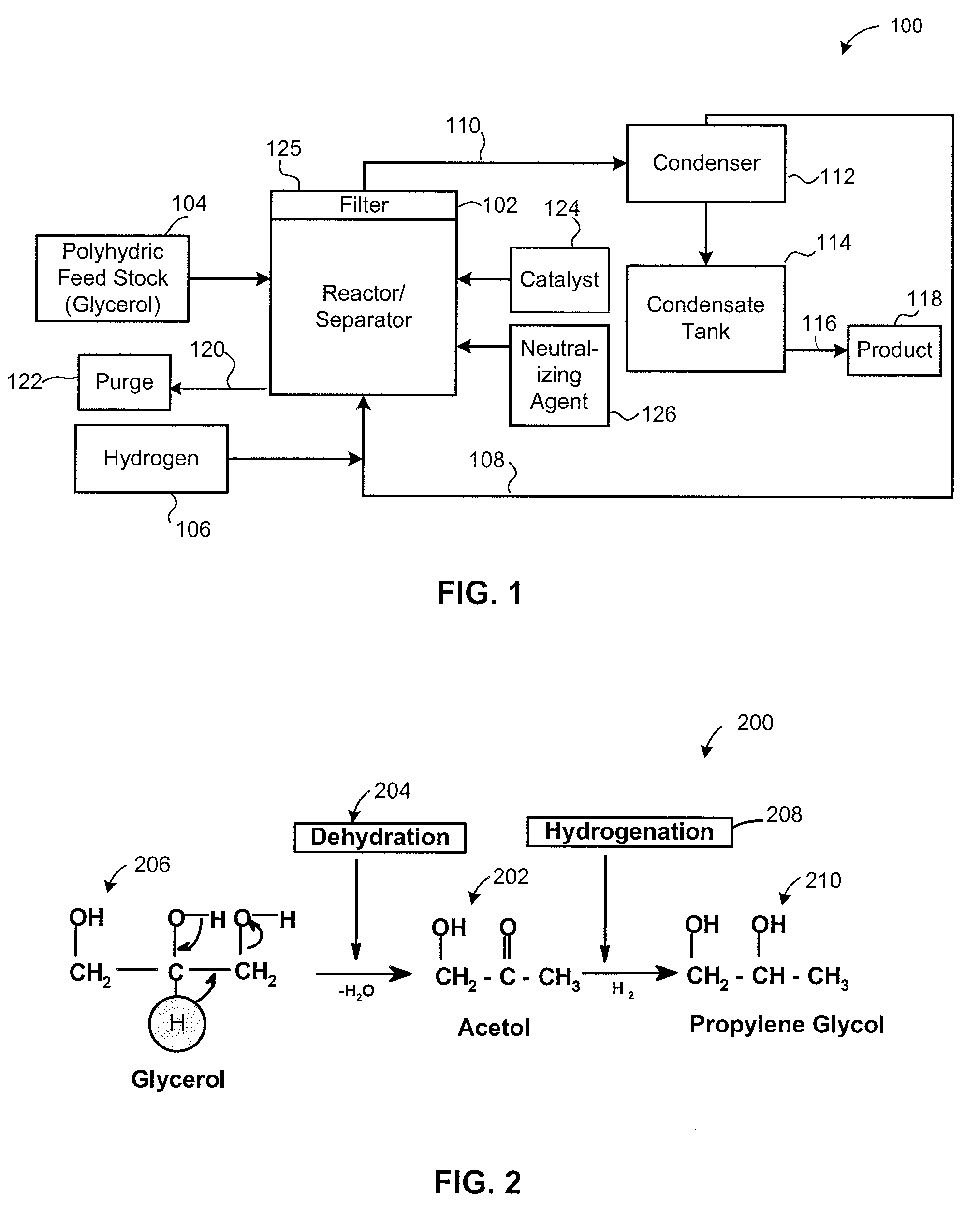

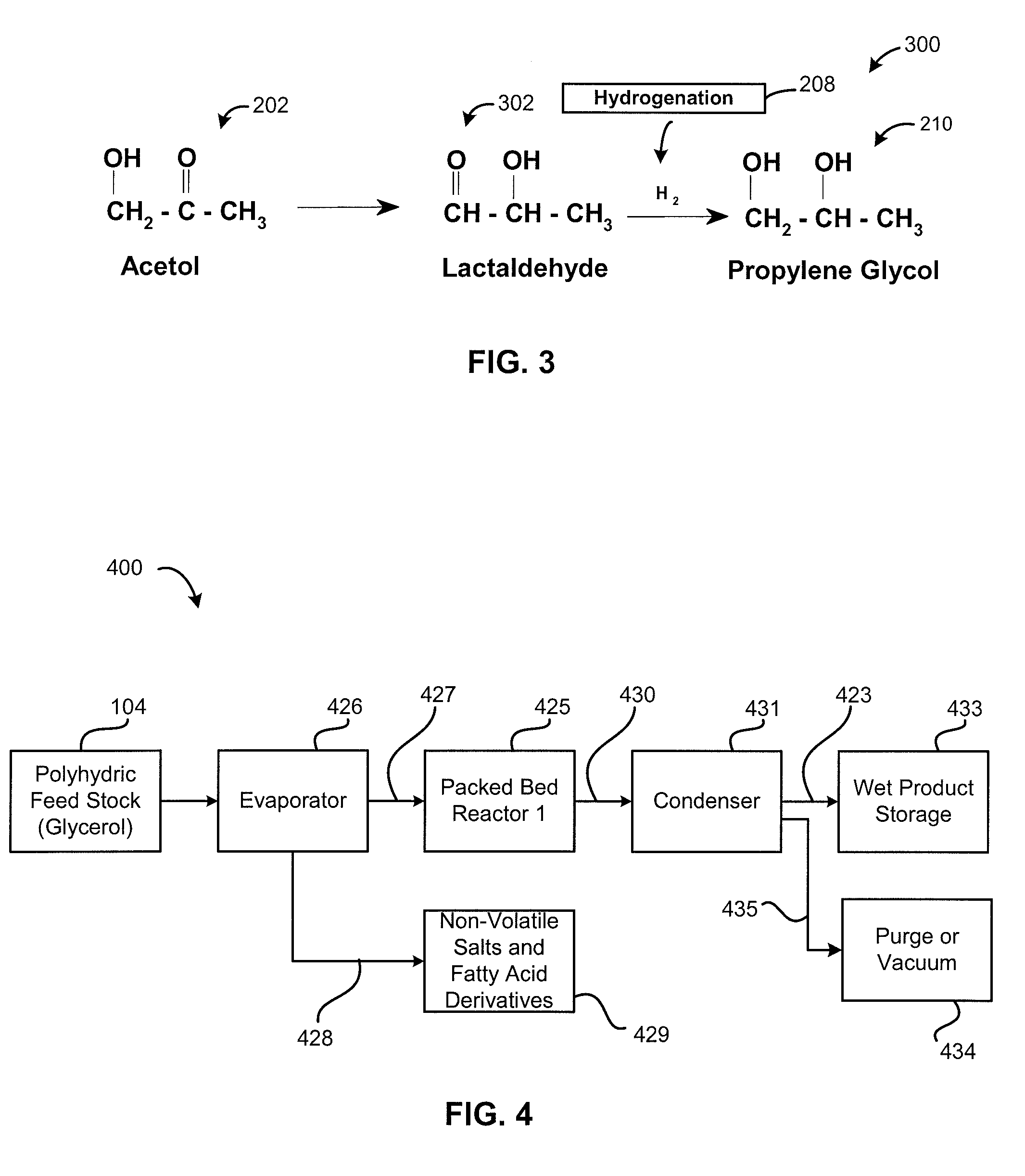

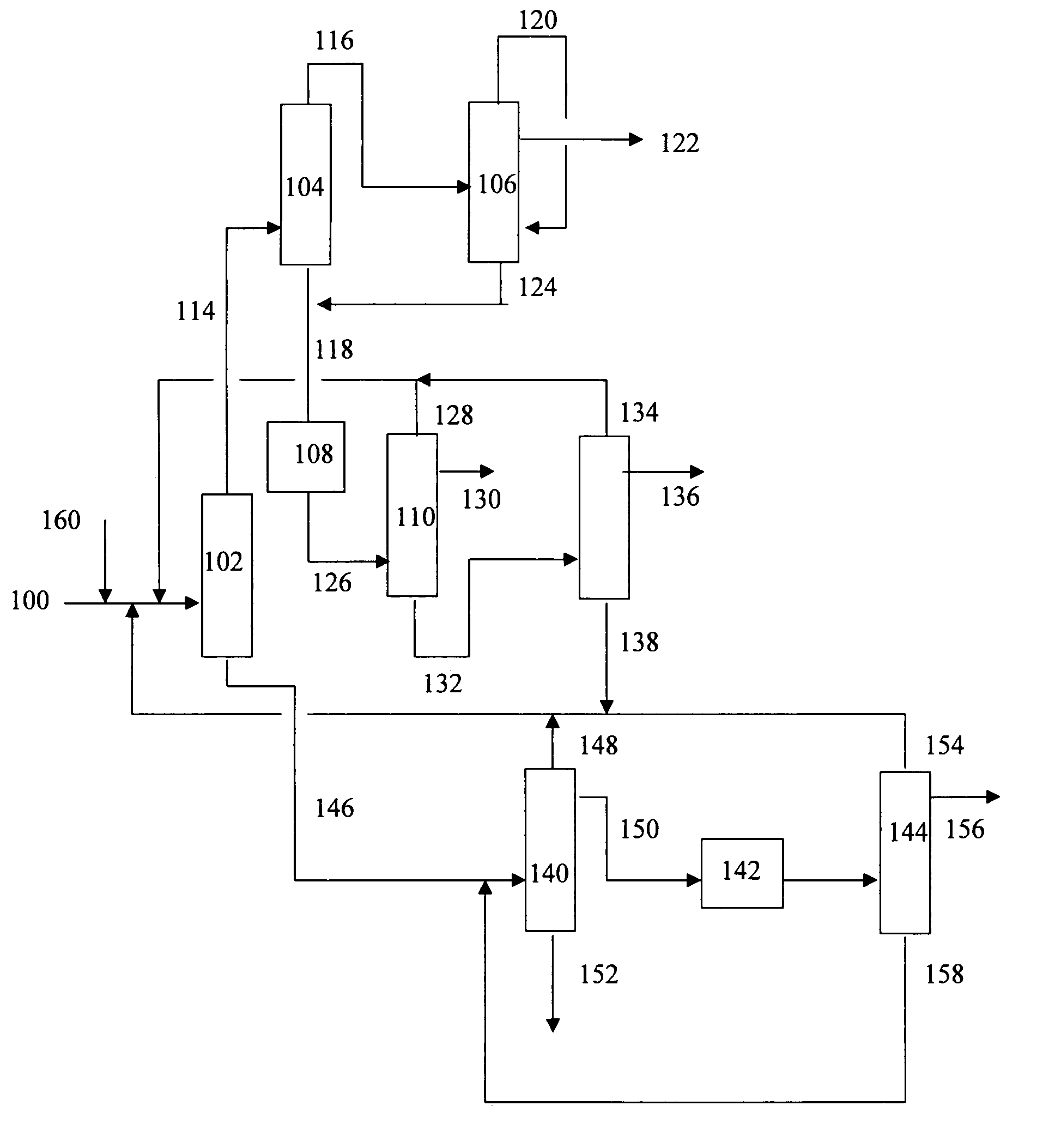

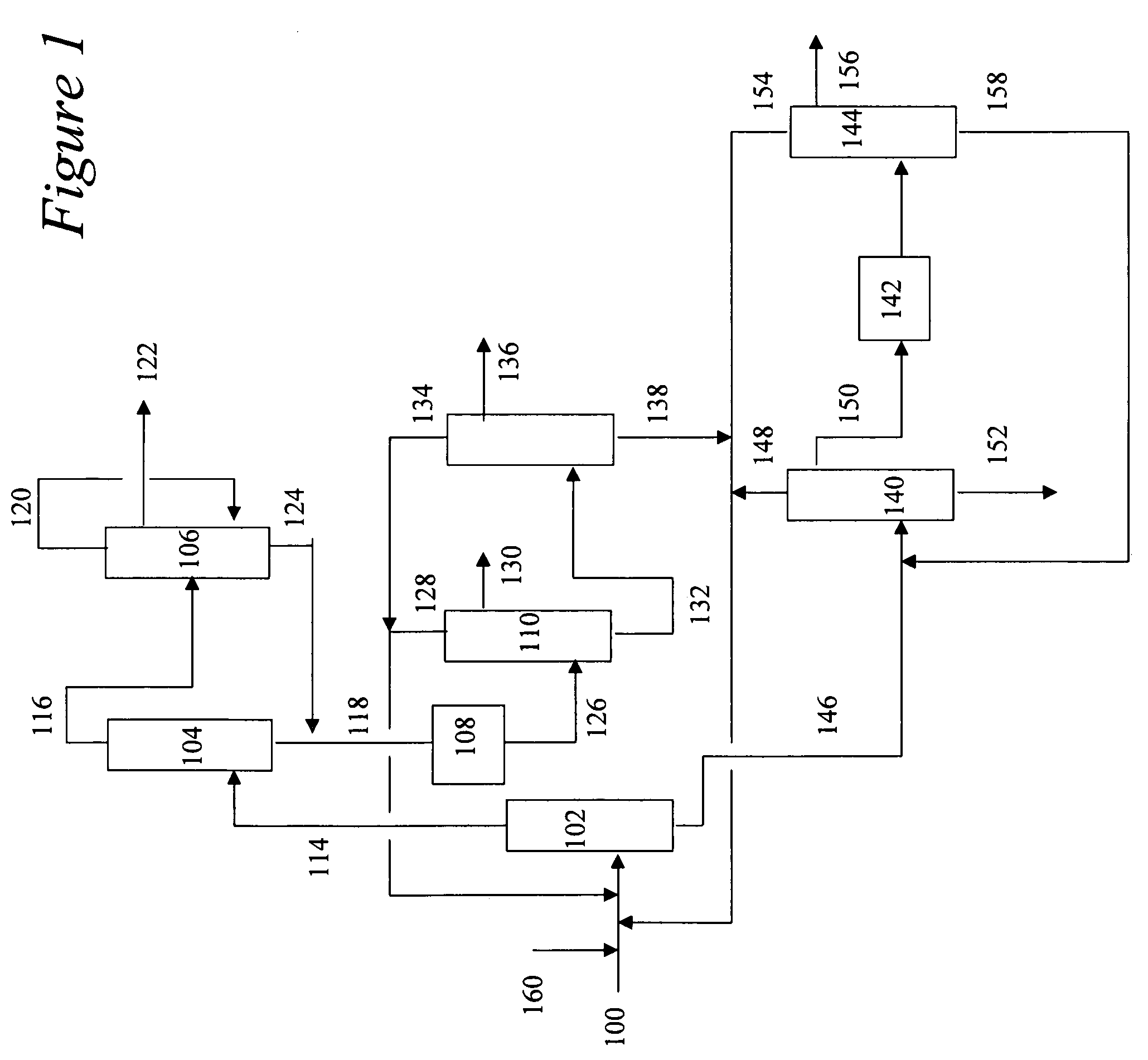

This invention relates generally to a process for value-added processing of fats and oils to yield glycerol and glycerol derivatives. More particularly, the process converts glycerol to acetol and then acetol to propylene glycol to produce a propylene glycol with ultra-low amounts of ethylene glycol. The propylene glycol thus produced may be used as an antifreeze, deicing compound, or anti-icing compound.

Owner:UNIVERSITY OF MISSOURI

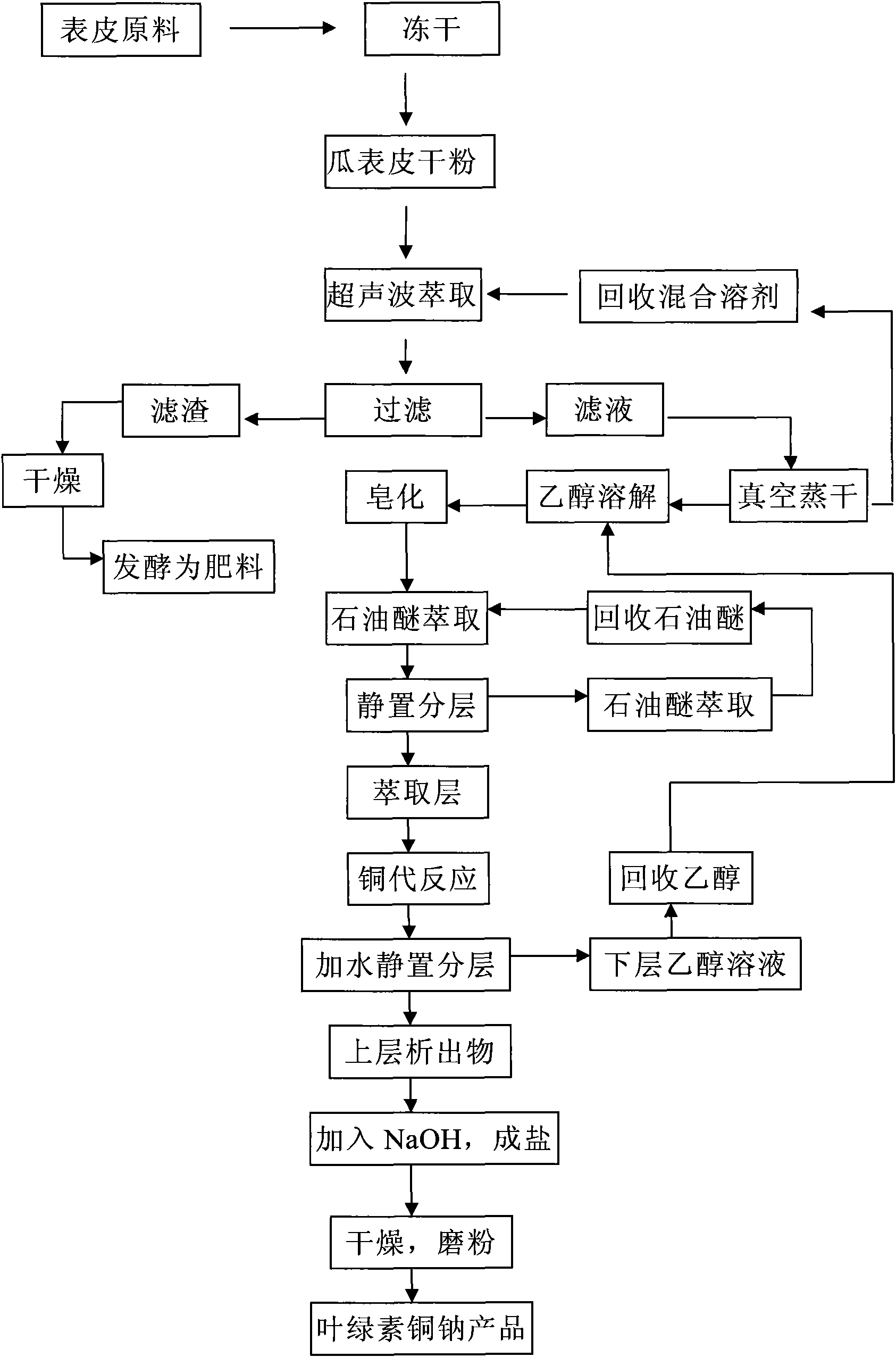

Method for preparing sodium copper chlorophyllin by using watermelon outer peel

InactiveCN101591339AAvoid lostRealize comprehensive utilizationCopper organic compoundsSolventChlorophyllin

The invention discloses a method for preparing sodium copper chlorophyllin by using watermelon outer peel, comprising the following steps: watermelon outer peel is pulverized and freeze-dried; acetone-alcohol mixed solvent is added into the processed watermelon outer peel powder, and the mixture is performed with ultrasonic extraction after being mixed evenly; the extract liquor is filtrated, the filtrate is dried by vacuum evaporation so as to obtain crude chlorophyll, the crude chlorophyll is dissolved in ethanol, the undissolved substance is eliminated, NaOH solution is used to adjust the acidity and alkaline of chlorophyll to alkalescence, and the produced sediment is eliminated; the process of heating, back flow and saponification are carried out; the saponification liquid is extracted with petroleum ether while oscillating until the petroleum ether extraction layer is faint yellow, then the petroleum ether is eliminated; 5% CuSO4-5H2O solution is added and the mixture is stirred and heated; pH is adjusted to be 1 by hydrochloric acid, the mixture is oscillated evenly after isopyknic distilled water is added, and then the mixture is poured into a separating funnel for standing; after standing for layering, liquid on the lower layer is eliminated to obtain copperchlorophyll; the obtained copperchlorophyll is poured into NaOH solution, then the pH is adjusted to be 11; the mixture is dried to obtain sodium copper chlorophyllin. The method needs no heating, and has small chlorophyllin loss, short extraction time, small solvent loss and high extraction efficiency.

Owner:BEIJING JIANJIAN KANGKANG BIO TECH +1

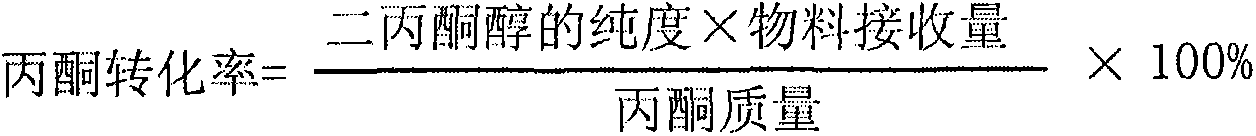

Synthesis process of diacetone alcohol

InactiveCN103724172ANot corrosiveExtend your lifeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDiacetone alcoholEvaporation

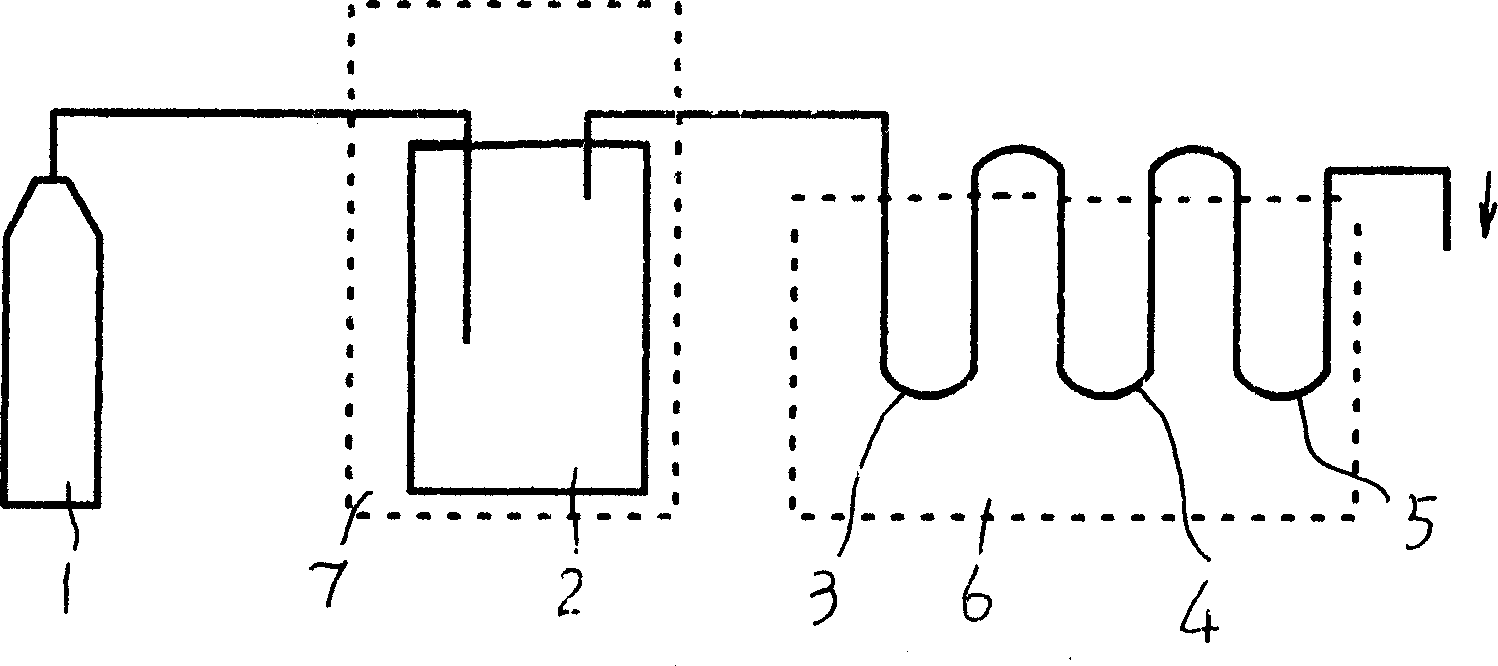

The invention relates to a synthesis process of a diacetone alcohol. According to the technical scheme, the synthesis process comprises the following steps: adding an acetone into a reaction container; heating and distilling; enabling the condensated acetone to pass through a storage tank in which a catalyst is contained and enabling the mixture to flow into a receiver; and stopping the heating until the acetone is complete dried in an evaporation manner. The per-pass conversion of the acetone reaches more than 16%, so that the reaction time is effectively reduced. The catalyst is prepared from inorganic polymer composite materials, so that the catalyst is non-corrosive and can be recycled times without number, namely, the service life of the catalyst is very long. For the synthesis process, the lower the reaction temperature, the better in the reaction, so that the energy consumption and the production cost are greatly reduced. Thus, according to the technical scheme, the synthesis process which is high in acetone per-pass conversion, short in reaction time as well as low in energy consumption and production cost is provided.

Owner:TIANJIN DAOFU CHEM NEW TECH DEVCO

UV hand feeling coating based on elastic urethane acrylate and preparation method of UV hand feeling coating

ActiveCN104559750AFlexibilityGood elasticityAnti-corrosive paintsPolyurea/polyurethane coatingsPolyesterDiacetone alcohol

The invention relates to a UV-curing hand feeling coating based on elastic urethane acrylate and a preparation method of the UV hand feeling coating. The UV-curing hand feeling coating comprises the following components in percentage by weight: 30-35% of elastic urethane acrylate, 5-8% of matt powder, 8-10% of a photoinitiator, 35-40% of diacetone alcohol, 0.2-0.5% of a levelling agent, 0.8-1.5% of a hand feeling auxiliary, and 5-21% of monomer. The UV-curing hand feeling coating has the following benefits: 1), elastic polyester glycol is used in the preparation process of urethane acrylate, the main chain of the elastic polyester glycol is a C-C straight chain and main chain molecules are coiled, and after film formation through crosslinking, the coiled molecule can be stretched and shows elasticity under the effect of external force, so that the elasticity and flexibility of the UV-curing hand feeling coating are excellent; 2), a preparation method is simple, the prepared coating is good in adhesive force, and high in curing speed, and the hand feeling of the coating can be adjusted conveniently.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Process for recovery of cumene hydroperoxide decomposition products by distillation

ActiveUS7186866B1Organic compound preparationCarbonyl compound separation/purificationDistillationDecomposition

Products from the decomposition of cumene hydroperoxide (CHP) are recovered by distillation. The majority of the undesirable by-product acetol (hydroxyacetone) is removed from the phenol stream by distillation wherein the majority of the acetol is carried with an overheads stream comprising acetone, cumene and alphamethylstyrene (AMS). Acetol is subsequently separated from acetone by distillation wherein acetone is taken as an overheads stream and acetol remains with a bottoms stream comprising cumene, AMS and phenol. The acetol, along with residual phenol, is extracted from the cumene and AMS by counter-current washing with an aqueous alkali metal hydroxide. The phenol stream is then distilled to separate phenol from cumene, alphamethylstyrene and higher boiling compounds. The phenol, containing only a small amount of acetol, can then be treated to remove methylbenzofuran by treatment with an acidic resin or solid superacid catalyst without formation of significant amounts of additional methylbenzofuran.

Owner:ADVANSIX RESINS & CHEM LLC

High flow flat imitating steam mold UV curing coating and production method, construction method

ActiveCN101418159AHigh fullnessImprove the level ofPretreated surfacesPaints with free metalsChemistryIsobutyl alcohol

The invention relates to a high-leveling vapor die imitating UV-curing coating, a production method and a construction method thereof. The coating comprises black primer or silver primer, a primer diluent and UV radiation curing varnish, wherein the primer diluent comprises 8 to 15 portions of ethylene glycol monobutyl ether, 5 to 10 portions of diacetone alcohol, 5 to 15 portions of ethylene glycol monoethyl ether, 5 to 15 portions of methylisobutylketone, 25 to 35 portions of ethyl acetate, 10 to 15 portions of isopropyl alcohol and 10 to 15 portions of isobutyl alcohol; and the UV radiation curing varnish comprises 10 to 15 portions of tripropylene glycol diacrylate, 10 to 15 portions of trimethylol-propane trimethacrylate, 20 to 30 portions of amino acrylate resin, 7 to 15 portions of Epocryl, 3 to 6 portions of 1-hydroxyl-cyclohexyl-phenyl ketone, 0.5 to 1 portion of 2, 4, 6(trimethylbenzene formacyl) diphenyl phosphine oxide, 15 to 25 portions of ethyl methyl ketone, 0.5 to 1.5 portions of polyacrylate leveling agent and 0.5 to 1.5 portions of polyether siloxane copolymer. The invention also provides a manufacturing method and a use method for the product. The high-leveling vapor die imitating UV-curing coating, is widely applied to treatment of plastic shells such as TV sets, so that the surface of a treated plastic substrate can achieve the effect of high-leveling vapor die imitating.

Owner:深圳市嘉卓成科技发展有限公司

Environment-friendly anti-ultraviolet finishing agent and outdoor cloth using same

ActiveCN110863343AExcellent film fastnessEasy to useLight resistant fibresDiacetone alcoholActivated carbon

The invention relates to an environment-friendly anti-ultraviolet finishing agent with excellent anti-ultraviolet effect, environmental protection and cost saving and outdoor cloth using the finishingagent. The environment-friendly anti-ultraviolet finishing agent comprises titanium dioxide, a coloring agent, diacetone alcohol, ethyl acetate, butyl ester and a dispersing agent. The product prepared by the invention is folded with the conventional product for thirty times, and the adhesive film fastness of the outdoor cloth prepared by the invention is obviously better; by detecting the ultraviolet resistance, the prepared outdoor cloth can reach UPF50+ or more, and the UVA passing rate is less than 5%; after the conventional product is dried at a high temperature of 210 DEG C for 15 seconds, the ultraviolet resistance of the conventional product is sharply reduced, and the outdoor cloth prepared by the invention has no obvious change. A coating process is adjusted, no potential safetyhazards exist, the environment-friendly anti-ultraviolet finishing agent is environment-friendly, does not pollute recycling activated carbon, and does not influence normal use of a toluene recyclingmachine either, the cost is saved, and the quality is excellent.

Owner:ZHEJIANG SHENGSHAN TECH TEXTILE

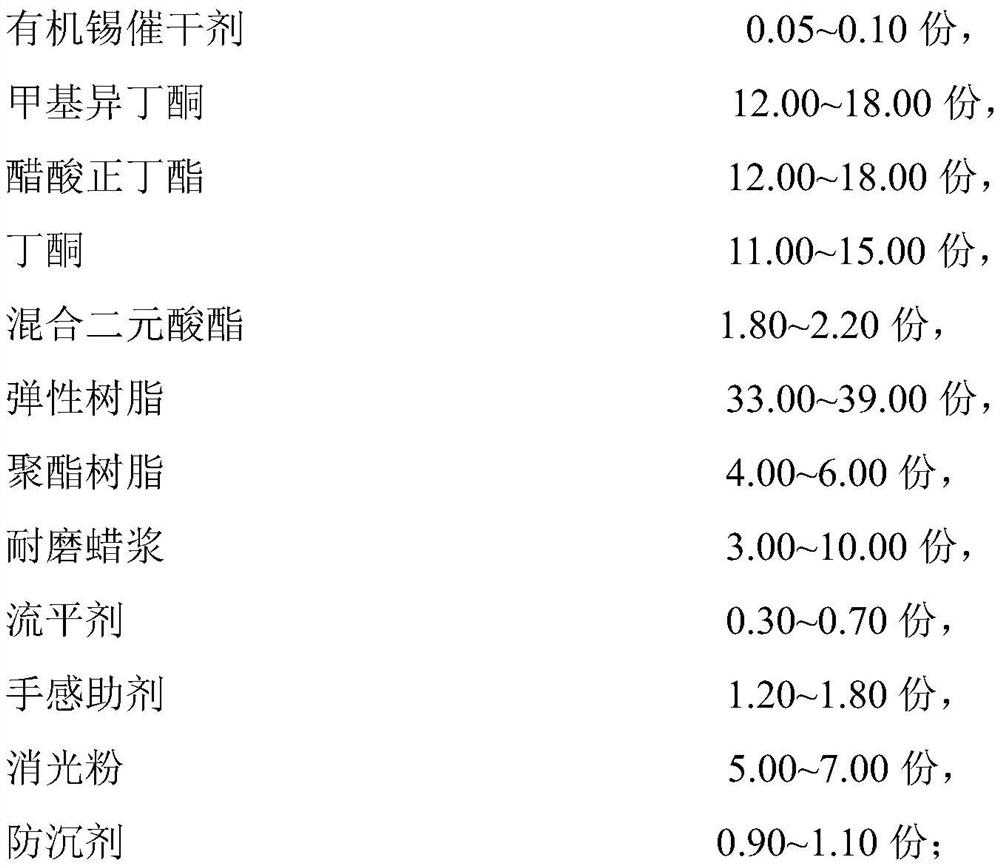

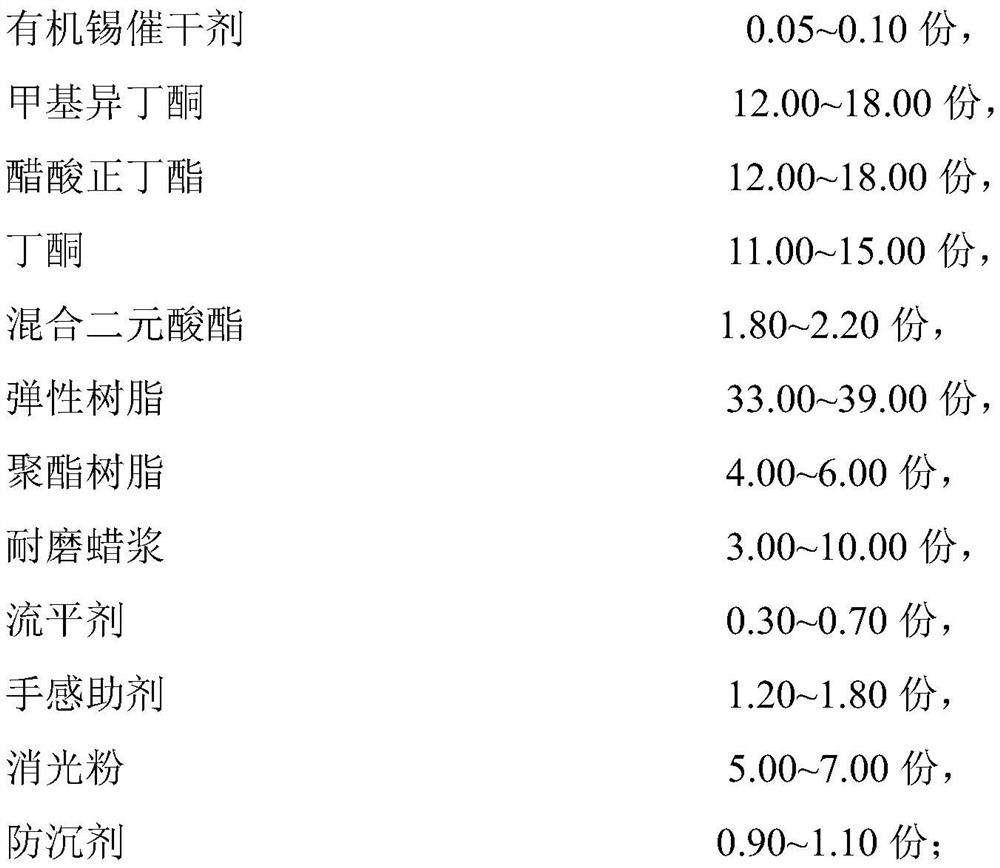

Quick-drying elastic paint and using method thereof

ActiveCN112175500AFast drying and curingShorten the lengthSiccativesPretreated surfacesDiacetone alcoholPolymer science

The invention relates to quick-drying elastic paint and a using method thereof. The quick-drying elastic paint is prepared from a main agent component A, a curing agent component B and a diluting solvent component C. The component A is prepared from an organic tin drier, methylisobutylketone, n-butyl acetate, butanone, mixed dibasic acid ester, elastic resin, polyester resin, wear-resistant wax slurry and the like; the component B is a curing agent resin, and the component C comprises ethyl acetate, diacetone alcohol, isopropanol, an organic tin drier and an organic tin complexing aid. Compared with the prior art, the drying and curing speed is high, the activation period is long, and the activation period and the drying speed of the elastic paint can be flexibly adjusted by adjusting theproportion of the organic tin drier in the main agent component A and the diluent component C.

Owner:DONGLAI COATING TECH SHANGHAI

Remote-controlled aircraft for hail mitigation and precipitation and hail mitigation and precipitation method

PendingCN107318546AImprove securityLoose airspace controlPiston type power plantsJet type power plantsJet engineSilver iodide

The invention discloses a remote-controlled aircraft for hail mitigation and precipitation and a hail mitigation and precipitation method. The remote-controlled aircraft is adopted to scatter silver iodide in a cloud layer, the safety is better, airspace control is relatively loose, and the adaptability is strong. The silver iodide is dissolved in an acetone-alcohol solution, the use of ammonium chlorate is avoided, pollution is decreased, and the remote-controlled aircraft has better environmental protection property. In addition, explosive materials are avoided, the aircraft is safer, and inventory management, transportation management and operation management are loose to control. Wings are foldable and are convenient to store, transport and operate, and the cost is reduced. The acetone-alcohol solution containing the silver iodide is burned at the tail portion of a jet engine, corrosion of the jet engine is avoided, and the service life is prolonged.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Long-lasting aluminum alloy surface treating agent with long shelf life

InactiveCN104109854AExtended shelf lifeStrong anti-corrosion and anti-oxidationMetallic material coating processesDiacetone alcoholEpoxy

The invention discloses a long-lasting aluminum alloy surface treating agent with a long shelf life. The agent is composed of an A component and a B component; wherein the A component is composed of the following raw materials in parts by weight: 1 to 2 parts of ursolic acid, 2 to 3 parts of triterpenoid saponin, 1 to 2 parts of epoxy chloropropane, 0.7 to 1 part of tetramethoxyl methyl glycoluril, 0.2 to 0.3 part of diatomite, 1 to 2 parts of potassium zirconium carbonate, 2 to 3 parts of diacetone alcohol, 5 to 6 parts of bis(gamma-triethoxysilylpropyl)tetrasulfide, and 52 to 60 parts of deionized water; and the B component is composed of the following raw materials in parts by weight: 0.9 to 1.4 parts of 2-thiol benzimidazole, 0.7 to 2 parts of triammonium molybdate, 0.6 to 1 part of dimethylamino propylamine, 4 to 6 parts of sodium fluosilicate, 2 to 4 parts of film-forming auxiliary agent, 6 to 9 parts of 3-aminopropyltrimethoxyl silane, and 50 to 60 parts of deionized water. The surface treating agent has a long shelf life, and has the advantages of strong anticorrosion and antioxidant performance, user-friendliness, low requirement on temperature, low energy consumption, prominent antirust effect, and little slag generation. The film formed by the surface treating agent has a good stability.

Owner:RUIZHAN TONGLING TECH

Acetone-based solution of a vinyl resin

InactiveUS20110201721A1Improve propertiesWiden the optionsAntifouling/underwater paintsPretreated surfacesDiacetone alcoholSolubility

Disclosed in this specification is a method and composition for producing a coating of a poly(vinyl chloride) (PVC) resin from an acetone-based solution. The solution includes a coating facilitator with terpineol and / or tertbutyl acetate. The coating facilitator also includes a second compound with a boiling point of at least 100° C. that acts to promote the solubility of the PVC resin. Also disclosed is an acetone-based solvent system that includes an additive selected from a terpene, diacetone alcohol and t-butyl acetate.

Owner:TARKSOL

Herbicide

The invention discloses a herbicide. The herbicide is prepared from, by weight, 30-50 parts of water, 10-15 parts of acetic acid, 5-10 parts of anhydrous cupric sulfate, 1.1-1.5 parts of 2-methylphenol, 2-8 parts of ethylene glycol, 1-6 parts of acetone alcohol, 3-5 parts of formaldehyde solution, 15-25 parts of methanol and 1.2-1.8 parts of 3-methylphenol. A preparation method of the herbicide comprises the following steps that S1, a certain amount of the acetone alcohol is obtained by weight and put into a stirring machine containing water, and then stirring is conducted; S2, a certain amount of the methanol is obtained by weight and put into the stirrer, and then stirring is conducted to make the acetone alcohol in a stable state; S3, a certain amount of the formaldehyde solution, a certain amount of the ethylene glycol and a certain amount of the 3-methylphenol are obtained by weight and put into the stirrer, the temperature is adjusted to 25-30 DEG C, and then uniform stirring is conducted. According to the herbicide, all the raw materials can be well mixed, weeds can be effectively removed, the herbicide itself is free of toxicity and can be widely used.

Owner:KUNMING XIANDI BIOTECH

Energy-saving and emission-reducing assistant for printing and dyeing and production method thereof

InactiveCN102021845ADyeing speed is fastUniform dyeing speedDyeing processDiacetone alcoholRare earth

The invention relates to an energy-saving and emission-reducing assistant for printing and dyeing, which comprises an assistant 1 and an assistant 2, wherein the assistant 1 comprises the following components in parts by weight: methylpyrrolidone, diacetone alcohol, salethyl, isopropyl salicylate and lauryl azone; and the assistant 2 comprises the following components in parts by weight: rare earth oxide, oxalic acid, water and ammonium carbonate. The production process of the assistant 1 comprises the steps of: adding the methylpyrrolidone in a reaction vessel, raising the temperature and then adding the diacetone alcohol, the salethyl,the isopropyl salicylate and the lauryl azone, reacting under the condition of preserving the temperature until the pH value is 6-6.5, and finally obtaining the assistant 1. The production process of the assistant 2 comprises the steps of: adding the oxalic acid and the water into the rare earth oxide La2O3, and then stirring with a high-speed stirring machine, adding the ammonium carbonate and the water, then stirring for 3-6min at a high speed, standing, and storing in a dark place.

Owner:陈家标

Anti-corrosive elastic coating

InactiveCN104449051ADelicate feelStrong sense of fleshAnti-corrosive paintsEpoxy resin coatingsCorrosionZinc

The invention discloses an anti-corrosive elastic coating comprising components with the following content proportions: 24-46 parts of diacetone alcohol, 14-18 parts of hydroxyethyl cellulose, 5-6 parts of aluminum chloride, 6-10 parts of elastic powder, 7-15 parts of epoxy acrylate, 4-11 parts of zinc-enriched epoxy powder, 2-6 parts of matting powder, 0.8-1.6 parts of a dispersing agent and 0.2-0.8 part of a thickening agent. By virtue of the mode, the anti-corrosive elastic coating disclosed by the invention is fine and smooth in hand feeling and strong in thickness feeling, also is relatively good in wear resistance and strong in corrosion resistance, can be suitable for harsh acidic or alkaline environments, and can be used for effectively protecting coated materials in acidic or alkaline environments.

Owner:SUZHOU MINGXUAN FLOORING COATINGS

Composite multi-carbon alcohol cosolvent and preparation method thereof

InactiveCN102399603AEfficient solubilizationLess corrosiveLiquid carbonaceous fuelsIsobutanolFractionation

The present invention discloses a composite multi-carbon alcohol cosolvent and a preparation method thereof. The composite multi-carbon alcohol cosolvent adopts offcuts from an ethanol production plant or a winery as raw materials, wherein the offcuts comprise 40-70% of ethanol, 5-15% of propanol and isopropanol, 5-15% of n-butanol, isobutanol and tert butyl alcohol, 1-5% of amyl alcohol, isoamyl alcohol, hexyl alcohol, heptanol, octanol, nonanol, decanol and other liquid multi-carbon alcohols, and 14-40% of water. With performing steps of the raw material pretreatment, pervaporation membrane dehydration, blending and the like, the composite multi-carbon alcohol cosolvent with the water content less than 0.5% is prepared. The composite multi-carbon alcohol cosolvent can be adopted as an alcohol oil cosolvent, and the assistant dissolution effect of the composite multi-carbon alcohol cosolvent is high. The composite multi-carbon alcohol cosolvent provides lower toxicity than the aromatic alcohol oil cosolvent, and provides lower corrosion than the acetone alcohol oil cosolvent. In the prior art, boiling points of the propanol, the isobutanol, the n-butanol and the like are close to the boiling point of the water, and the azeotrope effect is further generated, such that the dehydration is difficult to perform by the fractionation method. With the preparation method of the present invention, the disadvantage in the prior art is overcome. The production cost for the composite multi-carbon alcohol cosolvent is significantly lower than the production cost of the composite multi-carbon alcohol cosolvent produced by blending the corresponding monomer multi-carbon alcohol, and the assistant dissolution effect of the composite multi-carbon alcohol cosolvent is higher than the assistant dissolution effect of each monomer multi-carbon alcohol.

Owner:河南超燃清洁能源科技有限公司 +1

High-heat-conductivity anti-aging anti-rusting paint for outdoor equipment and preparation method of high-heat-conductivity anti-aging anti-rusting paint

InactiveCN104449250AImprove rust resistanceAnti-rust for a long timeAnti-corrosive paintsEpoxy resin coatingsDiacetone alcoholXylylene

The invention relates to a high-heat-conductivity anti-aging anti-rusting paint for outdoor equipment. The paint is characterized by being prepared from the following raw materials in parts by weight: 4-5 parts of phosphated residue, 3-5 parts of iron powder, 1-2 parts of diacetone alcohol, 3-5 parts of propylene glycol, 2-3 parts of zinc carbonate, 0.5-1.0 part of an anionic silicone emulsion, 2-3 parts of triethanolamine, 3-4 parts of dodecanol, 0.5-1.0 part of octadecanol polyoxyethylene ether, 1-2 parts of epoxy fatty acid butyl ester, 1-2 parts of a titanate coupling agent, 1-2 parts of cuprous oxide, 2-4 parts of oxidized petrolatum barium soap, 5-6 parts of titanium dioxide, 32-36 parts of bisphenol A epoxy resin, 18-24 parts of highly wear-resistant elastic resin, 10-14 parts of butyl acetate, 9-11 parts of xylene and 4-7 parts of auxiliaries. The paint provided by the invention is good in heat conductivity, high in ageing resistance, good in anti-rusting effect, remarkable in noise reduction, high in film hardness and good in glossiness, and has an excellent maintaining and preserving effect when being applied to a shell of the outdoor power equipment.

Owner:李勇智

High-temperature resistant polyvinyl chloride-polycarbonate composite material and preparation method thereof

InactiveCN103435934AImprove mechanical propertiesImprove high temperature resistanceDiacetone alcoholPhosphoric Acid Esters

The invention provides a polymer composite material, particularly relates to a polyvinyl chloride-polycarbonate composite material and a preparation method thereof, and belongs to the technical field of high polymer materials. The polyvinyl chloride-polycarbonate composite material comprises the following components in parts by weight: polyvinyl chloride, polycarbonate, carbon black, calcium carbonate, zinc acetate, zinc stearate, paraffin, titanate coupling agent, 2,6-di-tert-butyl-4-methylphenol, polyvinyl alcohol, ethylene glycol monobutyl ether, triethanolamine, diacetone alcohol, maleic anhydride resin, aminoacetic acid, sorbitol, tributyl phosphate ester, carnauba wax, trimethylol melamine and lead stearate. The polyvinyl chloride-polycarbonate composite material has the advantages that the mechanical property and the high-temperature-resistant property are good, the tensile strength is larger than 15 MPa, the breakage elongation is larger than 200%, and the vicat softening temperature is higher than 100 DEG C.

Owner:WUJIANG YINGLIDA PLASTIC PACKAGING

Antimicrobial aluminum electrode anti-corrosive paint and preparation method thereof

InactiveCN105860603AImprove corrosion resistanceEasy to operateAntifouling/underwater paintsPaints with biocidesDiacetone alcoholSodium diacetate

The invention discloses an antibacterial aluminum electrode anticorrosion coating, which is composed of the following raw materials in parts by weight: sodium diacetate 1-2, triethanolamine 0.1-0.13, lauroamphodiacetate disodium 0.1-0.2, hexadecane Trimethyl ammonium bromide 0.7‑1, magnesium sulfate 0.05‑0.06, benzotriazole 0.06‑0.07, octylphenol polyoxyethylene ether 1.7‑2, dodecylamine 0.3‑0.5, ethyl orthosilicate 46 ‑50, n-dodecyl trichlorosilane 0.3‑0.4, zirconium n-propoxide 13‑20, ethyl acetoacetate 7‑10, isopropanol 57‑60, silane coupling agent kh56010‑13, calcium stearate 0.4‑1, diacetone alcohol 2‑3, octylisothiazolinone 1‑2, calcium propionate 0.8‑1, lithium naphthenate 0.01‑0.02, butyl benzyl phthalate 0.2‑0.4. The invention effectively improves the antibacterial performance of the paint.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

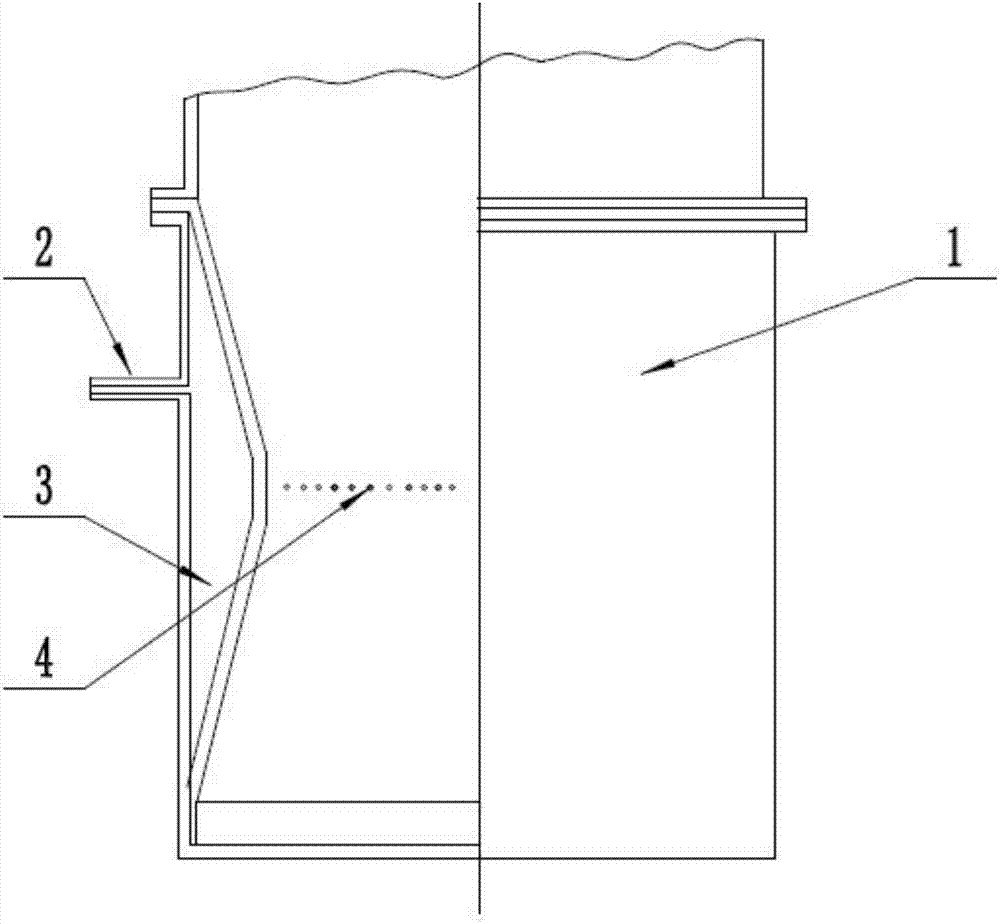

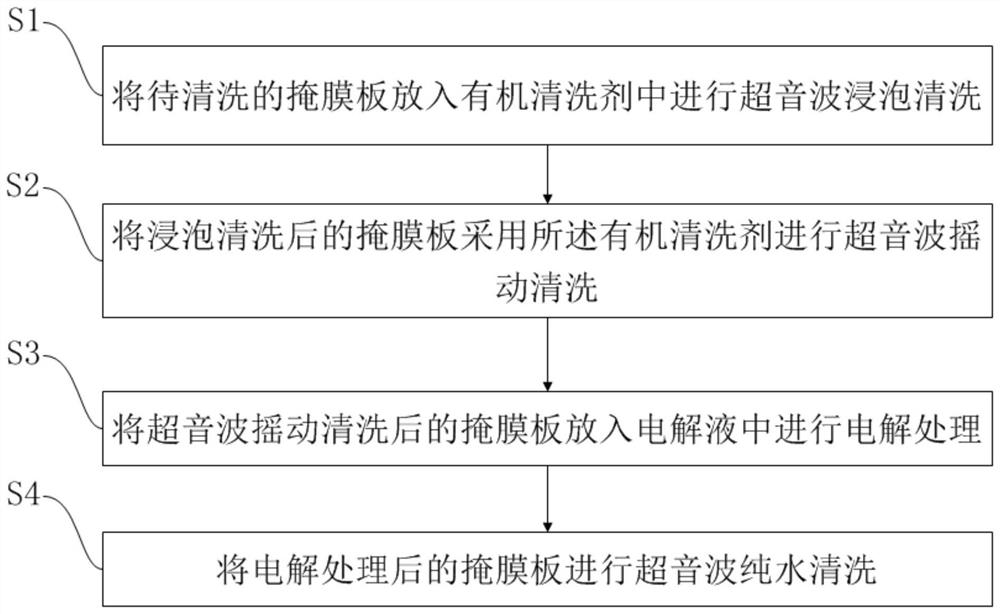

Mask plate cleaning method and device

InactiveCN112387693ADoes not release acidPut an end to superficial effectsOriginals for photomechanical treatmentCleaning using liquidsDiacetone alcoholElectrolytic agent

The invention discloses a mask plate cleaning method and device. The method comprises the following steps that a to-be-cleaned mask plate is put into an organic cleaning agent for ultrasonic soaking cleaning, and ultrasonic shaking cleaning is conducted on the mask plate subjected to soaking cleaning through the organic cleaning agent, and the mask plate subjected to ultrasonic shaking cleaning isput into an electrolyte for electrolytic treatment and ultrasonic pure water cleaning; wherein the organic cleaning agent is composed of the following raw materials in percentage by weight: 45-65% ofcyclohexanone, 0.5-10% of methylbenzene, 2-15% of diacetone alcohol and 20-50% of acetone. The organic cleaning agent in the invention does not damage the size of the mask plate and has reusability,and the effect of the organic cleaning agent is highly accepted by related manufacturers. Compared with an organic cleaning agent sold in the market at present, only one solvent is used before the electrolytic treatment step, cleaning is achieved at a time without classification, in addition, the elution effect is better, the European Union RoHS standard is met, it is guaranteed that the cleaned mask plate cannot release acid in the vacuum environment, and therefore the influence on the surface of the mask plate is eradicated.

Owner:深圳市海博源光电科技有限公司

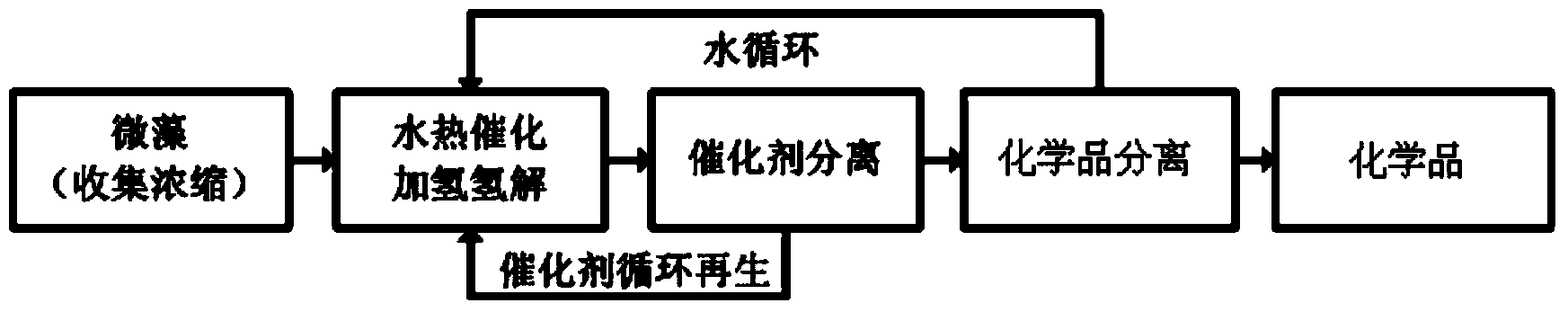

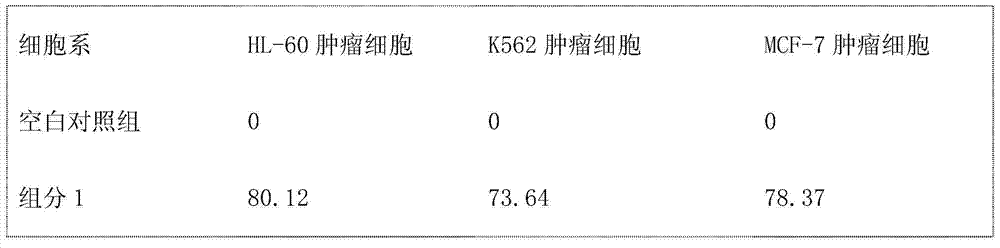

Method for preparing chemical products by direct hydrothermal hydrogenation of microalgae

ActiveCN103864573AShorten the growth cycleImprove carbon sequestration efficiencyOrganic compound preparationHydroxy compound preparationAlcoholRenewable biomass

The invention discloses a method for preparing chemical products by direct hydrothermal hydrogenation of microalgae. The method comprises the following steps: adding the microalgae and water into a reactor, and performing hydrogenation hydrogenolysis reaction in the presence of a catalyst with hydrogenation hydrogenolysis activity for 10-360 minutes to obtain the chemical products. The method can be used for preparing the chemical products with high added values such as dihydric alcohol and acetone alcohol, and CO2 can be subjected to high-efficiency biological fixation and chemical conversion as the microalgae as new environment-friendly renewable biomass energy resources are utilized.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

Chinese stellera root component patch

InactiveCN103933252AImprove pharmacological activityHigh activityAntipyreticAnalgesicsGradient elutionMacroporous resin

The invention relates to a Chinese stellera root component patch. The component is prepared by the following method: extracting Chinese stellera root by using an acetone-alcohol mixed solution; processing the extracting liquid with macroporous resin and then carrying out gradient elution by using preparative chromatography, wherein a mobile phase A is water and the mobile phase B is acetonitrile; collecting eluant within a time period of 45-50 minutes, concentrating and drying to obtain the Chinese stellera root component patch.

Owner:NANTONG CAMBRIDGE OLEIN

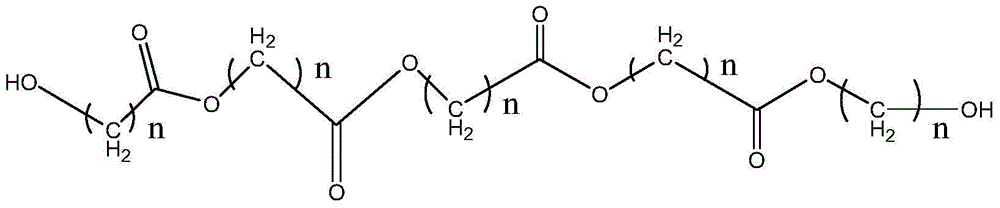

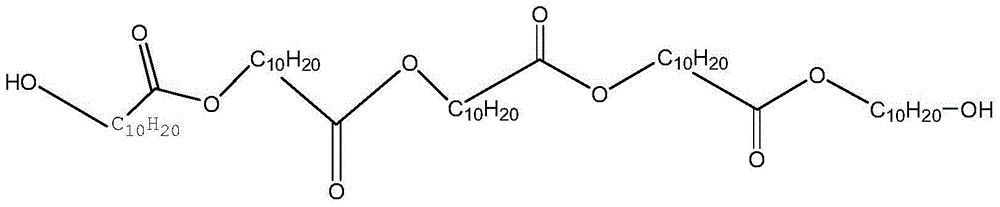

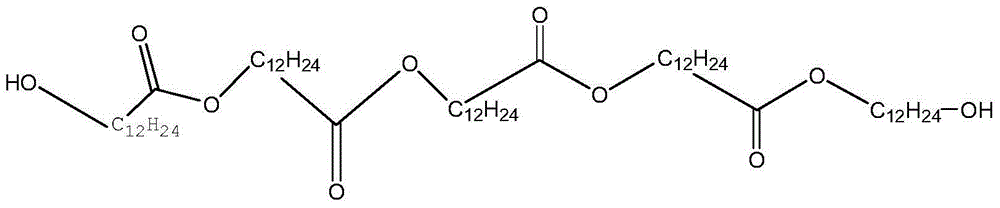

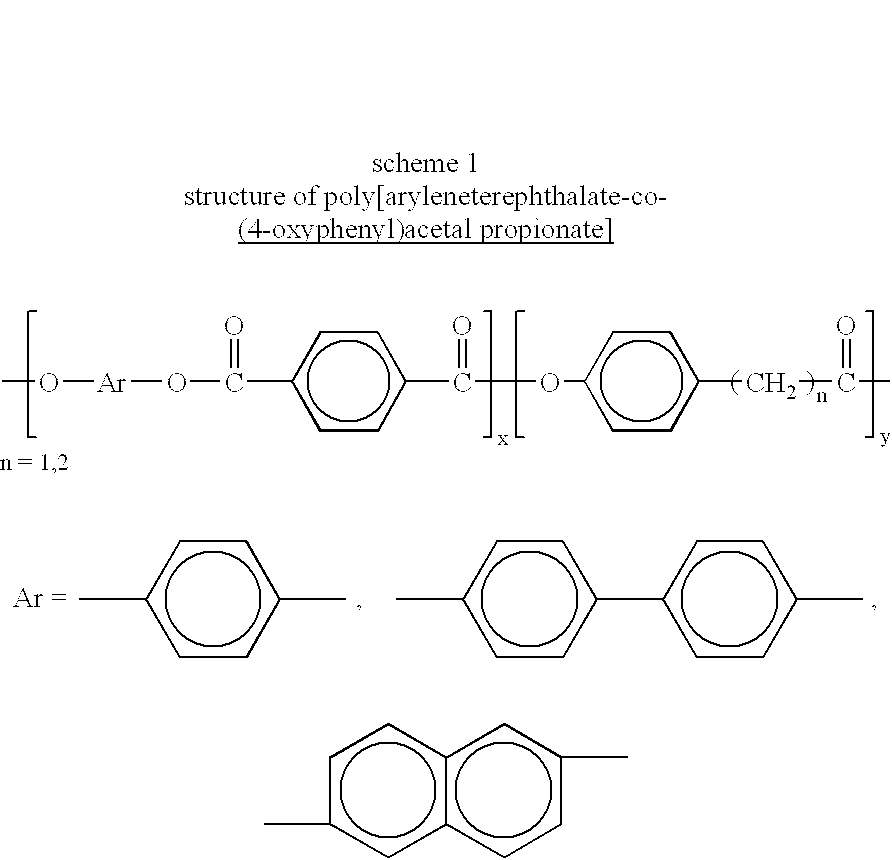

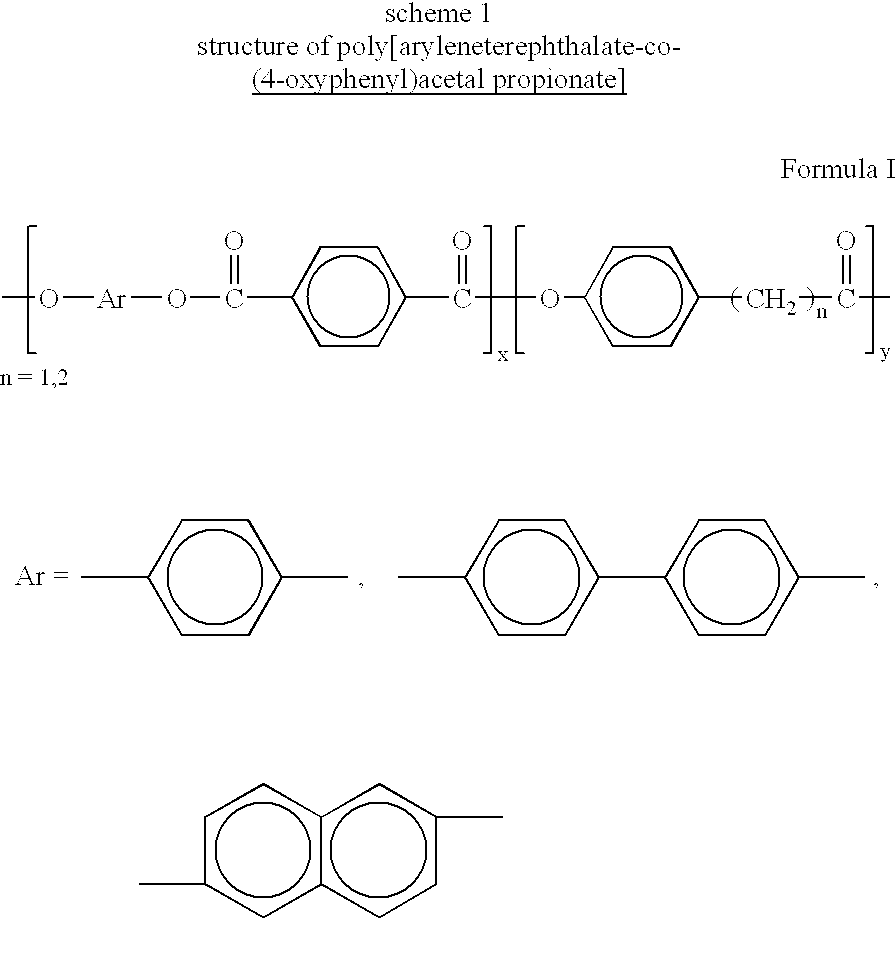

Melt processible thermotropic liquid crystalline terpolyesters and process for the preparation thereof

InactiveUS6409937B1High molecular weightLiquid crystal compositionsGroup 4/14 element organic compoundsLiquid crystallineAcetic acid

The invention relates to a process for the preparation of melt processable liquid crystalline terpolyesters of the general formula Iby the in situ acetylation of a monomer selected from (4-hydroxyphenyl) acetic acid / 3(4-hydroxyphenyl)propionic acid and hydroquinone / 4,4'-biphenol / 2,6-naphthylene diol followed by acidolysis polycondensation with or without a solvent and a catalyst, under reduced pressure for the efficient removal of acetic acid to effect higher molecular weight formation. Post polymerisation is effected at higher temperatures below the decomposition temperature purification by soxhlet extraction using solvent mixtures selected from acetone-alcohol, acetone-methylethyl ketone.

Owner:COUNCIL OF SCI & IND RES +1

Transparent hydrophobic protective agent for cultural relic protection as well as preparation method and use method thereof

The invention relates to a transparent hydrophobic protective agent for cultural relic protection as well as a preparation method and a use method thereof, and the transparent hydrophobic protective agent for cultural relic protection is prepared from the following raw materials: 50-150 parts of methyltrimethoxysilane, 20-80 parts of dimethyldimethoxysilane, 10-40 parts of 3-glycidoxypropyltrimethoxysilane, 4-15 parts of tetrabutyl titanate, 25-75 parts of a solvent, 10-40 parts of deionized water and 1-4 parts of a catalyst. The solvent is one or a combination of more of methanol, ethanol, 1-propanol, 2-propanol, acetone and diacetone alcohol; and the catalyst is one or a combination of more of glacial acetic acid, hydrochloric acid, nitric acid and phosphoric acid. The invention also provides a preparation method and a use method of the transparent hydrophobic protective agent for cultural relic protection. The protective agent is low in viscosity, good in permeability and good in weather resistance, has good binding power, adhesive force and compatibility with a cultural relic substrate after being coated on the surface of the cultural relic, has reversibility, is non-toxic and environment-friendly, and does not change the appearance of the cultural heritage.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

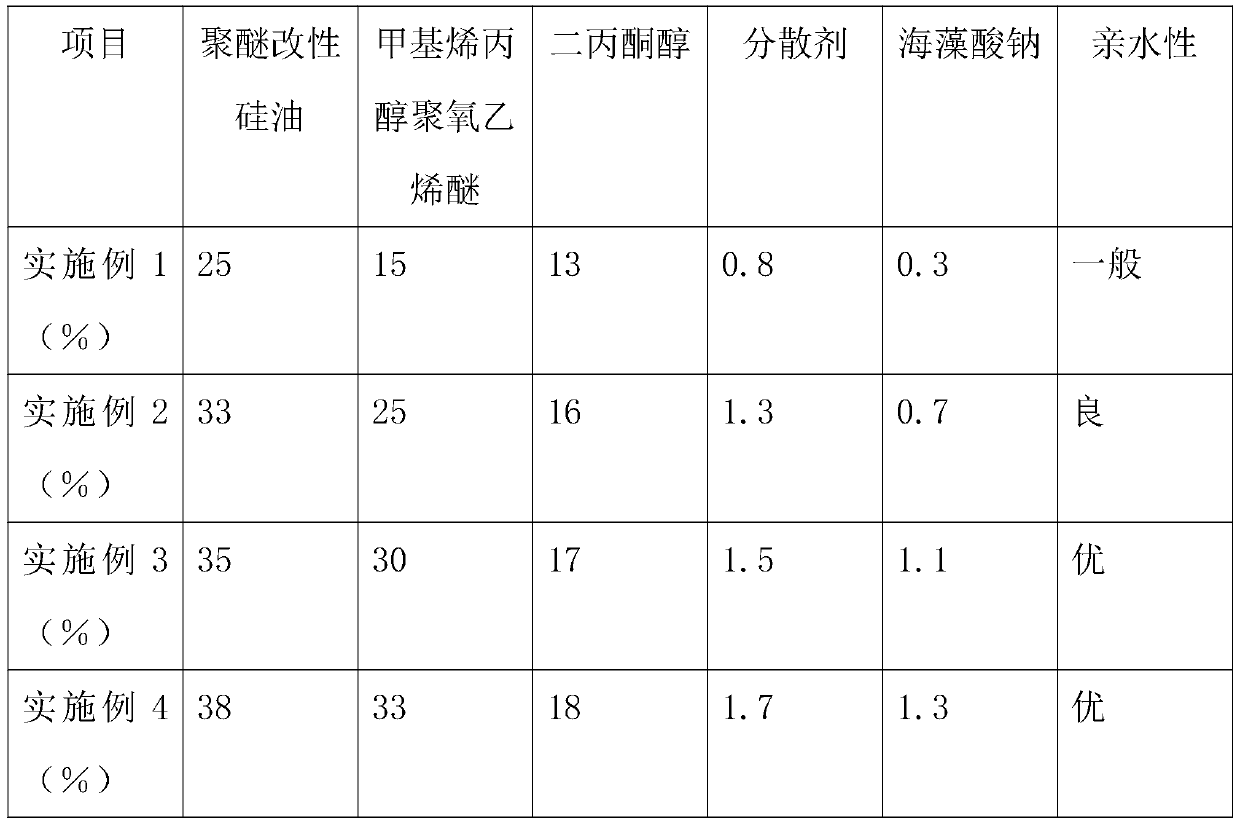

Preparation method of hydrophilic agent for agricultural rock wool

InactiveCN111286271AImprove water absorptionImprove water retentionPolyether coatingsDiacetone alcoholAlcohol

The invention belongs to the technical field of hydrophilic agents, and particularly, relates to a preparation method of a hydrophilic agent for agricultural rock wool. The preparation method specifically comprises the following steps: S1, taking 30-40% by weight of polyether modified silicone oil, 20-35% by weight of methylallyl alcohol polyoxyethylene ether, 15-20% by weight of diacetone alcohol, 1-2% by weight of a dispersing agent, 0.5-1.5% by weight of sodium alginate and the balance being pure water for later use. The components of the polyether modified silicone oil and the methyl allylalcohol polyoxyethylene ether can improve the water absorption of the agricultural rock wool; the surface tension and the hydrophilic stability of the hydrophilic agent are improved through the sodium alginate and the diacetone alcohol; due to the use of the dispersing agent, the dispersity of the hydrophilic agent is better, sufficient dissolution is achieved, the rock wool has high water-retaining property, when the rock wool is used, the hydrophilic agent is directly sprayed on a rock wool base material in a spraying mode, the purpose of enhancing the hydrophilicity of the rock wool is achieved, and the agricultural rock wool has high hydrophilicity, high hydrophilic long-term stability and high water-retaining property.

Owner:武汉思越化学技术有限公司

Production method of stereoscopic-impression decoration panel

ActiveCN103802193AWith multi-level three-dimensional effectNo releaseDecorative surface effectsThree-dimensional effectsGraphicsUltraviolet lights

The invention discloses a production method of a stereoscopic-impression decoration panel. The front face and the back face of the panel are evenly and respectively provided with a layer of ground color UV printing ink, and the ground color is selected as required, ultraviolet light is used for fast irradiating and baking, a layer of UV printing ink is printed again, the color of the UV printing ink is determined as required, and the thickness of the UV printing ink is 2 mm. The ultraviolet light is used for irradiating the front face of the panel coated with the UV printing ink through a first graph mask plate which is manufactured in advance, and soft cloth is wetted with acetone alcohol to scrub the UV printing ink which is not irradiated by the ultraviolet light. According to the production method of the stereoscopic-impression decoration panel, the UV printing ink is used multiple times on the surface of the panel, the graph mast plate is used multiple times for developing so that patterns with different colors can be overlapped in multiple layers, and especially depiction on pattern details can be meticulous and subtle. Thus, the surface of the manufactured panel has the multi-layer stereoscopic effect, and in addition, the decoration panel is completely made of green building materials and does not release formaldehyde.

Owner:嘉善县惠民街道中秀手袋厂

Polyvinylidene fluoride ultrafiltration membrane

The invention discloses a polyvinylidene fluoride ultrafiltration membrane which is prepared through the following steps: 1) a casting solution prepared from 45 g / L of polyvinylidene fluoride monomer, 1 g / L of acetone alcohol, 6 g / L of dimethyl sulfoxide, 15 g / L of dimethyl formamide, 2 g / L of alkylolamide polyoxyethane ether, 5 g / L of dimethyl acetamide , 1 g / L of isobutyl ketone, 1 g / L of n-butyl acetate, 3 g / L of tetramethyl urea, 8 g / L of trimethyl phosphate, 1 g / L of formamide, 1 g / L of cyclohexanone, 1 g / L of ethyl acetoacetate, 1 g / L of glycol ether ester and 3 g / L of oleic acid polyoxyethylene ester is injected into a vacuum fiber wiped-film mold to be prepared into a wet membrane; 2) the wet membrane is immersed at 50 DEG C into a precipitation tank filled with a gel solution prepared from 1-2 g / L of triethyl phosphate, 15 g / L of methyl alcohol, 1 g / L of isophorone, 1 g / L of allyl carbonate, 20 g / L of ethyl alcohol, 25 g / L of isopropanol, 1 g / L of glycol ether and 1 g / L of methyl isobutyl ketone to undergo phase transformation to be prepared into a membrane; 3) the membrane is dried at 65 DEG C to form a porous dry membrane. The polyvinylidene fluoride ultrafiltration membrane provided by the invention has a great amount of submicron uniform pores and high strength.

Owner:CHANGSHU 3F ZHENFU NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com