Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

173results about How to "Will not consume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

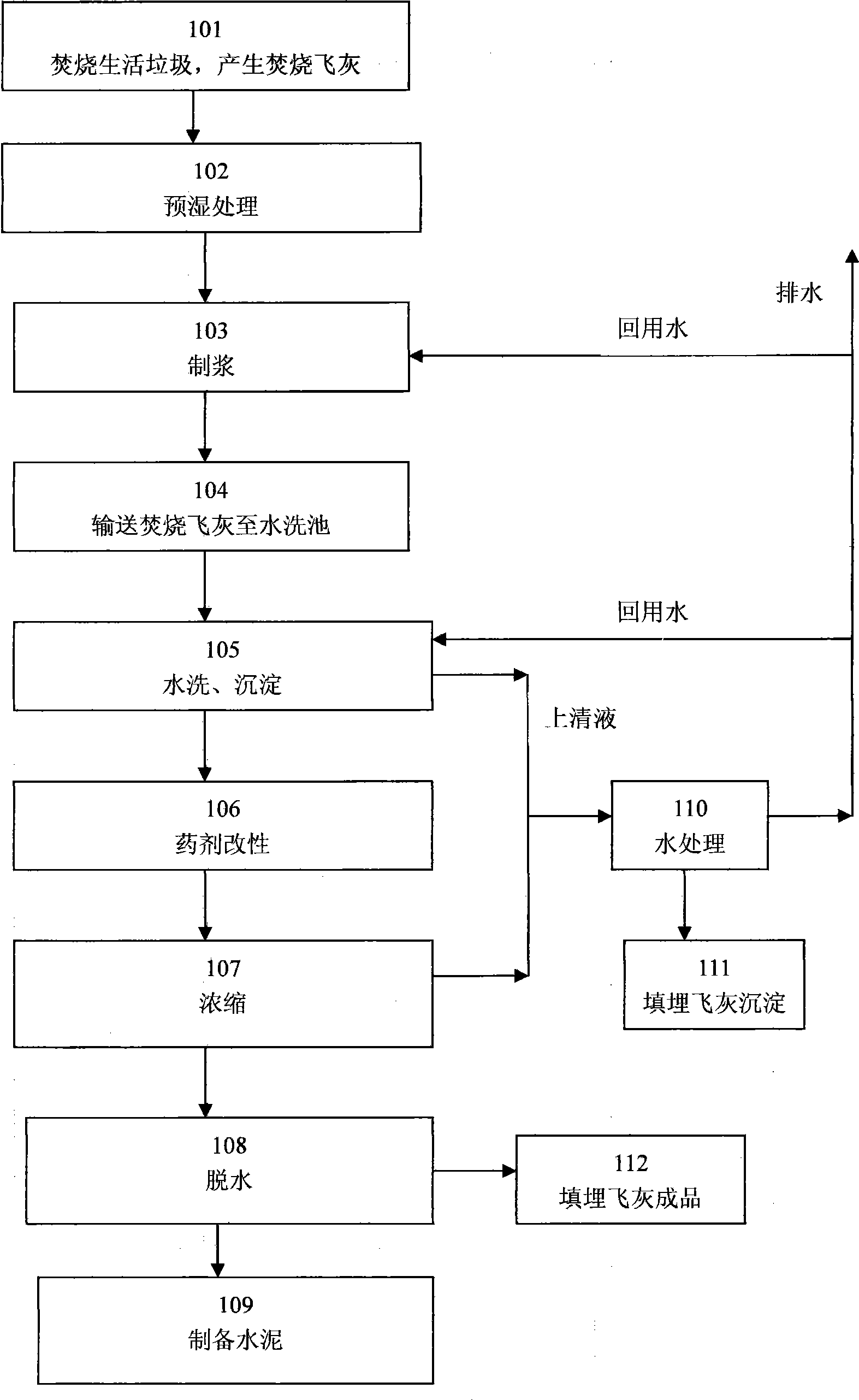

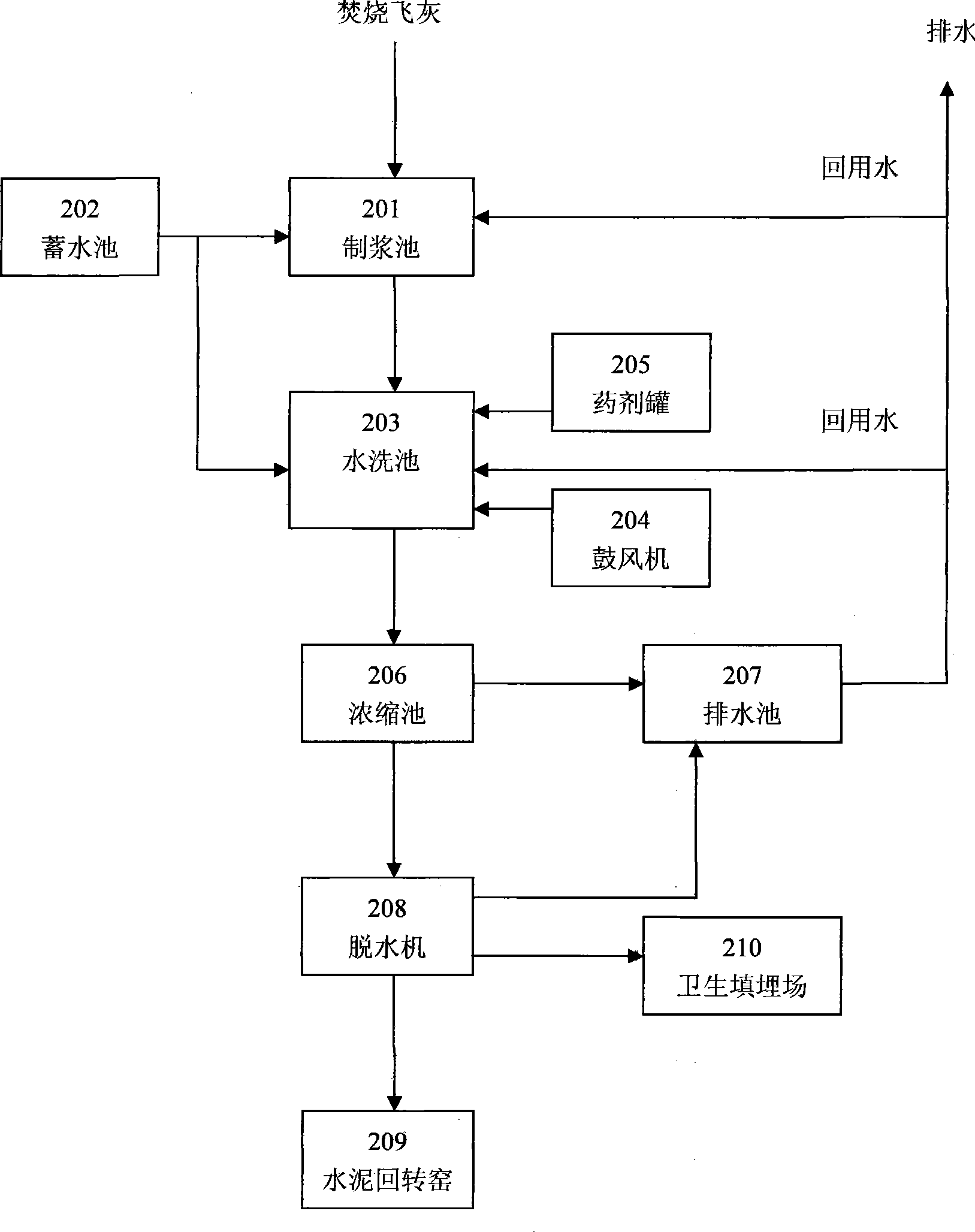

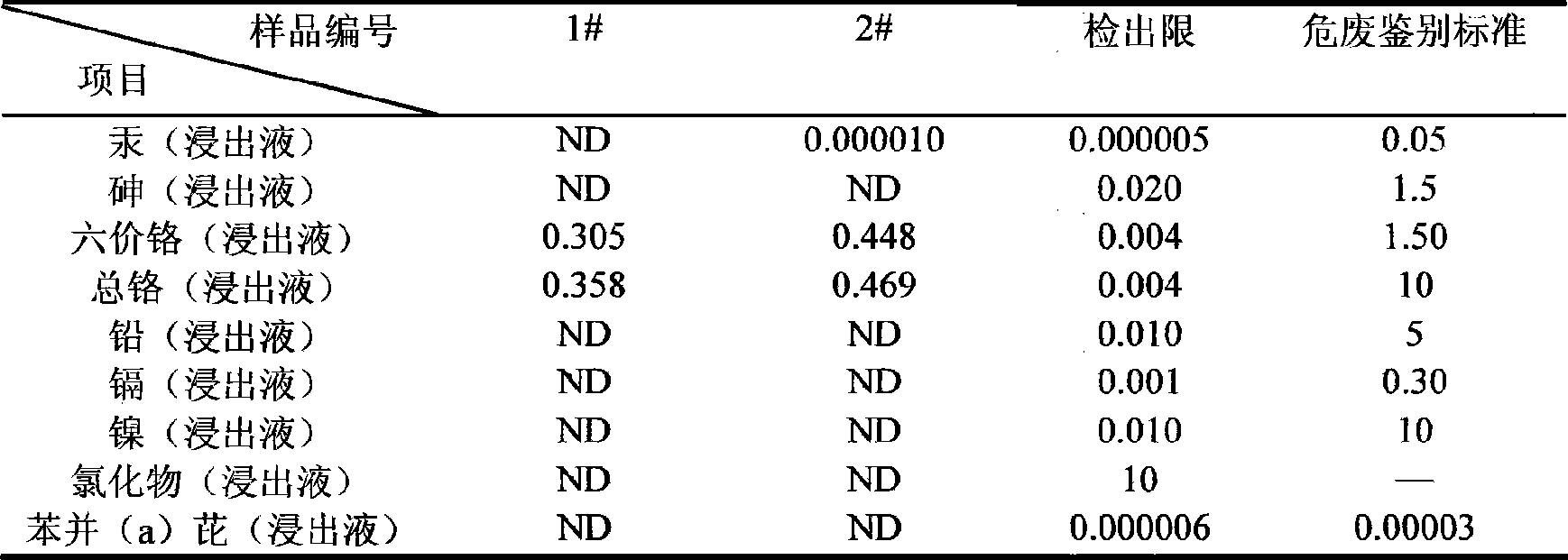

Innocent treatment method and apparatus for refuse burning flyash

ActiveCN101462835AReduce chlorine contentSolve the blockageSolid waste disposalCement productionWater qualitySlurry

The invention proposes a method for the innocent treatment of refuse burning fly ash. The method comprises the following steps: prewetting; pulping: mixing and stirring the fly ash and water in the proportion of 1:2 to 1: 20 to form ash slurry; water washing and precipitation: dissolving the soluble salts in the fly ash; modification through a reagent; concentration for reducing the water content of the ash slurry to 70 to 90 percent; dehydration for reducing the water content of the ash slurry to below 35 percent; water treatment: charging CO2 or acid to make the strongly basic supernatant with the pH value as high as 11 to 12 become the neutral water quality with the pH value of 6.0 to 8.5; flocculant addition for catching tiny particles and speeding up the precipitation process; cement preparation: heating up the fly ash end product in a cement rotary kiln to 1,000 to 1,450 DEG C, and decomposing dioxin and inhibiting the regeneration of the dioxin at the low temperature; and increase of the boiling point of heavy metals for passivating the volatility.

Owner:SHANGHAI SOLID WASTE DISPOSAL CENT +2

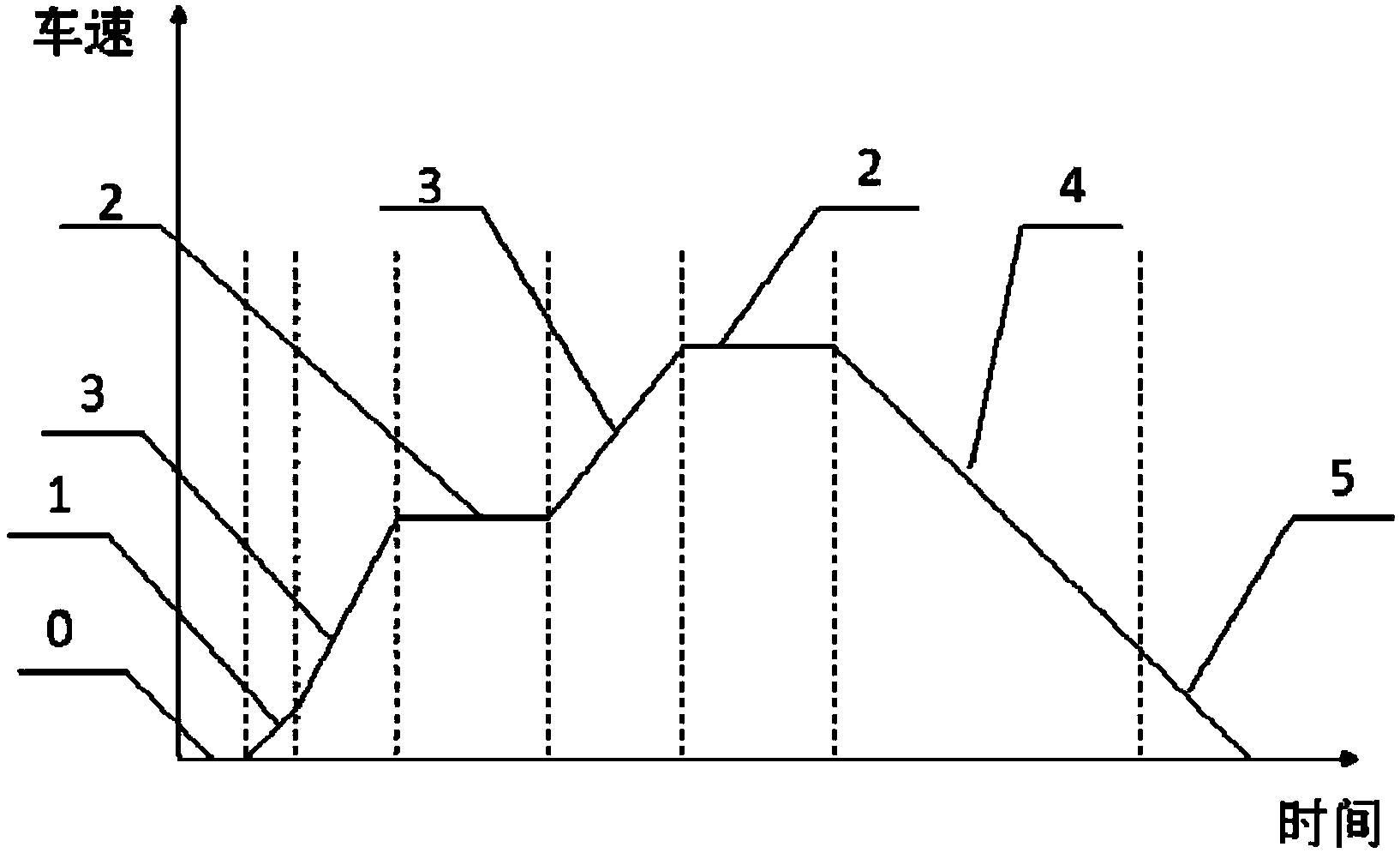

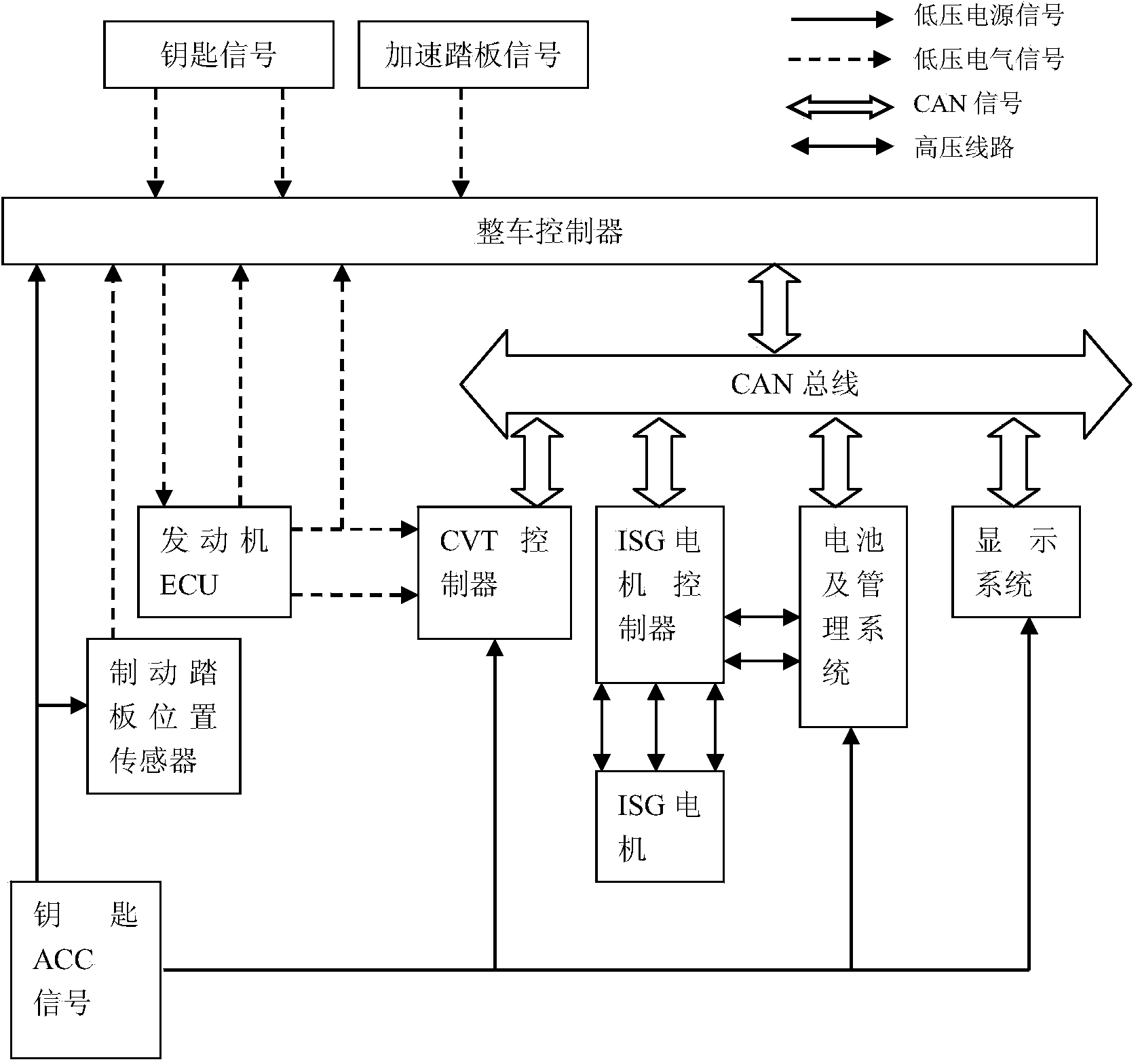

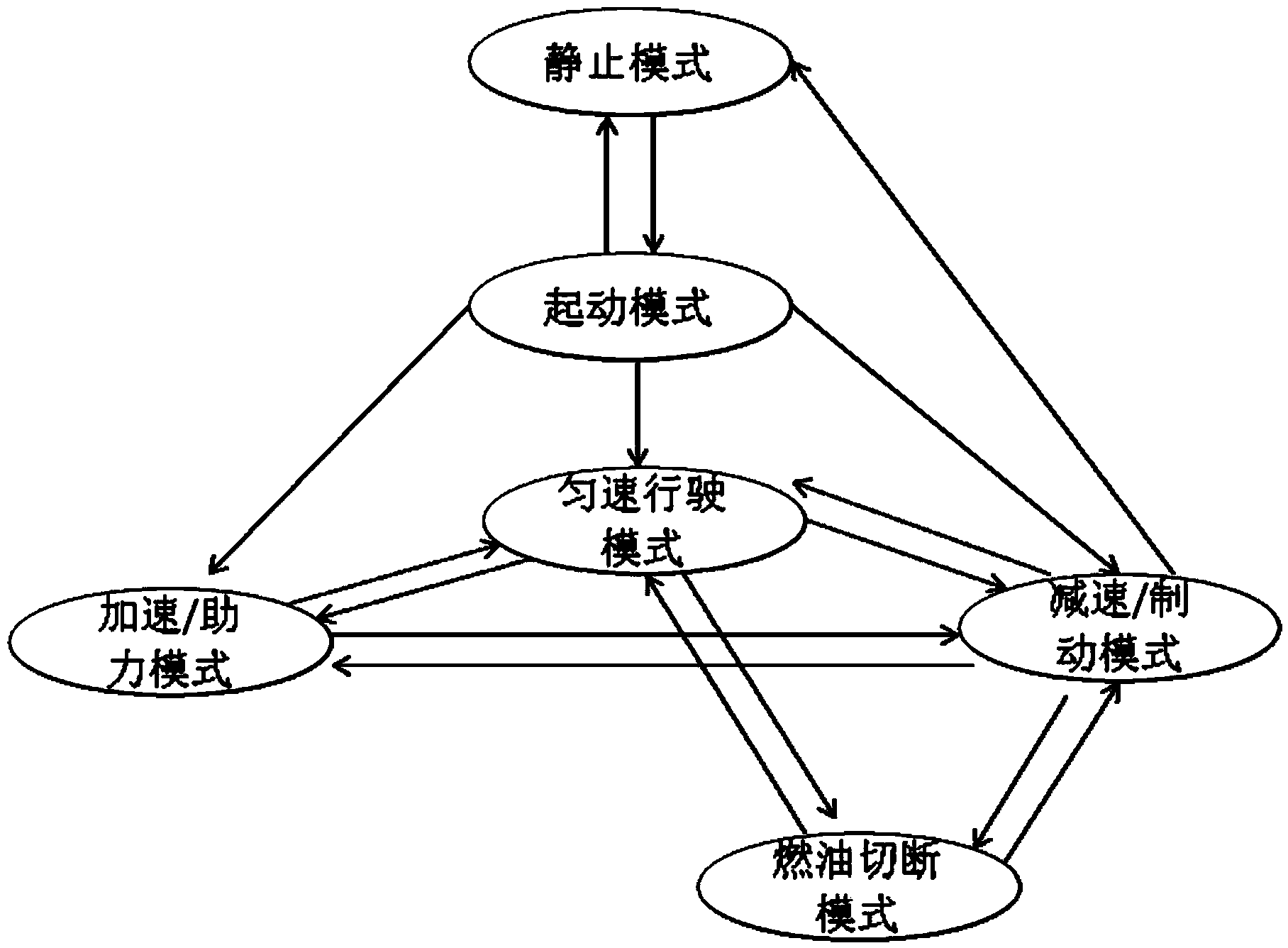

Method for controlling hybrid electric vehicle

ActiveCN103802836AReduce fuel consumptionImprove fuel economyHybrid vehiclesFuel supplyElectric vehicle

The invention discloses a hybrid electric vehicle control method. According to the hybrid electric vehicle control method, the operating mode of the whole vehicle is divided into a still mode, a starting mode, a constant-speed traveling mode, an acceleration / assisting mode, a deceleration / braking mode and a fuel cut-off mode. In the still mode, an engine is shut down, the speed ratio of a speed reducer reaches the maximum value, so that preparation is made for starting. In the starting mode, an ISG motor is used for driving the engine to start, so that the vehicle is started. In the constant-speed traveling mode, according to the SOC state of a battery and the speed of the vehicle, the vehicle travels at a constant low speed or a constant intermediate speed or a constant high speed, so that the engine runs in an economical area or a high-efficiency area. In the acceleration / assisting mode, the ISG motor supplies assisting power to the engine. In the deceleration / braking mode, the ISG motor is in the electricity generating state. In the fuel cut-off mode, fuel supply to the engine is cut off. According to the hybrid electric vehicle control method, the operating mode of the whole vehicle is detailed, the braking energy recovery function is achieved, fuel consumption of the whole vehicle is lowered, and emission is reduced.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

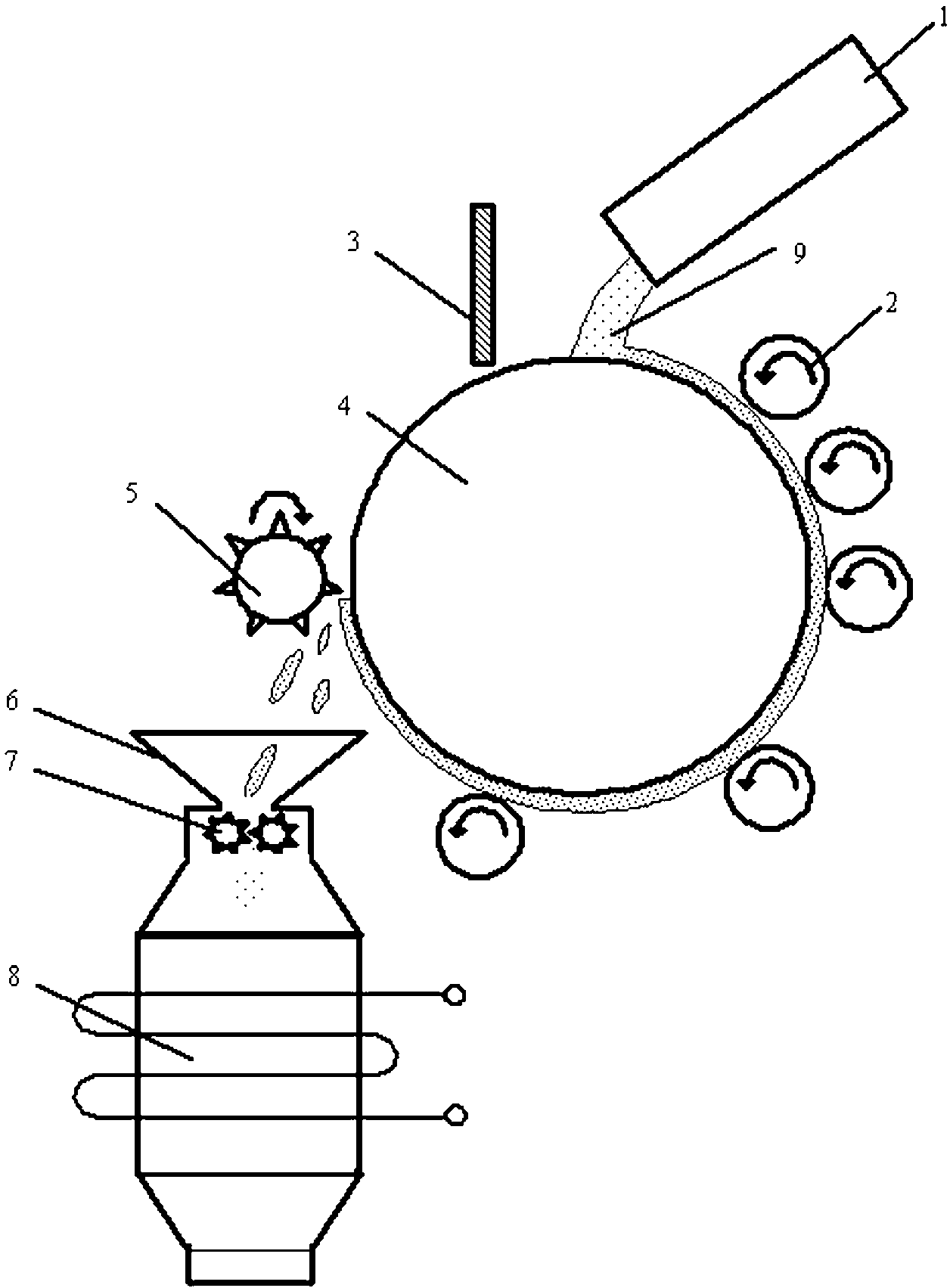

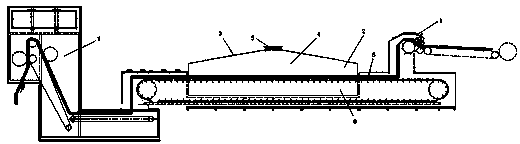

Device and method for quenching dry-method treatment and sensible heat recovery of high-temperature molten slag

ActiveCN103320553AEasily brokenReduce energy consumptionIncreasing energy efficiencyWaste heat treatmentCrusherMolten slag

The invention discloses a device and a method for quenching dry-method treatment slag and sensible heat recovery of high-temperature molten, wherein a slag stop plate, a slag guide groove, a cooling roll group and a slag removal roll in the device are sequentially arrayed on the outer surface of a rotary drum along the rotation direction of the rotary drum; a slag particle collector is arranged below the slag removal roll; a crusher is arranged on the lower part of the slag particle collector; a waste heat recovery device is arranged below the crusher. The method comprises the following steps of: placing the high-temperature molten slag on the surface of the rotating rotary drum via the slag guide groove; conveying the high-temperature molten slag to a space between the rotary drum and the cooling roll group by the rotary drum; extruding the high-temperature molten slag to be shaped like sheets, cooling and solidifying the high-temperature molten slag to form glass-body solid slag, and conveying the glass-body solid slag to the position of the slag removal roll; peeling the glass-body solid slag, and conveying the glass-body solid slag in the waste heat recovery device; dropping the glass-body solid slag in the crusher, and then forming particle slag after crushing; and then conveying the particle slag in the waste heat recovery device. The method disclosed by the invention has the characteristics of being simple to operate, suitable for industrialized production, capable of alleviating environmental pollution, low in process cost, and the like, as well as has a good application prospect.

Owner:NORTHEASTERN UNIV

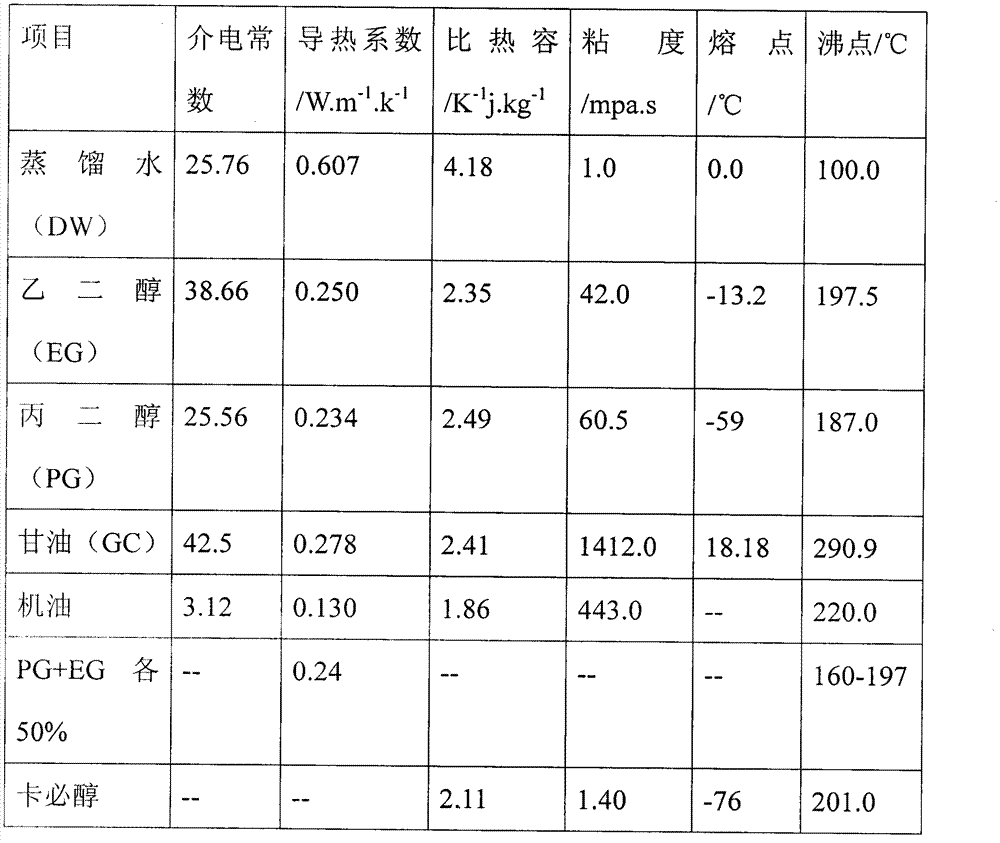

Nano long-acting liquid coolant

InactiveCN104263326AReliability benefitsHigh boiling pointHeat-exchange elementsFluorescenceCarbon nanotube

The invention discloses a nano long-acting liquid coolant. The nano long-acting liquid coolant comprises the following components of a base liquid which is composed of diatomic alcohol and a diluent, metal nanoparticles with a particle size of 3-100nm or carbon nano tube particles with a tube diameter of 8-100nm and length of 100-600nm, a dispersing agent, a corrosion inhibition additive, a pH regulator and a fluorescence colorant. The nano long-acting liquid disclosed by the invention is high in heat conductivity coefficient, good in heat transfer performance, good in liquidity and low in cost.

Owner:陈德全

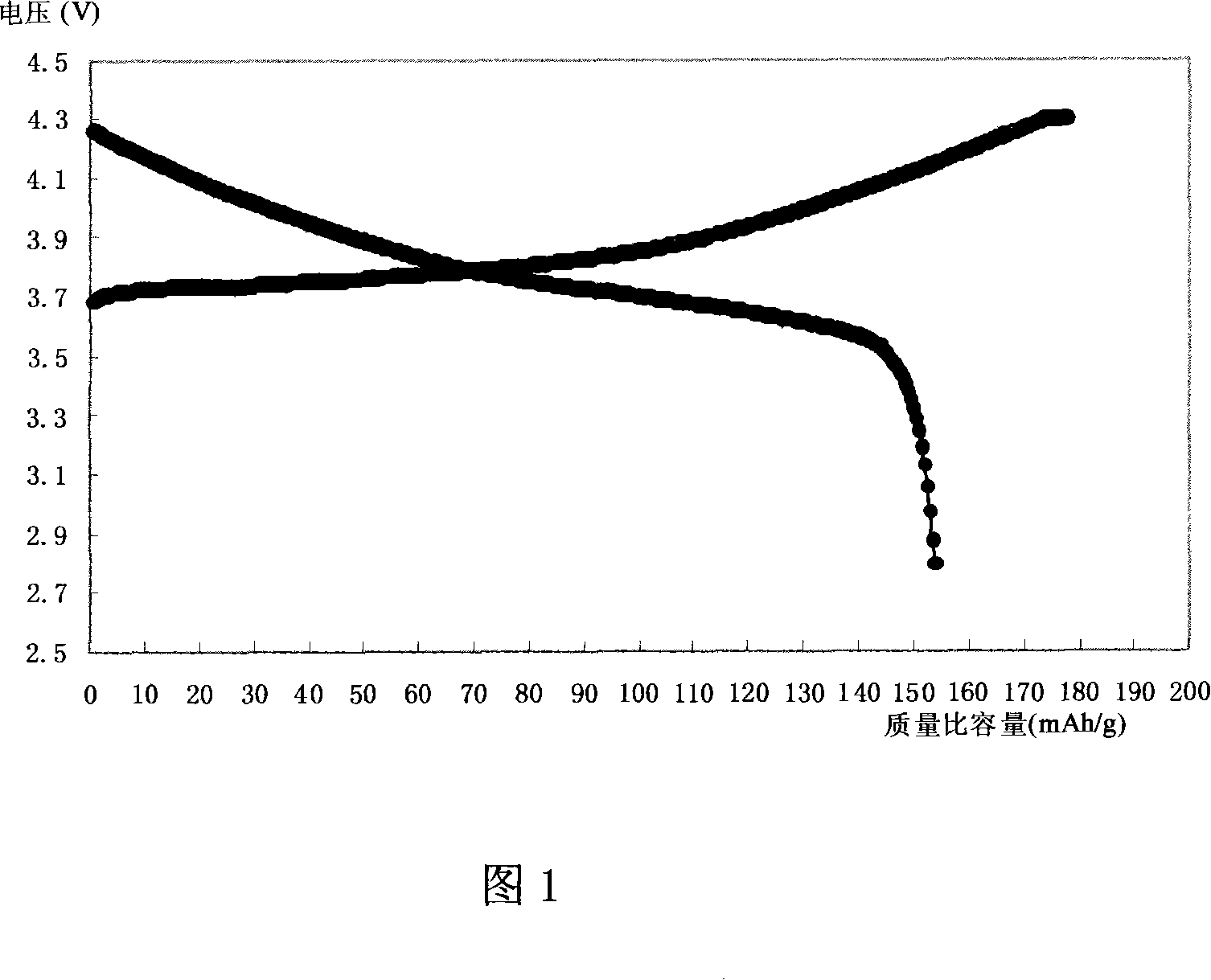

Method for preparation of high-density lithium ion battery anode material nickel cobalt manganic acid lithium

InactiveCN101226998AHigh tap densityQuality improvementElectrode manufacturing processesLithium compoundsManganeseNickel compounds

The invention discloses a method for preparing cathode material nickel cobalt manganese acid lithium of a high density lithium ion battery, which is characterized in that nickel compounds, cobalt compounds and manganic compounds are mixed and granulated in a heating rate of 3-10DEG C / m, a first sintering is done in a certain temperature and a certain time to obtain an oxide of an intermediate which is nickel, cobalt and manganese, the oxide is (Ni1 / 3Co1 / 3Mn1 / 3)3O4, then the oxide of the nickel, cobalt and manganese is evenly mixed with lithium compounds according to a certain radio in the hate rate of 3-10 DEG C / min, a second sintering is done in high temperature and a certain time, then sintering products are crashed and are graded in particle size, and thereby obtaining high density nickel cobalt manganese acid lithium. The invention has short production period, a large amount of water is not consumed during a production process, a large amount of waste water is not produced, and a synthetic product has the characteristics of high tap density and specific discharge capacity.

Owner:黄成钢

Catalytic aluminium internally electrolyzing process of treating sewage

InactiveCN1468810AEasy to handleHigh speedWater/sewage treatment by neutralisationElectrolysisSludge

The present invention relates to the treating process of sewage, and especially sewage with color and hard-to-degrade matter. Stuffing with aluminum, copper and cationic surfactant modified zeolite is used as catalyst is used in treating sewage. Aluminum replacing iron and copper constitute primary cell with high electromotive force, so that many heavy metal and organic pollutants can react on the electrode directly under oxygen-deficient condition. The aluminum and copper material used may be leftover from machining and the cationic surfactant modified zeolite is not expensive, so the present invention has low water treating cost. In addition, the process of the present invention has less sludge produced and the sludge has good deposition performance, so that the process of the present invention may be combined with catalytic iron internally electrolyzing process in treating sewage with color and hard-to-degrade matter.

Owner:TONGJI UNIV

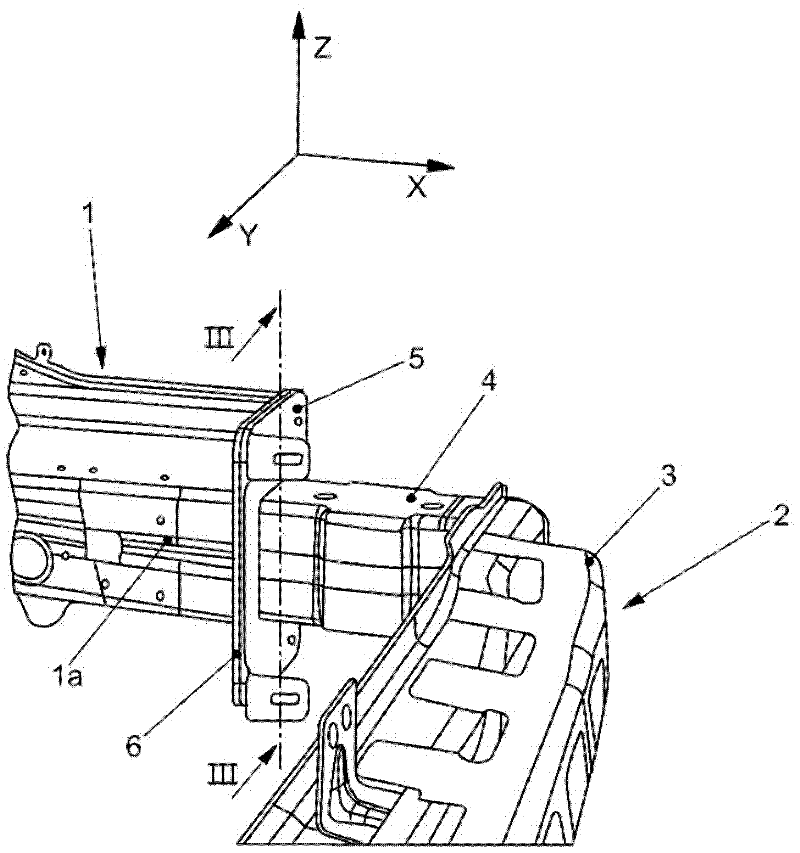

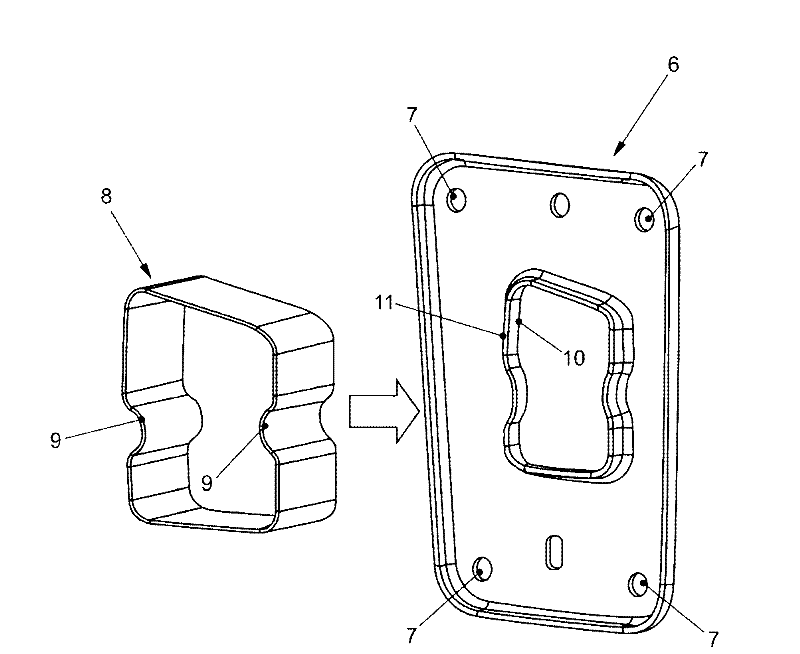

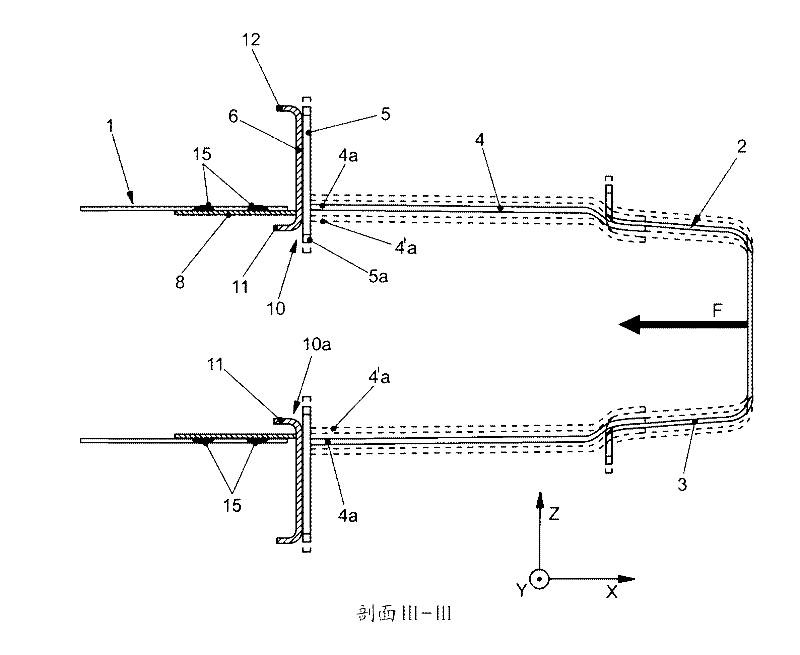

Vorrichtung, insbesondere am vorbau eines kraftfahrzeuges

ActiveCN102328695AHigh strengthAvoid deformationSuperstructure subunitsSuperstructure connectionsEngineering

Owner:VOLKSWAGEN AG

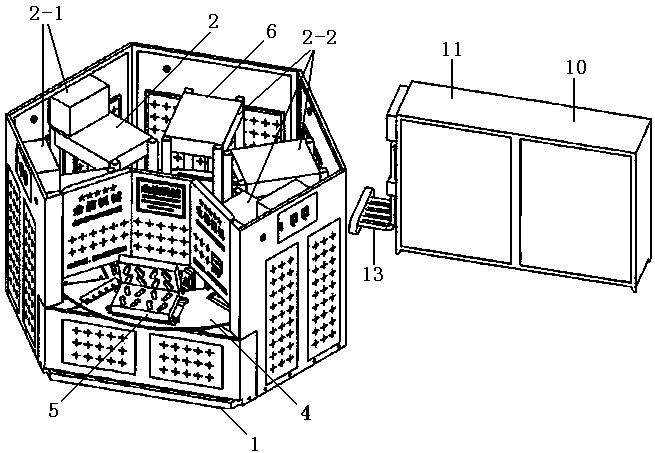

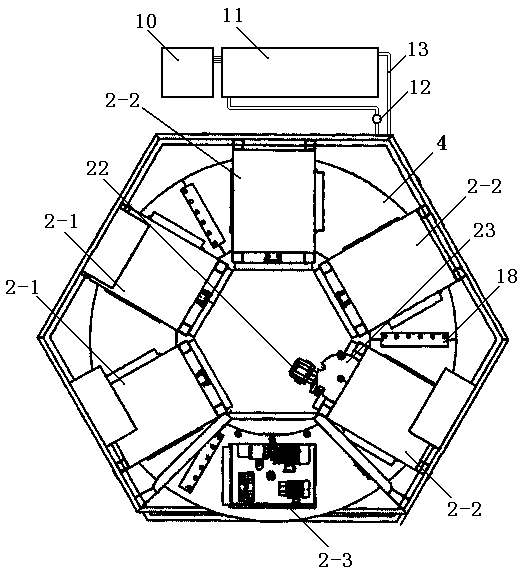

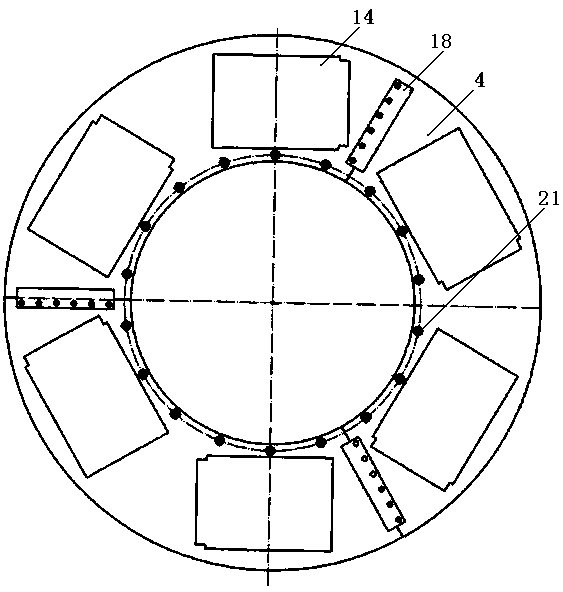

Full-automatic EVA secondary foaming disk molding machine

A full-automatic EVA secondary foaming disk molding machine belongs to the technical field of rubber and plastics machines and is composed of a mounting frame, mold stations, a cooling system, a heating plate, rotating disks, an intensive mold, a driving positioning assembly and a control system. The mounting frame is a hexagon planar structure and is a bearing frame of the molding machine. Each mold station is a vertical square framework with an upper cover plate and a bearing plate. There are six mold stations which comprise heating mold stations and cooling mold stations and are respectively installed at the middle position of each straight edge of the mounting frame. The cooling system is a sealed inner loop heat exchange system with a refrigerating machine as a cold source. The rotating disks are a combined disk structure and installed on the bearing plate in the square framework of each mold station. The intensive mold is an open structure for holding multiple product models. Thecontrol system controls the molding machine to automatically operate according to preset program parameters. Output of the molding machine and the intensive mold which fits with the mold stations is2 times and above greater than output of traditional equipment, but unit energy consumption of the invention is only 50-60% of unit energy consumption of traditional equipment.

Owner:晋江全信机械有限公司

Wood-plastic composite material prepared from waste and old plastic mixer and preparation method thereof

The invention relates to a wood-plastic composite material which is prepared by waste-old plastic mixture and a process for preparation, which relates to a wood-plastic composite material and a process for preparation. The invention solves the problems that the mechanical properties of the wood-plastic composite material which is prepared by the existing waste-old plastic mixture are bad and the like. The wood-plastic composite material is prepared by wooden fiber material, modified waste-old plastic blend and lubricating agent. the process for preparing comprises preparing modified waste-oldplastic blend, and then mixing the wooden fiber material, the modified waste-old plastic blend and the lubricating agent, and further adopting a continuous extrusion modeling technique, at last, getting wood-plastic composite material. Compared with the prior art, the bending strength of the wood-plastic composite material of the invention is improved by 30%-60%, and the impact strength is improved by 58%-140%. The process for preparing the wood-plastic composite material of the invention not only has simple technique and high production efficiency, but also reinforces the interface combination of the modified waste-old plastic blend and wooden fiber material, and the invention improves the mechanical properties of wood-plastic composite material.

Owner:广东海鹏竹材研究开发有限公司

Preparation method of mesoporous silica

The invention discloses a preparation method of mesoporous silica, which comprises the following steps of (1) breaking and sieving raw materials containing amorphous silica, (2) soaking the broken and sieved raw materials with an inorganic acid solution, filtering, and separating filter residues from acid liquid, (3) adding the filter residues into a sodium carbonate solution or a potassium carbonate solution, heating, stirring for reaction for 1-8h, and filtering, (4) adding a structure-directing agent into a filtrate, (5) stirring, ageing, filtering, returning the filtrate to Step (1) for recycling, and conducting vacuum drying on a filter cake, and (6) sending the dried filter cake into a muffle furnace, conducting temperature programming under nitrogen protection, removing the structure-directing agent or sending into a microwave digestion device for digestion, and removing the structure-directing agent. According to the preparation method, as the raw materials containing amorphous silica are directly adopted as a silicon source for producing mesoporous silica and an alkali solution is recycled, the reaction time is shortened, and the production cost of mesoporous silica is greatly lowered.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

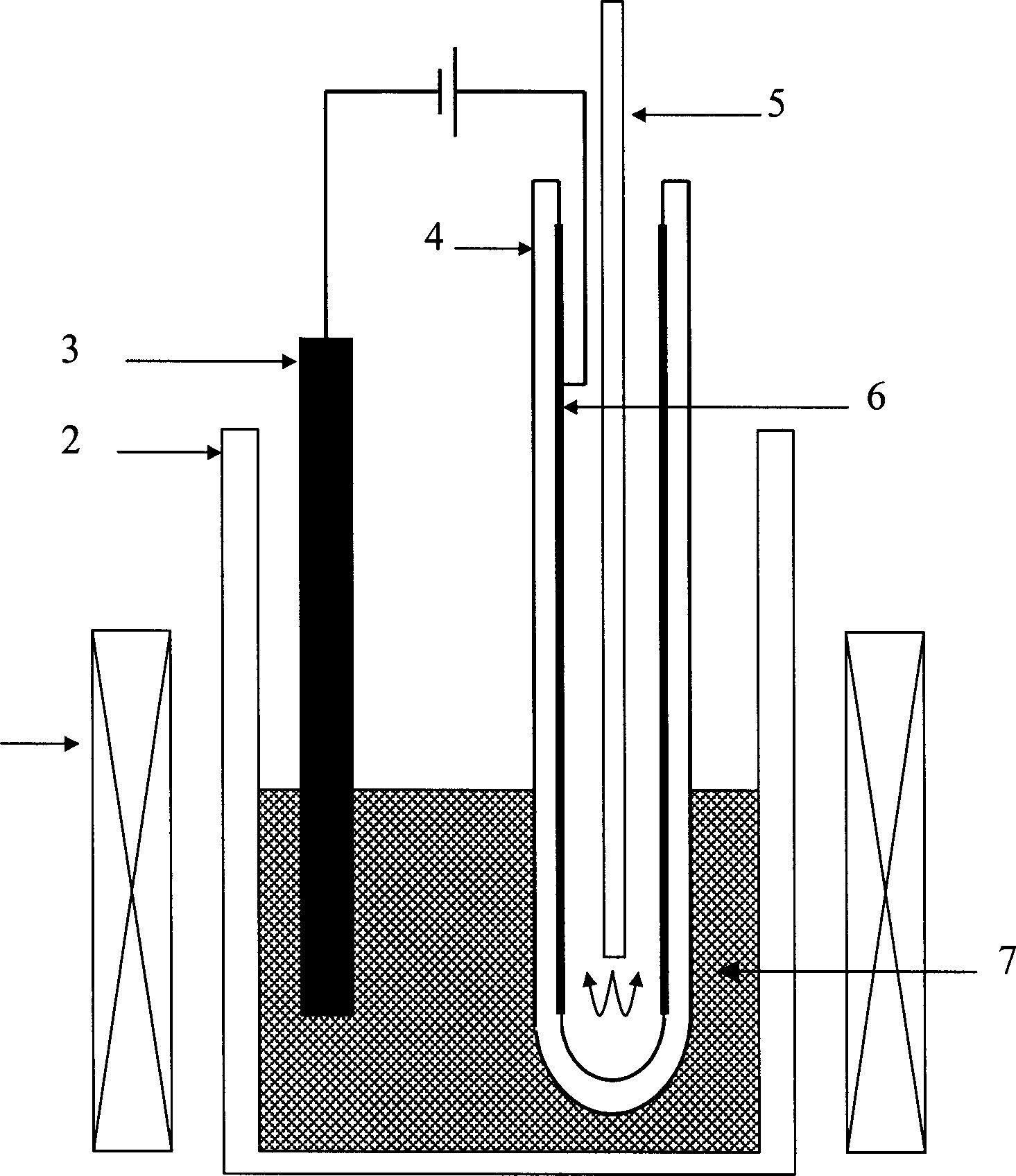

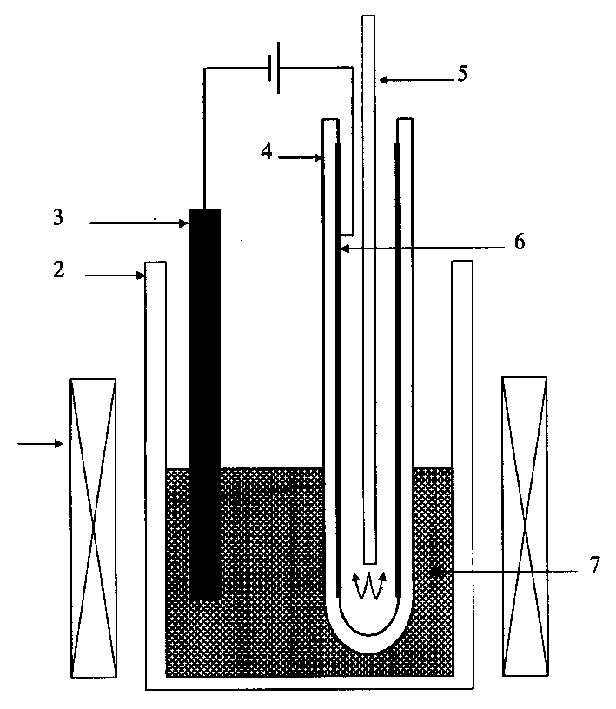

Process for preparing titanium sponge from titanium oxide composite ore

The present invention relates to a method for preparing spongy titanium by using titanium oxide composite ore, and said method includes the following steps: firstly, liquating the composite ore raw material containing titanium dioxide is a selected molten-salt system under the condition of 1000-1100 deg.C, then inserting the graphite cathode and tubular solid oxygen permeable membrane whose internal surface is covered with a porous metal ceramic coating layer as anode into the above-mentioned mixed molten-salt in a heating container or crucible together, and introducing hydrogen gas in the high-temp. ceramic pipe of anode end to make electrolysis under the action of a certain voltage and current of D.C. power supply, and finally obtaining metal titanium on the cathode end.

Owner:SHANGHAI UNIV +1

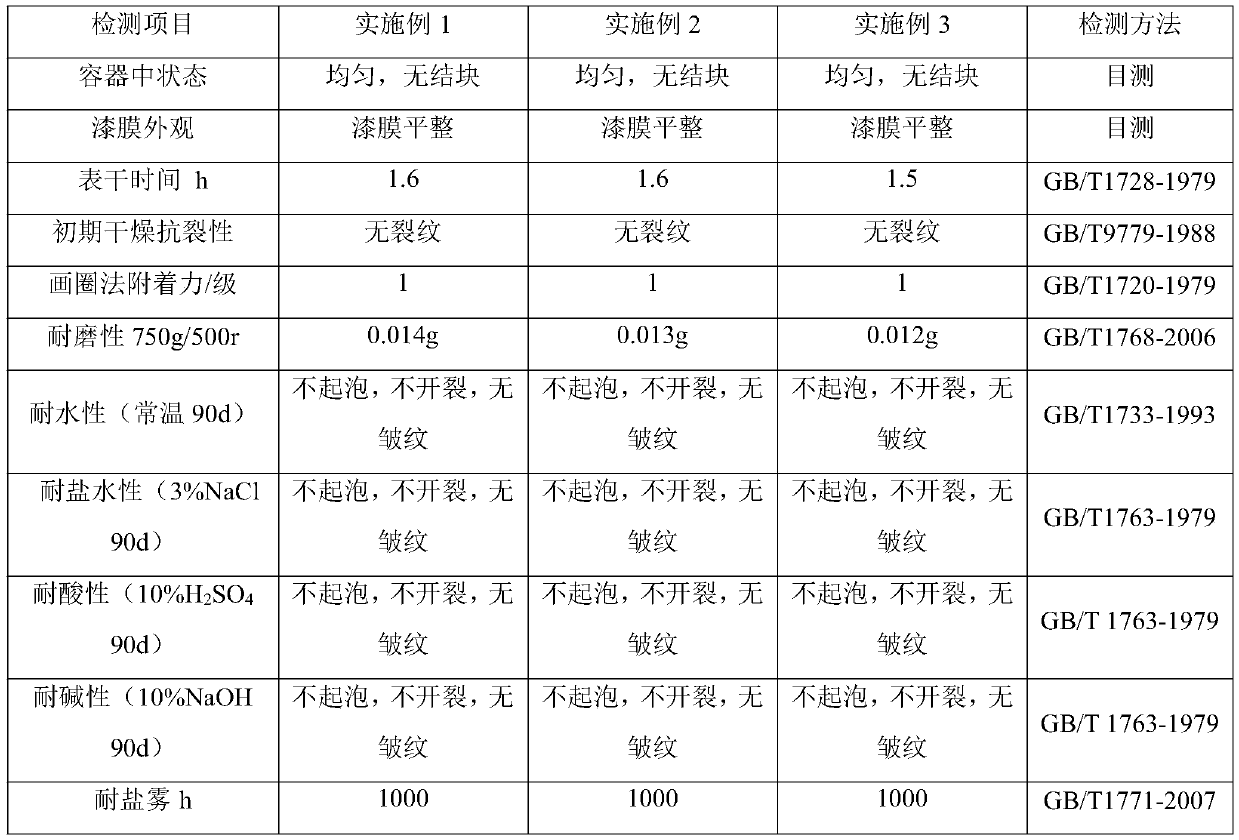

Steel structure anti-corrosion coating

ActiveCN110218504AAvoid reunionFull exposure to lightAntifouling/underwater paintsPaints with biocidesEpoxyMaterials science

The invention discloses a steel structure anti-corrosion coating and a preparation method thereof. The steel structure anti-corrosion coating is prepared from a component A and a component B in a weight ratio of 5:2 through mixing, wherein the component A is prepared from the following components in parts by weight: 25-55 parts of an epoxy resin mixture, 15-20 parts of composite nano powder, 5-10parts of modified graphene oxide, 5-18 parts of a filler, 5-10 parts of a dispersant, 0.4-0.6 part of a wetting agent, 0.8-1.2 parts of a thickening agent and 0.2-0.3 part of an anti-sinking agent. The coating disclosed by the invention adopts an aqueous epoxy resin as a matrix, modified nano composite powder and modified graphene oxide as additives are good in dispersibility in the matrix, and the coating layer of the coating has capabilities of photocathode protection and non-metal protection, has an excellent long-lasting comprehensive anti-corrosion capability and in addition has a capability of self cleaning.

Owner:沈阳市金海韵涂料有限公司

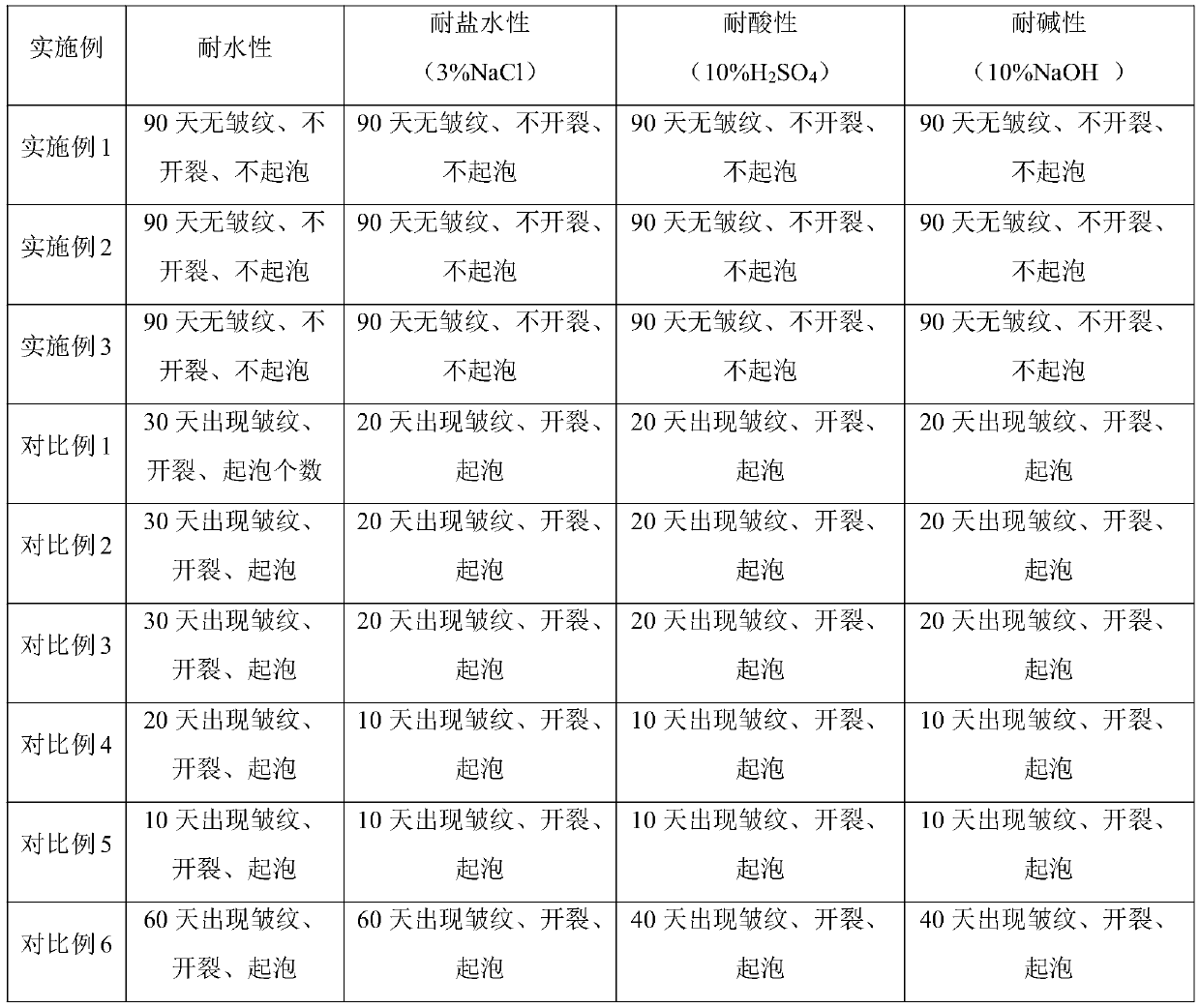

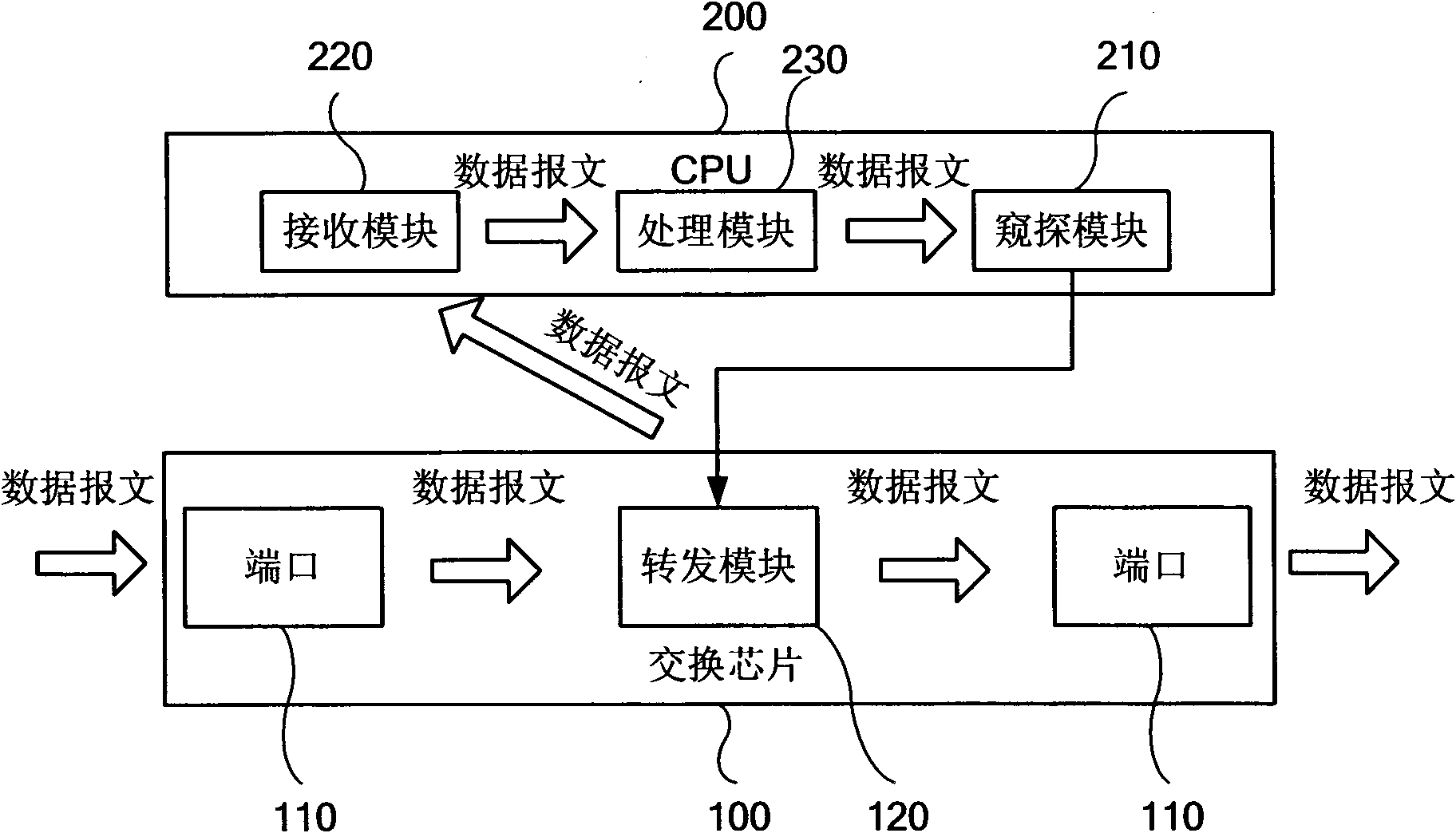

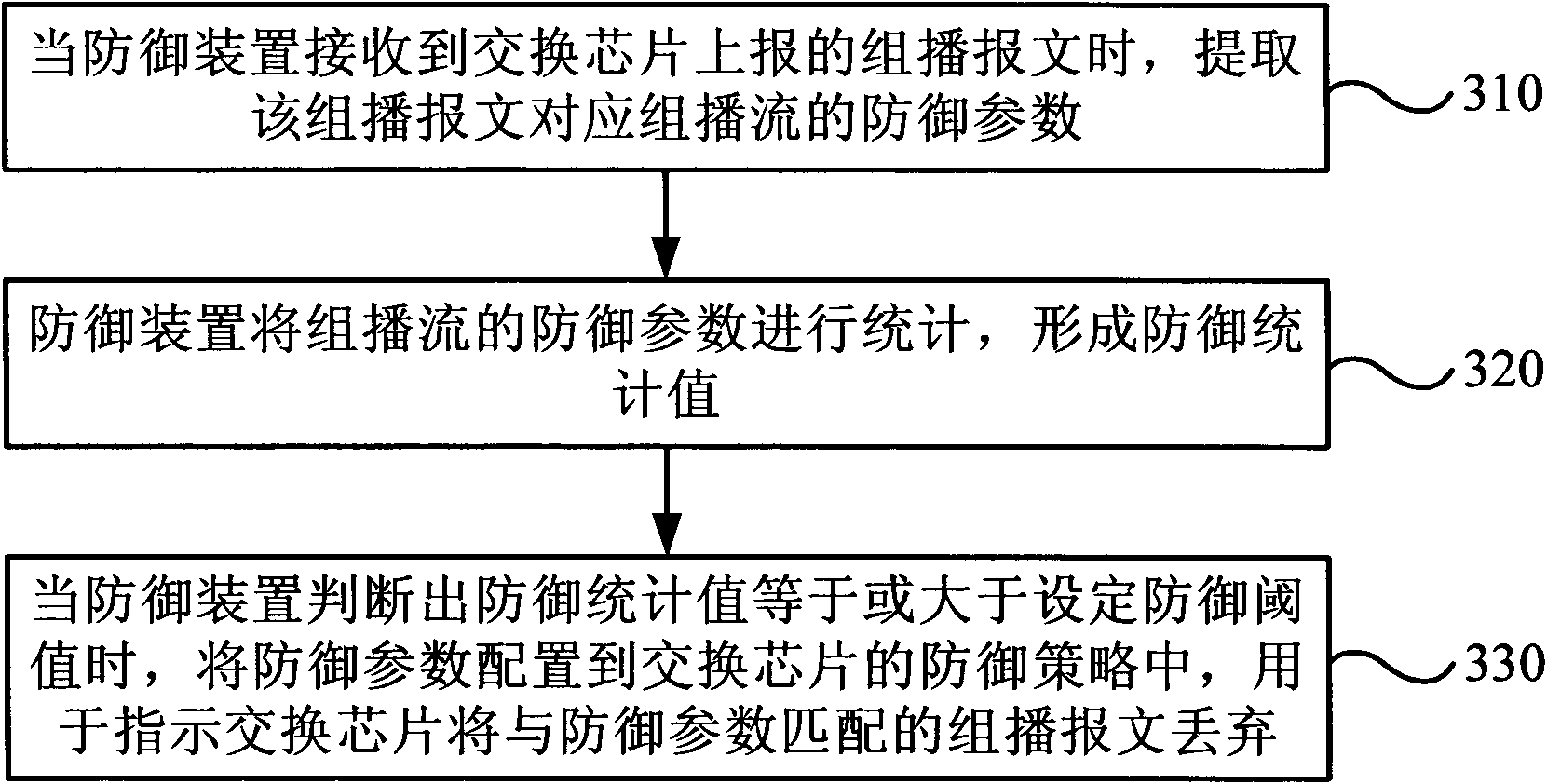

Multicast message processing method and device and equipment

InactiveCN101883054AReduce shockProtect normal operationSpecial service provision for substationMulticast messageReal-time computing

The invention discloses a multicast message processing method, a multicast message processing device and multicast message processing equipment. The method comprises the following steps that: when receiving a multicast message reported by an exchange chip, a defense device extracts defense parameters of a multicast flow corresponding to the multicast message; the defense device counts the defenseparameters of the multicast flow to generate a defense statistic value; and when judging that the defense statistic value is equal to or more than a set defense threshold value, the defense device configures the defense parameters into a defense strategy of the exchange chip, wherein the defense strategy is used for instructing the exchange chip to discard the multicast message which is matched with the defense parameters. In the invention, dynamic statistics and analysis are adopted and the customized defense strategy is carried out to deal with the corresponding defense parameters, so a multicast table entry resource is effectively protected from occupation by an attack multicast flow on the basis of guaranteeing the normal multicast flow forwarding as much as possible, the too much consumption of a CPU processing resource by the attack multicast flow is avoided, and the too much consumption of the hardware source of the exchange core is also avoided due to the fact that the defensestrategy is dynamically configured in the exchange chip.

Owner:BEIJING XINWANG RUIJIE NETWORK TECH CO LTD

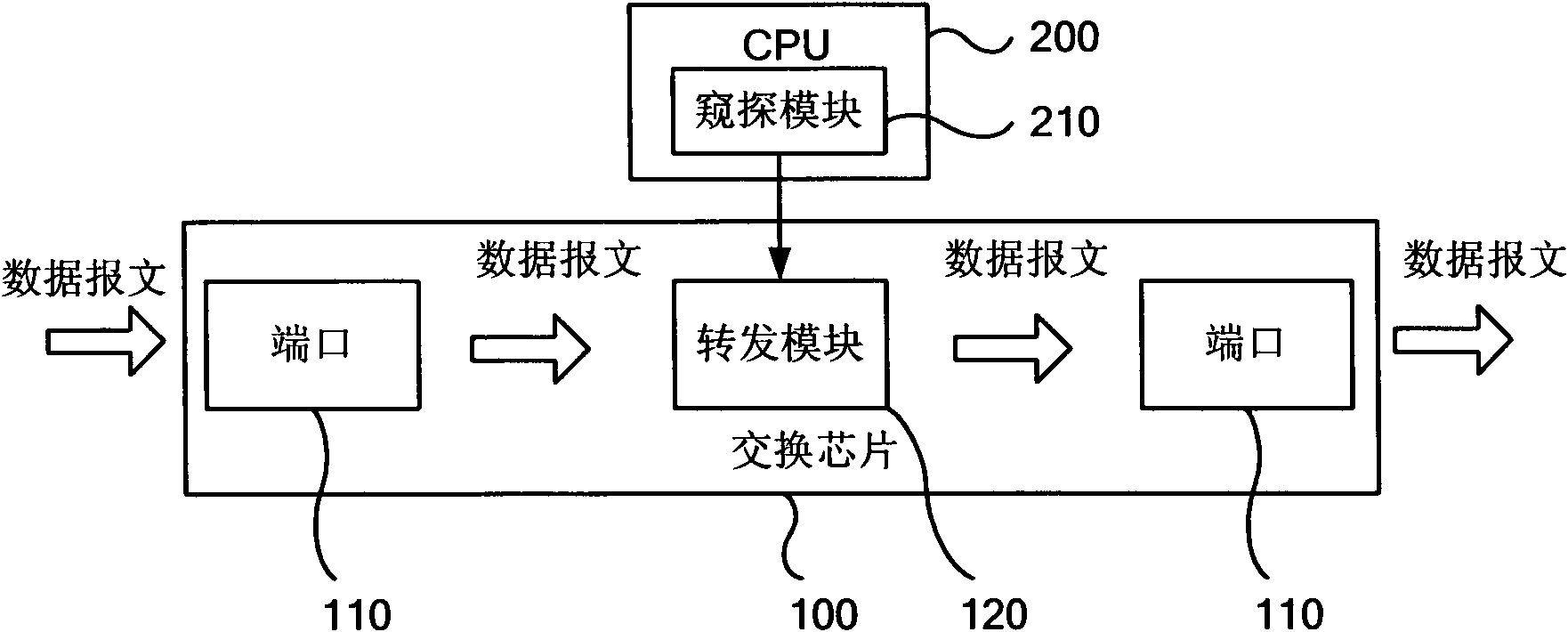

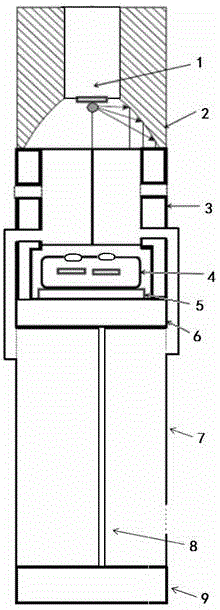

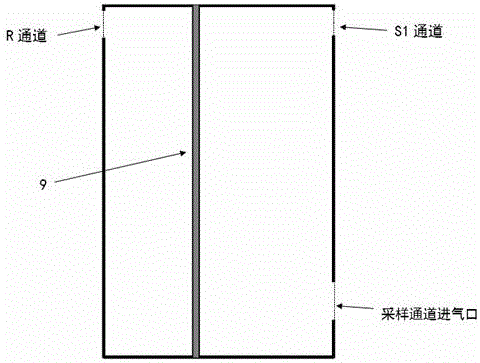

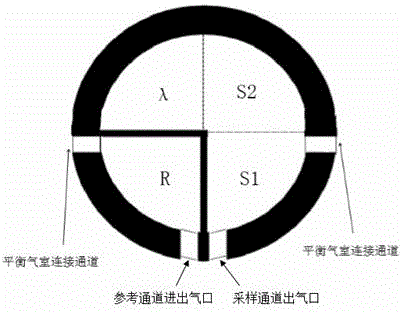

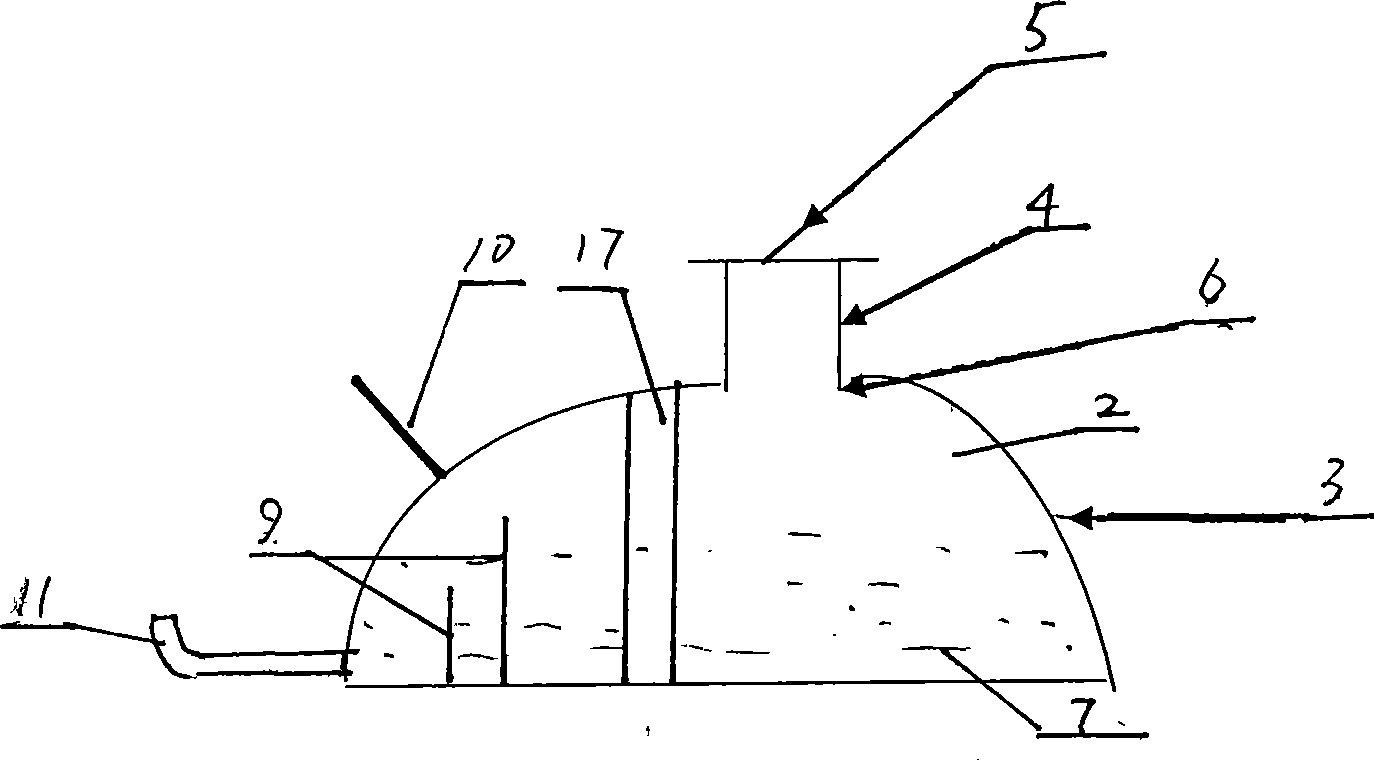

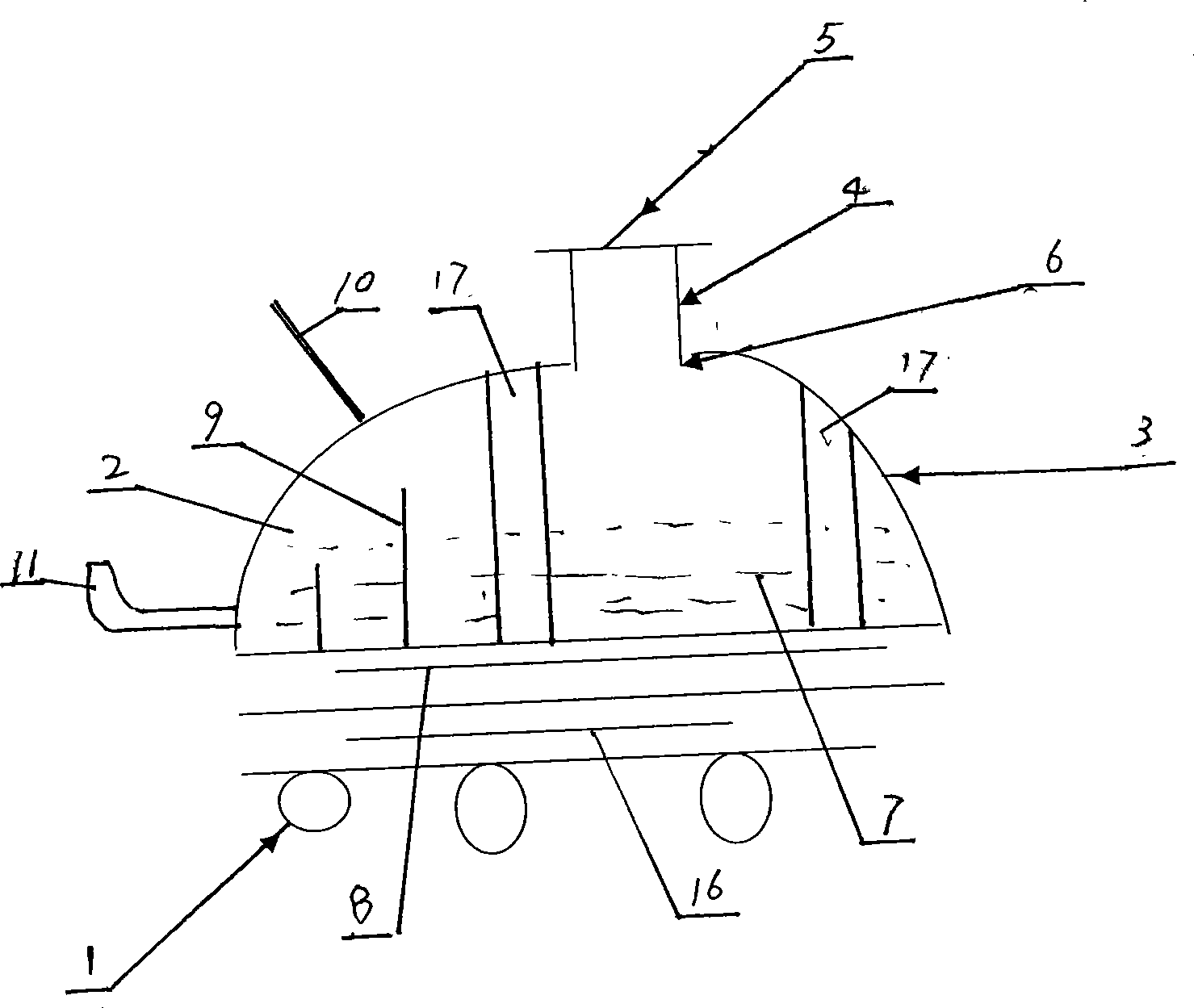

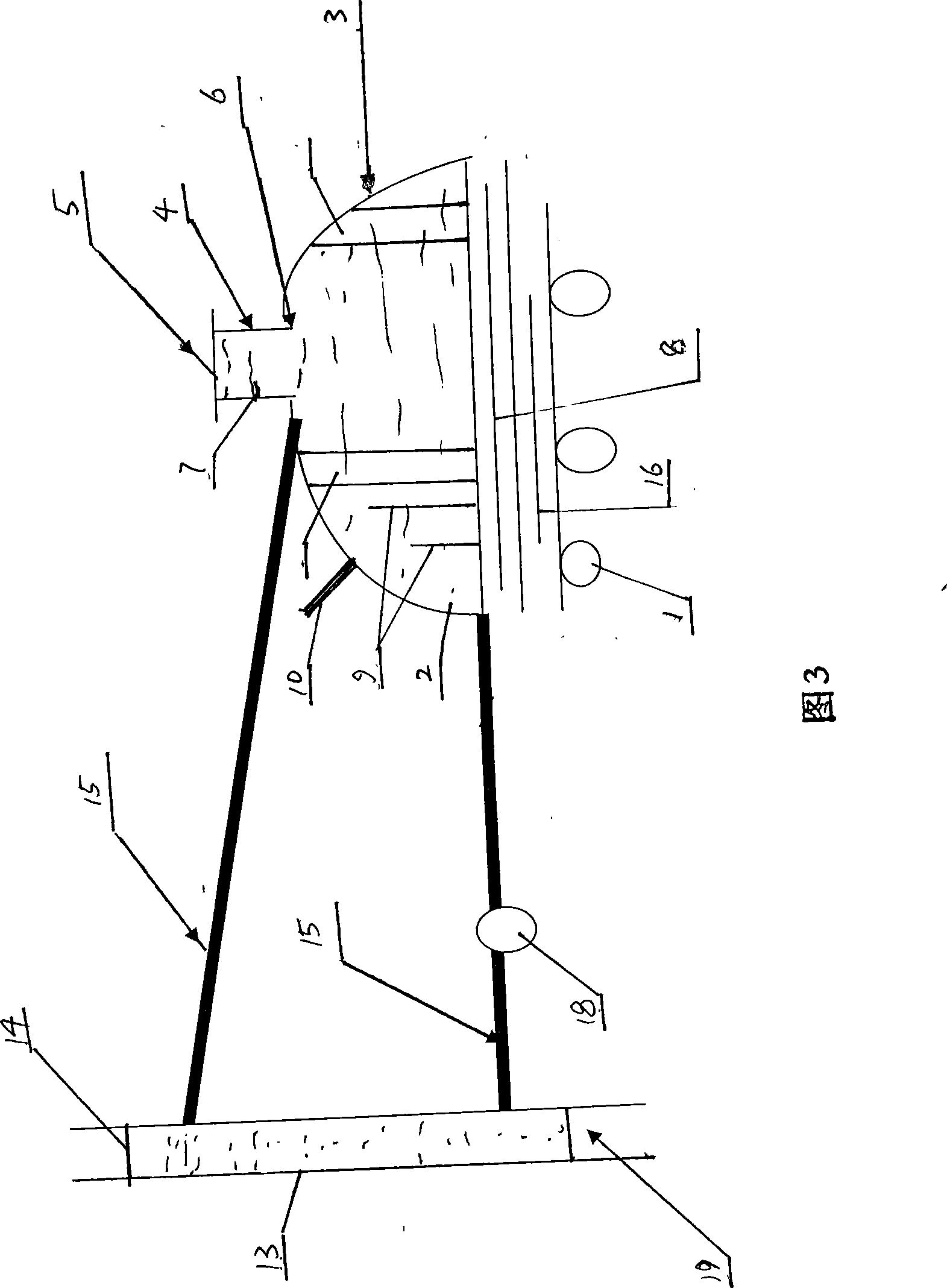

Temperature and pressure automatically-balanced spectrograph device and method for measuring oil and gas components while drilling

PendingCN105971582AReduce flicker noiseFast analysisSurveyMaterial analysis by optical meansComponents of crude oilOperation safety

The invention relates to a temperature and pressure automatically-balanced spectrograph device and method for measuring oil and gas components while drilling. The device comprises a parabolic reflector for collimating a light source and is characterized in that a sampling air chamber, a reference air chamber, a detector with four independent thermoelectricity units and temperature sensors, and a balance air chamber capable of automatically balancing the pressure of the reference air chamber and the pressure of the sampling air chamber are sequentially arranged below the reflector. A sliding piston is arranged in the balance air chamber. The device has the advantages that the analysis speed is high, and an analysis task can be completed within 5 s; the analysis cost is low, and no sample is consumed in the analysis process; real-time online analysis can be carried out, a detection analysis result can be transmitted to the ground in real time, the practical value is huge, and oil and gas field detection efficiency is improved; hydrogen sulfide qualitative detection is achieved besides oil and gas detection, the operation safety is increased, and the device is resistance to high pressure and temperature, small in size, low in power consumption and capable of being conveniently integrated into the equipment operated during drilling.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Modified activated carbon for removing formaldehyde and preparation method of modified activated carbon

InactiveCN107175074AImprove adsorption capacityExtend the life cycleGas treatmentPhysical/chemical process catalystsActivated carbonTrapping

The invention discloses modified activated carbon for removing formaldehyde and a preparation method of the modified activated carbon. According to the preparation method of the modified activated carbon, 5-10 parts of ultrafine particle titanium dioxide, 3-5 parts of nano silicon dioxide, 4-6 parts of a formaldehyde trapping agent and 0.5-1 part of a dispersant are added to water at the temperature of 60-80 DEG C and stirred for 5 min, 100 parts of activated carbon and 10-20 parts of a bonding agent are added, the obtained mixture is soaked for 3-4 hours and then dried at 80-100 DEG C for 1-2 hours, and a crude sample is taken out; the crude sample is air-dried; the air-dried crude sample is sieved with a 90-mesh sieve, and a product is obtained; a photocatalyst is supported on activated carbon and catalyzes and degrades formaldehyde on the activated carbon under the illumination condition, carbon dioxide and water are produced, secondary pollution of formaldehyde is avoided, the adsorption effect of the activated carbon is enhanced, and the life cycle of the activated carbon is prolonged.

Owner:HENAN XICHAO IND CO LTD

Heat radiation method for LED module

InactiveCN101418948AExtended service lifeMake up for lack of heat dissipationPoint-like light sourceSemiconductor/solid-state device detailsTemperature controlComputer module

The invention relates to a radiating method for an LED module, which is characterized in that an LED luminous component contacts the outer wall of a perfusion sealed container closely; the perfusion sealed container consists of a primary tank, a pipe nipple, and a cover, which are encircled by a heat conduction material, wherein the outer wall of the primary tank is provided with a connector, the primary tank is communicated with the pipe nipple through the connector, and the top of the pipe nipple is covered by the cover; and the primary tank is filled with water. Moreover, the method comprises the following steps: A. the amount of heat of the LED luminous component is transmitted into the water in the perfusion sealed container, and is stored by the water; and B. the amount of heat is removed through dissipation of the outer wall of the perfusion sealed container. The method has the advantages that the method has reasonable design, makes the best use of the greater specific heat and heat accumulation function of the water through a water tank for radiating, can fully control the temperature of the LED luminous component in a required temperature range, remedy the dissipation defect of a fin, and prolong the service life of the LED luminous component.

Owner:陈玉新

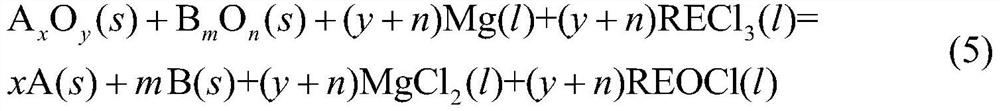

Method for preparing metal alloy powder through magnesiothermic reduction

The invention provides a method for preparing metal alloy powder by magnesiothermic reduction. The method comprises the following steps: preparing a mixed molten salt which at least comprises Mg and RECl3; preparing a mixed metal oxide precursor, wherein mixed metal oxides comprise two or more of titanium oxide, vanadium oxide, chromium oxide, zirconium oxide, hafnium oxide, tantalum oxide, niobium oxide, molybdenum oxide and tungsten oxide; and adding the mixed metal oxide precursor into the mixed molten salt, and carrying out heating until the reaction is finished to obtain the metal alloy powder. According to the method, the rare earth chloride RECl3 is added into the molten salt, and after the rare earth chloride RECl3 participates in the reaction, the oxygen content in the reduction product metal alloy powder can be reduced to 500 ppm or below.

Owner:KUNMING UNIV OF SCI & TECH

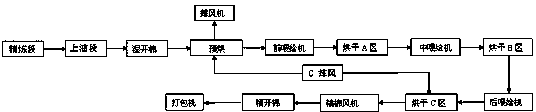

High-capacity viscose staple fiber post-treatment production line

InactiveCN103422290AIncrease washing timeWash Time GuaranteeSucessive textile treatmentsLiquid/gas/vapor removalProduction lineSingle process

The invention aims at providing a high-capacity viscose staple fiber post-treatment production line in order to reach the annual yield of 100 thousand tons. The production line comprises a refining system and a drying system. A refiner in the refining system comprises a refining section and an oiling section. The high-capacity viscose staple fiber post-treatment production line is characterized in that the breadth of the refiner of the refining system is 4000mm, the refining section is divided into 13-18 process areas, the oiling section is divided into 2 process areas and the length of a single process area is 2500mm. The viscose staple fiber post-treatment production line comprises the refining system and the drying system, and has the advantages that the production capacity is strong, the operation stability is high, the automation level is high and the product quality is guaranteed.

Owner:YIBIN GRACE +2

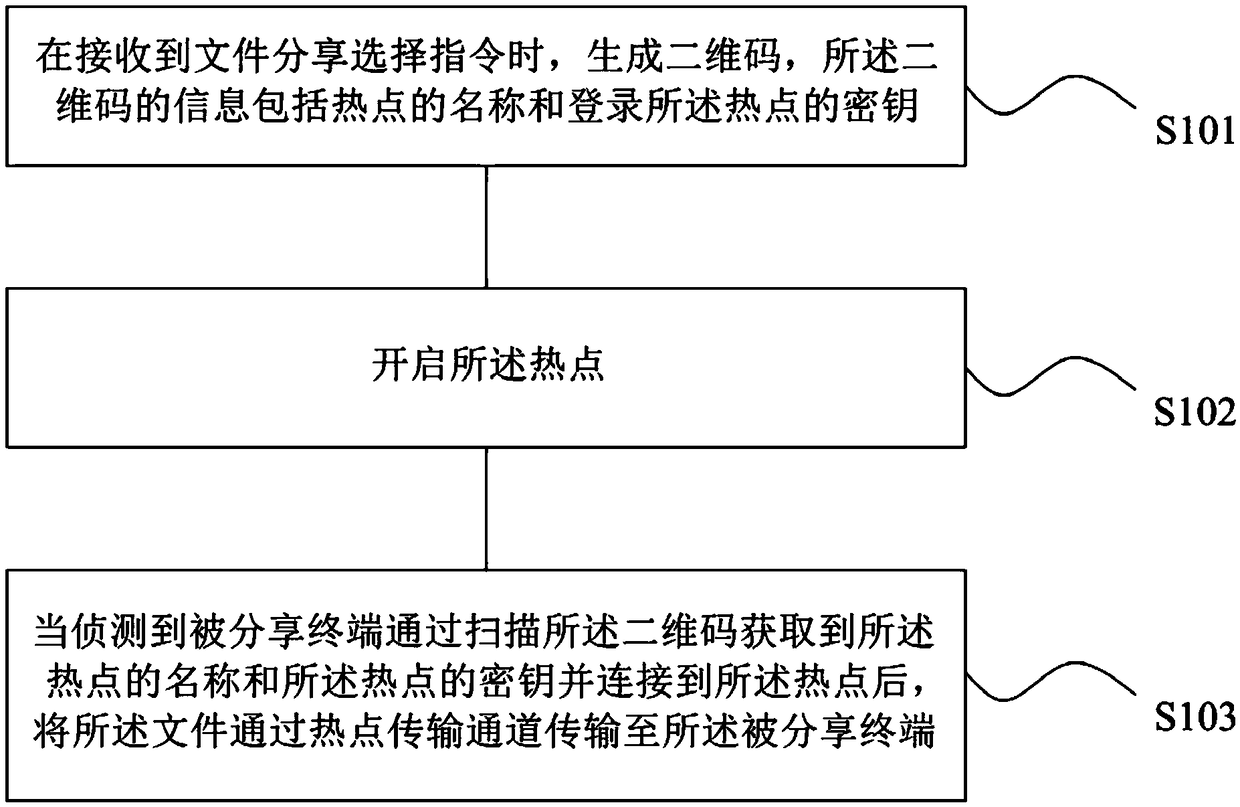

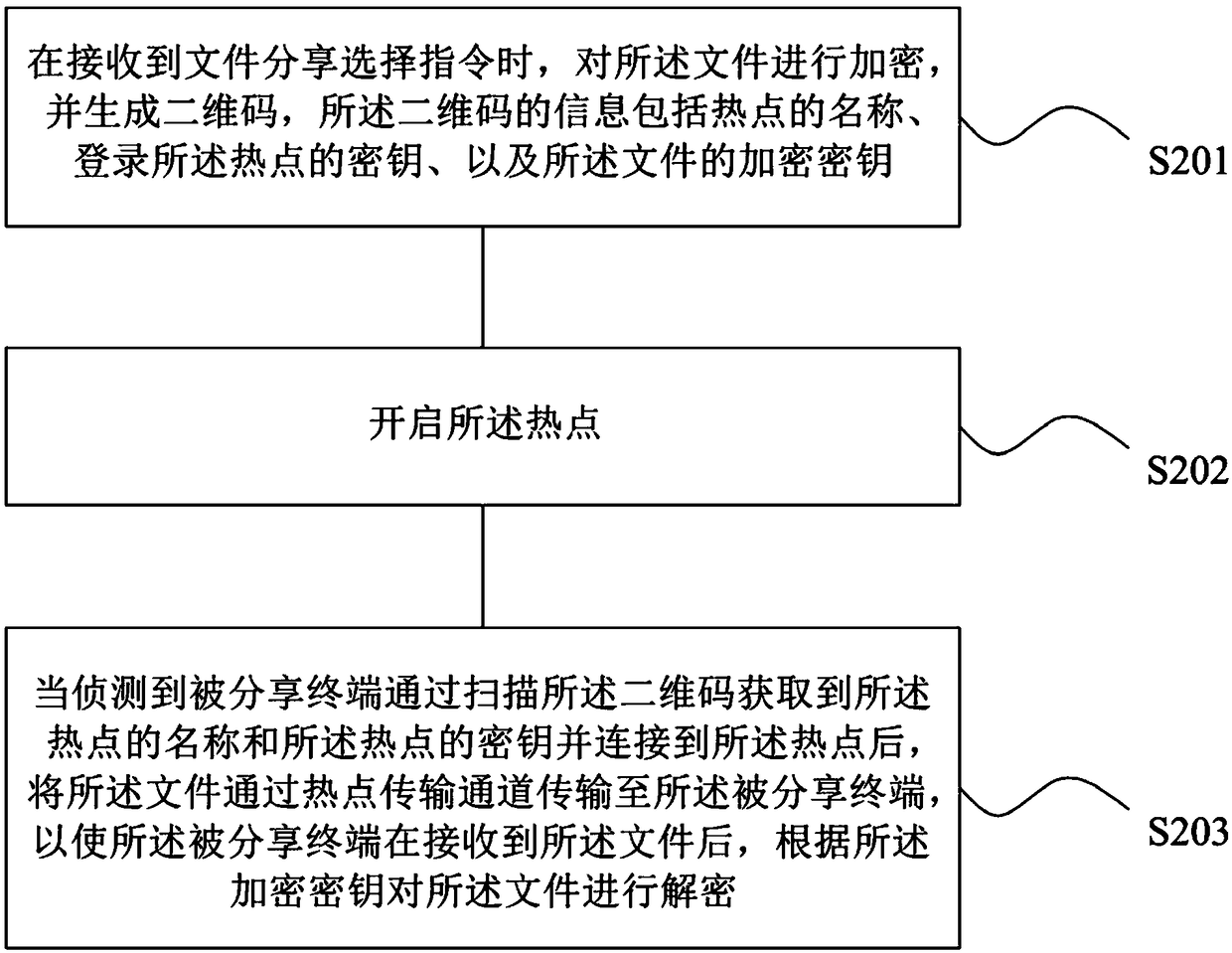

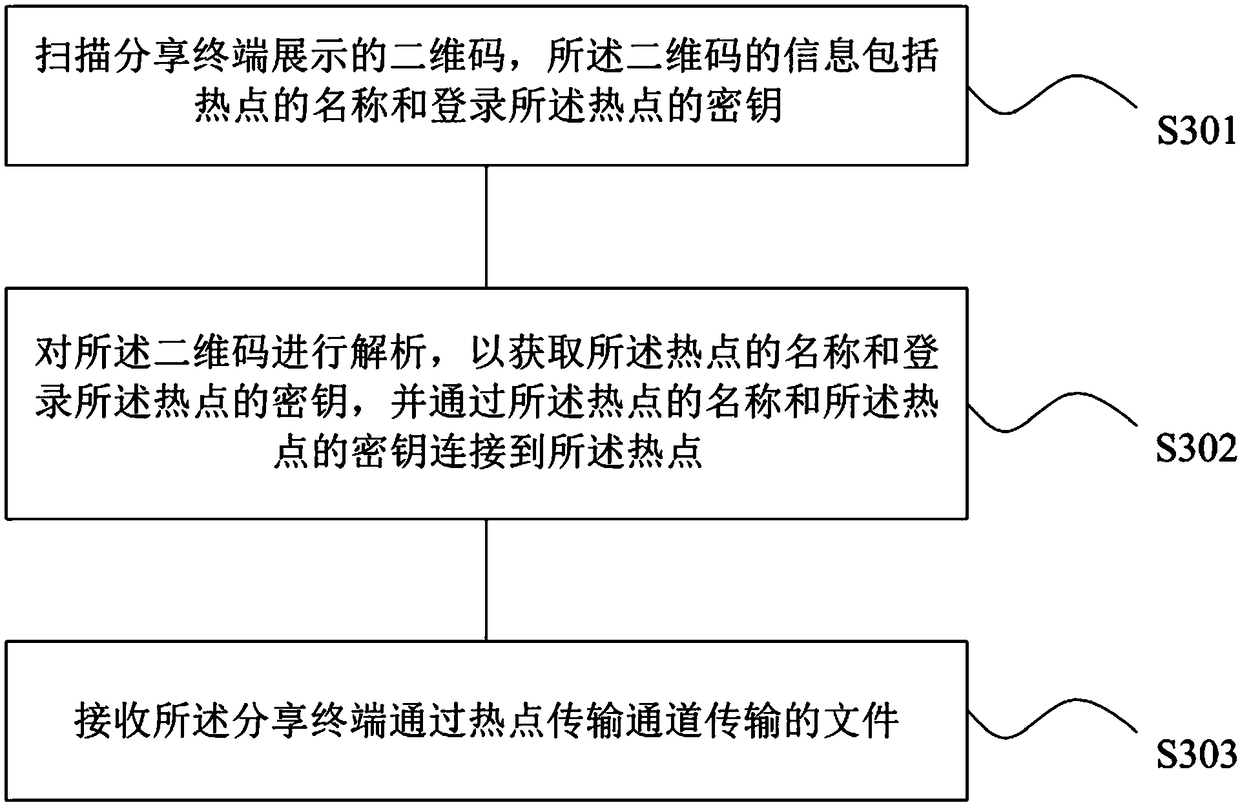

File sharing method and device, readable storage medium and mobile terminal

InactiveCN108966313AQuick sharePrivacy protectionAssess restrictionConnection managementComputer hardwareTransmission channel

The invention discloses a file sharing method and device, a readable storage medium and a mobile terminal. The method is applied to a sharing terminal, and the method comprises a step of generating atwo-dimensional code when receiving a file sharing selection instruction, wherein the information of the two-dimensional code includes the name of a hotspot and a key for logging in the hotspot, a step of turning on the hotspot, a step of transmitting a file to a shared terminal through a hotspot transmission channel when a condition that the shared terminal obtains the name and the key of the hotspot through scanning the two-dimensional code and accesses the hotspot is detected. According to the invention, the problems of flow consumption, low transmission speed and complicated operation of file sharing can be solved.

Owner:QIKU INTERNET TECH SHENZHEN CO LTD

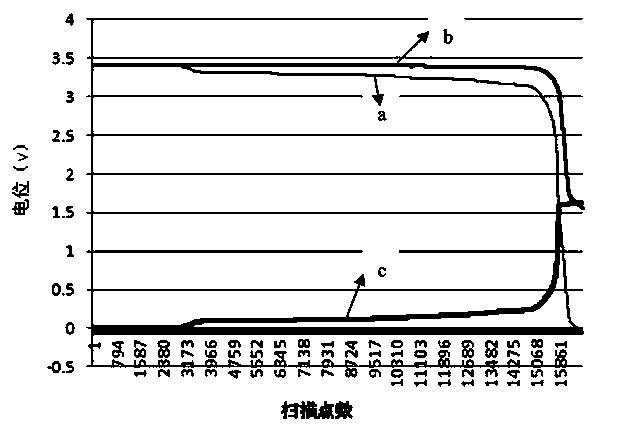

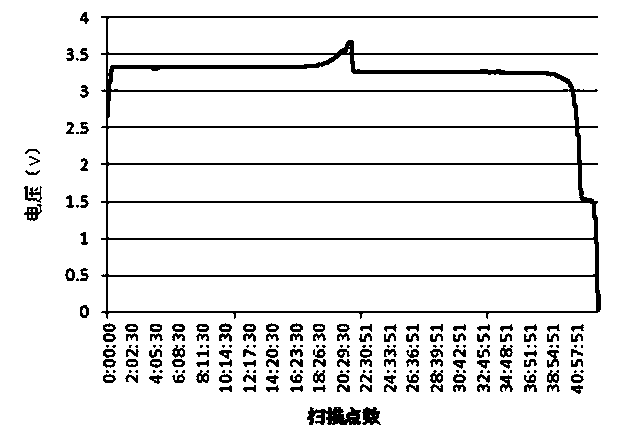

Lithium ion battery

ActiveCN103700880AExcellent anti-over-discharge abilityImprove performanceCell electrodesSecondary cellsLithium iron phosphateAlloy

The invention provides a lithium ion battery. The lithium ion battery comprises a shell, and an electrode group and an electrolyte which are sealed in the shell, the electrode group comprises a positive electrode, a negative electrode and a diaphragm positioned between the positive electrode and the negative electrode, a positive material layer comprises a lithium iron phosphate positive active material, iron phosphate, a conductive agent and a positive binder; the smallest particle size of the iron phosphate is not lower than 20mum; a negative material layer comprises a negative active material layer, and the negative active material layer comprises lithium and / or a lithium alloy, a negative active material and a negative binder; or the negative material layer comprises the negative active material layer and lithium and / or the lithium alloy adhered to the negative active material layer, and the negative active material layer comprises the negative active material and the negative binder; and the negative active material comprises graphite and lithium titanate. The over-discharge resistance capability of the lithium ion battery made in the invention is excellent.

Owner:BYD CO LTD

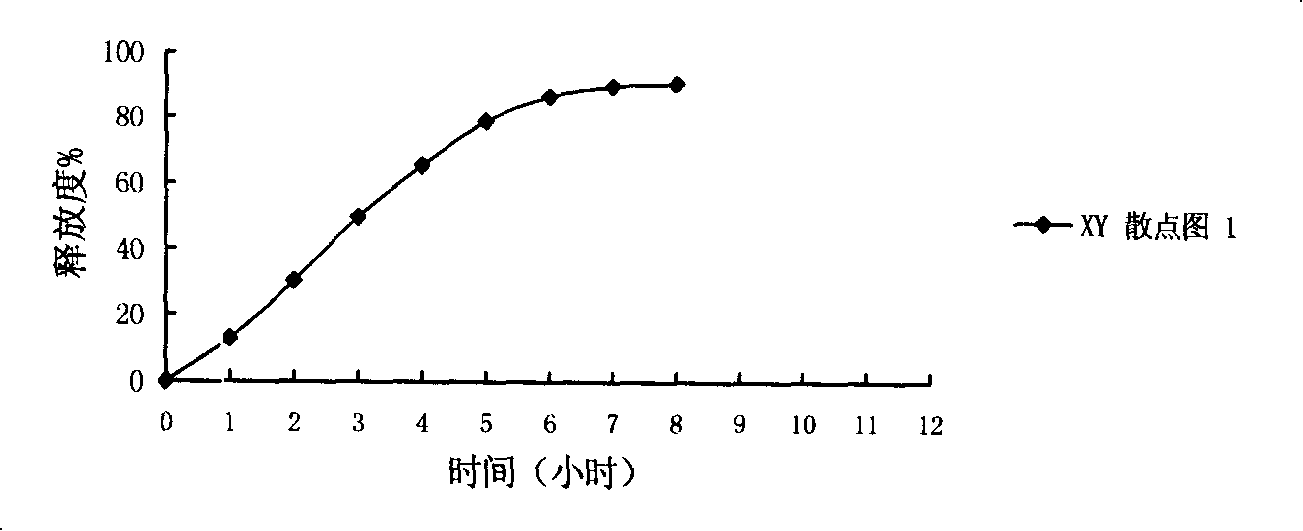

Alkaline drug enteric preparation and preparation method thereof

InactiveCN101190185ADoes not affect normal digestion and absorption functionAvoid discomfortDigestive systemPharmaceutical non-active ingredientsDiseaseMetabolic acidosis

Owner:李大鹏

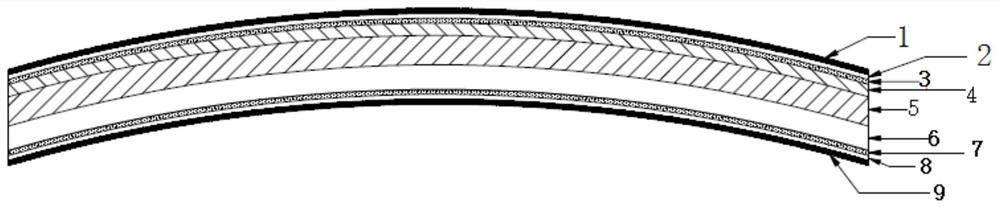

Spectacle lens comprising visible light cured color-changing coating layer

ActiveCN112239624AWith reversible color changing functionAdapt to use requirementsPolyurea/polyurethane coatingsOptical partsOligomerAcrylate ester

The invention relates to a spectacle lens comprising a visible light cured color-changing coating layer. The spectacle lens is provided with an antifouling layer (1), an antireflection layer (2), a hardened layer (3), a protective layer (4), the visible light cured color-changing coating layer (5), a substrate (6), a hardened layer (7), an antireflection layer (8) and an antifouling layer (9) fromtop to bottom. The visible light cured color-changing coating layer (5) is composed of 75.0 to 85.0 parts of an acrylate oligomer, 10.0 to 15.0 parts of a reactive diluent, 4.5 to 6.0 parts of a visible light photoinitiator, 2.5 to 5.0 parts of a photochromic dye, 2.5 to 6.3 parts of an auxiliary agent and 18.0 to 34.0 parts of a solvent. The visible light photoinitiator is one or more of bis-2,6-difluoro-3-titanium pyrrophenylferrocene (784) and camphorquinone, an excitation light source of the photoinitiator is one of visible light, Ar-laser (488 nm) and FD-Nd / YAG-laser (532 nm), and the energy density of the photoinitiator is greater than 2000 mJ / cm<2>. The photochromic coating layer provided by the invention is rapid in curing reaction and short in curing time, and is beneficial to improving the production qualification rate of the spectacle lens; in the curing process of the color-changing coating layer, a color-changing dye does not react with the photoinitiator, and the color of the coating layer is not abnormal.

Owner:WEIXING OPTICAL CO LTD

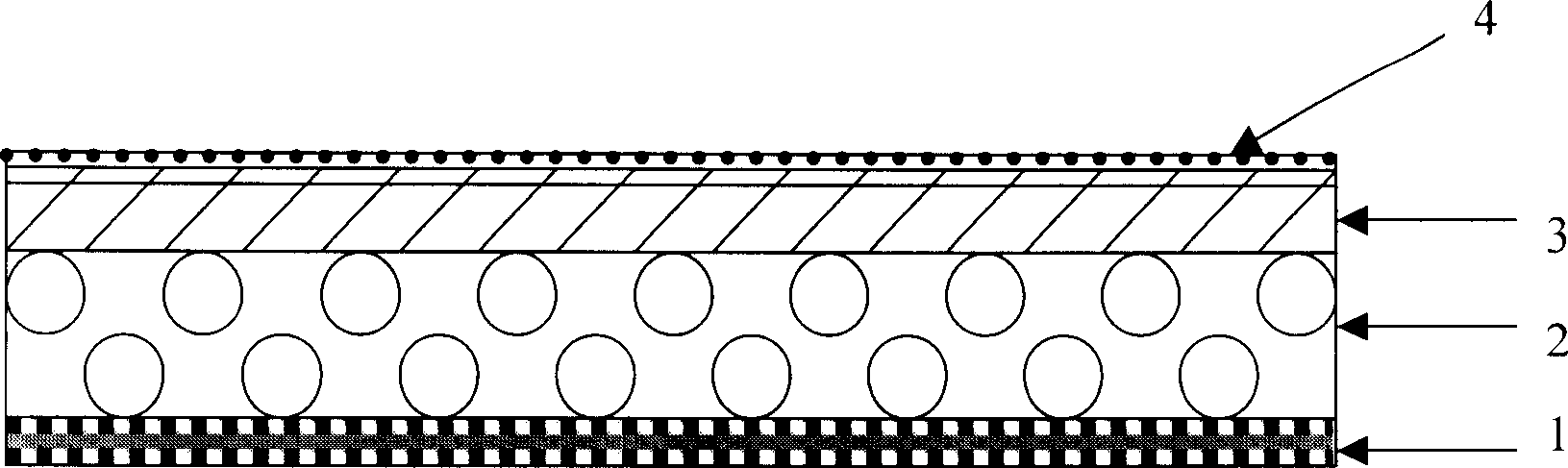

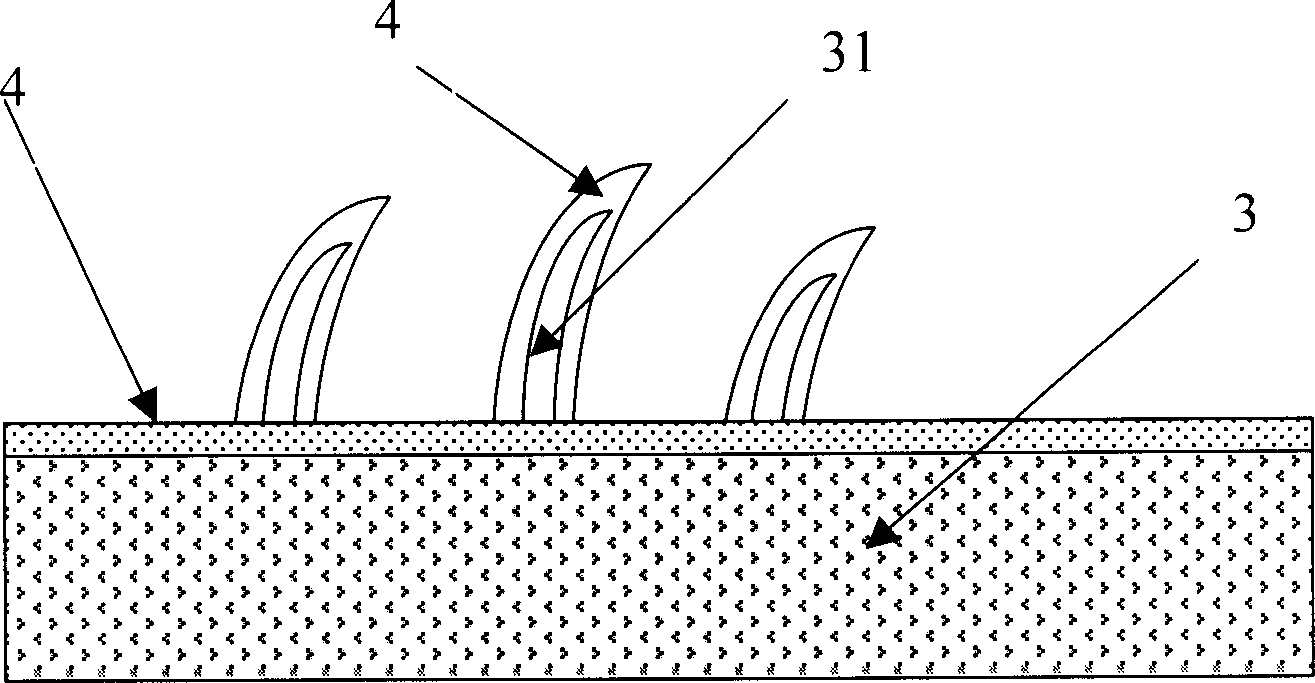

Sterilizing carpet

A disinfecting and sterilizing carpet is composed of a substrate layer made of fabric, a middle layer made of spray-finished wools for providing elastic structure and air permeable structure, and a surficial layer made of pile fabric. It features that the photocatalytic sterilizing paint prepared from anatase-type TiO2 nanoparticles is coated on the surfaces of substrate layer and surficial layer for disinfecting and sterilizing purpose.

Owner:上海温兴生物工程有限公司

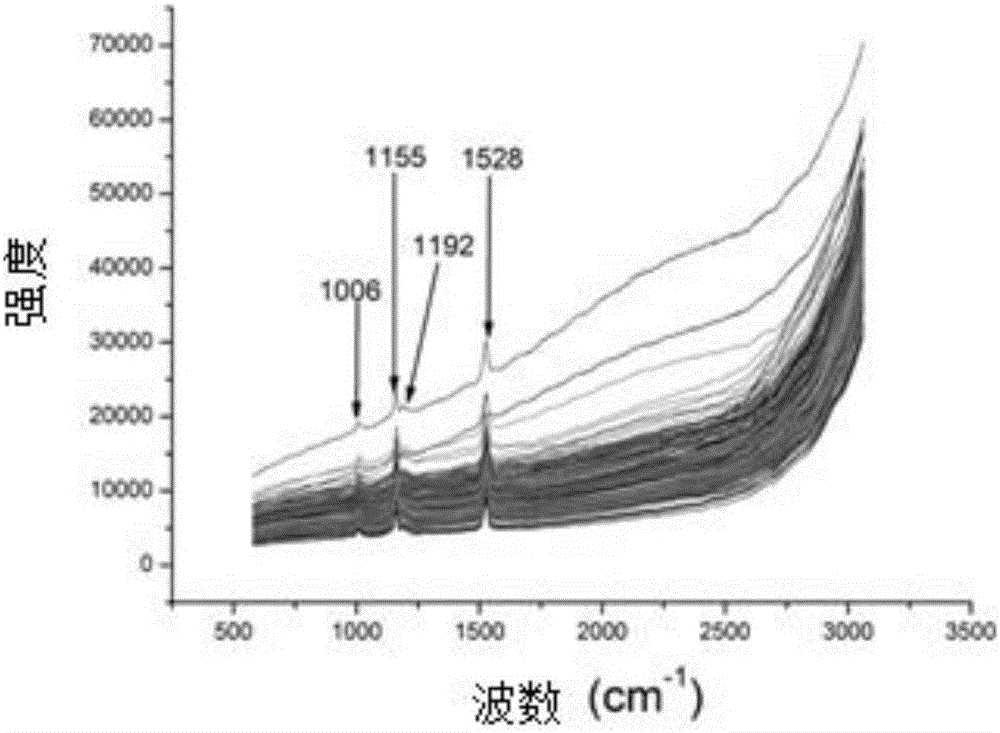

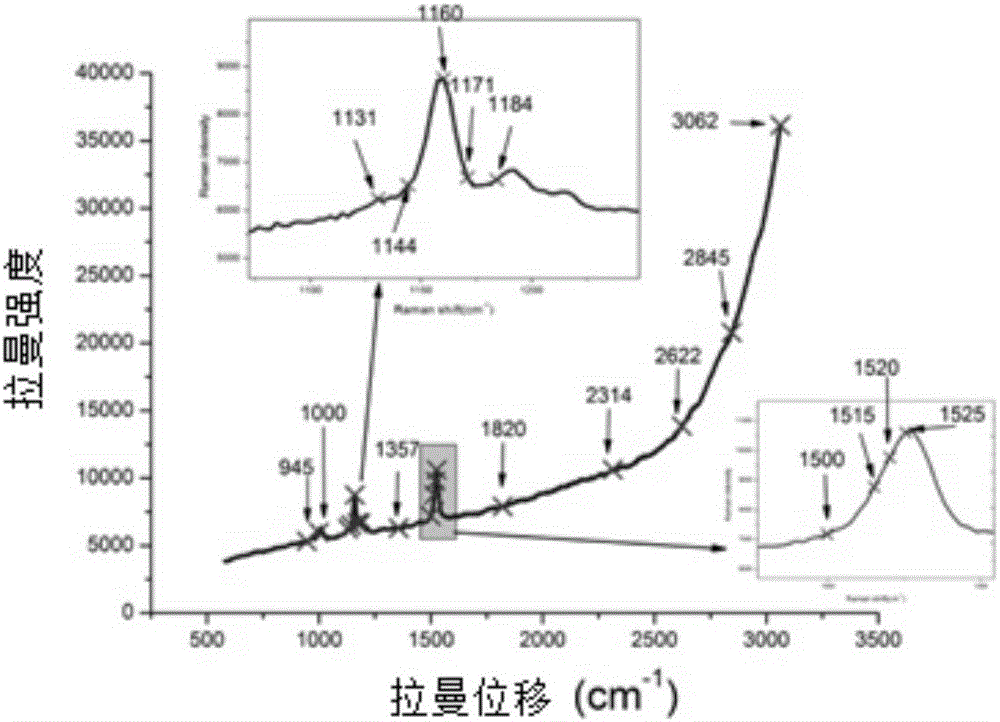

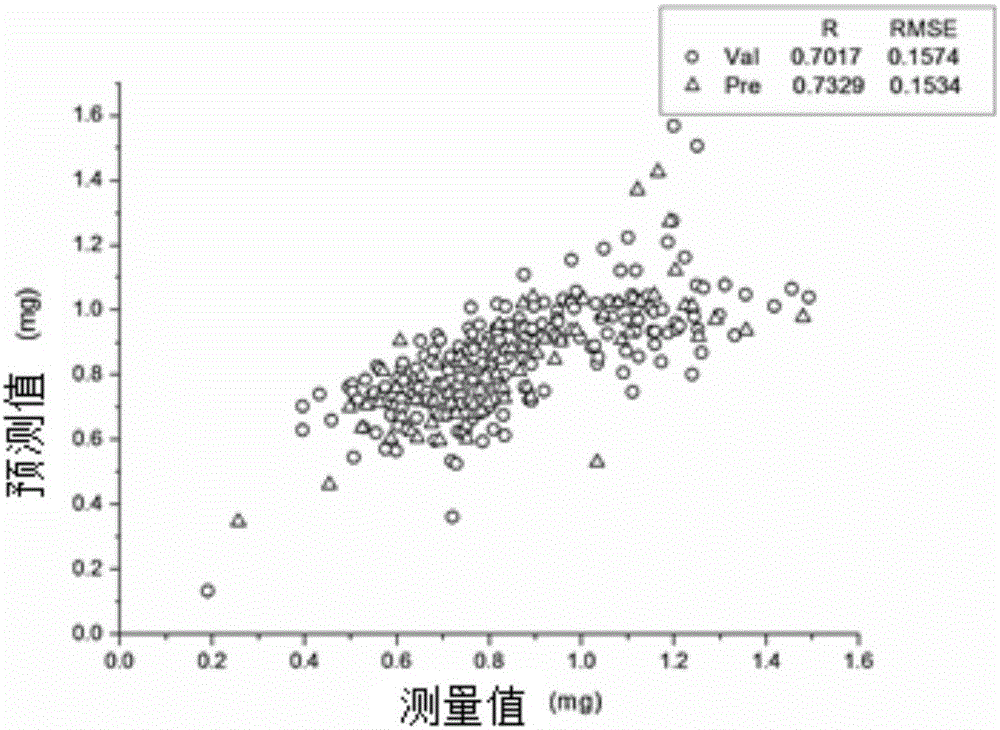

Method for detecting carotenoid content of tea leaves by confocal micro-Raman

The invention discloses a method for detecting the carotenoid content of tea leaves by a confocal micro-Raman. The method includes the steps: 1) placing a tea leaf sample on a sample table, acquiring Raman spectral information of the tea leaf sample by a Raman spectrometer and performing full-wave band integral compensation; 2) building a linear model by the Raman spectral intensity of 17 characteristic wave numbers; 3) acquiring the corrected spectral intensity of the tea leaf sample to be detected at the 17 characteristic wave numbers, predicting the carotenoid content of the tea leaves by the linear model, and realizing nondestructive and rapid detection of the carotenoid content of the tea leaves. The carotenoid content of the tea leaves can be rapidly and effectively detected in a nondestructive, low-cost and environment-friendly manner without complicated pretreatment and chemical analysis for the tea leaf sample, operation steps are greatly simplified, detection time is shortened, information of carotenoid components in the tea leaves is rapidly acquired, and detection accuracy is improved.

Owner:ZHEJIANG UNIV

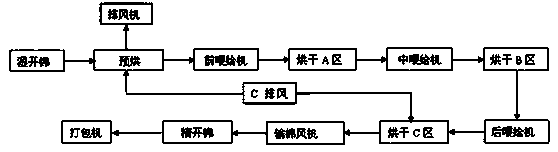

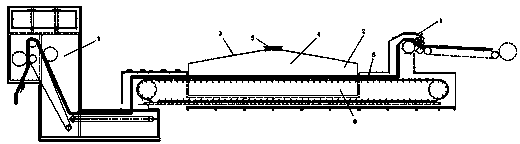

Drying process in viscose staple fiber production

InactiveCN103409957AReduce moisture contentIncrease temperatureTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsFiberPulp and paper industry

The invention relates to a drying process in viscose staple fiber production. The drying process is characterized in that viscose staple fibers are opened by a wet opener, enter a pre-drying device for pre-drying, are fed into a dryer for drying by a feeder, finally enter a fine opener for opening through a cotton conveying fan, and are packed, and waste heat discharged by the dryer enters the pre-drying device for direct pre-drying through an exhaust fan. The waste heat in the drying process is directly used for pre-drying the fibers, so that the water content of the fibers is reduced, and the temperature of the fibers is increased. Except that a driving motor and the exhaust fan consume energy, any other energy is not consumed.

Owner:YIBIN GRACE +2

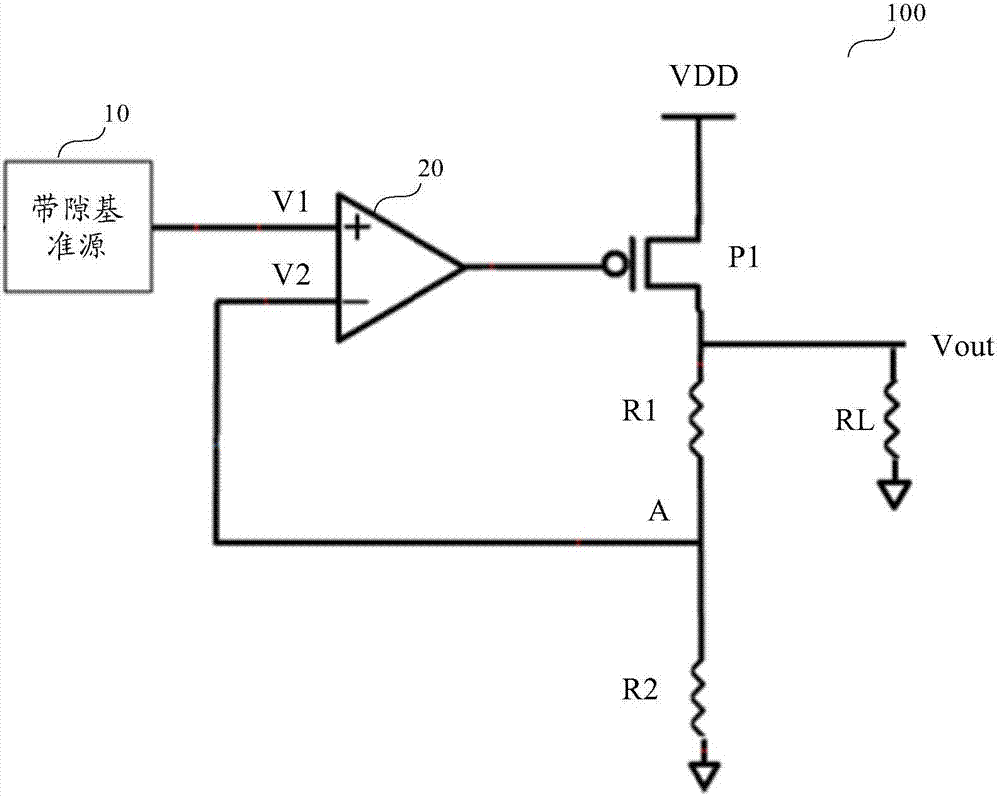

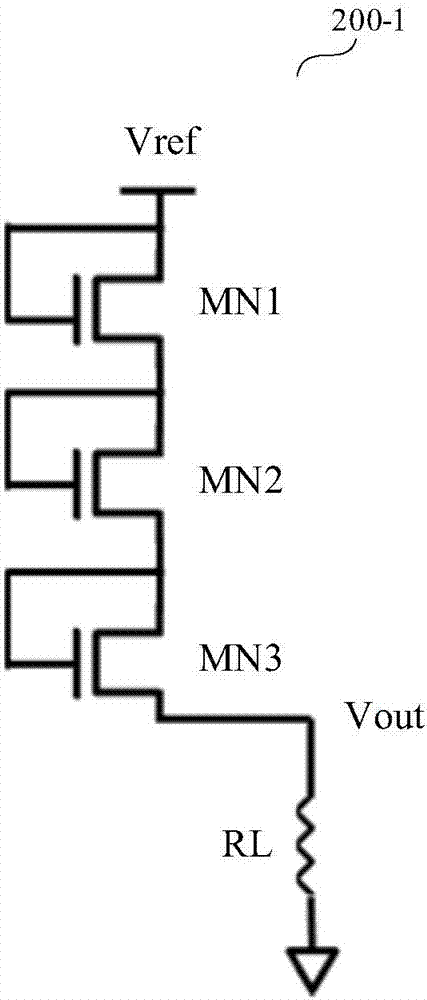

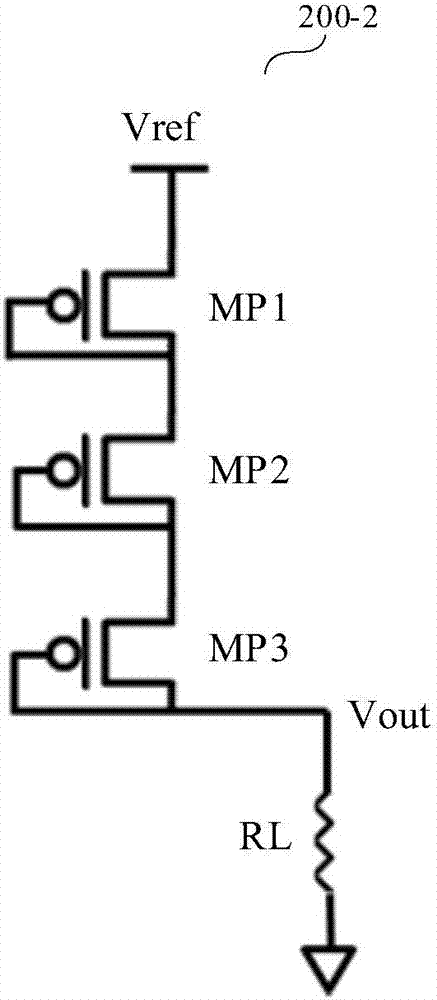

Voltage maintaining circuit applied to memory, memory and electronic equipment

ActiveCN107274920AWill not consumeReduce power consumptionStatic storageEngineeringPower consumption

The invention discloses a voltage maintaining circuit applied to a memory, the memory and electronic equipment. The voltage maintaining circuit applied to the memory comprises a charge-discharge circuit and a voltage holding circuit, wherein the first end of the charge-discharge circuit is connected with a power source through a first switching circuit, and the first switching circuit is switched on or off under the action of a first control signal; and the first end of the voltage holding circuit is connected with the output end of the voltage maintaining circuit and connected with the first end of the charge-discharge circuit through a second switching circuit, and the second switching circuit is switched on or off under the action of a second control signal, wherein the on-off state of the first switching circuit and the on-off state of the second switching circuit are opposite, when the first switching circuit is switched on, the power source charges the charge-discharge circuit, and when the second switching circuit is switched on, the charge-discharge circuit discharges the voltage holding circuit. Through the scheme, the voltage maintaining circuit applied to the memory is low in power consumption, and the precision of output voltage is easy to control.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

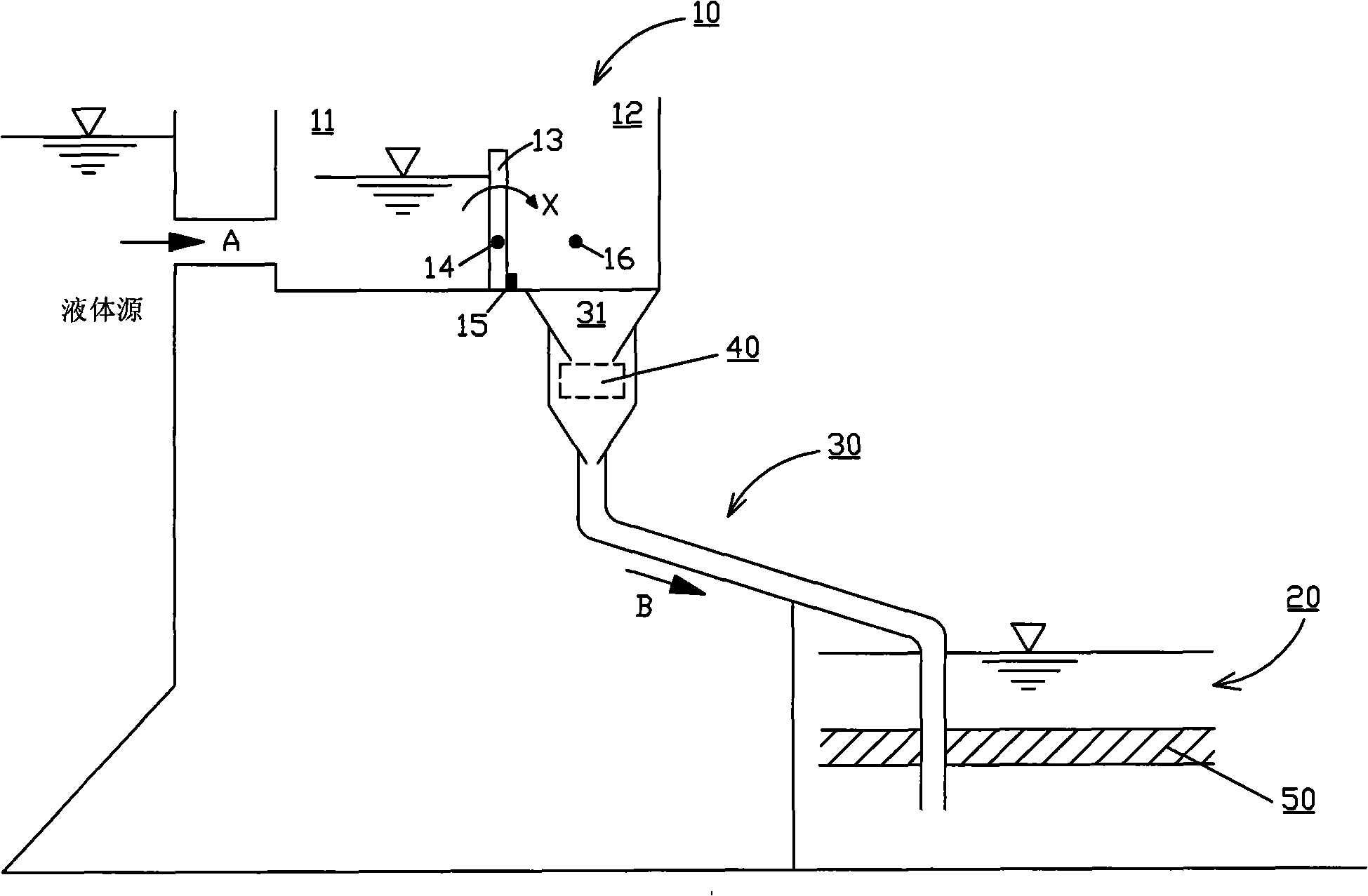

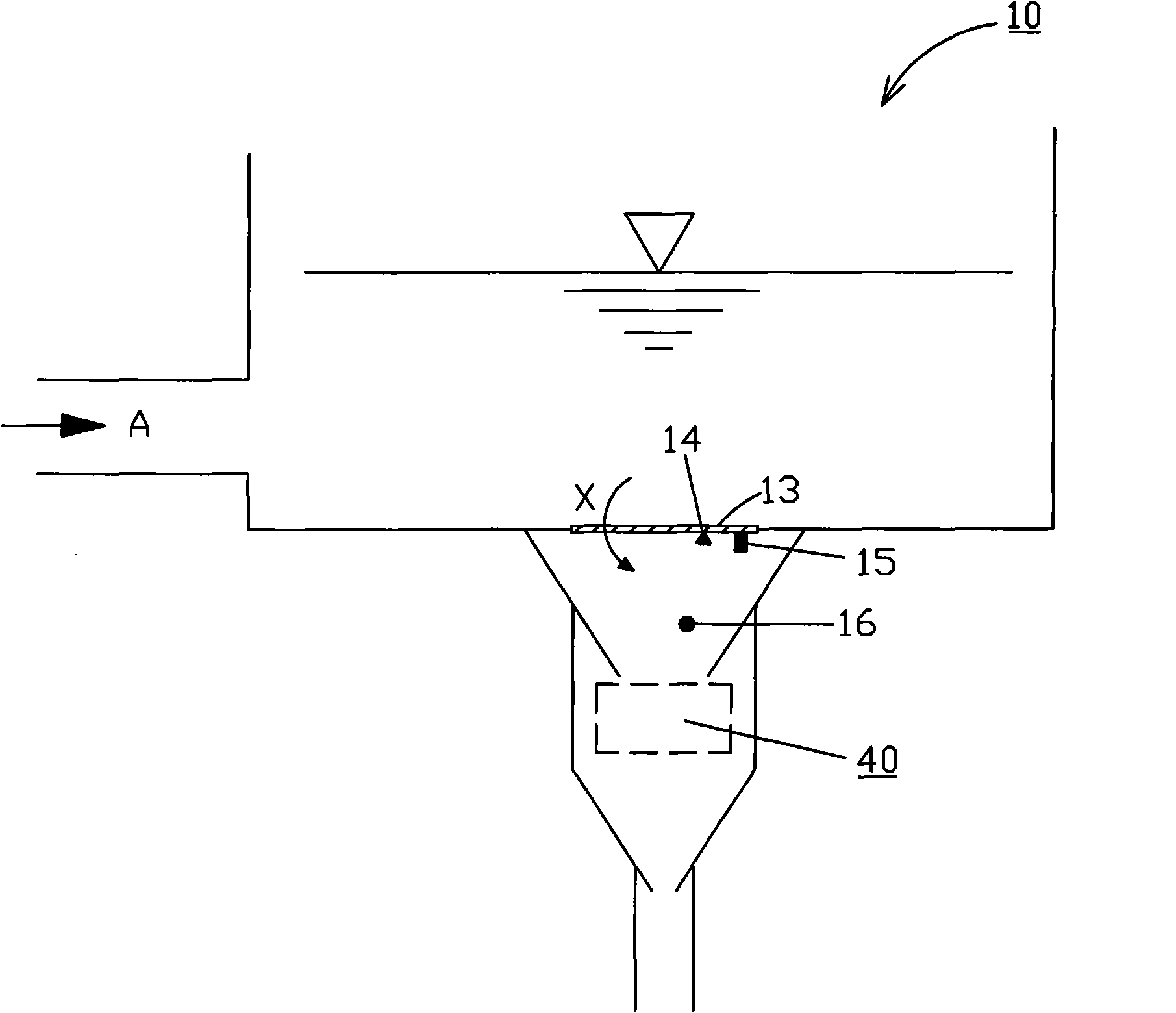

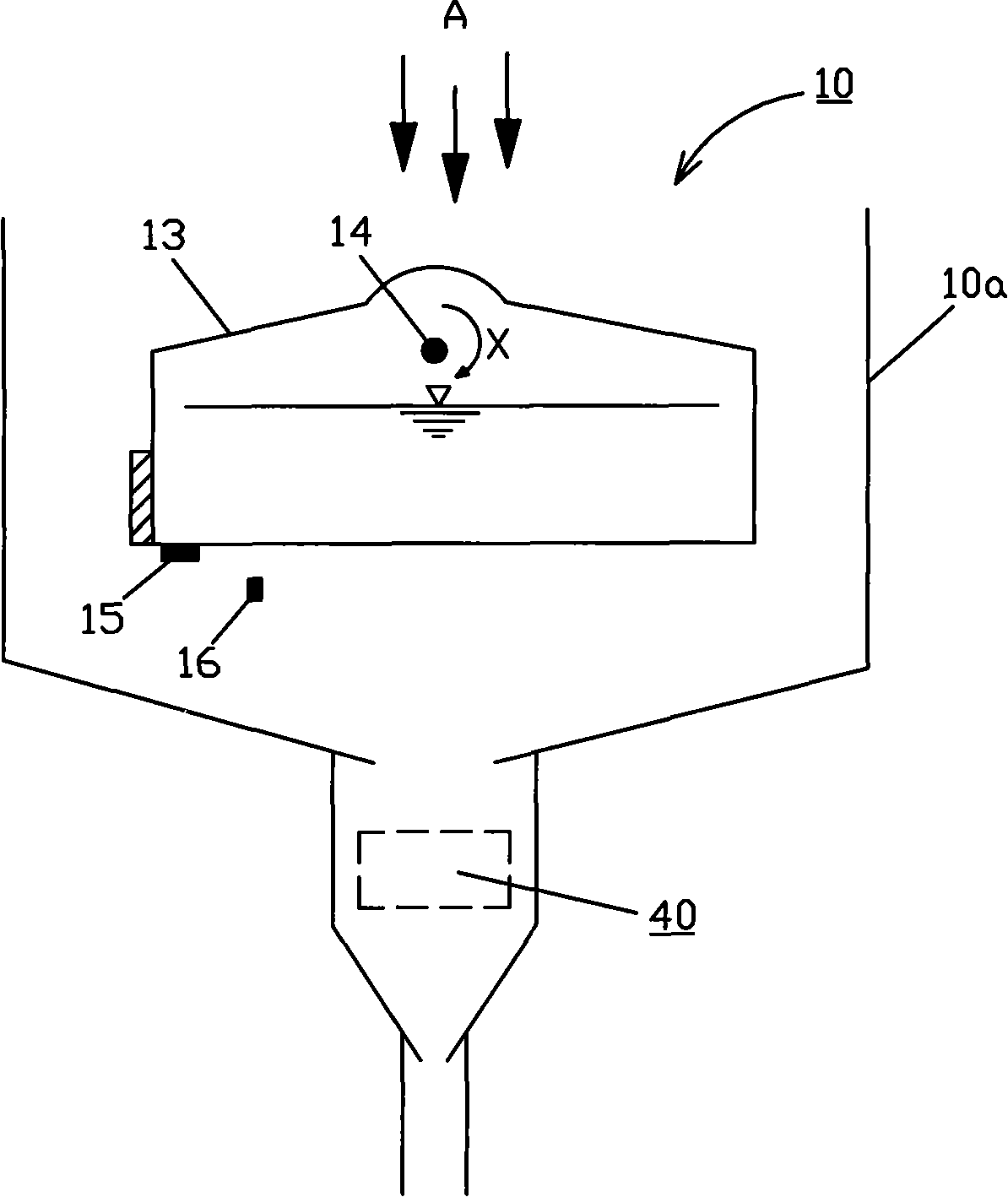

Liquid gas injection system

ActiveCN101357802AWill not consumeWill not polluteTreatment using aerobic processesTransportation and packagingEngineeringLiquid gas

The invention provides a liquid gas injection system which comprises: an upstream intermittent liquid supply device for receiving liquid from a liquid source; a downstream liquid storage device for intermittently and quantitatively receiving the liquid from the intermittent liquid supply device; and a pipeline which is connected between the upstream intermittent liquid supply device and the downstream liquid storage device, an outlet of the pipeline is positioned below liquid surface in the liquid storage device, thereby leading the liquid in the upstream intermittent liquid supply device to utilize the liquid level difference between the upstream and the downstream devices to be intermittently and quantitatively flowed into the downstream liquid storage device through the pipeline, and gas in the pipeline is simultaneously injected into the liquid in the liquid storage device. The gas injection system of the invention utilizes the liquid level difference which is generally existed in nature to automatically inject the gas into the liquid, the gas injection system does not need to use a blower and other gas injection devices, so the liquid gas injection system can not consume energy or pollute the environment; furthermore, the liquid gas injection system can greatly save the cost.

Owner:白冬生

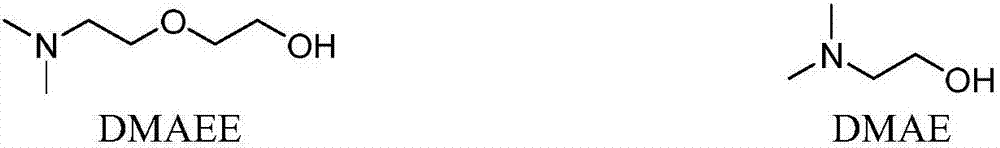

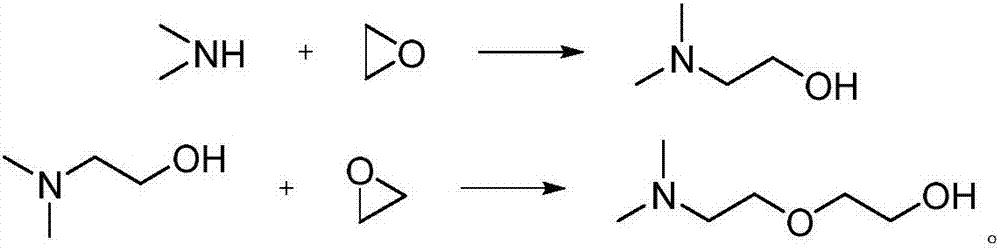

Method for producing N,N-dimethyl diglycolamine and co-producing N,N-dimethyl ethanolamine

InactiveCN107011191ARealize continuous productionWill not consumeOrganic compound preparationAmino-hyroxy compound preparationEthylene oxideDimethyl ethanolamine

The invention discloses a method for producing N,N-dimethyl diglycolamine and co-producing N,N-dimethyl ethanolamine. The method comprises the following steps: 1) heating dimethylamine aqueous solution and ethylene oxide as reaction raw materials at a temperature of 40-140 DEG C and a pressure of 0-1.5MPa for 2-6 hours according to the molar ratio of dimethylamine to ethylene oxide of 1:1-2.5, and introducing nitrogen during reaction to keep pressure; and (2) distilling the reacting product in the step (1) at reduced pressure after the reaction is finished so as to obtain N,N-dimethyl diglycolamine aqueous solution serving as a light component and N,N-dimethyl ethanolamine serving as a heavy component.

Owner:ZHEJIANG UNIV

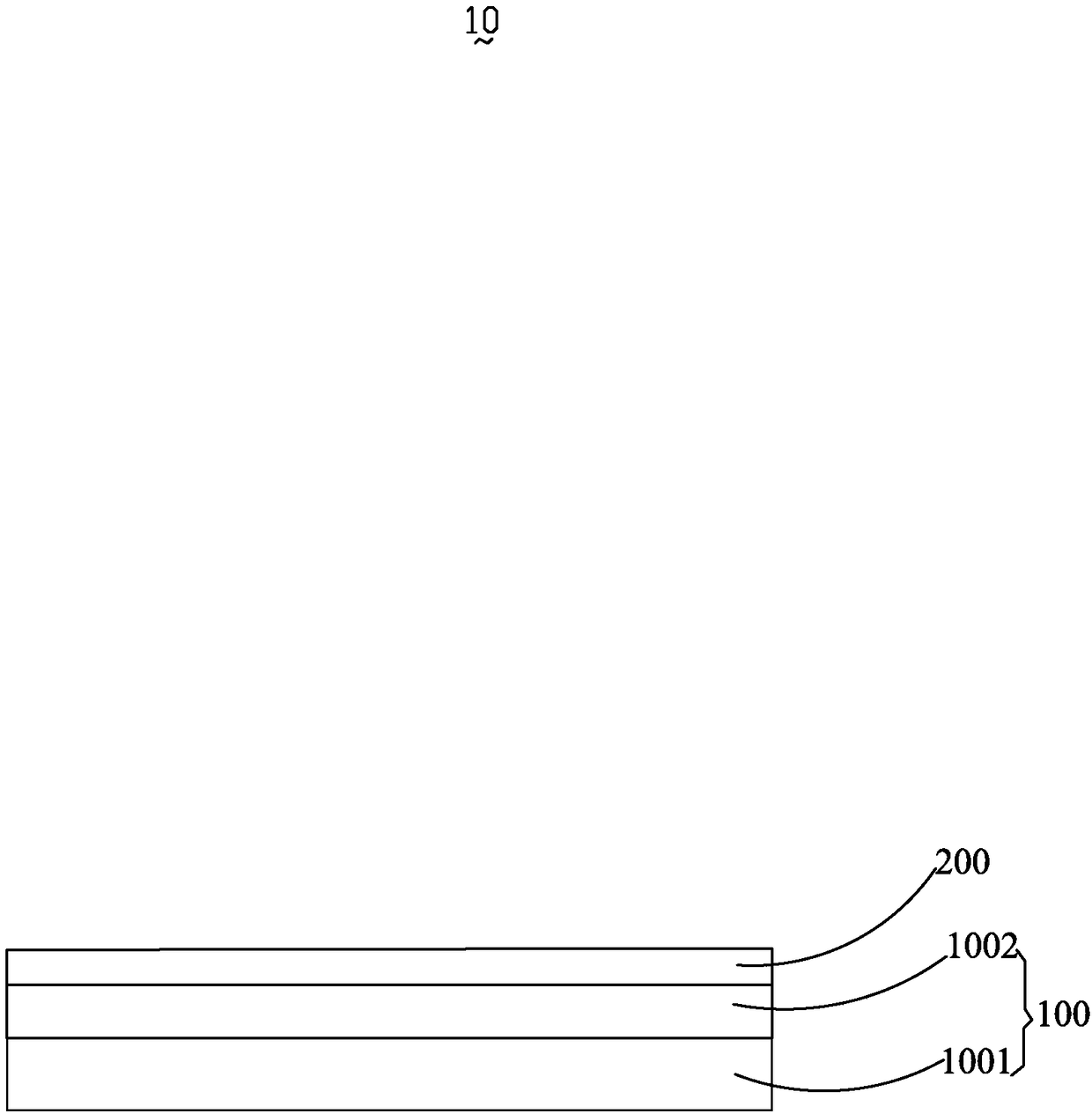

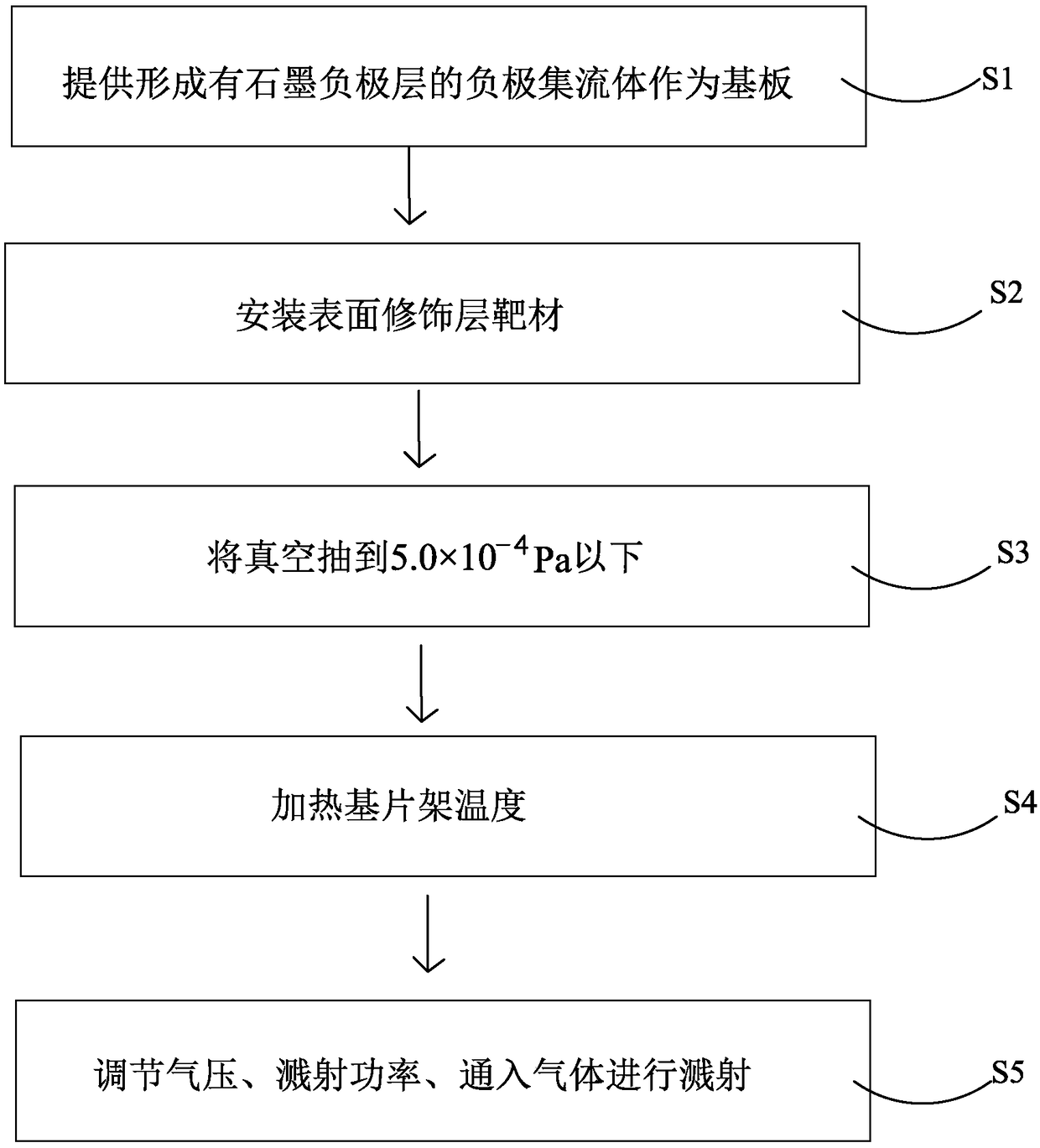

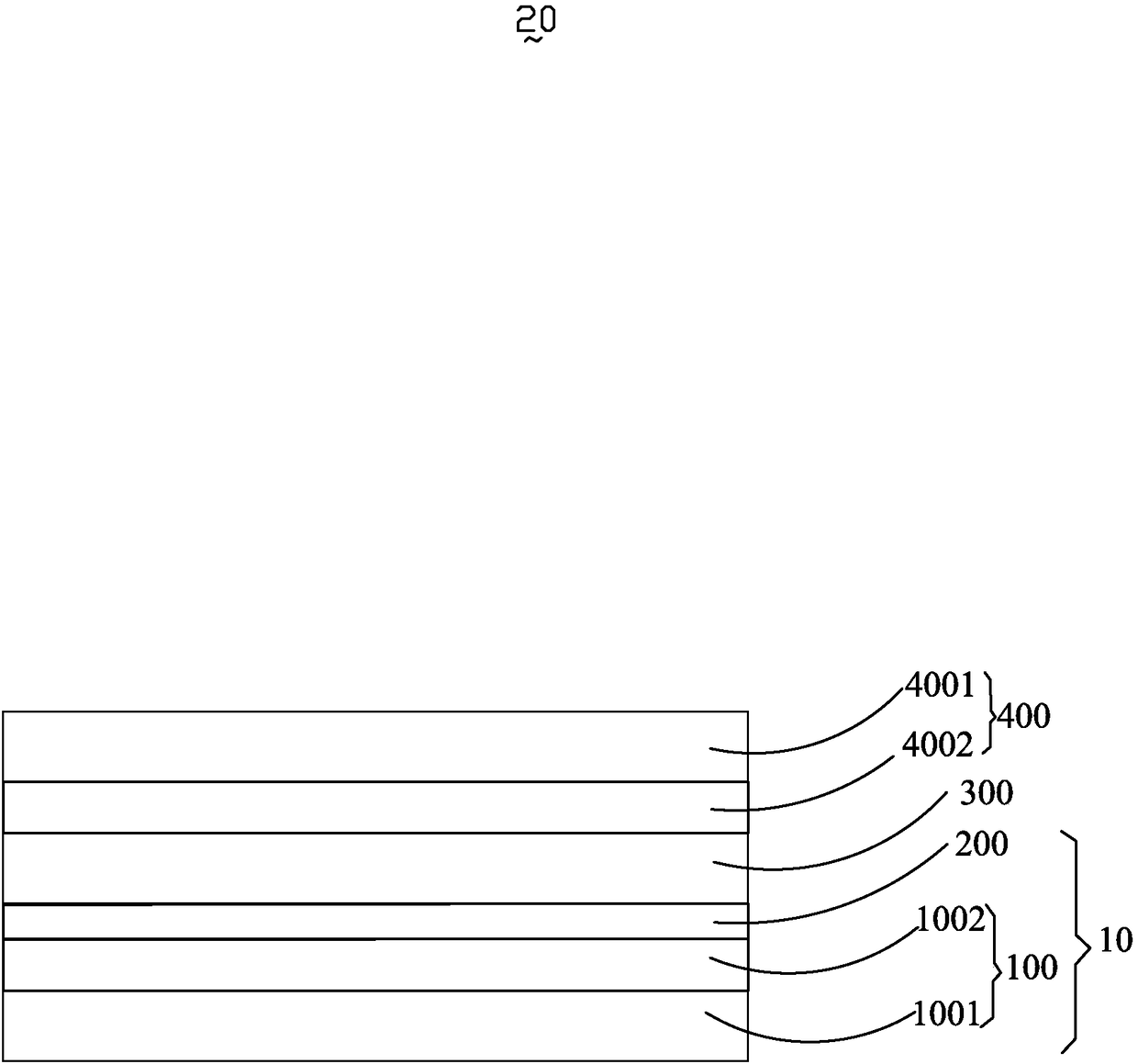

Graphite negative electrode structure combination and preparation method thereof, and lithium battery cell

PendingCN108365167AEnsure normal conductionPrevent peelingNegative electrodesSecondary cellsGraphiteLithium compound

The invention relates to the technical field of a lithium battery, particularly a graphite negative electrode structure combination and a preparation method thereof. The graphite negative electrode structure combination comprises a negative electrode structure and a surface modification layer formed on the negative electrode structure; the negative electrode structure comprises a negative electrode current collector and a graphite negative electrode layer formed on the negative electrode current collector; the negative electrode current collector, the graphite negative electrode layer and thesurface modification layer are arranged in an overlaid manner; the graphite negative electrode layer comprises a graphite active material; and the surface modification layer comprises a lithium compound with the ionic conduction characteristic. By taking the surface modification layer as a stable artificial SEI membrane, lithium ion damage in the charging cycle process can be well reduced, the initial charging and discharging coulombic effect is improved, and the specific capacity density of the graphite negative electrode layer is improved; and meanwhile, the surface modification layer can well block macromolecule groups from being nested into the graphite negative electrode layer along with lithium ions, so that stripping of graphite can be avoided, the structural stability of the negative electrode structure can be maintained, and stable conductive performance can be achieved.

Owner:成都大超科技有限公司

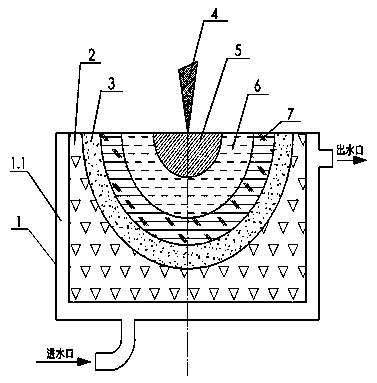

Semi-fusion type crucible heating device

The invention discloses a semi-fusion type crucible heating device, and belongs to the technical field of crucible application. The semi-fusion type crucible heating device comprises a water cooling tank (1), a heat preservation layer (2) and a crucible layer (3). A cooling tank (1.1) is arranged in the water cooling tank (1), the heat preservation layer (2) is further arranged in the water cooling tank (1) in a filling mode, and the crucible layer (3) is arranged on the heat preservation layer (2). The semi-fusion type crucible heating device has the advantages of being capable of effectively heating materials with the boiling temperature being above 2000 DEG C and meeting the heating requirement, simple in structure, low in cost, and capable of effectively prolonging the service life of a crucible in the heating process.

Owner:JIANGSU BOQIAN NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com