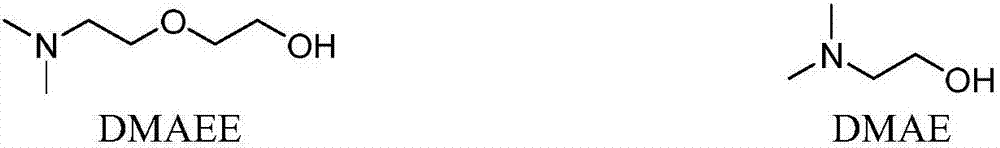

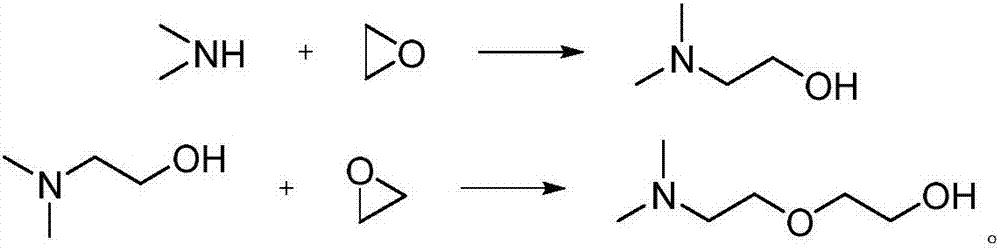

Method for producing N,N-dimethyl diglycolamine and co-producing N,N-dimethyl ethanolamine

A technology of dimethyl diglycolamine and dimethylethanolamine, which is applied in chemical instruments and methods, preparation of amino hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as not being widely used and side reactions, and achieve atomic High economy, high total yield, resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, a kind of technique of producing DMAEE and coproducing DMAE. With ethylene oxide (EO), 33% dimethylamine (DMA) aqueous solution as starting material, carry out following steps successively:

[0038] (1) Synthesis:

[0039] Add 68g of dimethylamine aqueous solution (0.5mol) into a 250ml autoclave, replace the reactor with nitrogen three times, fill with 44g (1mol) of ethylene oxide, then fill with nitrogen to 1.2MPa, heat up to 80°C for reaction, The reaction time is 4h. 112 g of the resulting reaction solution was collected.

[0040] (2) Separation:

[0041] The reaction solution in step (1) was distilled under reduced pressure (20mmHg). Separately collect 40~70℃, 90~95℃ fractions. The obtained light component is 48.7g of DMAE aqueous solution; the obtained heavy component is 61.5g of DMAEE. DMA conversion was 100%. Based on amino groups, the yield of DMAE was 7.8%, and the yield of DMAEE was 91.6%.

[0042] (3) Loop:

[0043] Measure (2) step DMA...

Embodiment 2

[0046] Embodiment 2, a kind of technique of producing DMAEE and coproducing DMAE. Taking EO and 33% DMA aqueous solution as starting materials, the following steps are carried out in sequence:

[0047] (1) Synthesis:

[0048] Add 68g of dimethylamine aqueous solution (0.5mol) into a 250ml autoclave, replace the reactor with nitrogen 3 times, fill it with 44g (1mol) of ethylene oxide, keep the reactor at normal pressure, raise the temperature to 80°C for reaction, and the reaction time for 2h. The resulting reaction solution was collected.

[0049] (2) Separation:

[0050] The reaction solution in step (1) was distilled under reduced pressure (20mmHg). Separately collect 40~70℃, 90~95℃ fractions. The obtained light component is 81.5 g of DMAE aqueous solution; the obtained heavy component is 12.1 g of DMAEE. DMA conversion was 100%. EO conversion was 59.3%. Based on the amino group, the yield of DMAE was 82.1%, and the yield of DMAEE was 18.3%.

[0051] (3) Loop:

[0...

Embodiment 3

[0055] Embodiment 3, a kind of technique of producing DMAEE and coproducing DMAE. Taking EO and 33% DMA aqueous solution as starting materials, the following steps are carried out in sequence:

[0056] (1) Synthesis:

[0057] Add 68g of dimethylamine aqueous solution (0.5mol) to a 250ml autoclave, replace the reactor with nitrogen 3 times, then fill in 22g (0.5mol) of ethylene oxide, the reactor is at normal pressure, and heat up to 40°C for reaction. The time is 2h. 88.6 g of the resulting reaction solution was collected.

[0058] (2) Separation:

[0059] The reaction solution in step (1) was distilled under reduced pressure (20mmHg). Collect 40~70℃, 90~95℃ fractions. The light component obtained was 87.2 g of DMAE aqueous solution; the heavy component obtained at the bottom of the kettle was 1.2 g of DMAEE. DMA conversion was 100%. EO conversion rate 95%. Based on amino groups, the yield of DMAE was 95.0%, and the yield of DMAEE was 4.7%.

[0060] (3) Loop:

[0061...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com