A kind of water-based wood stain and coloring method

A coloring agent and wood technology, applied in wood treatment, wood treatment details, wood processing utensils, etc., can solve the problems of uneven wood permeability, poor coloring effect of wood surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A water-based wood stain, the formula is: 5 parts of Tempo-oxidized nanocellulose (CNC), 60 parts of carbon black, 12 parts of dopamine, 20 parts of polyacrylate resin, 200 parts of water.

[0038] This embodiment also provides the preparation method of the water-based wood stain, comprising: adding Tempo-oxidized nanocellulose (CNC) into water according to the formula and ultrasonically vibrating for 15 minutes at about 65°C; Stir in a homogenizer for 30 minutes, then add dopamine and polyacrylate resin, and stir for 1 hour at a speed of 200r / min.

[0039] This embodiment also provides a wood coloring method, comprising: performing plasma pretreatment on wood before coloring; and using the water-based wood colorant of this embodiment for coloring. Specifically, the wood was pretreated with a plasma spray gun DBD, the working gas was He, the plasma was generated in the gun and sprayed onto the wood surface, and the gas velocity was 20 L / min. The power supply is a high-...

Embodiment 2

[0047]A water-based wood stain, the formula is: 8 parts of Tempo-oxidized nanocellulose (CNC), 40 parts of titanium dioxide, 10 parts of dopamine, 15 parts of polyurethane resin, and 180 parts of water.

[0048] This embodiment also provides the preparation method of the water-based wood stain, comprising: adding Tempo-oxidized nanocellulose (CNC) into water according to the formula and ultrasonically vibrating for 30 minutes at about 65°C; Stir in a homogenizer for 30 minutes, then add dopamine and polyurethane resin, and stir for 2 hours at a speed of 200r / min.

[0049] This embodiment also provides a wood coloring method, which differs from Embodiment 1 only in that: the coloring agent of this embodiment is formulated into a 4% aqueous solution, the wooden board is soaked in it for 20 hours, and then air-dried.

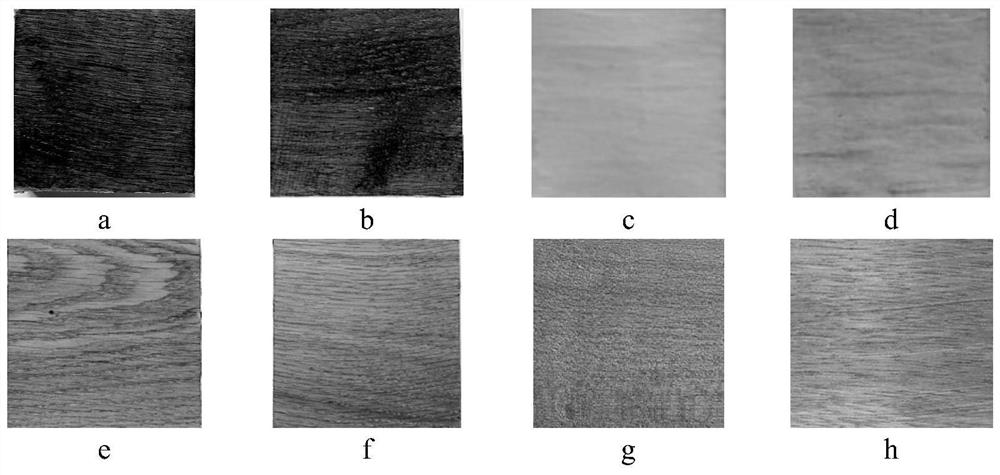

[0050] See the results of the wood coloring experiment figure 1 c.

Embodiment 3

[0057] A water-based wood stain, the formula is: 10 parts of Tempo-oxidized nanocellulose (CNC), 50 parts of iron yellow, 6 parts of dopamine, 13 parts of epoxy resin, 160 parts of water.

[0058] This embodiment also provides the preparation method of the water-based wood stain, including: adding Tempo-oxidized nanocellulose (CNC) into water according to the formula and ultrasonically vibrating for 30 minutes at about 65°C; Stir in a homogenizer for 30 minutes, then add dopamine and epoxy resin, and stir for 1.5 hours at a speed of 200r / min.

[0059] This embodiment also provides a wood coloring method, and the only difference from Embodiment 1 is that the coloring agent of this embodiment is formulated into a 3% aqueous solution, and the wooden board is soaked in it for 15 hours and air-dried.

[0060] See the results of the wood coloring experiment figure 1 e.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com