Synthesis process of diacetone alcohol

A synthesis process, a technology of diacetone alcohol, applied in the preparation of carbon-based compounds, the preparation of organic compounds, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of fast catalyst deactivation, long reaction time, Problems such as short catalyst life, to achieve the effect of low production cost, short reaction time, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

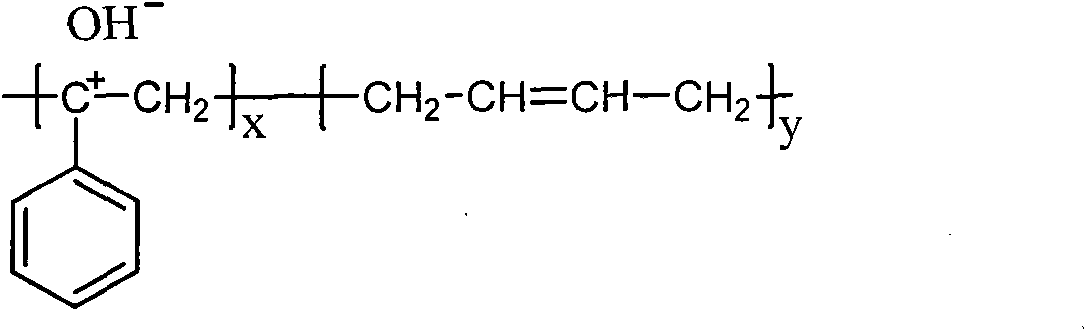

Method used

Image

Examples

Embodiment 1- Embodiment 6

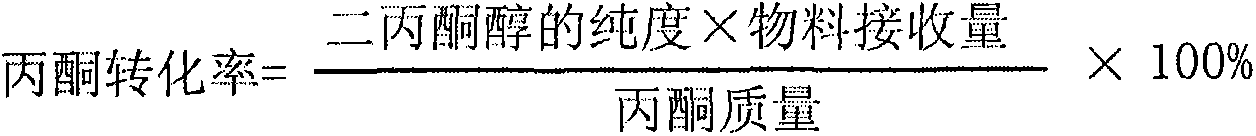

[0025] Experiment 1. Diacetone alcohol conversion rate experiment: Add 1000ml acetone into a 1000ml three-neck flask, heat and distill, after condensation, the acetone passes through the storage tank equipped with catalyst and the material flows into the receiver. The temperature of the jacket of the catalyst storage tank is 10± After the acetone was completely evaporated to dryness at 1°C, the heating was stopped, and the material in the receiver was detected by gas chromatography to obtain the purity of diacetone alcohol. According to the purity of diacetone alcohol, the single-pass conversion rate of acetone was calculated. The specific data are shown in Table 1.

[0026] Table 1

[0027]

Acetone dosage / ml

Catalyst dosage / g

Material receiving volume / ml

Acetone conversion

Example 1

1000

200

980

16.2%

Example 2

1000

200

986

15.9%

Example 3

1000

200

982

16.6%

Example 4

100...

Embodiment 7- Embodiment 12

[0031] Experiment 2. Catalyst dosage experiment: Add 1000ml of acetone into a 1000ml three-neck flask, heat and distill, and after condensation, the acetone enters the storage tanks containing catalysts of different weights and makes the materials flow into the receiver. The temperature of the jacket of the catalyst storage tank is 10± 1°C, stop heating after the acetone is completely evaporated to dryness, passes through the catalyst storage tank and all materials flow into the receiver, and conducts gas chromatography detection on the materials in the receiver to obtain the purity of diacetone alcohol, and calculate the acetone according to the purity of diacetone alcohol The single-pass conversion rate, the specific data are shown in Table 2.

[0032] Table 2

[0033]

[0034] The data in table 2 shows that the quality of catalyzer and the mass ratio of acetone are advisable with 1: 4~1: 2, wherein the quality of catalyzer and the mass ratio of acetone are the b...

Embodiment 13- Embodiment 17

[0036] Experiment 3. Reaction temperature experiment: Add 1000ml of acetone into a 1000ml three-necked flask, heat and distill, and after condensation, the acetone enters the storage tank with catalyst and makes the material flow into the receiver. The temperature of the jacket of the catalyst storage tank is 5±1°C . Chromatographic detection obtains the purity of diacetone alcohol, and calculates the single pass conversion rate of acetone according to the purity of diacetone alcohol, and concrete data is as shown in table 3, and temperature in table 3 refers to the temperature of catalyst storage tank jacket.

[0037] table 3

[0038]

[0039] The data in Table 3 shows that the lower the reaction temperature is, the more favorable the reaction is, and the higher the acetone conversion rate is; the higher the reaction temperature is, the more unfavorable the reaction is, and the lower the acetone conversion rate is.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com