Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Wood stain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood Stain is a type of paint used to color wood. Wood stain consists of colourants dissolved and/or suspended in a 'vehicle' or solvent. Vehicle is the preferred term, as the contents of a stain may not be truly dissolved in the vehicle, but rather suspended, and thus the vehicle may not be a true solvent. The vehicle often may be water, alcohol, a petroleum distillate, or a finishing agent such as shellac, lacquer, varnish and polyurethane. Coloured or stained finishes do not typically deeply penetrate the pores of the wood and may largely disappear when the finish deteriorates or is removed.

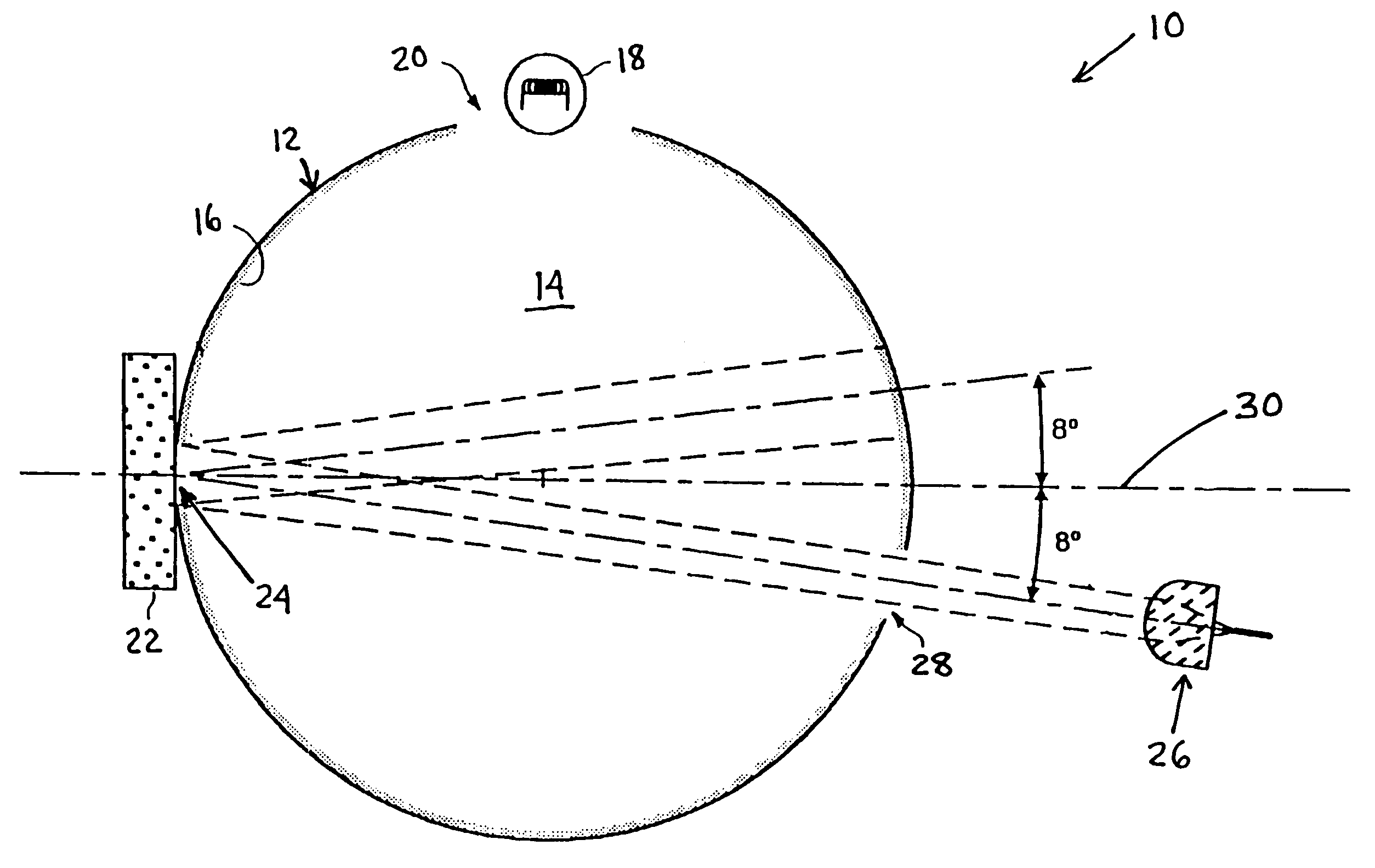

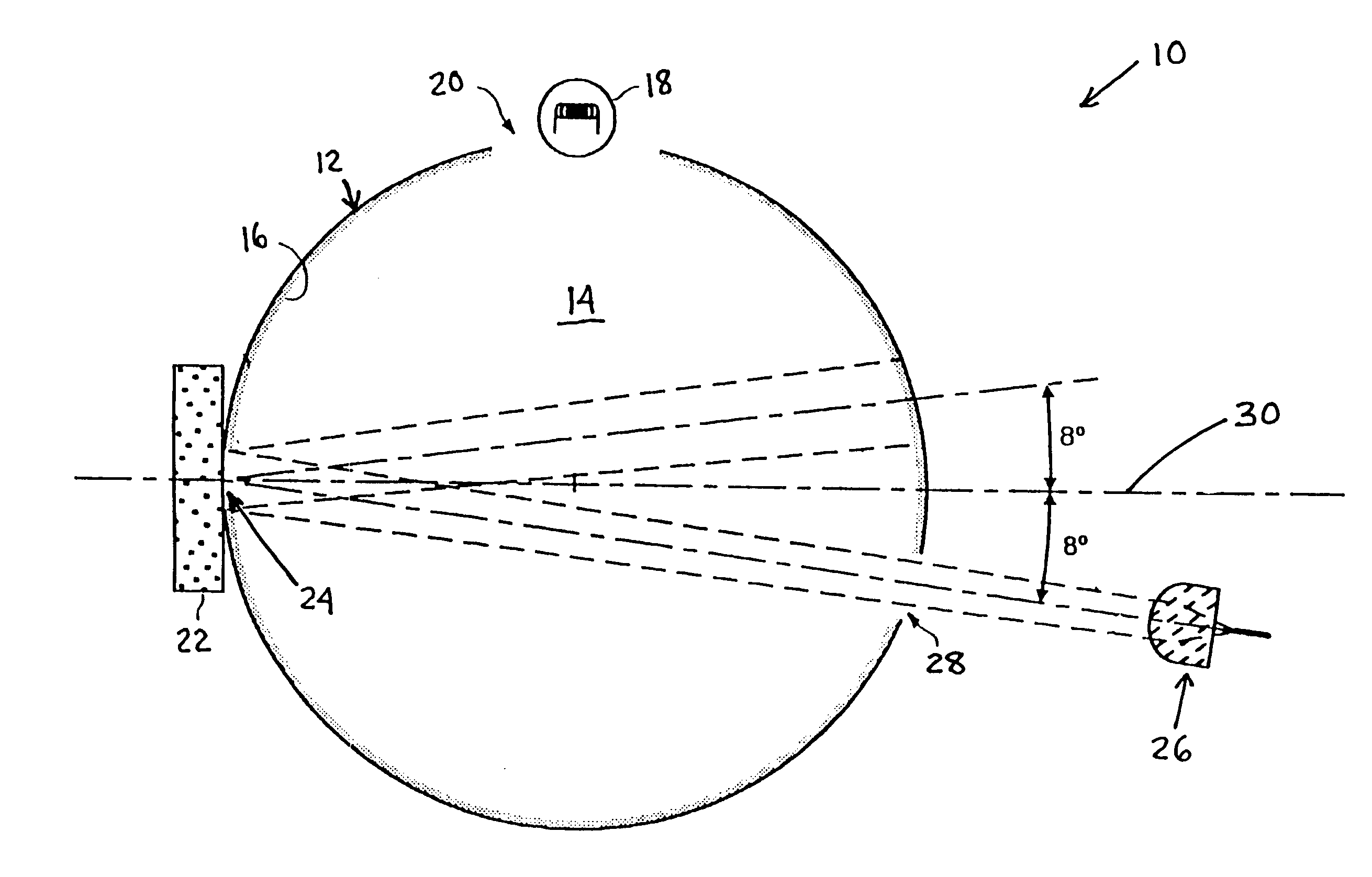

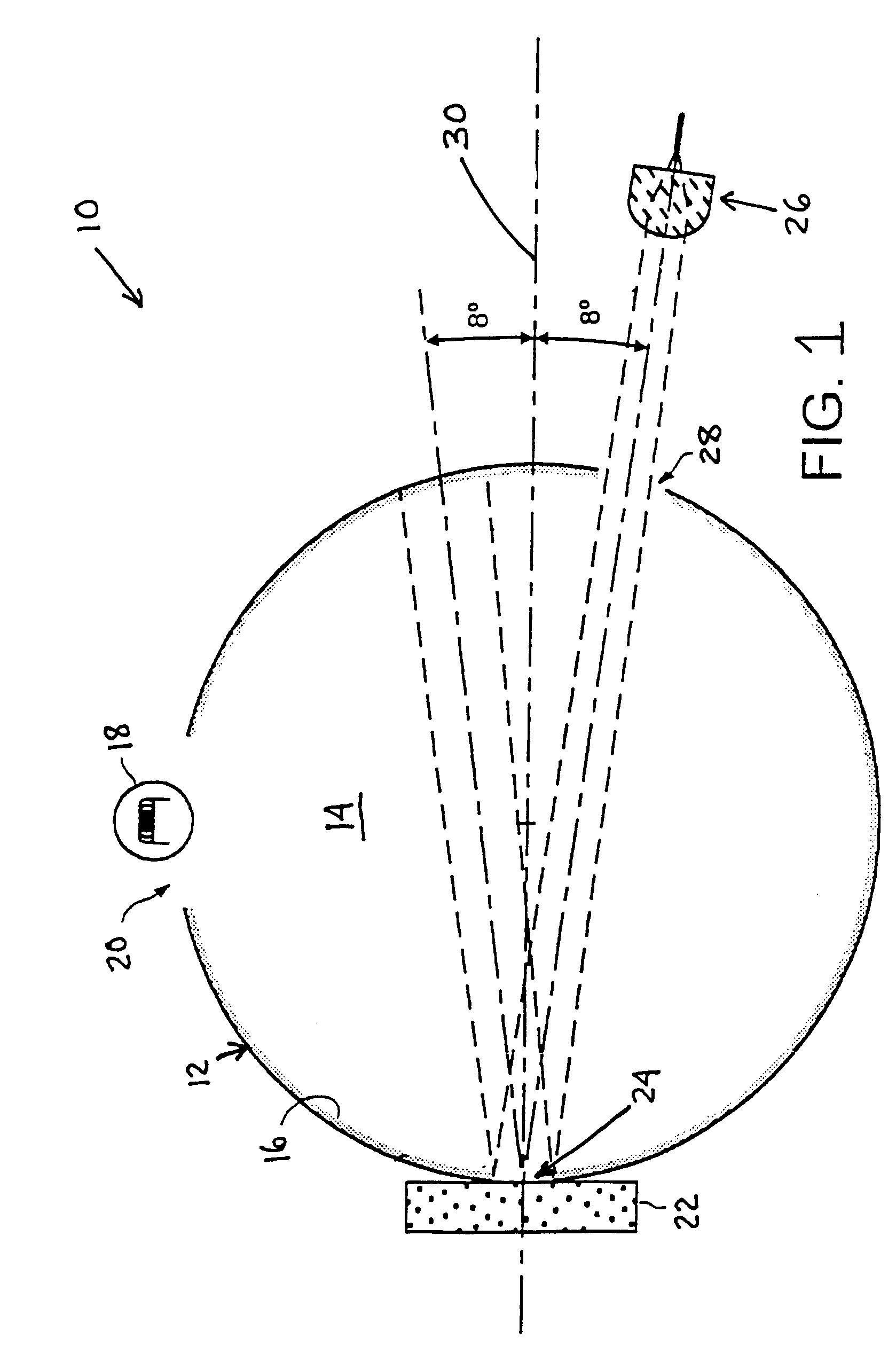

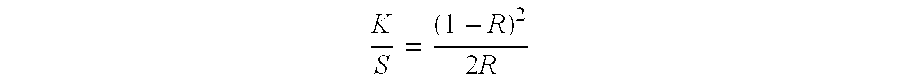

Method of color matching wood stains

InactiveUS7116420B2Radiation pyrometryVacuum evaporation coatingReflectivity measurementComputer science

A method of producing a finish for a selected wood substrate, wherein the finish provides the selected wood substrate with a color that matches the color of a target object. In accordance with the method, calculations are performed to determine the quantities of at least one group of colorants required to produce a semitransparent wood stain from a vehicle, wherein when the semitransparent wood stain is applied to the selected wood substrate, the selected wood substrate will have a color that matches the target object. The calculations are performed using reflectance measurements of the target object obtained using a spectrophotometer and previously obtained spectral data of the colorants as applied to at least one type of wood. The colorants used to form the semitransparent wood stain do not include a white colorant.

Owner:THE SHERWIN-WILLIAMS CO

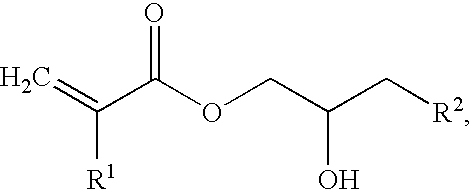

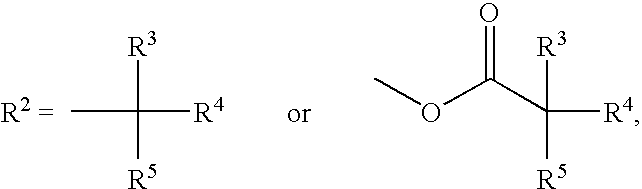

Coating compositions suitable for use as a wood stain and/or toner

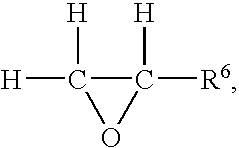

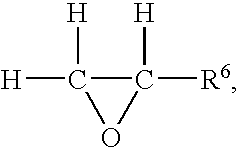

ActiveUS20070256256A1Easy to optimizeLiquid surface applicatorsImpression capsPorous substrateDiluent

Coating compositions are disclosed that include a film-forming resin, a colorant, a long chain alkyl group containing polymerizable ethylenically unsaturated compound, and a diluent. Also disclosed are substrates at least partially coated with such compositions, substrates at least partially coated with a multi-layer composite coating comprising at least one coating layer deposited from such compositions, and methods for improving the adhesion of a multi-layer composite coating system to a porous substrate.

Owner:PPG IND OHIO INC

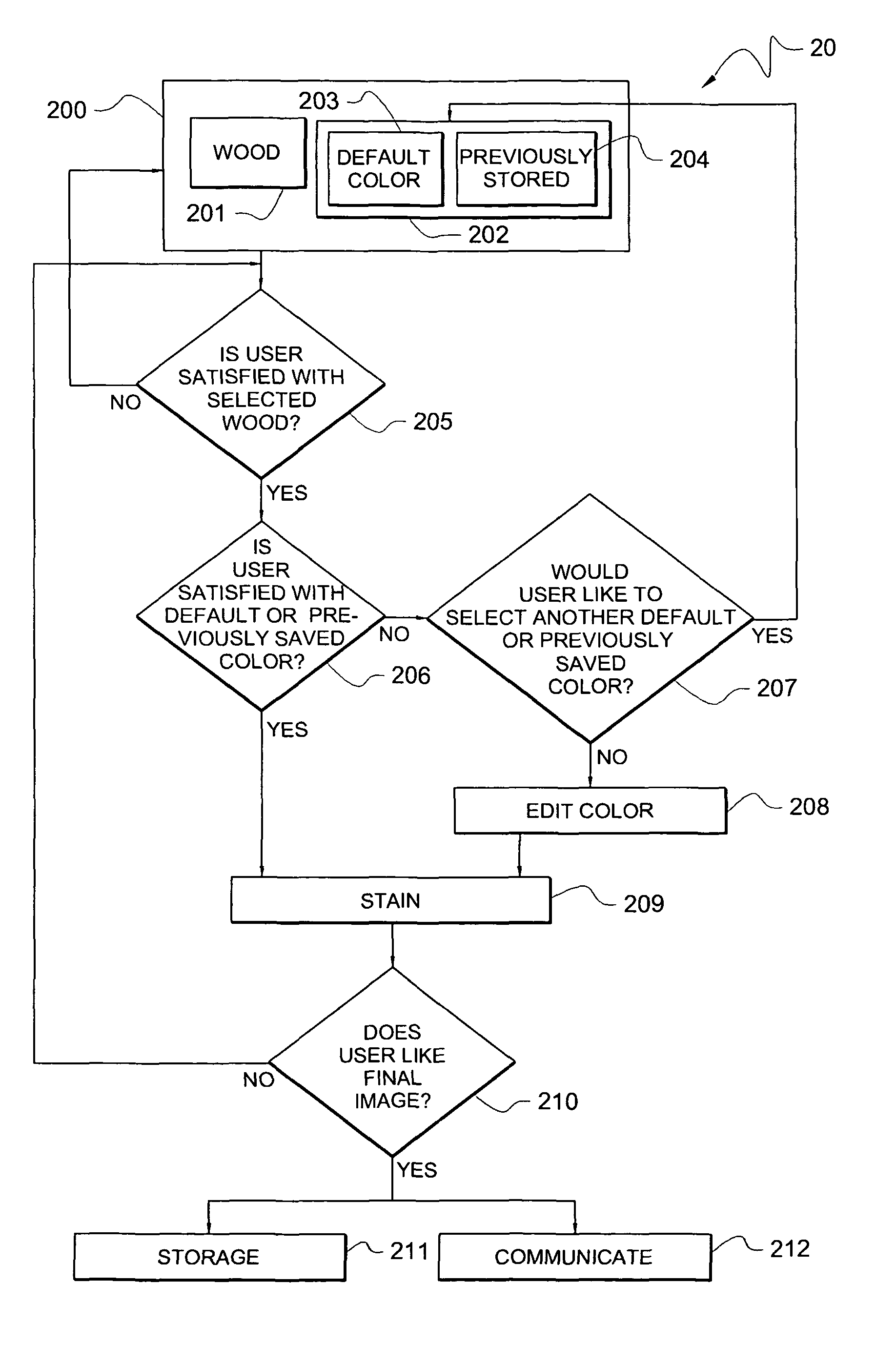

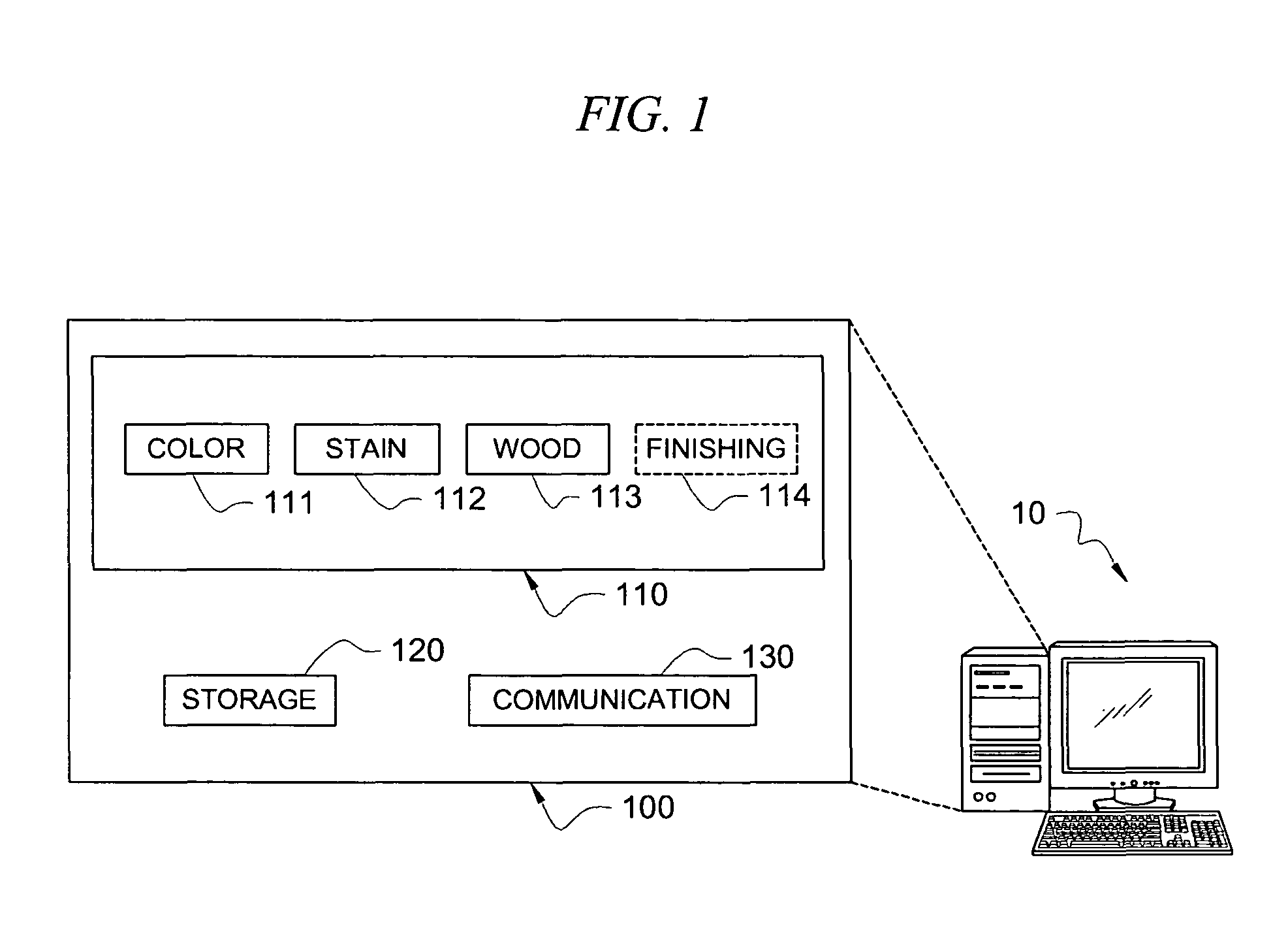

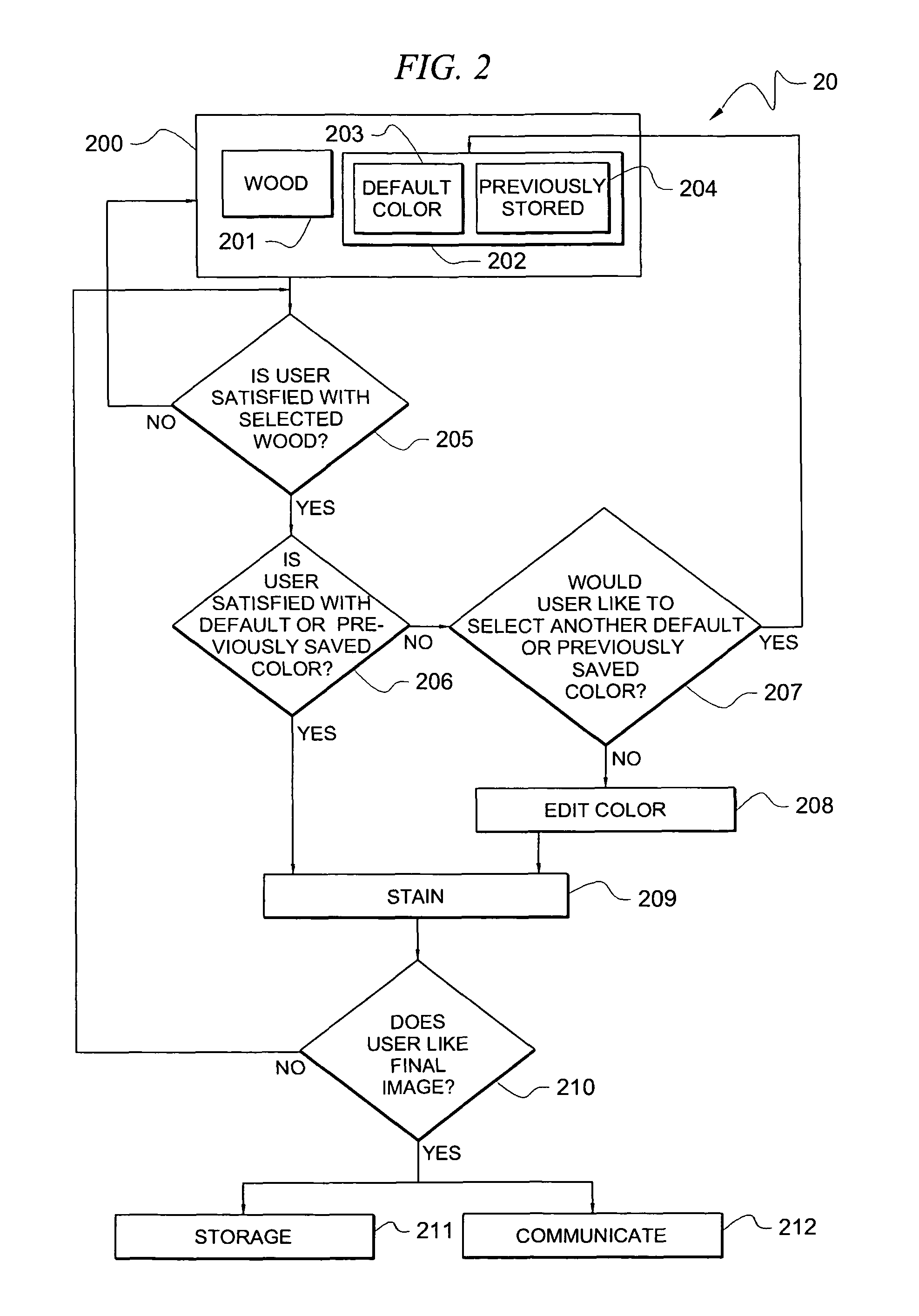

System and method for creating, selecting and matching a stain color for wood

InactiveUS7764831B1Color measuring devicesCharacter and pattern recognitionComputer graphics (images)Stain

A method and system are disclosed for creating, selecting and / or matching a stain color for wood. A user can create various colors by adding or reducing the amount of a particular color to the color that a user is creating. After a color is created, a new image can be created that illustrates the created color. When a user is satisfied with the created color, the created color can be applied to the wood so that an image of the wood stained with the created color is created for the user to view. The effects that the wood grain patterns of the wood have on the stained wood are illustrated in the image of the stained wood. The created color may be stored so that it can be accessed at a later time. In addition, any created color may also be communicated to others whereby others may use the created color as specified by a user of the system and method that created the color.

Owner:PICK RANDAL +1

Liquid hardening

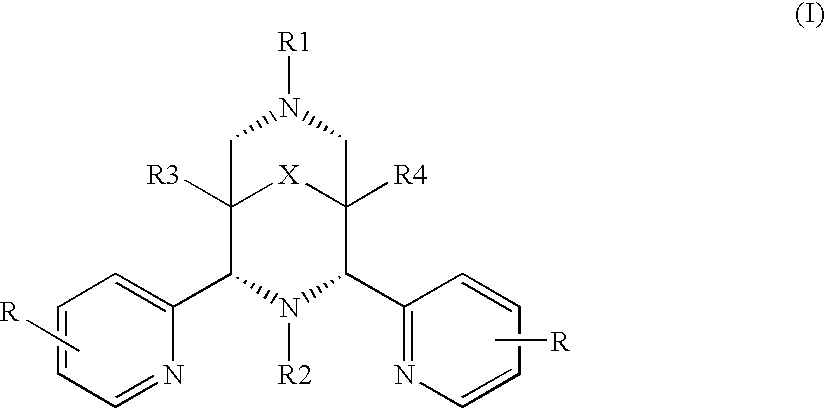

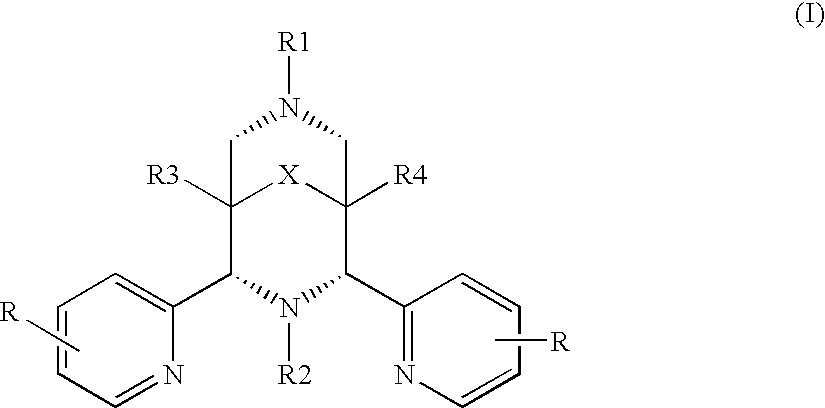

ActiveUS8013044B2Facilitates drying and curing and setting and hardeningOrganic chemistrySiccativesNitrogenManganese

Owner:OMG UK TECH

Method for carrying out painting through automatically configuring painting devices by utilizing timber coloring agents

InactiveCN109127266AUniform textureAvoid cross-colorLiquid surface applicatorsRotary stirring mixersLabor operationsWood stain

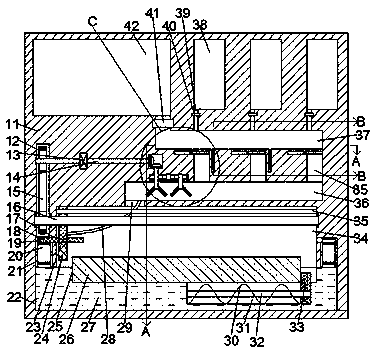

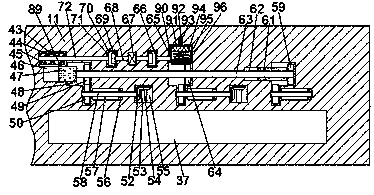

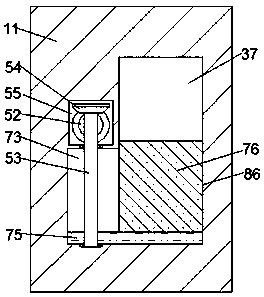

The invention discloses a method for carrying out painting through automatically configuring painting devices by utilizing timber coloring agents. A device used in the method comprises a device main body, a coloring device, a painting device and a stirring device, wherein the coloring device, the painting device and the stirring device are arranged in the device main body; a pass-out pipeline is arranged between the coloring device and the stirring device in a communication manner; and multiple switch structures are arranged in the coloring device and control multiple connection channels whichare communicated with the pass-out pipelines. The device is capable of automatically driving a coloring agent to be automatically matched and driving a timber to be painted; during the painting; a brush uniformly moves to drive the timber to uniformly move, so that the painting effect is uniform; during the painting, the coloring agent is stirred to ensure that the coloring gent is uniform in character; meanwhile, the device can work for a long time, so that the efficiency is improved and the labor operation time is saved; and after automatic coloring, mixtures pass through respective different channels so as to avoid color crossing.

Owner:王文齿

Wood stain composition and finishing method

InactiveUS20100048787A1Improve efficiencyConsiderable costWood treatment detailsPolyester coatingsHydrocarbon solventsGlycol ethers

A stain composition includes a stable blend of a light fast dye, a pigment, a hydrocarbon solvent, an alkyd resin, and a compatibilizer solvent. The stain composition may further include one or more oxygenated solvents in addition to the compatibilizer solvent, which may be a glycol ether solvent. The compositions of the present invention facilitate replacing, in a single tinting step, the separate dye tinting and pigment tinting steps used in conventional wood finishing schedules.

Owner:THE SHERWIN-WILLIAMS CO

Method of verifying color and strength properties of batches of wood stains

A method of verifying the color and tinting strength of a manufactured batch of a semi-transparent wood stain. In accordance with the method, a standard batch of the wood stain is formed and then mixed with a specified amount of a white colorant to form a standard measurement batch. A test sample of the manufactured batch is obtained and is also mixed with a specified amount of the white colorant to form a test measurement sample. Layers of the standard measurement batch and the test measurement sample are formed on the substrates and complete hide obtained. Reflectance measurements of the layers are made using a spectrophotometer. The reflectance measurements are used to determine if the color and the tinting strength of the manufactured batch is within an acceptable deviation range of the color and tinting strength of the standard batch. This allows for objective color difference and tint strength difference calculations, and adjustments can be made therefrom, therefore eliminating the past visual trial and error methods.

Owner:THE SHERWIN-WILLIAMS CO

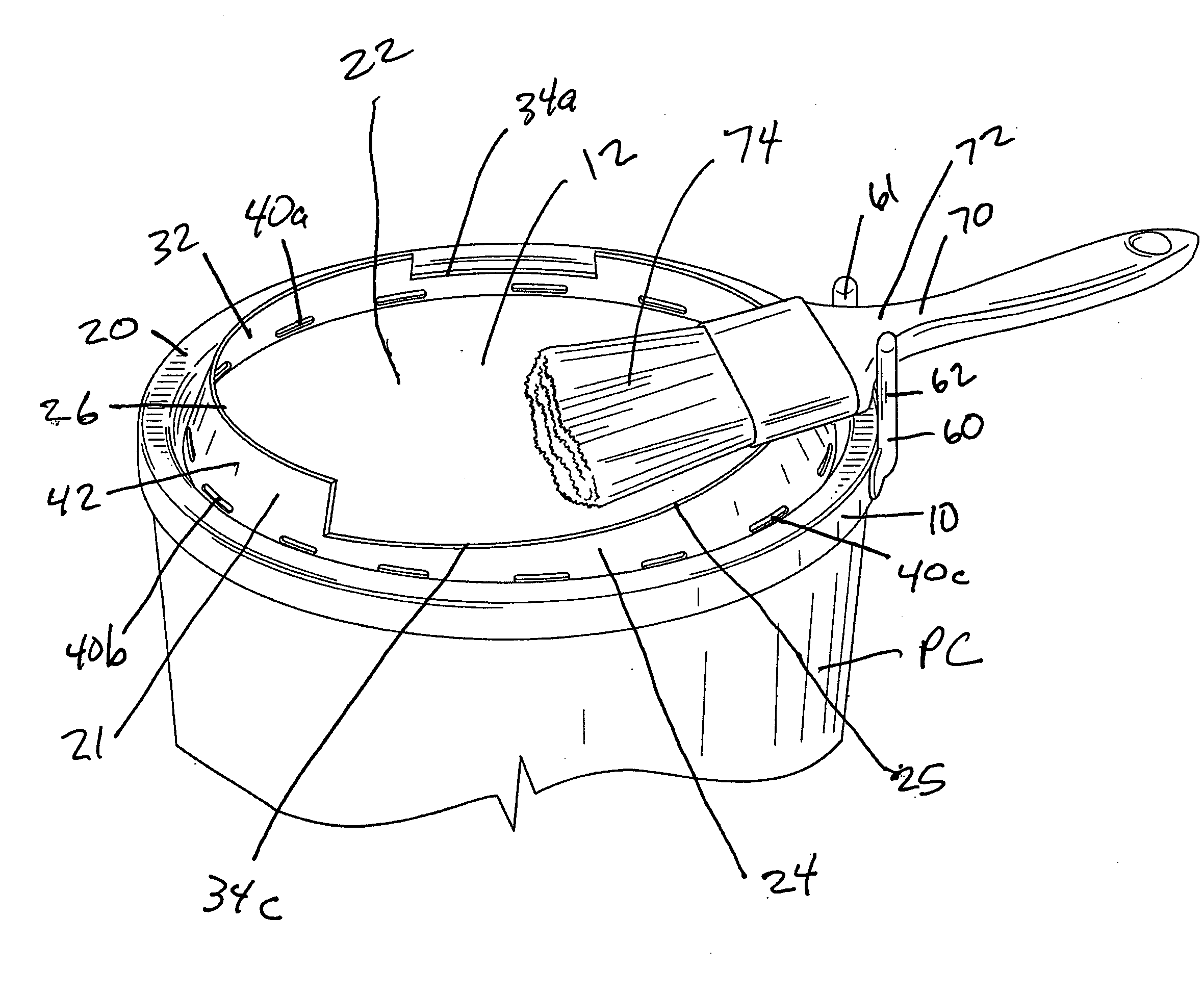

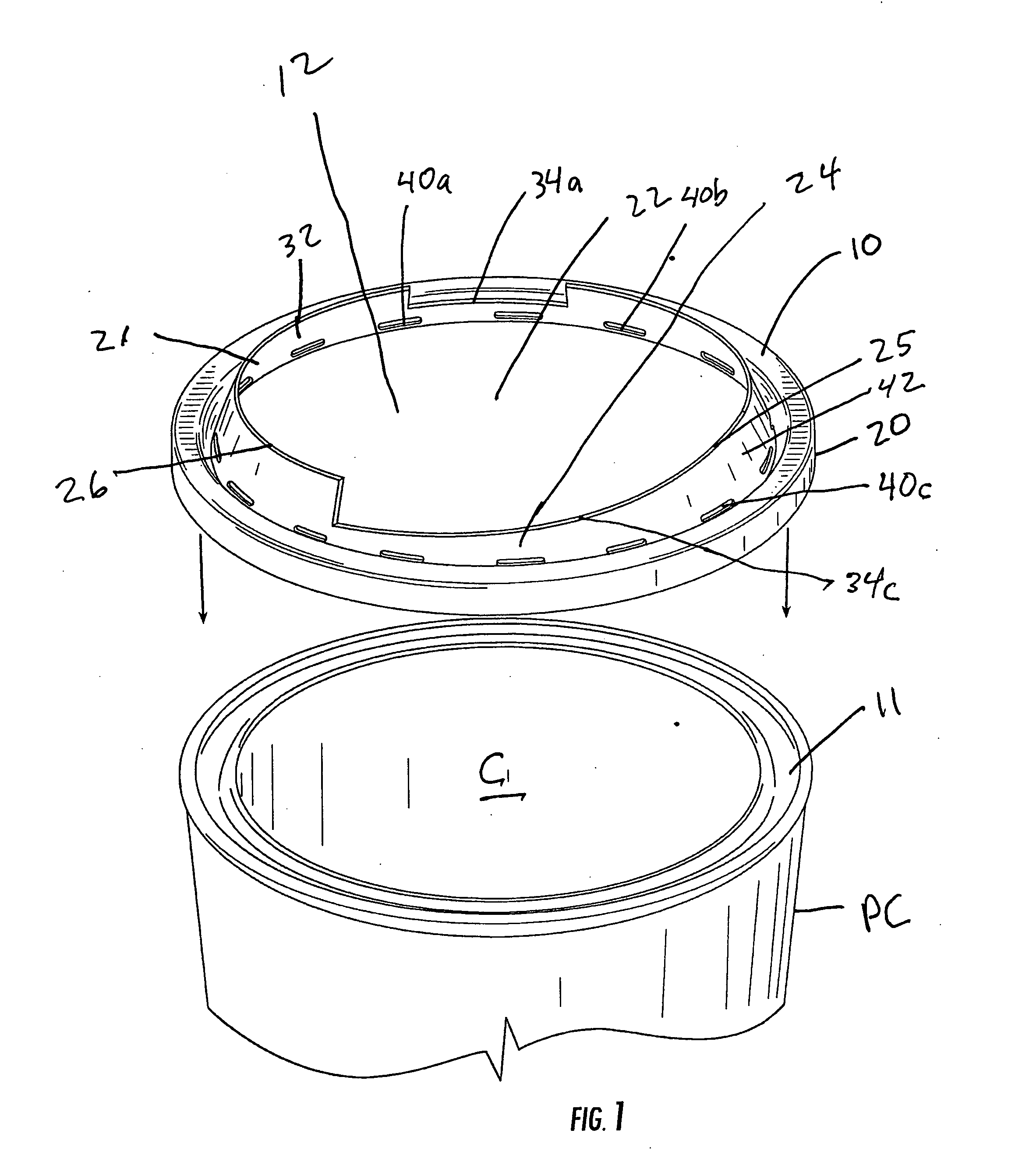

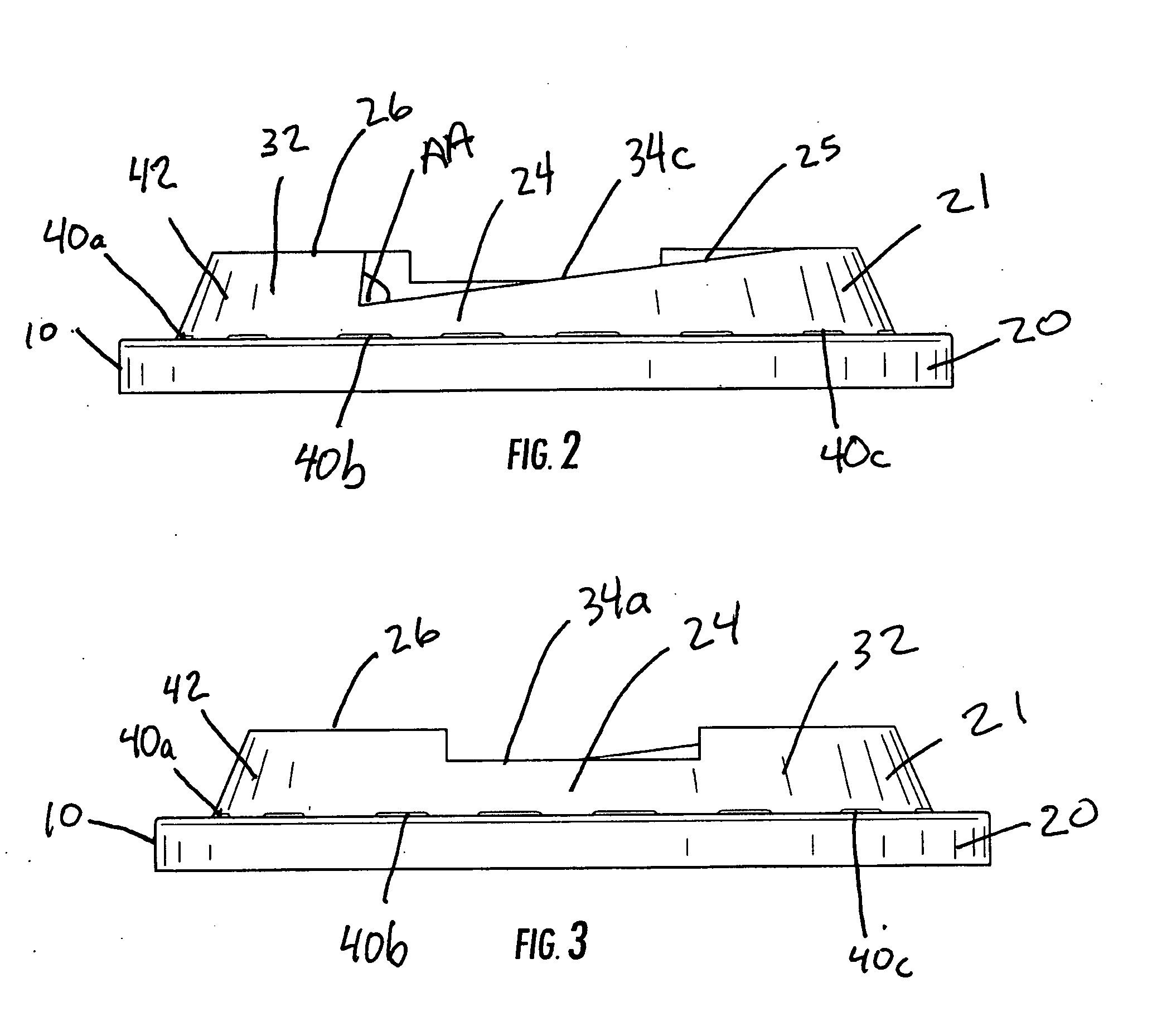

Protective Cover For Paint Can

InactiveUS20100116834A1Extending life of brushNeater jobLarge containersContainer/bottle contructionShortest distanceShort distance

Protective covers for cans of paint or wood stain having a circular cap with an inner and an outer lip, wherein the inner and outer lips are downwardly disposed to cooperatively and frictionally engage a lid rim of a paint or wood stain can, and a circular flange extending upwardly from the circular cap and extending circumferentially around the lid rim of the can, wherein the circular flange curves inwardly toward the center of the can to define an opening through which the contents of the can may be accessed, and wherein a portion of the outer edge of the flange extends a shorter distance upward from the cap than the rest of the flange to provide a recessed edge against which excess liquid may be scraped from a paint brush and drain back into the can.

Owner:SULICK JR THOMAS M

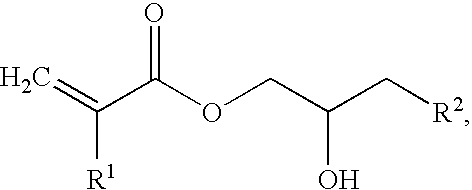

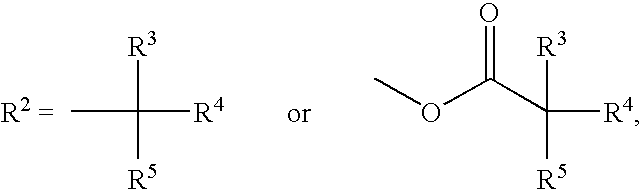

Coating compositions suitable for use as a wood stain and/or toner

Coating compositions are disclosed that include a film-forming resin, a colorant, a long chain alkyl group containing polymerizable ethylenically unsaturated compound, and a diluent. Also disclosed are substrates at least partially coated with such compositions, substrates at least partially coated with a multi-layer composite coating comprising at least one coating layer deposited from such compositions, and methods for improving the adhesion of a multi-layer composite coating system to a porous substrate.

Owner:PPG IND OHIO INC

Coating compositions suitable for use as a wood stain and/or toner

ActiveUS7351475B2Synthetic resin layered productsCellulosic plastic layered productsPorous substrateDiluent

Coating compositions are disclosed that include a film-forming resin, a radiation cure initiator, a colorant, and a diluent. These compositions are substantially free of radiation curable material. Also disclosed are substrates at least partially coated with such compositions, substrates at least partially coated with a multi-layer composite coating comprising at least one coating layer deposited from such compositions, and methods for improving the adhesion of a multi-layer composite coating system to a porous substrate.

Owner:PPG IND OHIO INC

Method for automatic color matching of transparent wood stains

ActiveUS7623241B2Radiation pyrometryVacuum evaporation coatingReflectivity measurementComputer science

A method of producing a finish for a paper substrate, wherein the finish provides the paper substrate with a color that matches the color of a target object. In accordance with the method, calculations are performed to determine the quantities of at least one group of colorants required to produce a semitransparent wood stain from a vehicle, wherein when the semitransparent wood stain is applied to the paper substrate, the paper substrate will have a color that matches the target object. The calculations are performed using reflectance measurements of the target object obtained using a spectrophotometer and previously obtained spectral data of the colorants as applied to a paper substrate. The colorants used to form the transparent or semitransparent wood stain do not include a white colorant or black-and-white masstone.

Owner:ARCH SAYERLACK COATINGS

Method for automatic color matching of transparent wood stains

A method of producing a finish for a paper substrate, wherein the finish provides the paper substrate with a color that matches the color of a target object. In accordance with the method, calculations are performed to determine the quantities of at least one group of colorants required to produce a semitransparent wood stain from a vehicle, wherein when the semitransparent wood stain is applied to the paper substrate, the paper substrate will have a color that matches the target object. The calculations are performed using reflectance measurements of the target object obtained using a spectrophotometer and previously obtained spectral data of the colorants as applied to a paper substrate. The colorants used to form the transparent or semitransparent wood stain do not include a white colorant or black-and-white masstone.

Owner:ARCH SAYERLACK COATINGS

Use of fungal pigments from wood-staining fungi as colorants in wood finishes and paints

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

Even wood stain

InactiveCN101905473AReduce the possibility of saggingGreat market potentialWood treatment detailsCyclohexanoneDibasic ester

The invention relates to an even wood stain, belonging to the technical field of paints. The even wood stain is characterized by being prepared by the method comprising the following steps: proportioning the following components in percentage by weight: alkyd resin: 3-7, 1 / 2 nitrocotton with the concentration of 30%: 6-12, butyl ester: 13-19, cyclohexanone: 7-10, aliphatic dibasic esters: 0.5-1.5, defoaming agent: 0.01-0.06, flatting agent: 0.05-2, dimethylbenzene: 22-30, methylbenzene: 23-32, ethyl ester: 5-8 and drier: 0.15-0.3; then numbering the materials according to the color, adding required color concentrate, evenly stirring, and directly spraying. The even wood stain reduces the possibility for the product to be subject to sagging, greatly shortens construction time, and simultaneously adopts a paint film removing technology to ensure that the dried wood stain can be rapidly dissolved, once uneven coloring exists, the even wood stain can amend colors quite easily, and lower the technical requirements for construction workers, thereby ensuring that coloring is simple and no waste product appears.

Owner:FOSHAN SHUNDE DIGITAL PAINT

Dyeing agent for wooden boards

InactiveCN107778997AReduce consumptionImprove product added valueWood treatment detailsWood veneerColor effect

The invention discloses a wood board stain and belongs to the technical field of wood modification. The dyeing agent is composed of reactive dyes, leveling and dyeing accelerators, color fixing agents, penetrating agents and water. The wood veneer can be evenly dyed under the conditions of a temperature of 70-75°C, a dyeing time of 45-60 minutes, and a fixing time of 30-40 minutes. The combination formula of the wood board stain agent of the invention is reasonable, and has the advantages of good technical performance, uniform color, good coloring effect, less energy consumption, low cost and the like.

Owner:广西贵港市长雄干燥科技有限公司

Coating compositions suitable for use as a wood stain and/or toner

ActiveUS20060222843A1Easy to optimizeSynthetic resin layered productsCellulosic plastic layered productsPorous substrateDiluent

Coating compositions are disclosed that include a film-forming resin, a radiation cure initiator, a colorant, and a diluent. These compositions are substantially free of radiation curable material. Also disclosed are substrates at least partially coated with such compositions, substrates at least partially coated with a multi-layer composite coating comprising at least one coating layer deposited from such compositions, and methods for improving the adhesion of a multi-layer composite coating system to a porous substrate.

Owner:PPG IND OHIO INC

Wood staining method

InactiveCN108748547AUniform colorEasy to operateWood treatment detailsCoating impregnationStainingHazardous substance

The invention discloses a wood staining method. The wood staining method comprises the following steps of (1) boiling of wood: boiling the wood in a dye liquid; (2) preparing of coating peat: modifying the peat in a constant-temperature drying box at the temperature of 130 to 160 DEG C, and soaking the modified peat into the dye liquid, so as to obtain the coating peat; (3) baking and staining: coating the wood by the coating peat, drying, and clearing the peat at the surface of the wood, so as to obtain the stained wood. The wood staining method has the advantages that the obtained wood is coated by the coating peat and then baked, the dye liquid gradually permeates into the wood, and the staining of the obtained stained wood is more uniform; after coating by the peat, the harmful mattersand irritation odor of the dye liquid are adsorbed by the peat, so that the obtained wood is environment-friendly and harmless; the operation procedures are simple, and the cost is greatly reduced.

Owner:芜湖瑞祥木业包装有限公司

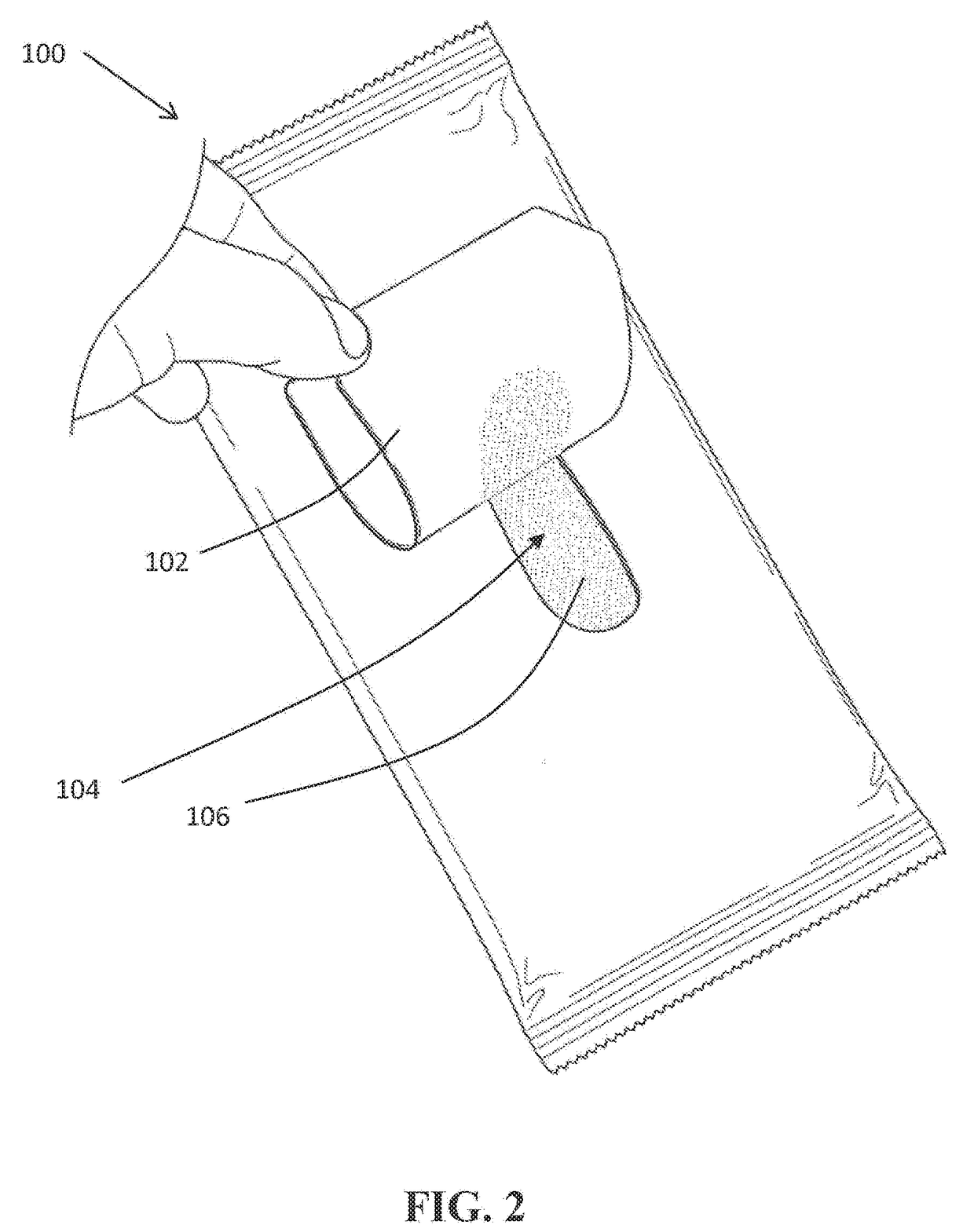

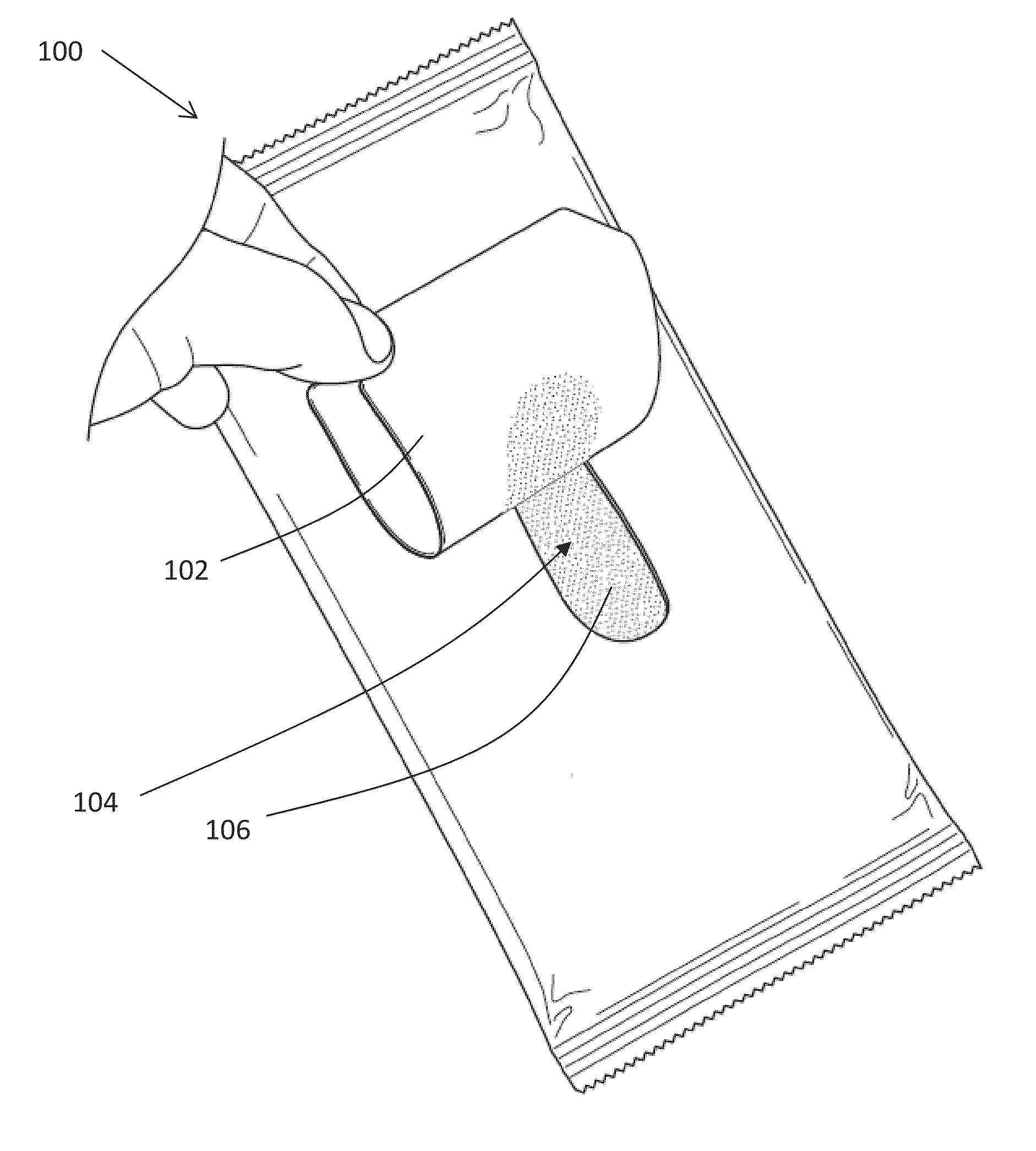

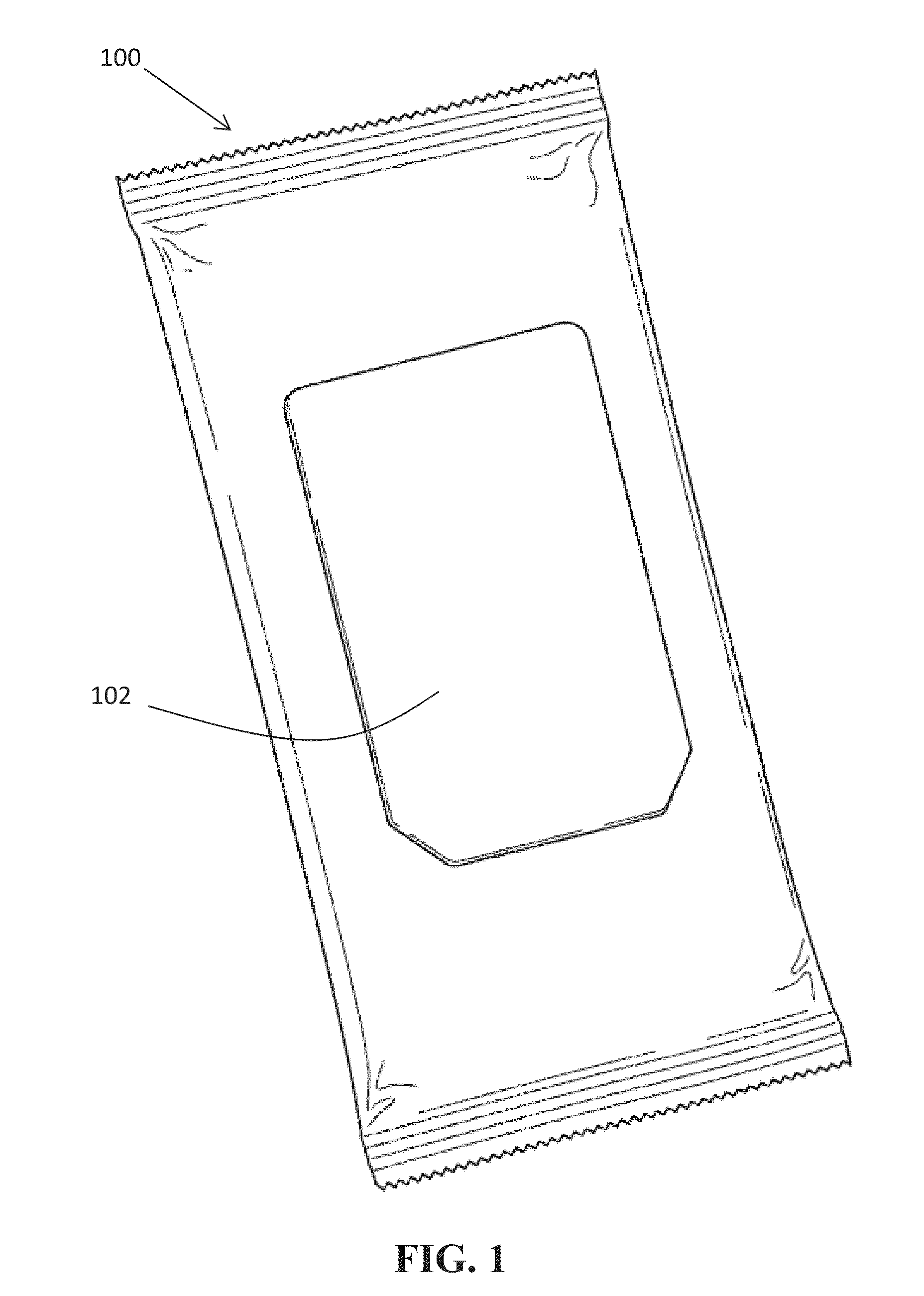

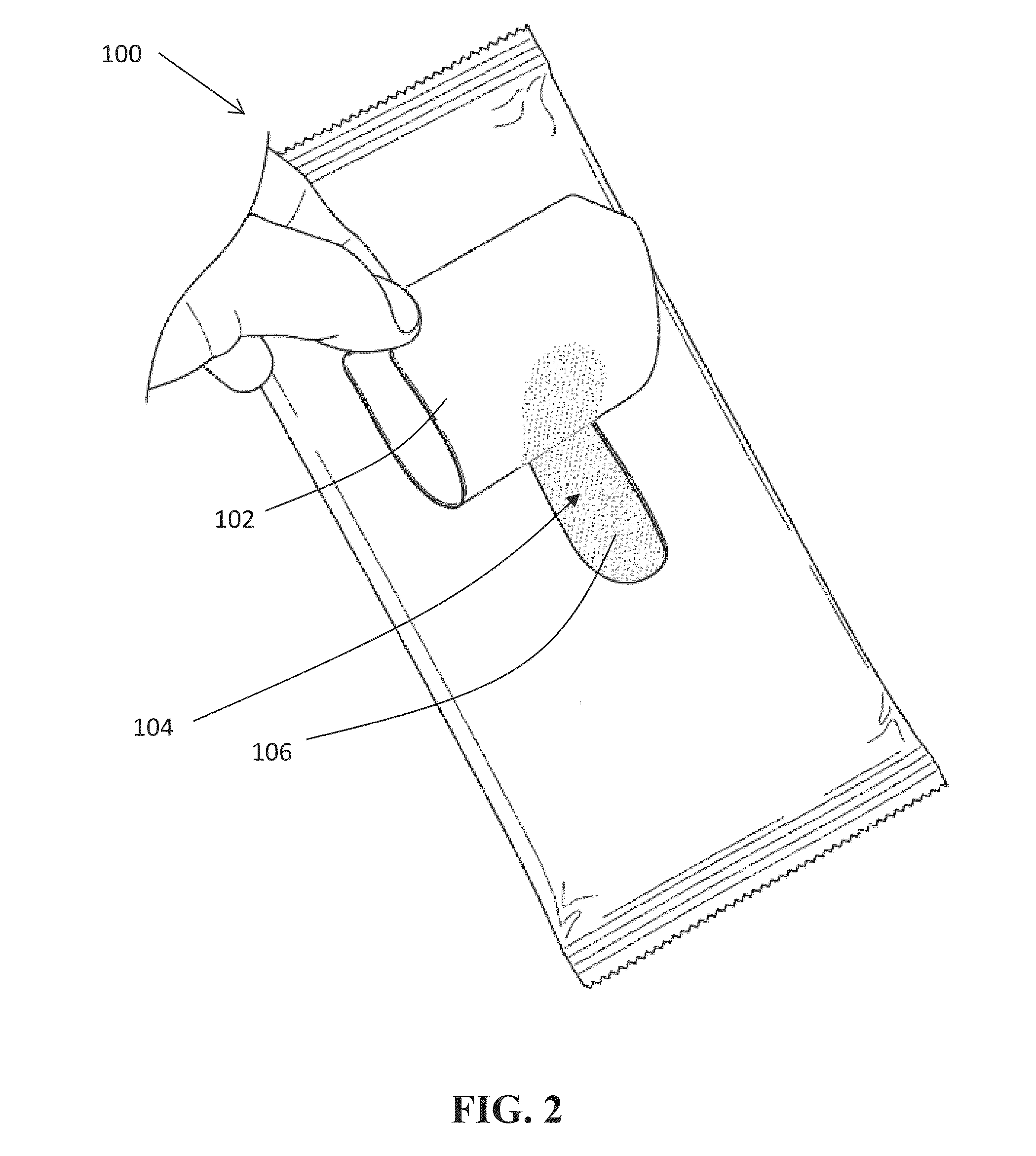

Wood staining and finishing wipes and method of manufacturing same

A pre-treated wipe is disclosed. The pre-treated wipe includes an absorbent substrate impregnated with a solution. The solution includes a colorant capable of imparting a change in color to a wood surface. The solution further includes a finishing composition. The solution further includes a thickening agent. The solution has a finished viscosity that is greater than an original viscosity of the solution when prepared without the thickening agent. The absorbent substrate is impregnated with the solution before being disposed in a package.

Owner:THE SHERWIN-WILLIAMS CO

Automated and semi-automated process for staining wood with fluorescent dyes & pigments

A process for staining / finishing a wood article, preferably unfinished wood, and / or wood articles from which the finish has been removed, with a stain formulation (oil or water based) containing a plurality of fluorescent dyes and / or pigment. The process can be performed manually, or with a system having automated paint staining / finishing equipment; and / or in a semi-automated system, more specifically a combination of automated, and manual processing. The automated paint staining / finishing can be performed with (a) automated flatline staining / finishing systems, (b) a hangline automated wood staining / finishing system and / or (c) the towline automated wood staining / finishing system. The enhancement of a grain pattern, by staining a wood art can be enhanced by treating the wood with a bleach to substantially reduce the contrast between the heartwood and sapwood features of the wood grain.

Owner:卡洛斯蒙伽罗

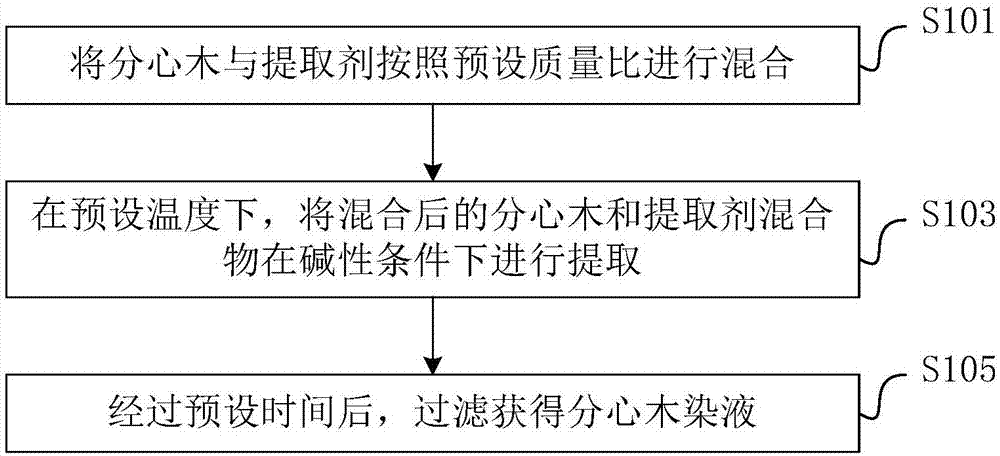

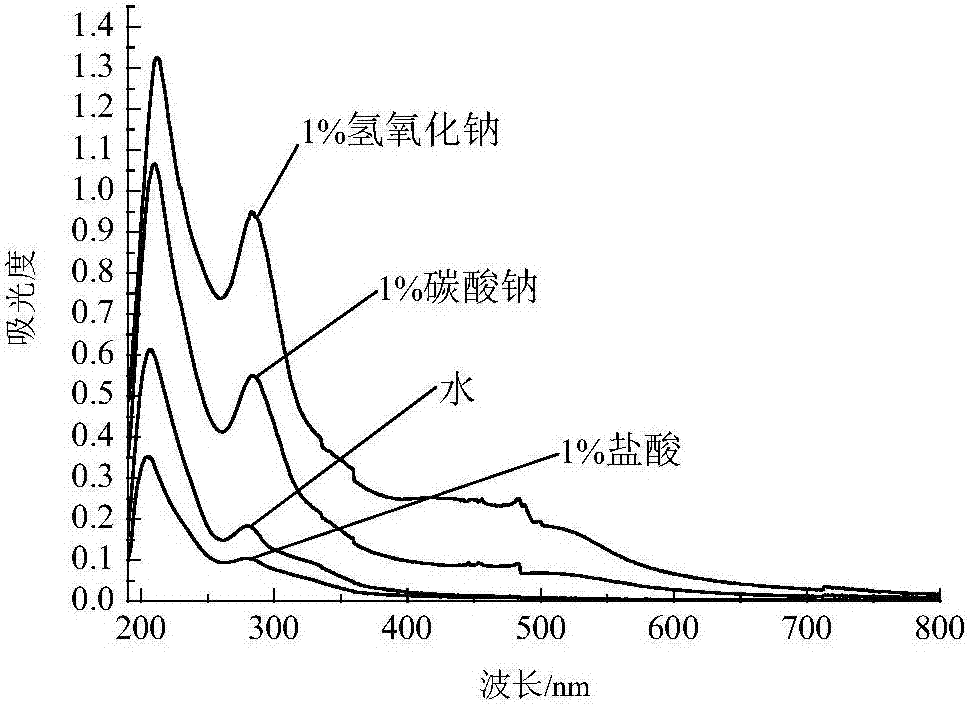

Dye extraction method and Semen Juglandis dye liquor

The invention discloses a dye extraction method. The dye extraction method comprises the following steps: mixing Semen Juglandis with an extractant according to a preset mass ratio; extracting an obtained mixture of the Semen Juglandis and the extractant at a preset temperature; and carrying out filtering after a preset time so as to obtain a Semen Juglandis dye liquor. The Semen Juglandis dye liquor obtained by using the method provided by the invention can be used for dying of textile products, especially used for dyeing of silk fabrics. No adverse influence on the environment is caused in the processes of dye extraction and application.

Owner:NANTONG UNIVERSITY

Coating compositions suitable for use as a wood stain and/or toner

Owner:PPG IND OHIO INC

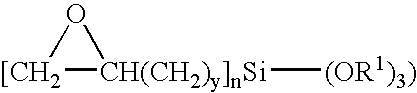

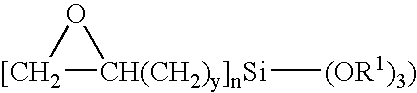

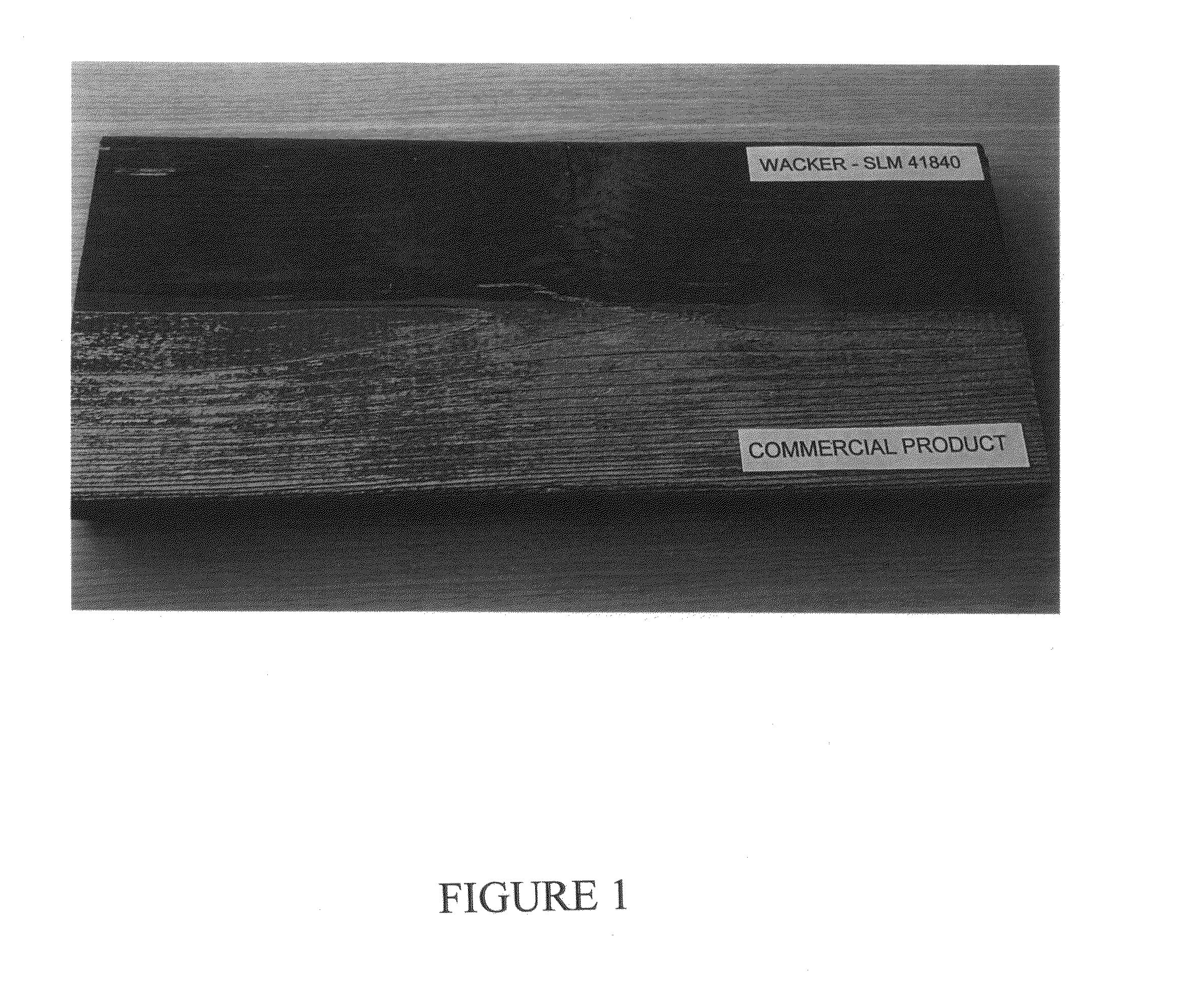

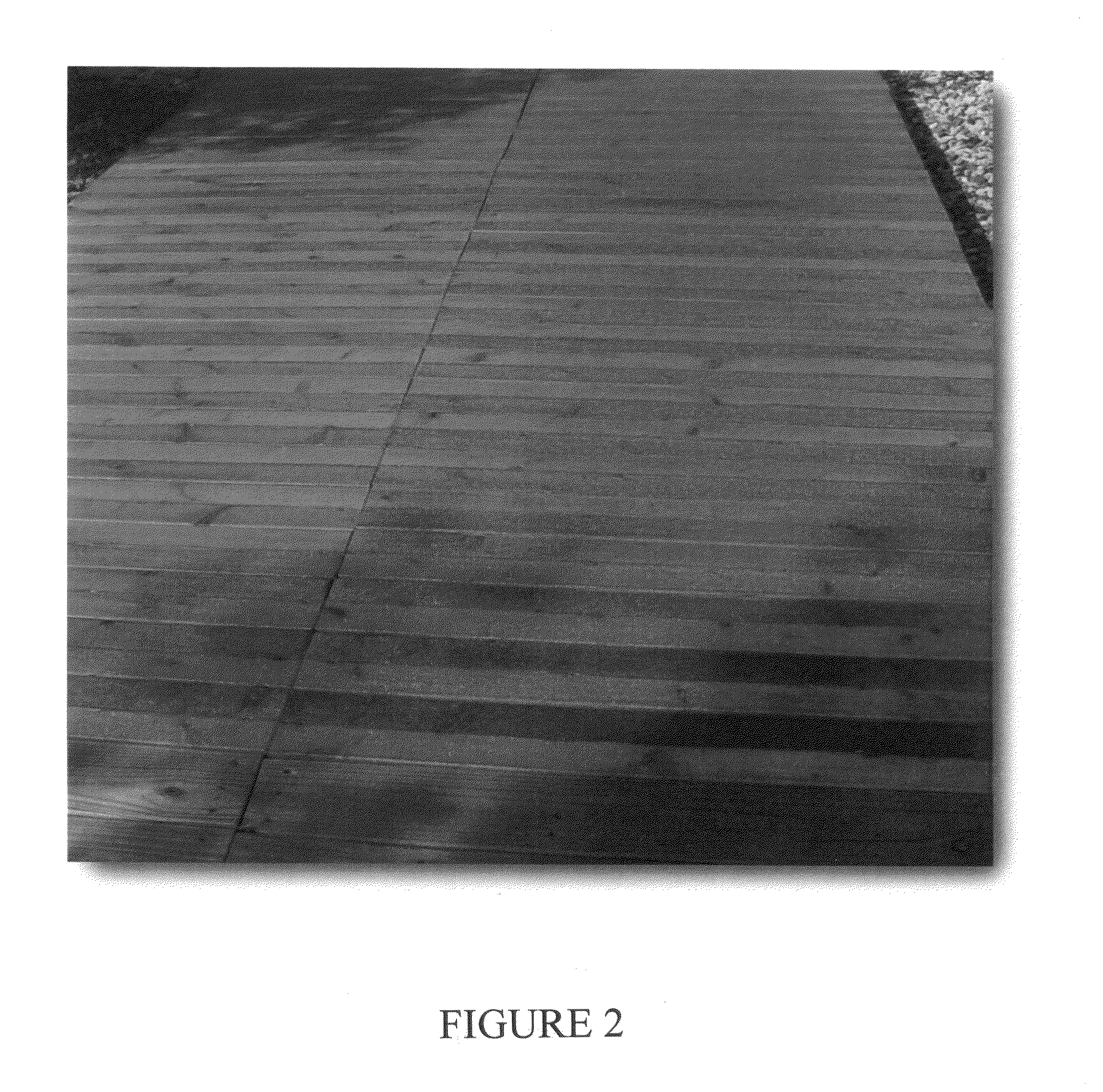

Water repellant wood stains with improved weatherability

InactiveUS20140213717A1High in initial water repellencyMaintain repellencyMaterial nanotechnologyDyeing processWaxPolymer science

Woodstains of improved weatherability are prepared by incorporating polymer coated nanoparticles, and preferably at least one silicone, fluorocarbon, organosilane or wax water repellant into the woodstain.

Owner:WACKER CHEM CORP

Wood staining and finishing wipes and method of manufacturing same

A pre-treated wipe is disclosed. The pre-treated wipe includes an absorbent substrate impregnated with a solution. The solution includes a colorant capable of imparting a change in color to a wood surface. The solution further includes a finishing composition. The solution further includes a thickening agent. The solution has a finished viscosity that is greater than an original viscosity of the solution when prepared without the thickening agent. The absorbent substrate is impregnated with the solution before being disposed in a package.

Owner:THE SHERWIN-WILLIAMS CO

Bamboo and wood protecting agent

InactiveCN1209024CBroad-spectrumImprove mildew resistanceBiocideWood treatment detailsPentachlorophenolChlorothalonil

The invention is a bamboo wood protective agent. It is characterized in that based on zinc salt, boric acid and borate, one or two of fluoride, quaternary ammonium salt, chlorothalonil, sodium pentachlorophenate and phoxim emulsion are added, and the weight ratio of each component is : zinc salt: boric acid: borate: one or both of fluoride, quaternary ammonium salt, chlorothalonil, sodium pentachlorophenate, phoxim emulsion = 1.8~2.2: 0.8~1.2: 2.4~3.6: 2~3. The present invention has high efficiency, anti-insect, anti-mildew and anti-corrosion effects, has broad spectrum, good water solubility and fixability (i.e. leaching resistance), low cost, low toxicity, basically harmless to the environment, and has no effect on the treated materials. Dyeing effect, can maintain natural color.

Owner:王文久 +2

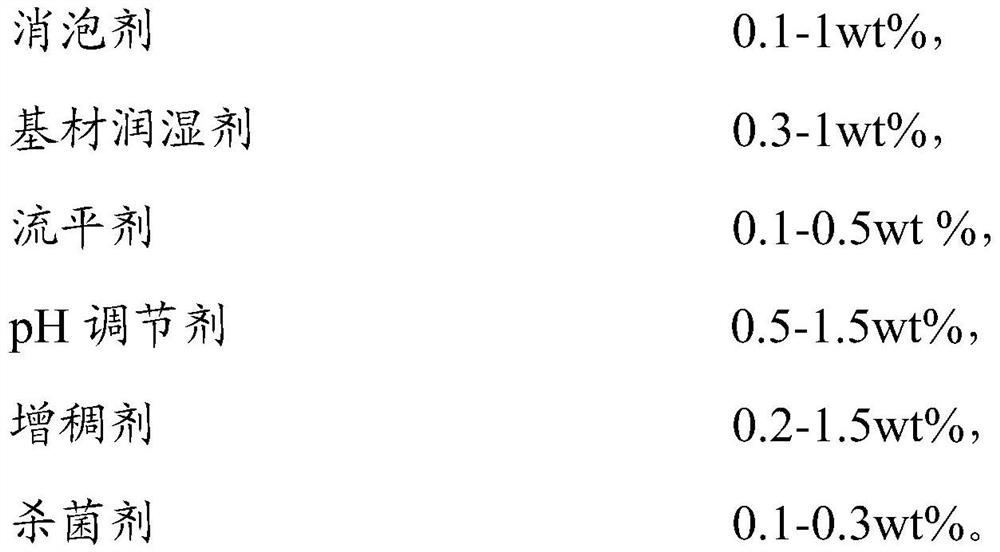

A kind of water-based stain-resistant white finish for woodware and preparation method thereof

ActiveCN110628289BIntegrity guaranteedGuaranteed adhesionAntifouling/underwater paintsPaints with biocidesSulfonatePolymer science

The invention belongs to the technical field of water-based wood ware paint, and particularly relates to a water-based wood stain-resistant white finish paint and a preparation method thereof. The water-based wood stain-resistant white finish paint includes a main paint A and a curing agent B; the main paint A includes: water-based acrylic acid Emulsion, 48‑60wt%, coalescent, 4‑8wt%, water-based additive, 1.3‑5.8wt%, titanium dioxide, 18‑24wt%, matting powder, 0.3‑1.2wt%, water, 1.0‑28.4wt% %; Curing agent B is a sulfonate hydrophilic modified HDI trimer. On the basis of maintaining its excellent hardness, scratch resistance and adhesion, the water-based stain-resistant white finish paint for woodware of the present invention has good resistance and tolerance to different stains, especially for red wine, mustard, coffee, alkali stains, etc. Has obvious anti-fouling effect.

Owner:WANHUA CHEM GRP CO LTD +1

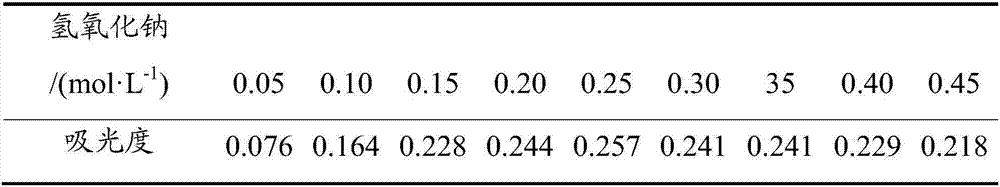

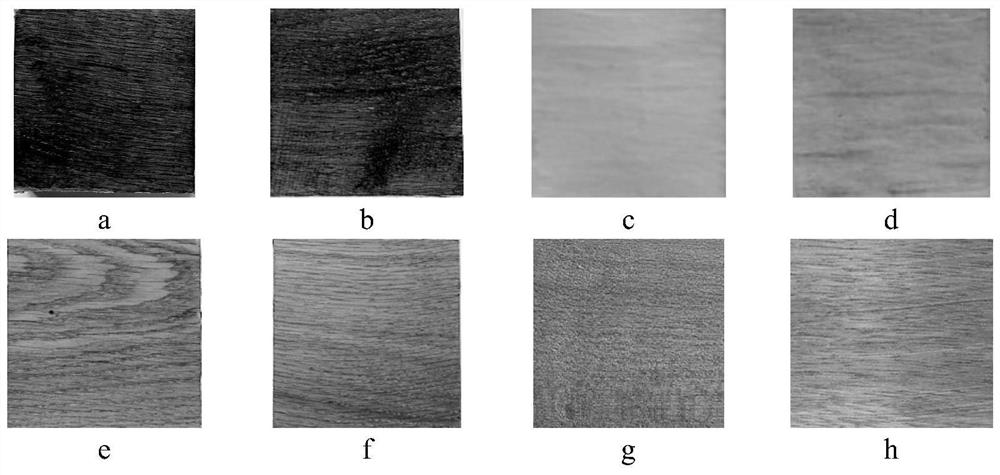

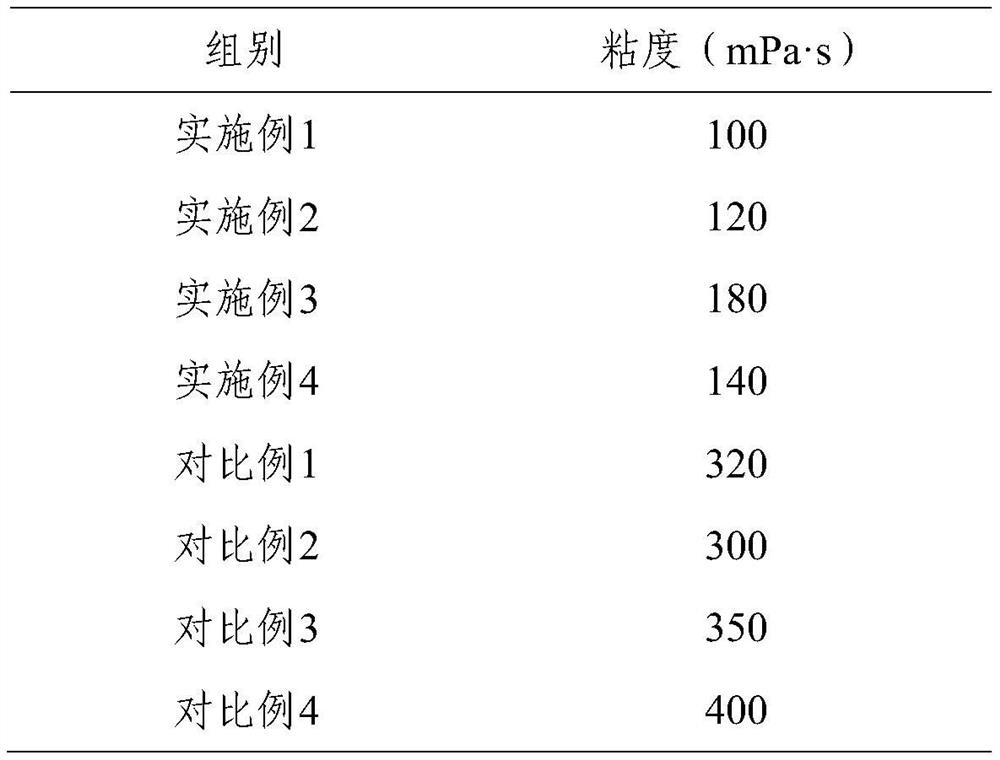

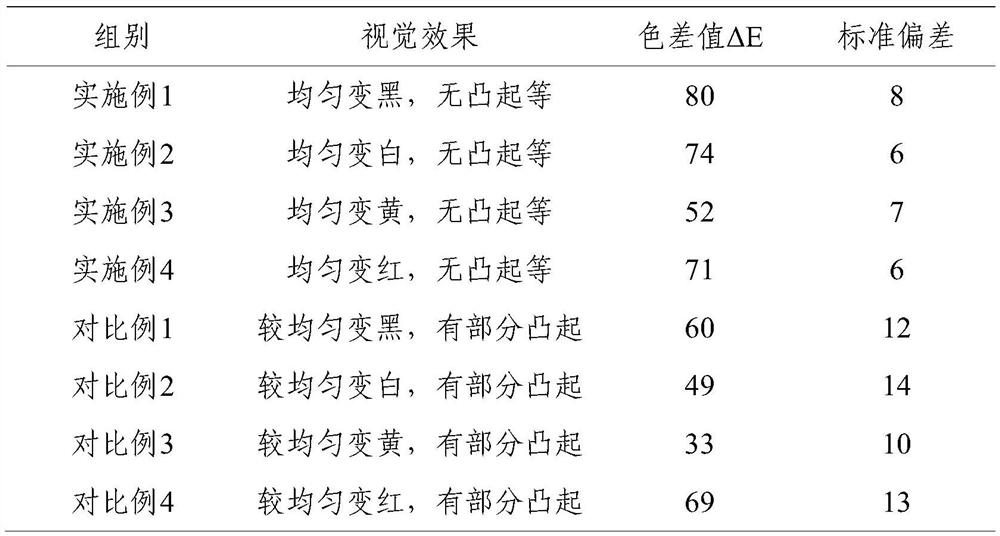

A kind of water-based wood stain and coloring method

ActiveCN110154186BImprove surface roughnessEasy to spreadWood treatment detailsPolymer sciencePolymer resin

The invention relates to the technical field of wood coloring, in particular to a water-based wood colorant and a coloring method. The main components of the water-based wood colorant of the invention include pigments, dopamine, nanocellulose and water-based polymer resin. The invention solves the problems of uneven wood permeability and poor wood surface coloring effect in the existing wood coloring technology, and the water-based wood colorant provided has moderate viscosity, strong adhesion, small particle size, good dispersion effect, and is easier Penetrates into the wood.

Owner:RES INST OF FORESTRY NEW TECH CHINESE ACAD OF FORESTRY

Combination Wood Stain and Sealant and Method of Application

A method is shown for treating a wood substrate which both stains and simultaneously seals. First a sealant composition is formulated by combining a commercially and industrially sold stain with a micro-crystalline pre-mixture, the micro-crystalline pre-mixture being comprised of a micro-crystalline wax in an organic solvent blend. Next, the wood substrate is contacted with the sealant composition and the solvent blend is allowed to flash away, leaving a substantially solvent free micro-crystalline wax residue barrier. The solvent blend can be a mixture of hexane and xylene but is not limited to these two particular solvents.

Owner:PROMXX LLC

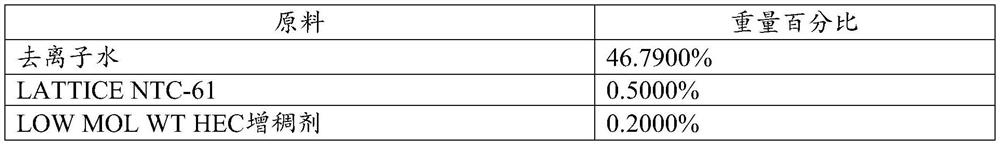

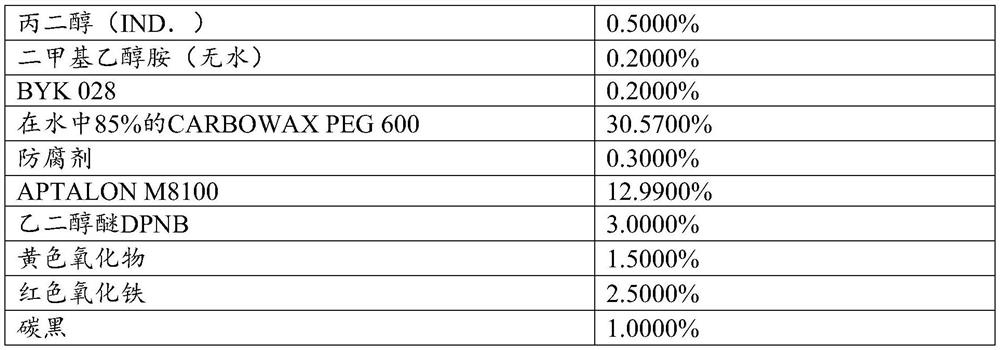

Non-lapped water-based wood coloring agent

A wood stain composition for providing improved application characteristics and complying with the regulatory VOC limits, the wood stain composition comprising or consisting essentially of a water miscible polyol having a molecular weight of less than 1000 Da, a water dispersible hydrophobic polymer, and a pigment dispersion.

Owner:SWIMC LLC

Wood staining method

InactiveCN108748504AUniform colorEasy to operateWood treatment detailsWood impregnation detailsEnvironmental resistanceStaining

The invention discloses a wood staining method. The wood staining method comprises the following steps of (1) soaking of wood: soaking the wood into a dye liquid; (2) preparing of coating peat: modifying the peat in a constant-temperature drying box at the temperature of 130 to 160 DEG C, and soaking the modified peat into the dye liquid, so as to obtain the coating peat; (3) baking and staining:coating the wood by the coating peat, drying, and clearing the peat at the surface of the wood, so as to obtain the stained wood. The wood staining method has the advantages that the obtained wood iscoated by the coating peat and then baked, the dye liquid gradually permeates into the wood, and the staining of the obtained stained wood is more uniform; after coating by the peat, the harmful matters and irritation odor of the dye liquid are adsorbed by the peat, so that the obtained wood is environment-friendly and harmless; the operation procedures are simple, and the cost is greatly reduced.

Owner:芜湖瑞祥木业包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com