Temperature and pressure automatically-balanced spectrograph device and method for measuring oil and gas components while drilling

A measurement method and spectrometer technology, applied in measurement devices, measurement, instruments, etc., can solve the problems of inability to conduct real-time online analysis of oil and gas components, high cost of quantum cascade lasers, and inability to meet high temperature environments, and achieve a wide natural operating temperature range. , huge practical value, low power consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

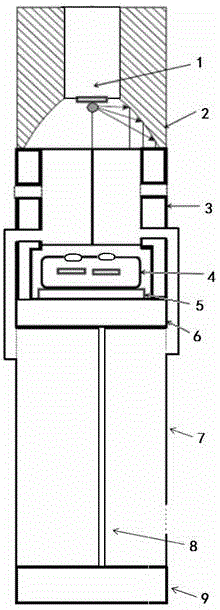

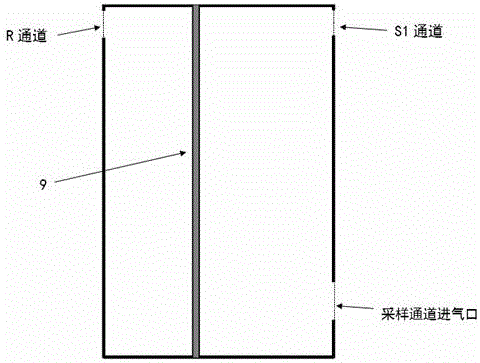

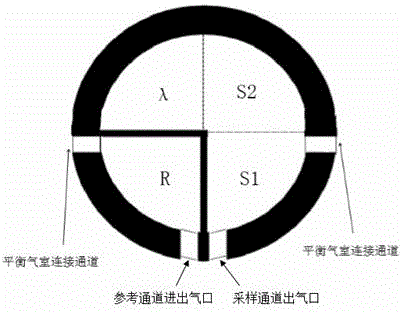

[0045] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a parabolic reflector 2 for collimating the light-emitting point of the light source 1. The light source 1 is installed in the parabolic reflector 2, and its light-emitting point is located at the focus of the parabolic reflector 2, and the emitted light is emitted in parallel to achieve collimation. The chamber body 3 of the gas chamber is connected with the parabolic reflector 2, the balance gas chamber 7 and the mounting bases 6, 9 in sealing connection, and the two ends of the gas channel are equipped with projection windows for sealing design. There are four channels in the cavity 3 of the sampling gas chamber and the reference gas chamber, and the reference channel and the sampling channel communicate with both sides of the balance gas chamber 7 to ensure that the pressures of the connected channels are the same. The detector 4 has four channels and four indepe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com