Drying process in viscose staple fiber production

A viscose staple fiber and process technology, applied in the field of viscose staple fiber, can solve the problems of small production capacity of cyclone conveying, complicated equipment, unfavorable air conveying, etc., and achieve good drying effect, uniform moisture content and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

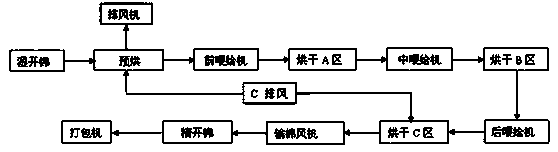

[0035] The drying process in the production of viscose staple fiber. After the viscose staple fiber is opened by the wet opener, it enters the pre-drying device for pre-drying, and then is sent to the dryer by the feeder for drying, and finally enters through the cotton conveying fan. The fine opener opens and packs the cotton; the waste heat discharged from the dryer enters the pre-drying device through the exhaust fan for direct pre-drying.

[0036] The total installed power of the equipment of the present invention is reduced from 5253Kw to 4509KW, a drop of 744KW. This shows that the present invention can effectively reduce costs and save energy consumption.

Embodiment 2

[0038] The drying process in the production of viscose staple fiber. After the viscose staple fiber is opened by the wet opener, it enters the pre-drying device for pre-drying, and then is sent to the dryer by the feeder for drying, and finally enters through the cotton conveying fan. The fine opener opens and packs the cotton; the waste heat discharged from the dryer enters the pre-drying device through the exhaust fan for direct pre-drying.

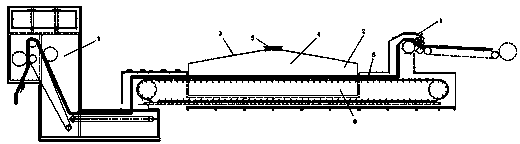

[0039] The pre-drying device includes an oven and a chain conveyor for transporting fibers. The chain conveyor passes through the oven from the outside. The bottom of the chain in the oven is an air intake chamber, and the top of the chain is an exhaust chamber; There are small holes on the plate surface of the plate conveyor, and the exhaust port of the exhaust chamber is connected with the exhaust fan.

Embodiment 3

[0041] The implementation mode of this embodiment is basically the same as embodiment 2, on this basis:

[0042] The air inlet chamber is provided with a plurality of air inlets, and the area of the air inlets is 0.5m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com