Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Stable precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical palladium plating solution

InactiveCN101709462AReduce utilizationIncrease profitLiquid/solution decomposition chemical coatingPrinted circuit boardStabilizing Agents

The invention relates to a chemical palladium plating solution, in particular to a chemical palladium plating solution which can directly form a palladium film with good adhesive force on a chemical nickel plating film formed on a printed circuit board (PCB) and does not affect the chemical nickel plating film serving as a base film. The chemical palladium plating solution contains a soluble palladium salt, a first complexing agent, a second complexing agent and a stabilizing agent, wherein the first complexing agent is one out of ammonia and diamine compounds, and the second complexing agent is one or more out of alcohol amine compounds with 2-7 carbon atoms, amine compounds with less than 7 carbon atoms and aminocarboxylic acid compounds. The palladium plating solution has stable pH, stable deposition rate, long bath service life and excellent bath stability, does not generate cracks, and can obtain the palladium plating film with very low phosphorus content and excellent corrosion resistance, solder connectivity and lead weldability.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

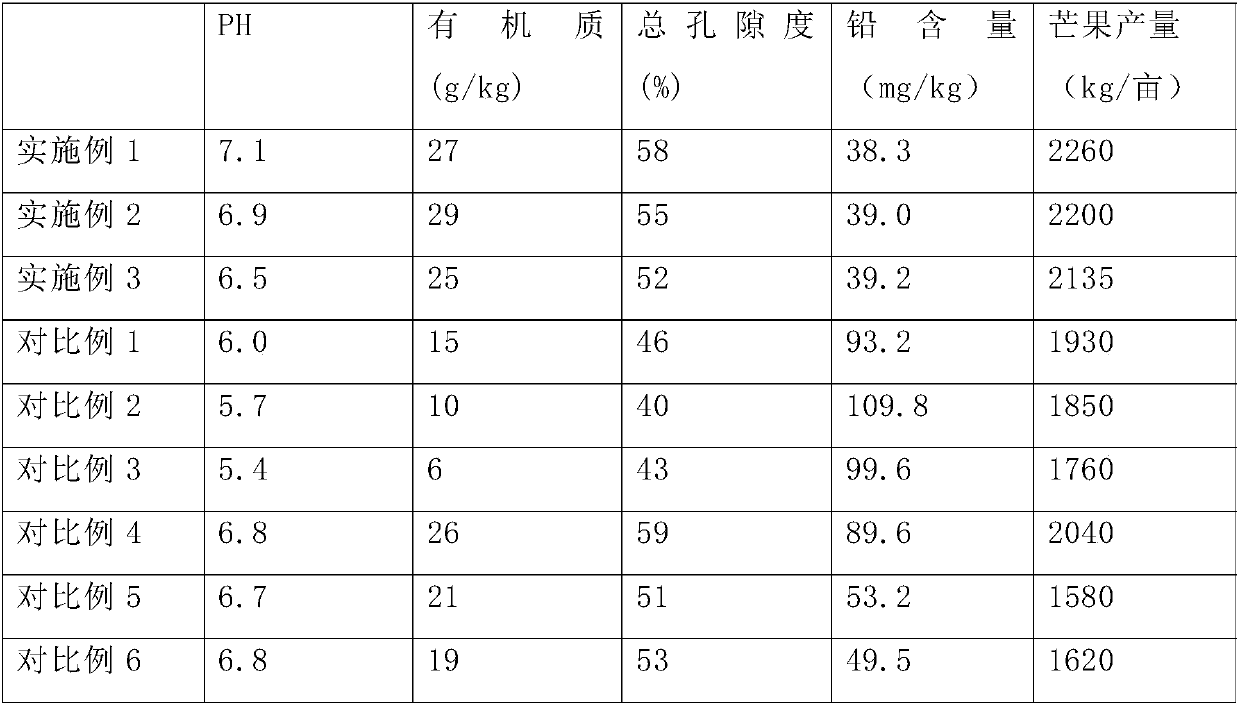

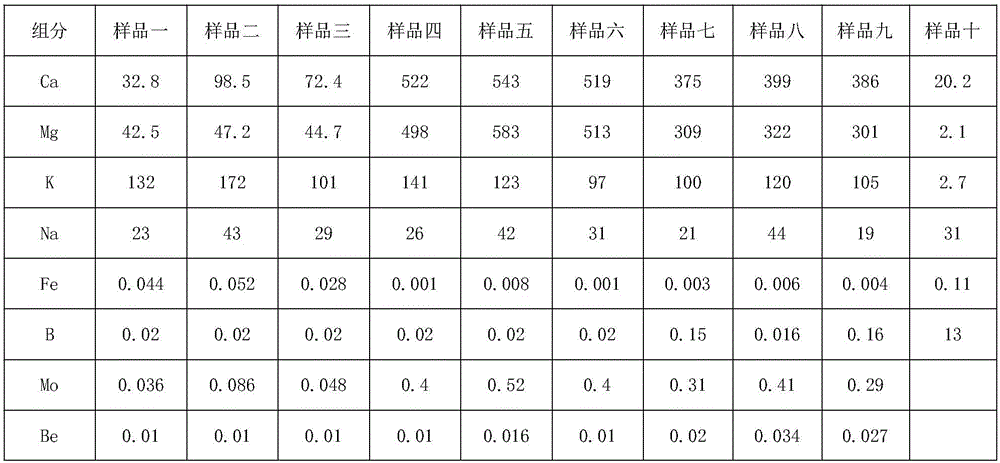

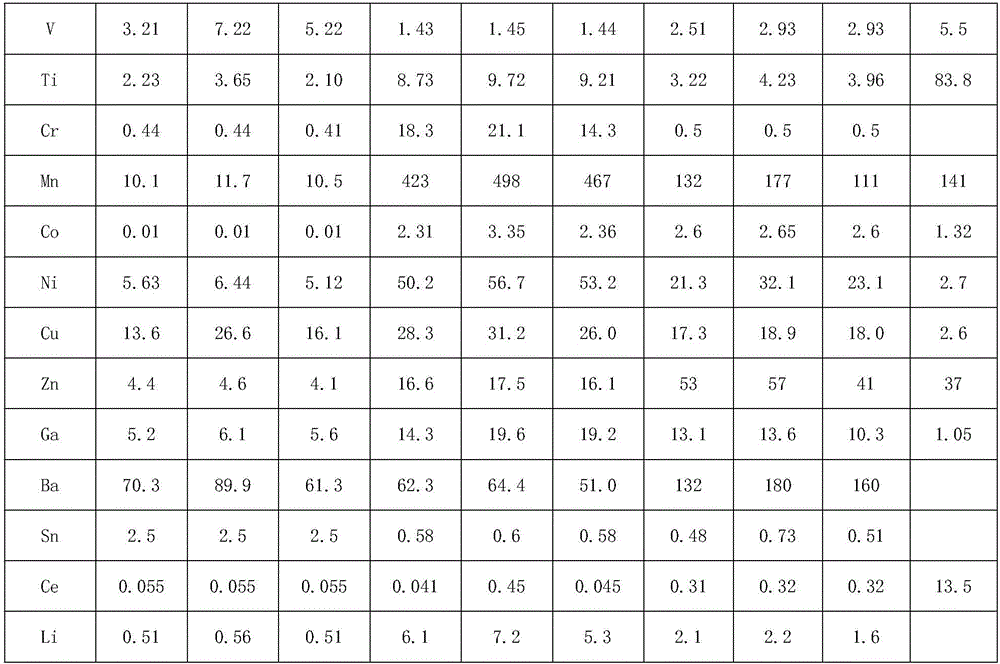

Comprehensive method for soil conditioning and restoration

ActiveCN107580818AExtended release timeIncrease profitFertilising methodsSoil-working methodsOysterPotassium

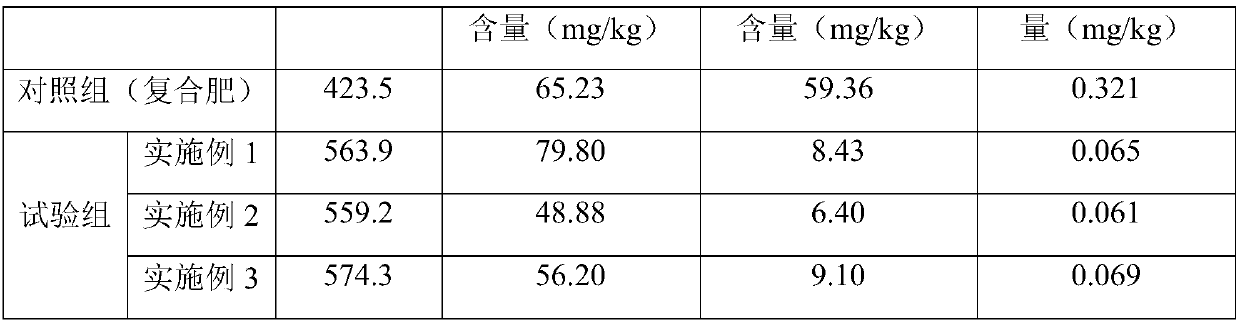

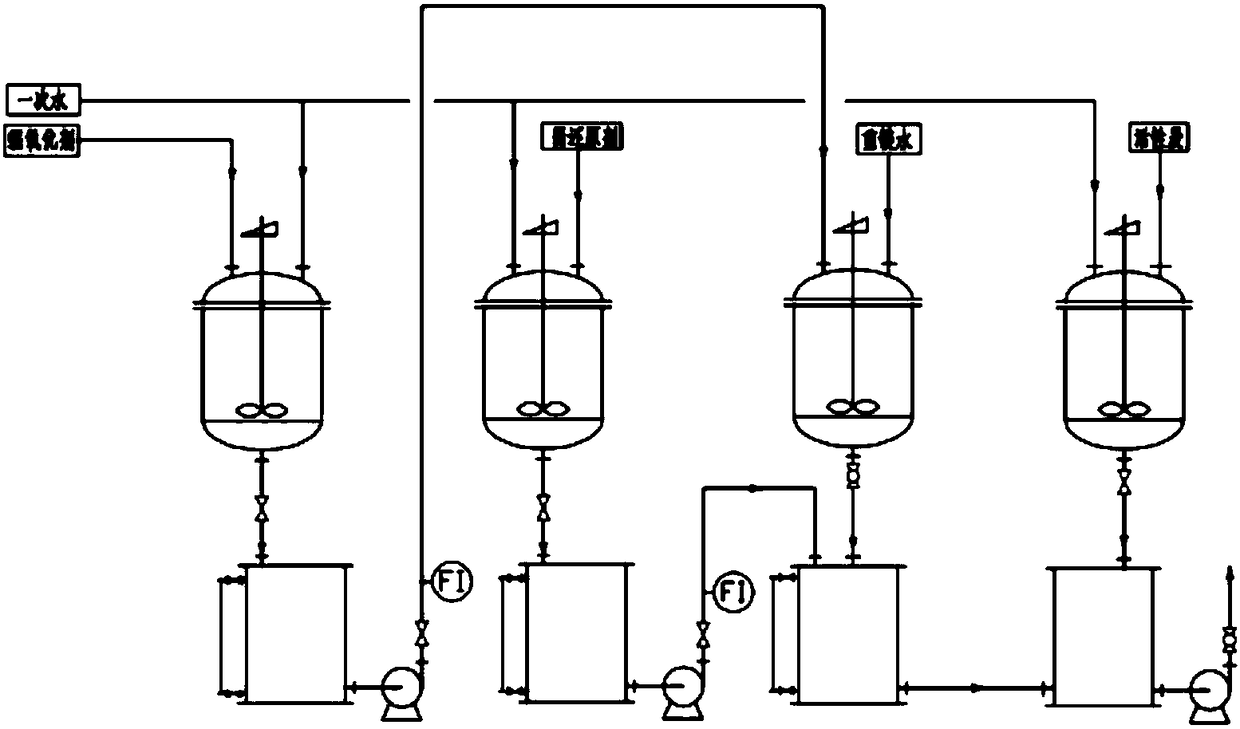

The invention provides a comprehensive method for soil conditioning and restoration. The method comprises the following steps: before crops are planted or after fruit trees are harvested, oyster shellpowder, silicon-calcium-potassium-magnesium fertilizer, biological organic fertilizer, a biological control agent and ternary compound fertilizer are applied to soil; before the fruit trees are sprouted and bloomed, a macroelement water-soluble fertilizer and humic acid water-soluble fertilizer are applied to the soil; during a swelling period of young fruits of the fruit trees, silicon-calcium-potassium-magnesium fertilizer and a composite microbial bacterial liquid are applied to the soil; and during a fruit strengthening period of the fruit trees, high-potassium fertilizer and seaweed fertilizer are applied to the soil. The method is used for conditioning and restoring the soil, so that the pH of the soil tends to be neutral, and the acidification degree is obviously reduced; the organic matter content of the soil is obviously increased, the soil becomes loose and breathable, and the soil layer is deep and thick; and the heavy metal content in the soil is reduced, so that securityof the planted crops is improved, and the yield is improved. The method provided by the invention does not interrupt growth of the crops in the soil, enables the crops to grow healthily while conditioning and restoring the soil, and improves quality of the crops, so that economic benefits of growers are guaranteed.

Owner:四川微施地健土壤修复技术有限公司

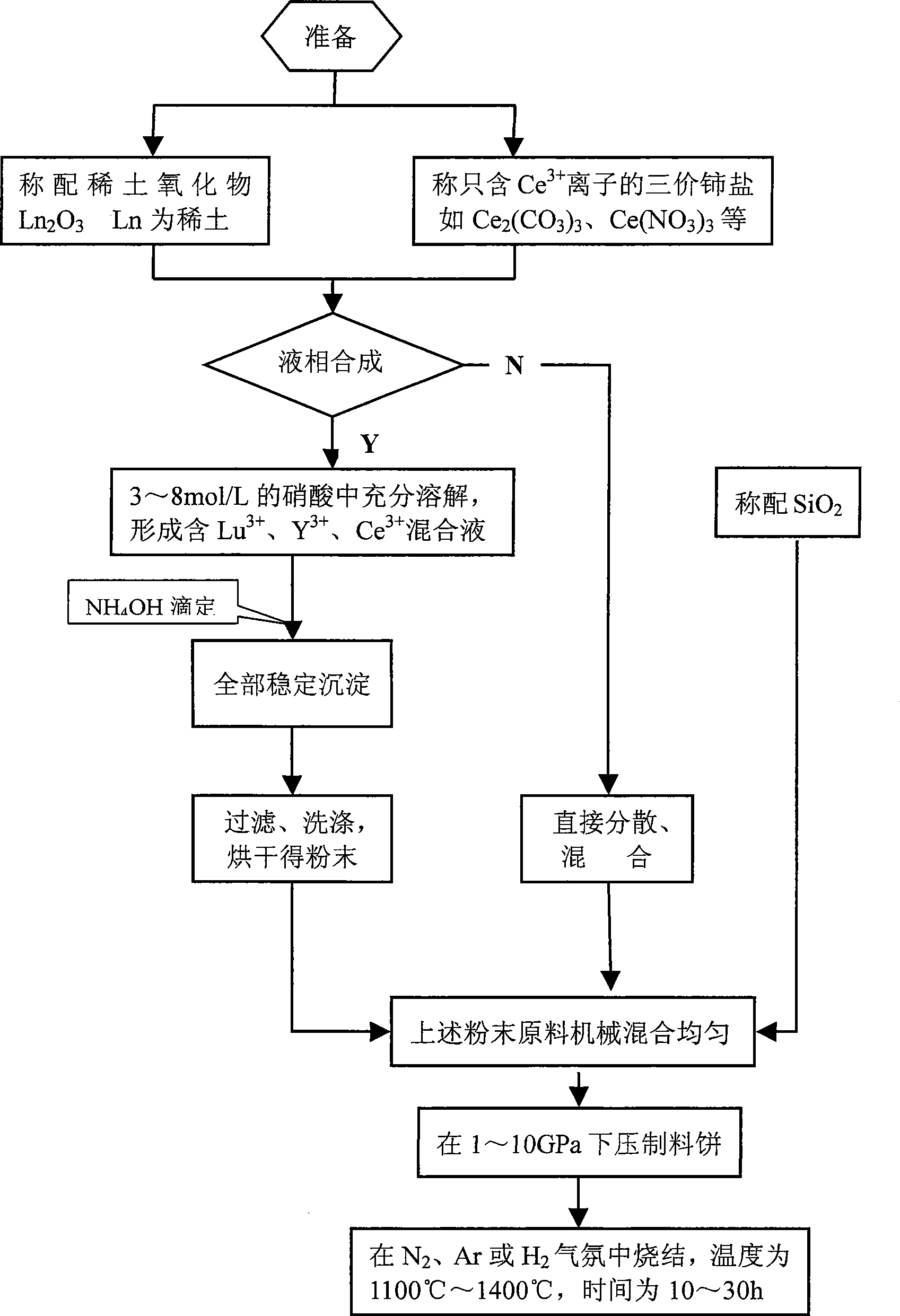

Rare earth silicates polycrystal material doped with Ce<3+> and preparing method thereof

InactiveCN101377020ALower sintering temperatureHigh purityPolycrystalline material growthSingle crystal growth detailsRare earthQuenching

The invention relates to a cerous ion-doped rare earth silicate polycrystal material and a preparation method thereof, which is characterized in that the rare earth silicate is lutecium silicate, yttrium silicate or lutecium and yttrium silicate; the mol percentage of the doped cerous compound is 0.2 percent to 2 percent; the general formula of the doped rare earth silicate is Ln<2(1-x)>Ce2xSiO3, wherein, x is equal to0.002 to 0.02, and Lu is one or two types of Y and Lu. The doped cerous compound is Ce2(CO3)3, Ce(NO3)3, Ce2(C2O4)3, Ce(CH3COO)3 or Ce(OH)3. The polycrystal material is directly synthesized or prepared by doping the cerous compound and liquid-phase mixing. The invention most reduces the introduction of Ce<+4> raw material, eliminates the quenching impact of the Ce<+4> on the luminescence of Ce<+3>, reduces the sintering temperature of the polycrystal material, and improves the scintillation properties of the material, such as light output, energy resolution and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

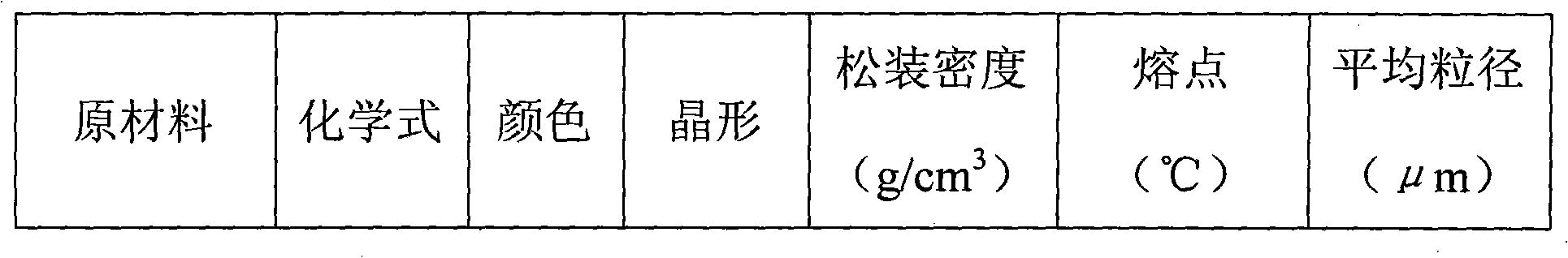

Preparation method of zinc oxide pressure-sensitive ceramic slurry and pressure-sensitive ceramic resistor material

The invention relates to a preparation method of zinc oxide pressure-sensitive ceramic slurry and a pressure-sensitive ceramic resistor material. The preparation method comprises the following steps: weighing raw materials including main raw material ZnO and additives; adding water to proportionally prepared additives, and ball-milling for 1-4 hours; and putting the weighed ZnO, milled additives, pure water and mixing assistant into a mixing tank, quickly dispersing in a homo-mixer for 20-60 minutes, opening the valve, starting a pipeline type high-shear dispersion emulsion machine to circularly disperse for 1-3 hours, driving into a liquid storage tank, and starting a basket type mill to mill for 2-4 hours, thereby obtaining the slurry. The zinc oxide pressure-sensitive ceramic resistor material comprises the following components in percentage by mol: 93-95% of ZnO, 0.6-0.9% of Bi2O3, 0.9-1.3% of Sb2O3, 1.0-1.3% of Co2O3, 0.5-0.8% of MnCO3, 0.5-0.8% of Cr2O3, 0.5-0.8% of NiO and 1.0-1.5% of SiO2. The invention has the advantages of simple preparation procedure and high efficiency, and impurities can not be easily incorporated in the manufacturing process. The prepared slurry is even and stable and has favorable flowability.

Owner:厦门ABB避雷器有限公司

Stabilization and solidification agent for high-concentration arsenic alkali residues

The invention discloses a stabilization and solidification agent for high-concentration arsenic alkali residues. The stabilization and solidification agent is composed of following components including an oxidizing agent composed of hydrogen peroxide and persulfate, a stabilizing agent composed of molysite and / or ferrite, and a conditioner composed of kaolin and / or attapulgite, red mud and pulverous coal. The synergistic interaction effect between all the components of the stabilization and solidification agent is obvious, efficient stabilization and solidification of the high-concentration arsenic alkali residues can be achieved, a method for using the agent is simple, cost is low, and the stabilization and solidification agent is suitable for application and popularization.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

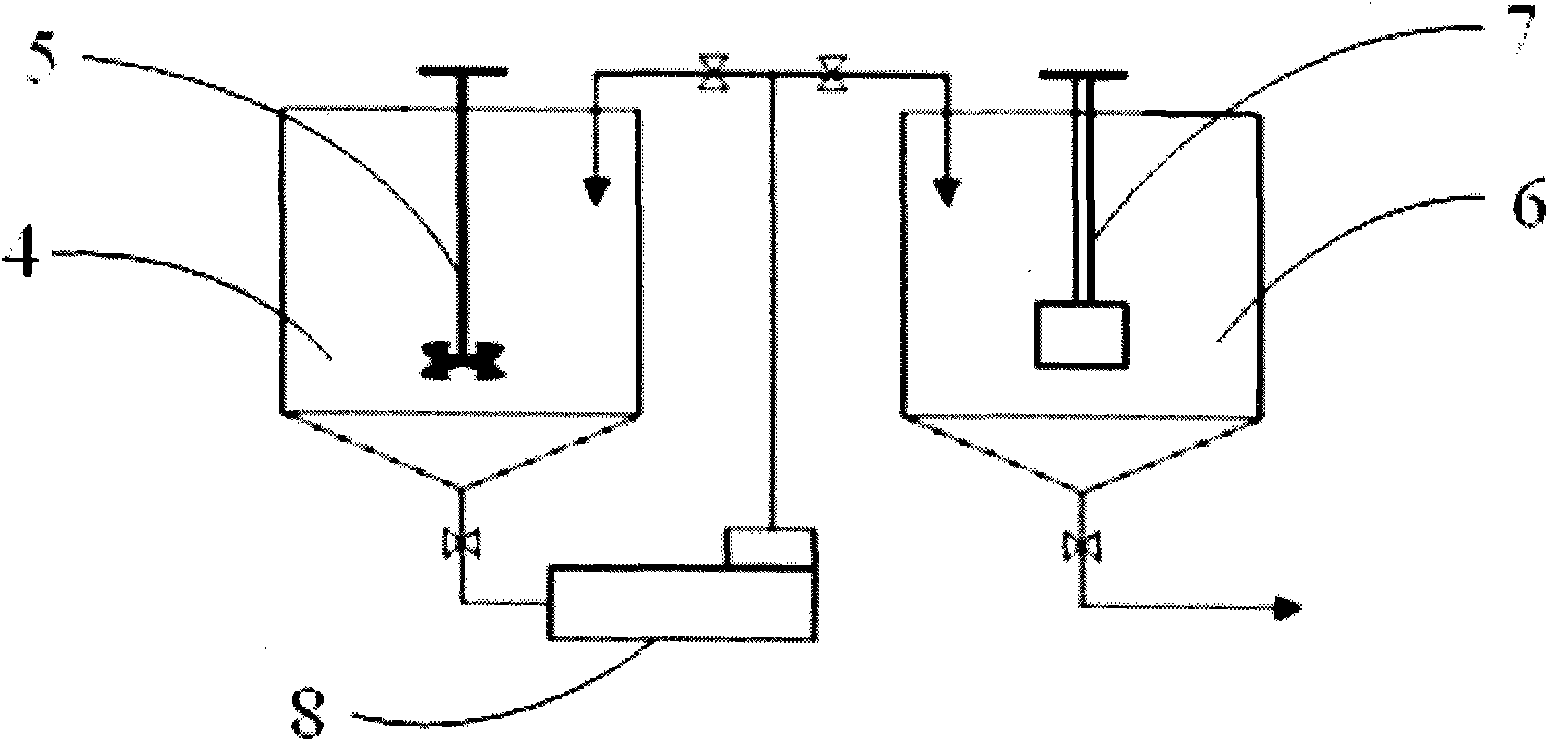

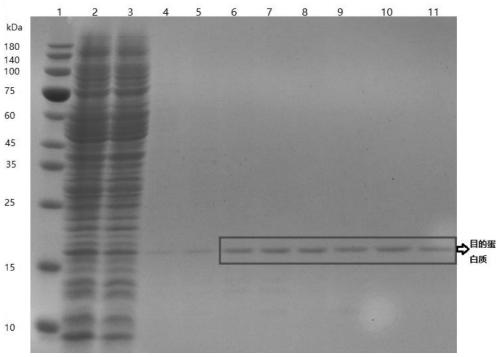

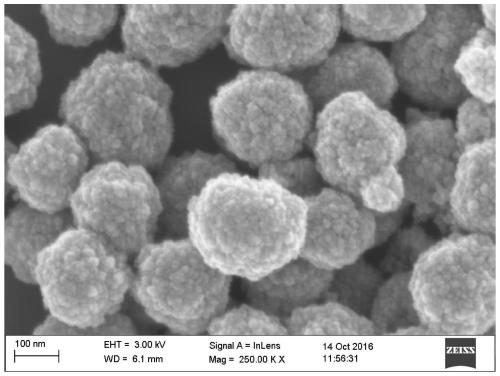

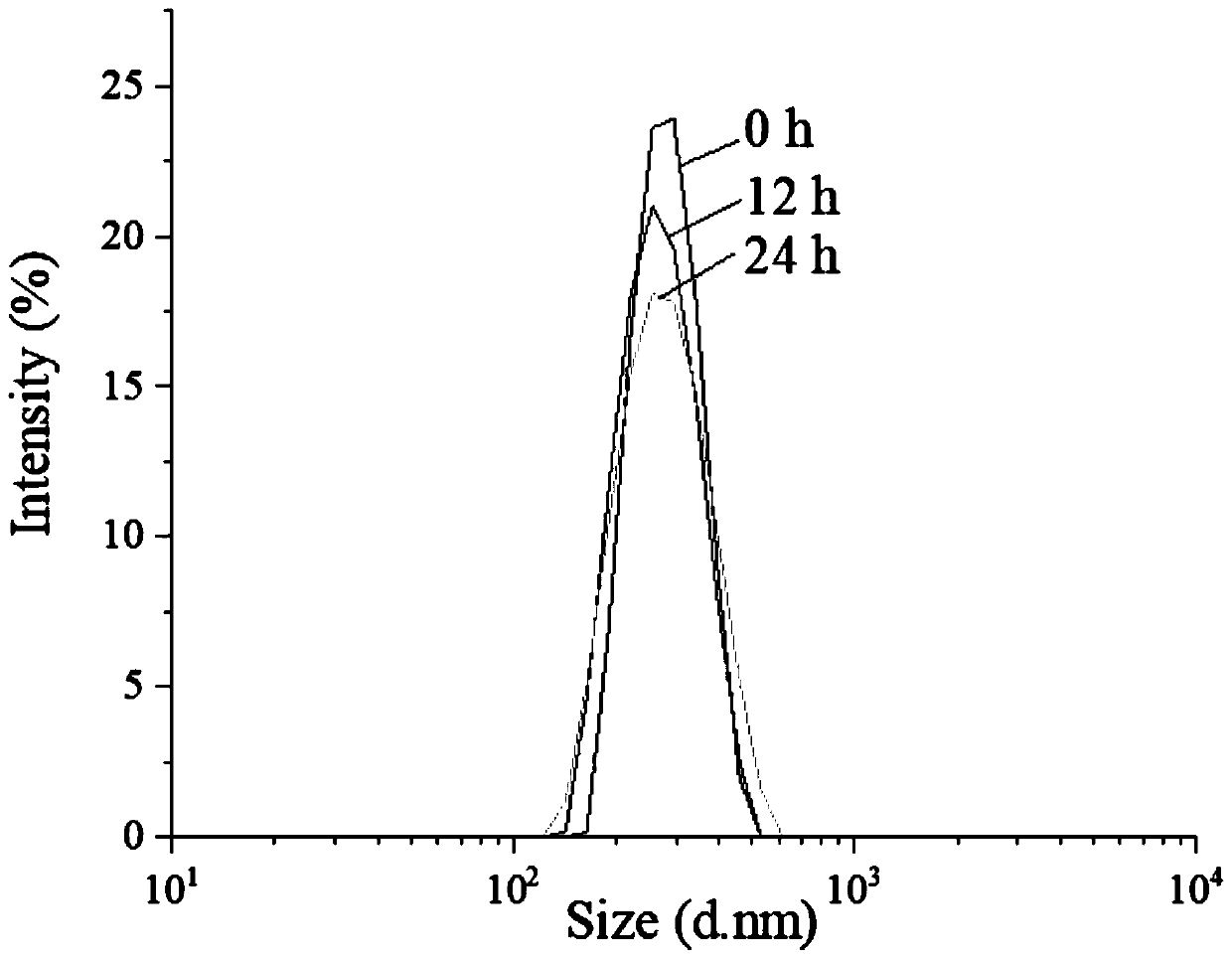

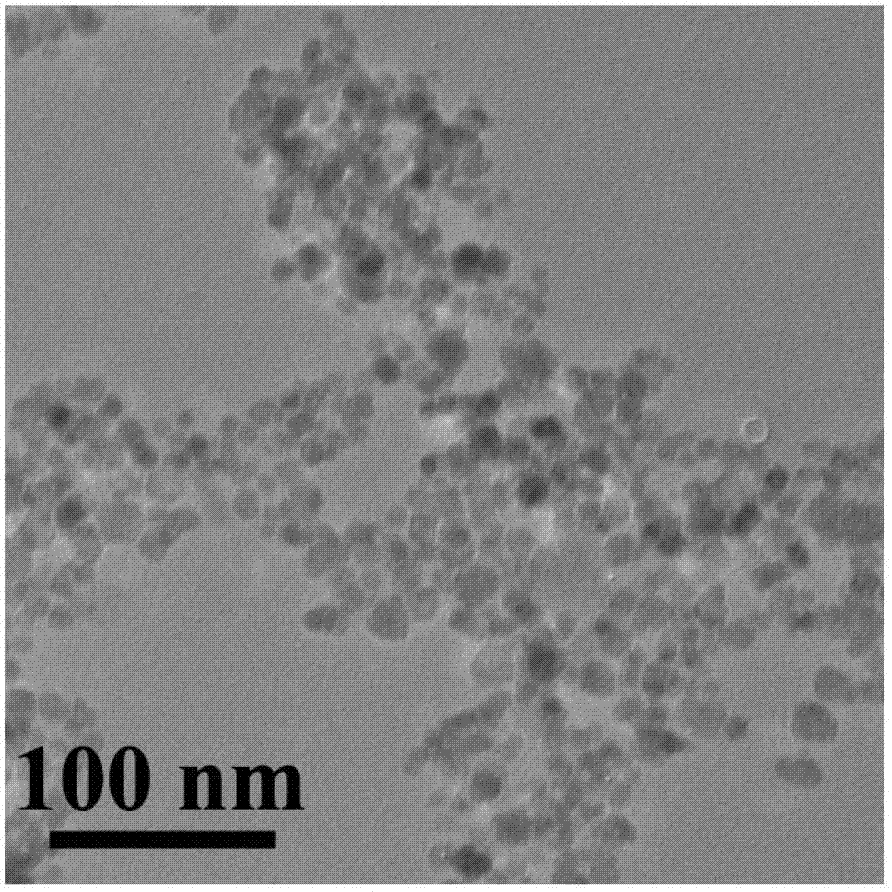

Preparation method of nano magnetic beads for purifying histidine tagged protein

ActiveCN109758989ARapid purificationEasy to separateMicroballoon preparationMicrocapsule preparationCross-linkMagnetic bead

The invention discloses a preparation method of nano magnetic beads for purifying histidine tagged protein. The method comprises the following steps: taking sodium alginate, FeCl3.6H2O, NaAc.3H2O andPEG as raw materials, taking ethylene glycol and deionized water as solvent, reacting through a solvothermal method to generate monodispersed sodium alginate / Fe3O4 nano magnetic beads, subsequently further carrying out an epoxy chloropropane cross-linking reaction and activation on the nano magnetic beads and the newly added sodium alginate, then introducing an iminodiacetic acid (IDA) chelating agent so as to obtain water-stable nano magnetic beads efficiently chelated with metal nickel or cobalt ions; and efficient, rapid, simple and low-cost separation and purification of the histidine tagged protein are realized. The method disclosed by the invention is simple, rapid and stable to operate and low in cost; the synthesized nano magnetic beads are large in specific surface area and stablein a water phase and not prone to agglomeration and precipitation; the purification efficiency of the histidine tagged protein is greatly improved; and the large-batch industrial production of the nano magnetic beads can be realized.

Owner:南京青柠生物科技有限公司

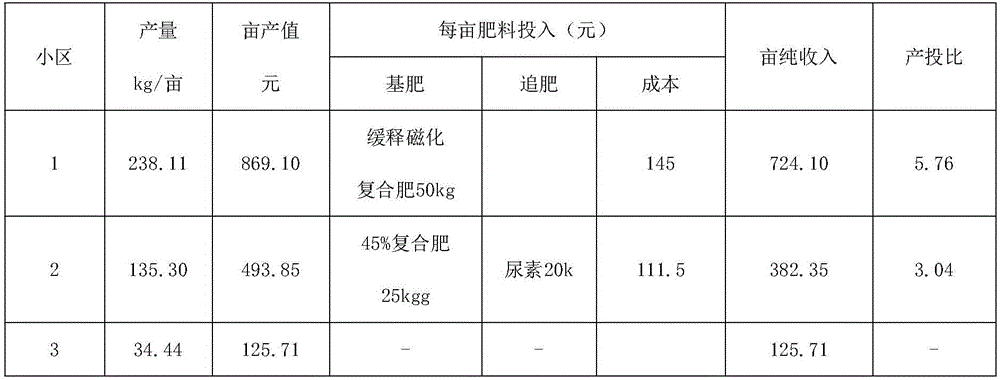

Slow-release magnetized composite fertilizer for planting rapeseed and its preparation method

InactiveCN106187587AIncrease or decrease usageEarly administrationCalcareous fertilisersMagnesium fertilisersPhosphateRapeseed

The invention relates to slow-release magnetized composite fertilizer for planting rapeseed and its preparation method. The slow-release magnetized compound fertilizer for planting rape includes the following raw materials in parts by weight: 24-28 parts of urea, 18-22 parts of potassium dihydrogen phosphate, 3 to 5 parts of calcium powder, 10 to 16 parts of potassium chloride, 2 to 2.5 parts of humic fertilizer, 0.2 to 0.5 part of selenium-rich fertilizer, 0.5 to 1 part of magnesium sulfate heptahydrate, 1 to 2 parts of starch ether, 4 to 8 parts of fertilizer additives, and 34 to 40 parts of magnetic carrier. The slow-release magnetized composite fertilizer for planting rapeseed is characterized in that the iron mineralized tailing sand compound fertilizer is magnetized, the soil environment is improved, the fertilization period of the fertilizer is enhanced, the nutrition absorption of the crop is enhanced, the lodging resistance and disease resistance of the rape are enhanced, yield and earnings are increased, and the environment is protected.

Owner:ANHUI JINLU COMPOSITE MAGNETIC FERTILIZER

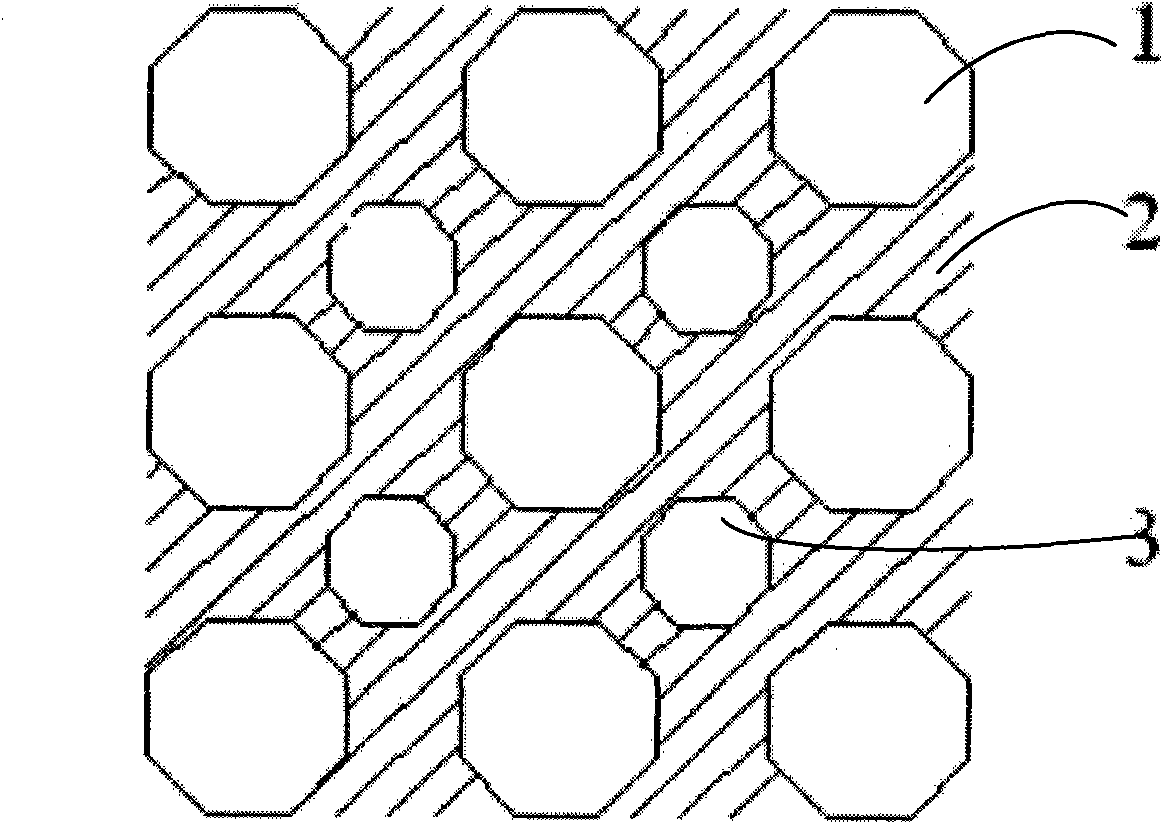

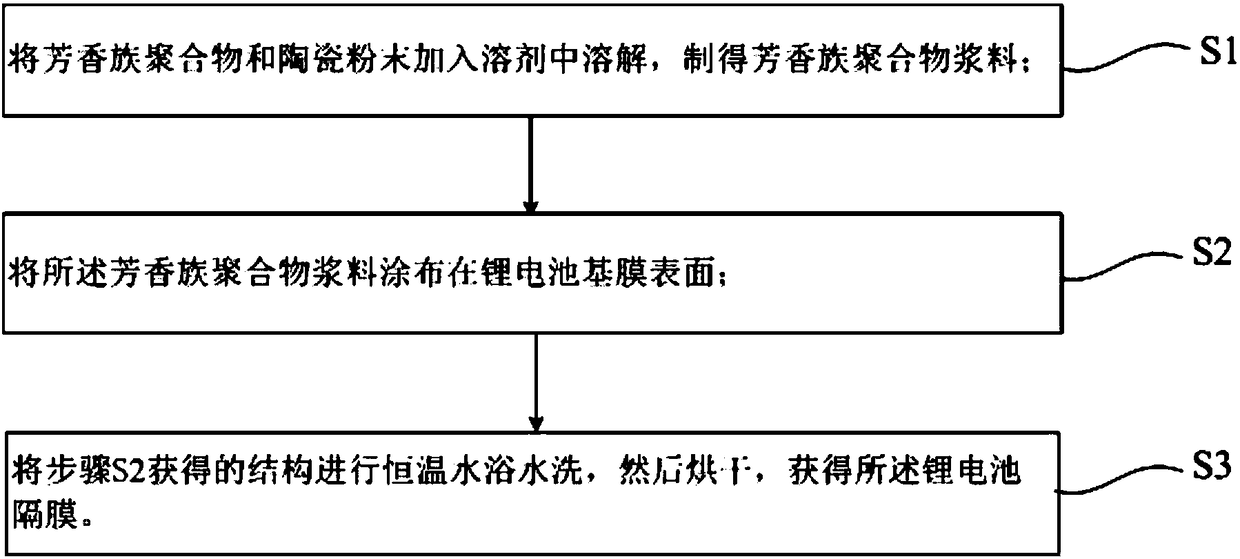

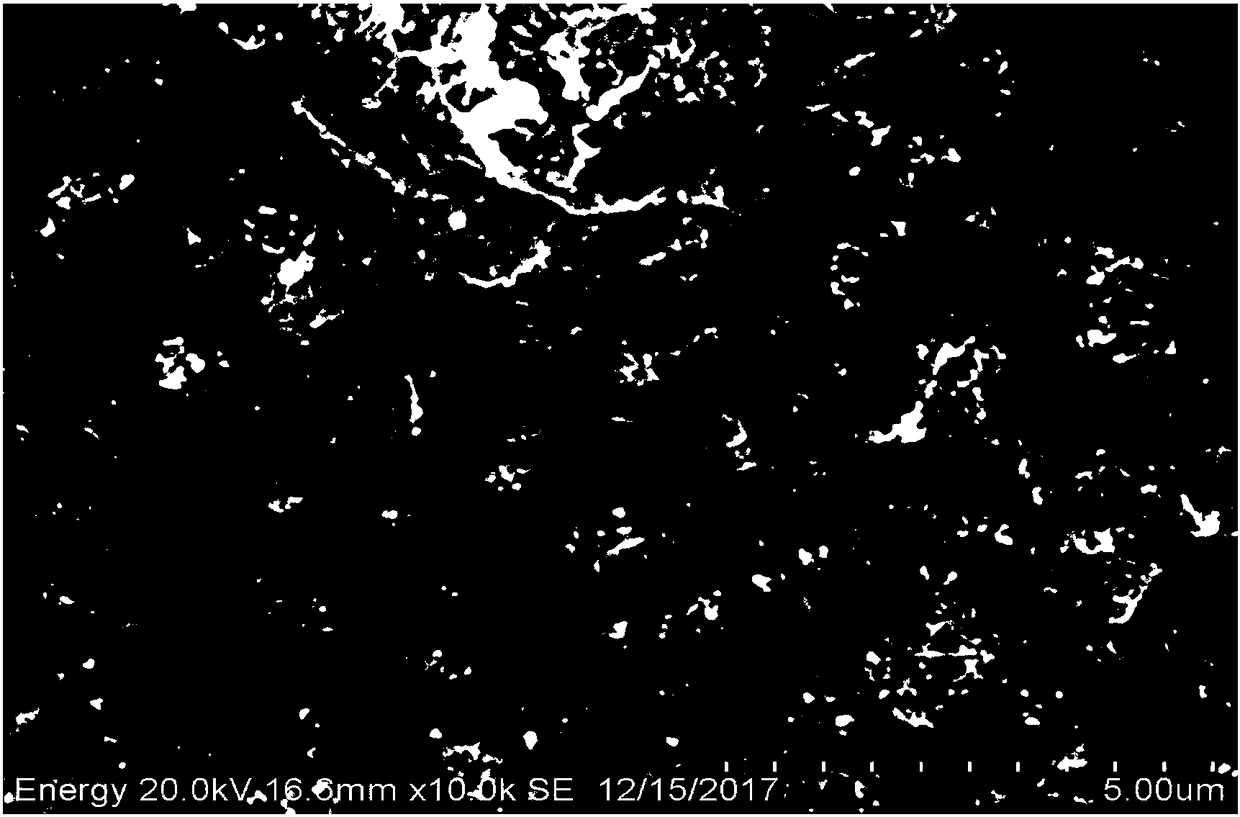

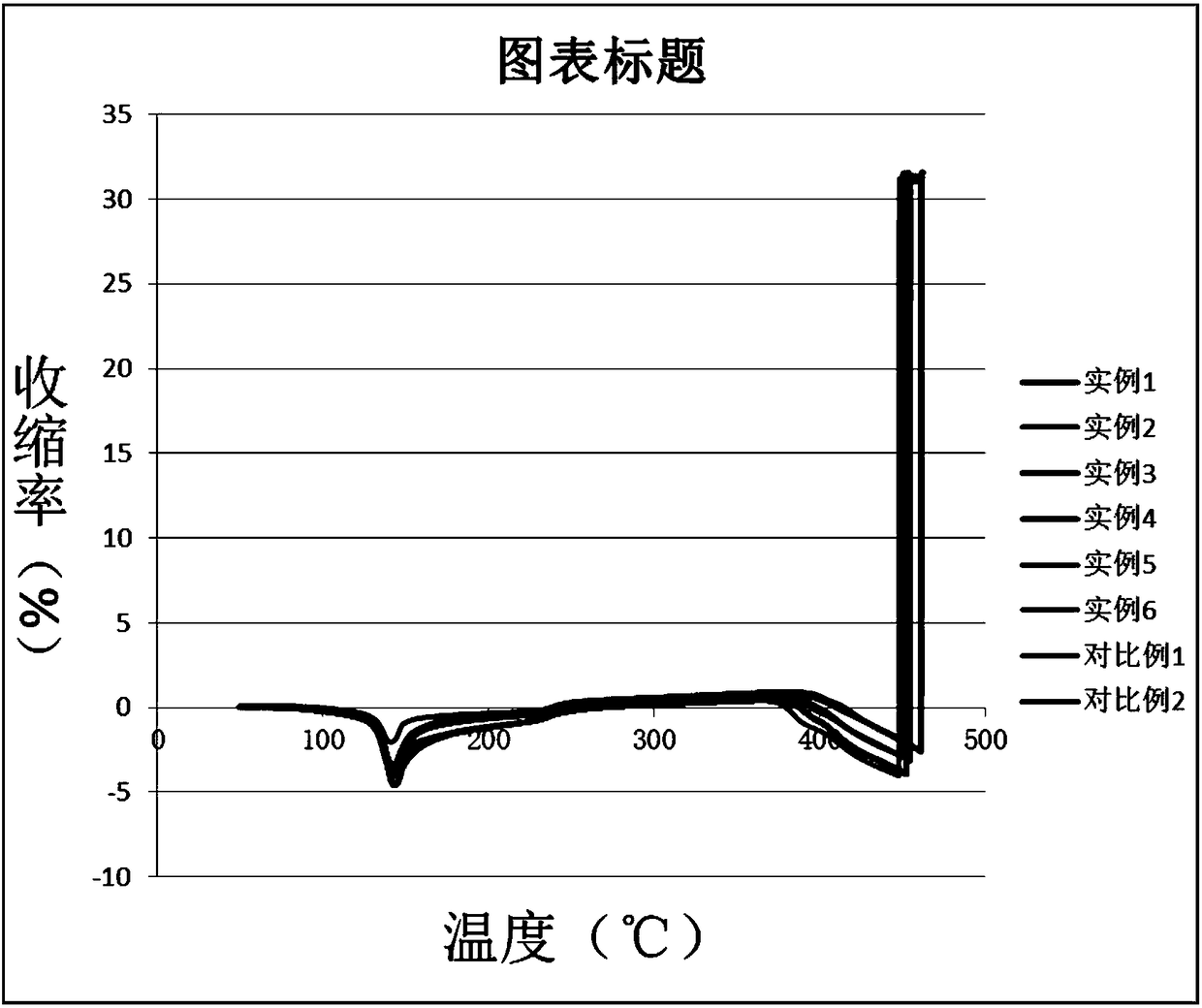

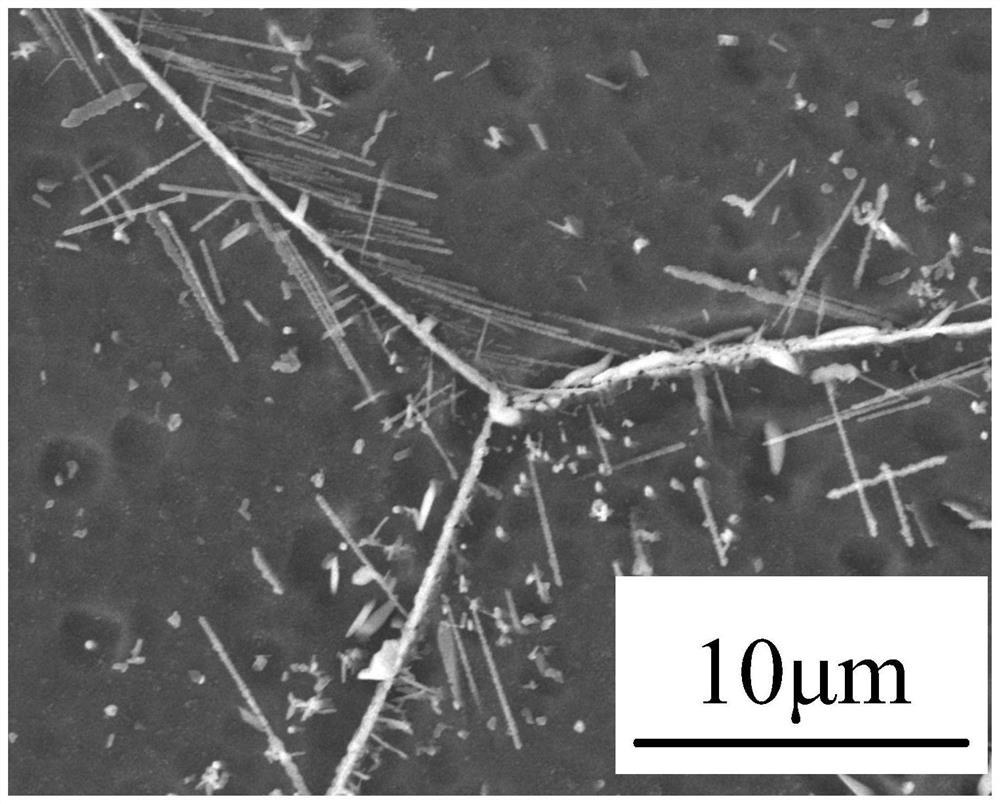

Lithium battery diaphragm and preparation method thereof

ActiveCN108565379AStable and even heatingStable and uniform absorbencySecondary cellsCell component detailsWater bathsPolymer science

The invention provides a lithium battery diaphragm and a preparation method thereof. The method includes the steps that 1, an aromatic polymer and ceramic powder are added into a solvent to be dissolved to prepare aromatic polymer slurry; 2, the surface of a lithium battery base membrane is coated with the aromatic polymer slurry; 3, the structure obtained in step 2 is subjected to constant-temperature water bath washing and then dried to obtain the lithium battery diaphragm. According to the preparation method, after the surface of the base membrane is coated with the aromatic polymer slurry,the net-shaped morphology of fibers is crystallized and separated out at a proper speed, and a three-dimensional net-shaped fiber structure is formed. The stereoscopic net-shaped fiber structure serves as a framework, so that the aromatic polymer coating membrane has excellent heat resistance; in addition, net holes in the three-dimensional net-shaped fiber structure enable the diaphragm to haverelatively high air permeability. Compared with the prior art, a temperature and humidity processing link is omitted, the process flow is simplified, the production efficiency is improved, the production cost is reduced, and manpower and material resources are saved.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

Agricultural ammonium polyphosphate capable of being chelated with medium trace elements and preparation method of agricultural ammonium polyphosphate

ActiveCN104529623AEvenly distributedImprove chelation abilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersTrace elementWater soluble

The invention discloses agricultural ammonium polyphosphate capable of being chelated with medium trace elements. The agricultural ammonium polyphosphate is characterized by comprising the following components in parts by weight: 10000 parts of agricultural ammonium polyphosphate, 200-2000 parts of a trace element additive, 1-100 parts of a sulfur-containing agent, 1-50 parts of a precipitation inhibitor, 1-50 parts of an emulsifying agent, 1-20 parts of an acid and alkali regulating agent, 1-5 parts of an oxidant and 1-5 parts of an amino acid type nutrient. A water-soluble agricultural ammonium polyphosphate fertilizer is compounded so that ammonium polyphosphate and the additive which are originally incapable of being chelated with metal ions or are low in chelation quantity have the chelating capability; the prepared chelated type ammonium polyphosphate is moderate in acid-base property; the solution is stable and free of precipitates within three months; the suitable application temperature range is from -15 DEG C to 40 DEG C; the agricultural ammonium polyphosphate is convenient to popularize and use nationwide.

Owner:SINOCHEM YUNLONG

Chemical palladium immersing solution

InactiveCN103726037AImprove solderabilityImprove conductivityLiquid/solution decomposition chemical coatingCompound (substance)Carboxylic acid

The invention relates to a chemical palladium immersing / palladium replacement plating solution, and particularly relates to a chemical palladium immersing solution which is capable of directly forming a palladium film with good adhesiveness on a chemical nickel plating coating film formed in a PCB (Printed Circuit Board). The chemical palladium immersing solution does not influence a chemical nickel plating film as a base film. The chemical palladium immersing solution contains a soluble palladium salt, a first complexing agent, a second complexing agent, a pH regulating agent and a brightening agent. The first complexing agent is one or more of ammonia and diamine, and the second complexing agent is one or more of amino carboxylic acid compounds and hydroxy carboxylic acid compounds. The chemical palladium immersing solution has the characteristics of stable pH, stable deposition rate, long bath service life and excellent bath stability; a uniform and flat palladium plating film with excellent solder connectivity and lead weldability can be obtained.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Medicament for reducing and removing heavy metal ion in wastewater in coal cutting subsidence area, and processing method

InactiveCN101050009AStable precipitationReduce loadWaste water treatment from quariesWater contaminantsIon contentHeavy metal chelation

This invention relates to a reagent for reducing heavy metal ion content in wastewater in coal mining collapse area, and a method for treating wastewater with the reagent. The reagent is polymer with large amounts of polar groups and long chains obtained by reaction between polyamine and CS2. The sulfur atoms in the dithiocarbamate of the reagent can chelate with heavy metal ions through coordination bonds to obtain stable crosslinked chelate precipitate. Thus, heavy metal ions in wastewater in coal mining collapse area are effectively removed. The method comprises: diluting the heavy metal ion chelating reagent, adding into wastewater, and stirring, reacting for a certain time to obtain chelate precipitate, standing, filtering, draining, and recovering the precipitate. The method lays a necessary basis for ecological remediation of wastewater in coal mining collapse area, and reduces the load of biological treatment and plant remediation.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for achieving stabilized solidification of high-concentration arsenic soda slag

ActiveCN106422151AStabilization and curing effect consolidation and improvementStable precipitationChemical protectionHigh concentrationHydrogen peroxide

The invention discloses a method for achieving stabilized solidification of high-concentration arsenic soda slag. The method comprises the steps that the arsenic soda slag is crushed into arsenic soda slag particles; an oxidizing agent composed of hydrogen peroxide and persulfate is added into the arsenic soda slag firstly and stirred evenly; then a stabilizing agent composed of ferric salt and / or ferrous salt is added into the arsenic soda slag and stirred evenly; and finally, a conditioner composed of red mud, coal ash, kaolin and / or attapulgite is added and stirred evenly, and maintenance is conducted. According to the method, by the adoption of the stabilizing agent, the synergistic interaction for solidifying components of reagents is remarkable, high-efficient stabilized solidification of the high-concentration arsenic soda slag can be achieved, and the method is easy to implement, low in cost and suitable for application and popularization.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Preparation method of ginsenoside extract for beverage

The invention discloses a preparation method of a ginsenoside extract for a beverage. The preparation method aims to solve the technical problems that a current ginsenoside extract is prone to being turbid after being dissolved in water and is difficultly applied to addition in the beverage with a certain requirement for clarity. The preparation method comprises the approximate steps: ginsenosidein raw ginseng is subjected to liquid extraction firstly, and grease in ginsenoside extraction filtrate is removed through diatomite; then insoluble tiny impurities in the ginsenoside extraction filtrate are removed by filtering through a three-stage filtration system; and finally, spray drying is conducted, by combing the difference between the molecular weight of proteins and the molecular weight of the ginsenoside and ultrafiltration membrane separation, the unstable macromolecular proteins are separated, and thus the ginsenoside extract with high solution stability is obtained. A clarifiedsystem can be formed by the ginsenoside extract obtained through the preparation method and a solution, thus it is ensured that the obtained ginsenoside extract has the great solution stability, theapplication concentration of the ginsenoside in the beverage is greatly increased, and the stability of the ginsenoside in the beverage is greatly improved.

Owner:广东青云山药业有限公司

Roller kiln low-temperature sintered colorful halo crystal glaze and preparation method thereof

The invention relates to the technical field of new ceramic materials, and particularly discloses a roller kiln low-temperature sintered colorful halo crystal glaze which comprises a ground glaze anda cover glaze, and the ground glaze comprises the following components in parts by weight: 80 to 90 parts of lead-zinc frit and 10 to 20 parts of pigment; the cover glaze is prepared from the following components in parts by weight: 50 to 70 parts of high-boron frit, 5 to 10 parts of titanium dioxide, 10 to 20 parts of zinc oxide, 5 to 15 parts of talc, 0 to 10 parts of calcite and 17 to 30 partsof seeding colorant, wherein the seeding colorant is prepared from manganese dioxide, vanadium pentoxide and copper oxide. The preparation method of the roller kiln low-temperature sintered colorful halo crystal glaze comprises the steps of preparing the ground glaze and cover glaze, glazing and sintering, wherein the highest sintering temperature is 1125 to 1135 DEG C, and the sintering period is190 to 210 min. The crystal glaze suitable for roller kiln low-temperature sintering is prepared, the glaze surface can show a circle of colorful halo under the sun, and the process effect of metal and crystal glaze is achieved.

Owner:佛山市玉矶材料科技有限公司

Microorganism passivation method for remedying heavy metal lead polluted soil

The invention discloses a microorganism passivation method for remedying heavy metal lead polluted soil. The microorganism passivation method comprises the steps that trehalose is added into a culturemedium, microorganism bacteria solution fermentation cultivation is conducted to obtain a microorganism bacteria solution, the microorganism bacteria solution is added into vinegar residues, and a microorganism bacteria solution / vinegar residue mixture is prepared; the microorganism bacteria solution / vinegar residue mixture is evenly spread in the soil, ploughing is conducted, and thus the pH ofthe soil is lowered to acidic; and finally phosphorus-containing materials and sodium silicate are evenly mixed, a mixture of the phosphorus-containing materials and the sodium silicate is evenly spread in the soil, and ploughing is conducted again. Through the microorganism passivation method, colonizing capacity of microorganisms can be improved, operation is simple, the microorganism passivation method is economical, efficient and suitable for acid, alkaline and neutral soil, the properties of the polluted soil are improved, and soil fertility is improved.

Owner:NANJING UNIV OF TECH

Method for preparing high-purity magnesium oxide

The invention discloses a method for preparing high-purity magnesium oxide. The method comprises the following steps: 1) detecting iron content in a magnesium hydrogen carbonate solution, adding an excessive strong oxidant, performing oxidation on Fe2+ to Fe3+ under condition that a pH value is 6-8, and precipitating the material to obtain iron hydroxide precipitate; 2) after oxidation is completed, according to an excessive value of the strong oxidant, adding a weak reducing agent for a neutralization reaction, 3) adding active carbon to absorb the iron hydroxide precipitate, filtering the iron hydroxide precipitate to obtain low-iron magnesium hydrogen carbonate solution with an iron content being less than or equal to 0.6 mg / L; and 4) performing pyrolysis, filtering and calcining on thelow-iron magnesium hydrogen carbonate solution in order to obtain the high-purity magnesium oxide. The method has the advantages of stable operation and high iron removal rate, iron hydroxide precipitated during whole process flow cannot be easily re-dissolved, the iron content of a magnesium product is low, and quality of the product can be increased to analytically pure by an industrial article.

Owner:青海美盛新材料科技有限公司

Cadmium-lead compound contaminated soil repairing agent and application thereof

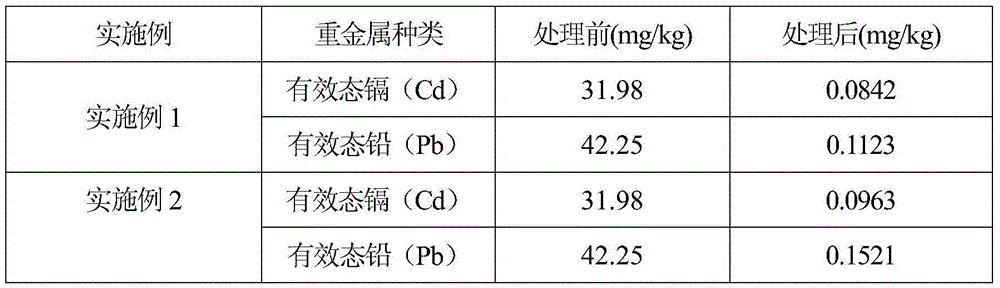

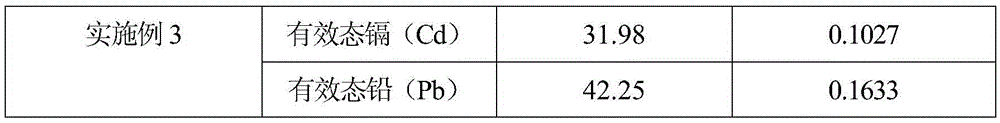

InactiveCN105602573AHigh porosityHigh adsorption valueOther chemical processesContaminated soil reclamationTreatment effectAdditive ingredient

The invention provides a cadmium-lead compound contaminated soil repairing agent which consists of the following ingredients in percentage by weight: 30-50% of biomass charcoal, 10-20% of potassium humate, 10-20% of a 13X molecular sieve, 10-20% of sodium dodecyl sulfate and 10-20% of iron powder. The ingredients give full play to a synergistic effect; by virtue of effects such as reduction, sedimentation, adsorption, improvement and PH value regulation, available heavy metals in soil are greatly reduced, and the prepared soil repairing agent has a favorable effect on repairing cadmium-lead compound contaminated soil. The repairing agent provided by the invention has the advantages of simple preparation method, feasibility and good treatment effect.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

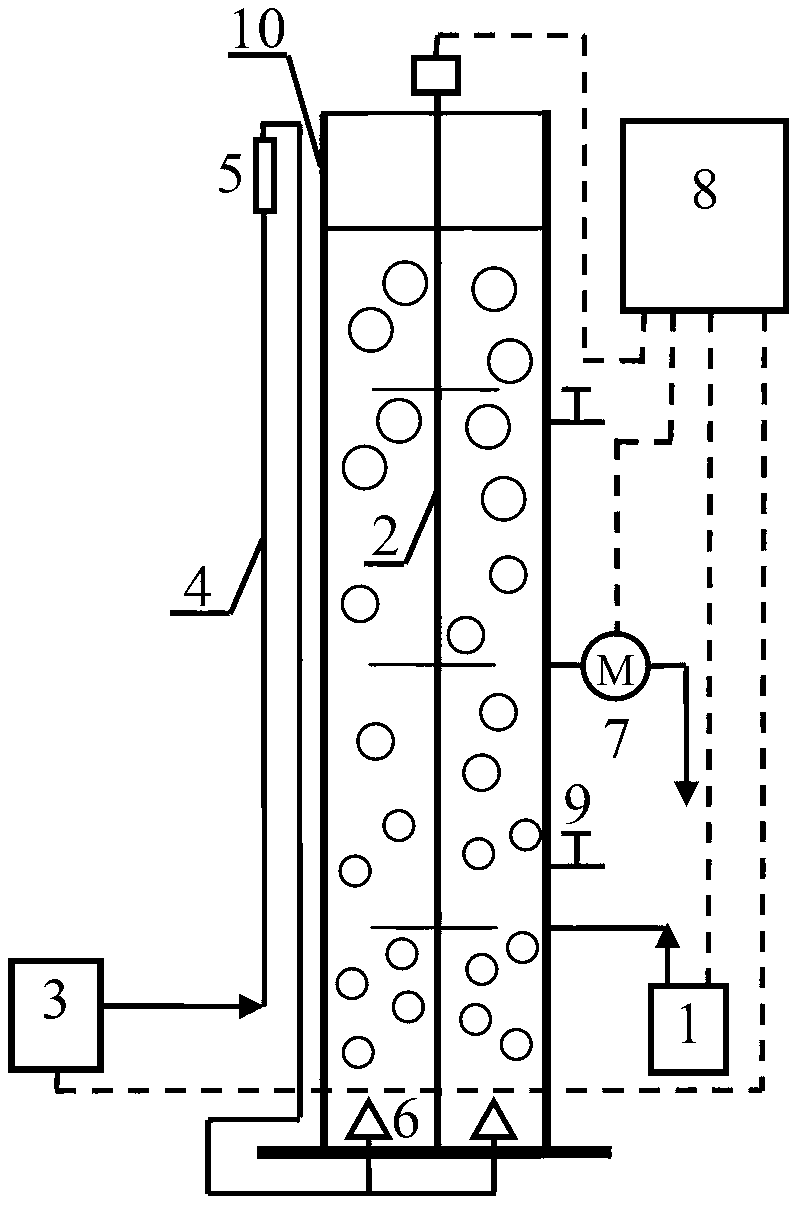

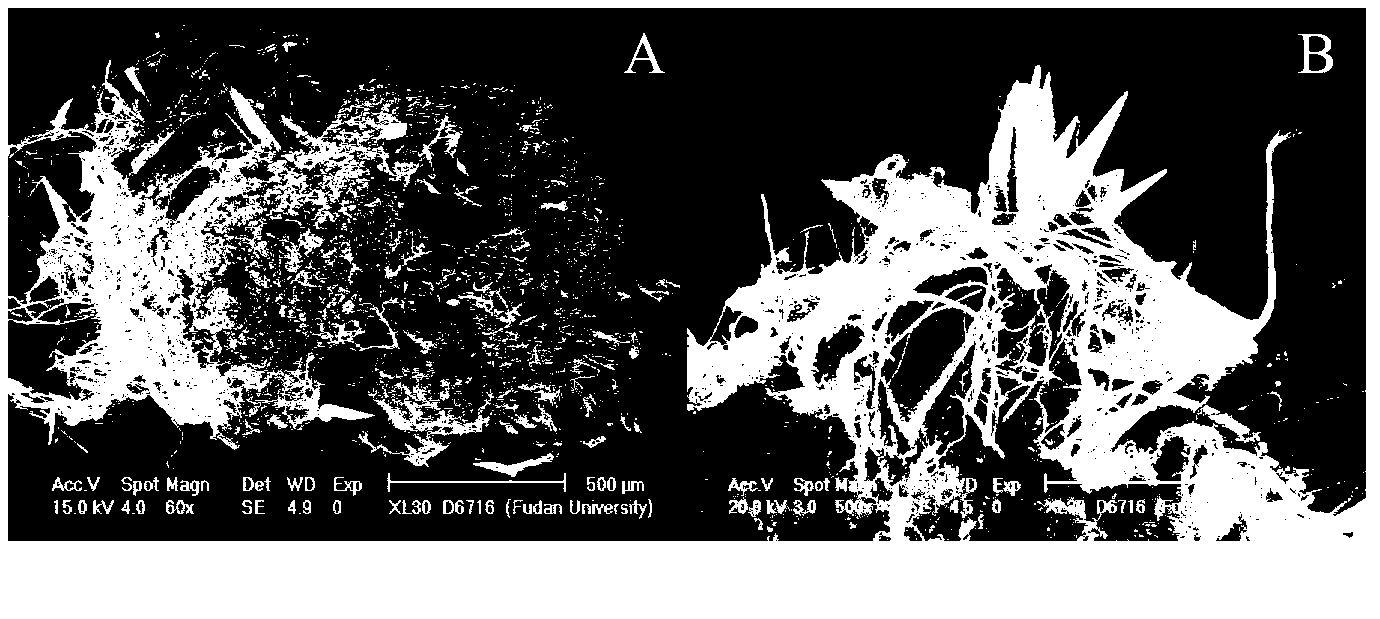

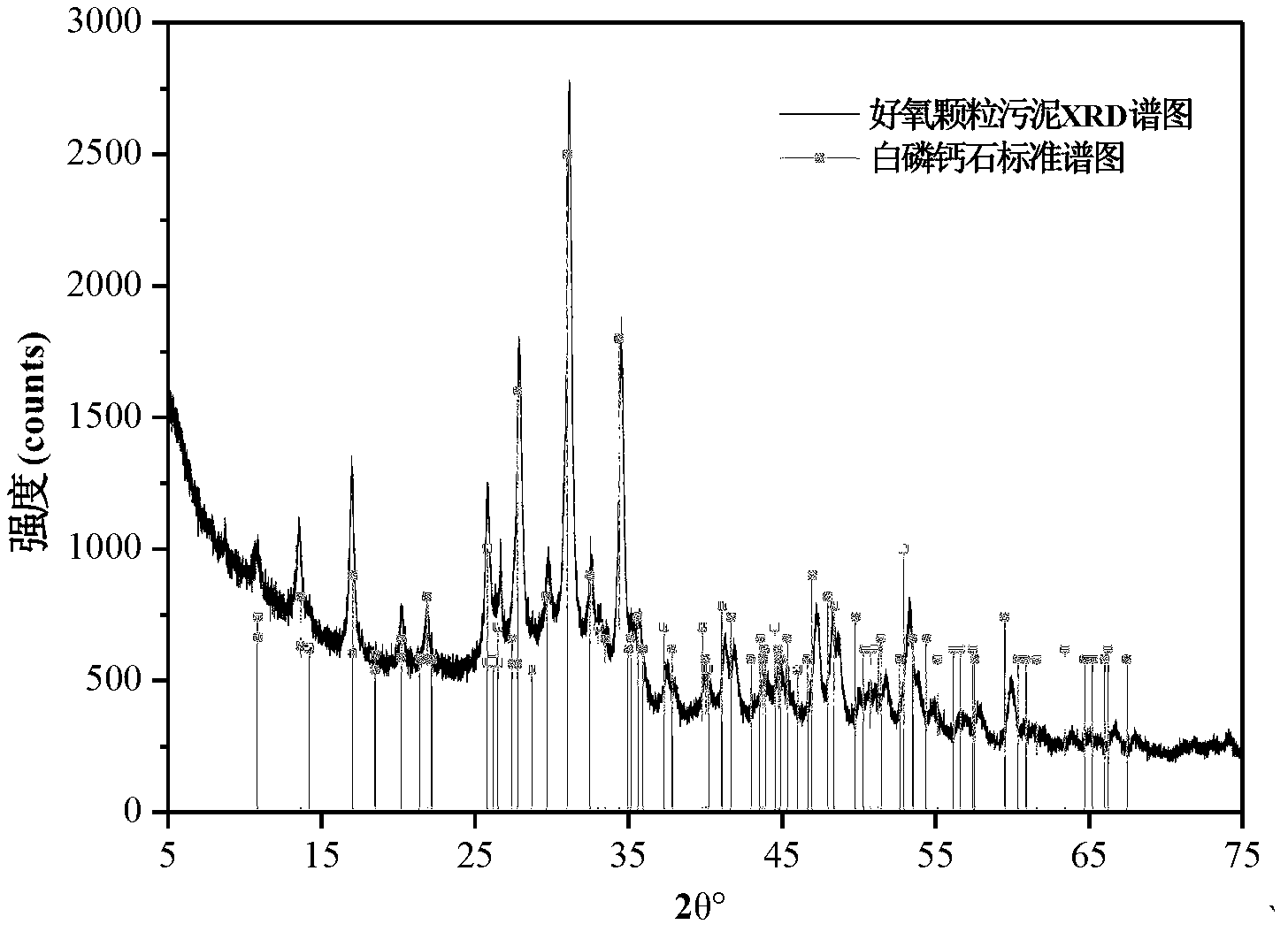

Method for enriching phosphorus by using aerobic granular sludge

ActiveCN103214087AGood settlement performanceParticle size and specific gravitySustainable biological treatmentBiological water/sewage treatmentSpecific gravityChemistry

The invention belongs to the field of wastewater treatment and phosphorus resource recovery, and relates to a method for enriching phosphorus by using aerobic granular sludge. The method comprises the following steps of: (1) inoculating flocculent sludge which is precipitated and concentrated to a sequencing batch reactor, then introducing water into the sequencing batch reactor, continuously aerating to acclimate the sludge, then precipitating, and discharging supernatant liquid to a water outlet of the reactor; (2) introducing water; (3) aerating; (4) precipitating; (5) draining; (6) idling; and (7) repeating the steps (2) to (6), thereby obtaining high-phosphorus-enriched aerobic granular sludge. The phosphorus-enriched aerobic granular sludge prepared by the method has excellent sedimentation characteristics, the particle diameter and specific gravity of particles are large, and meanwhile, the denitrification and decarburization effects are good, so that the capital construction cost of a sewage treatment plant can be reduced in actual projects, and the process is simple.

Owner:TONGJI UNIV

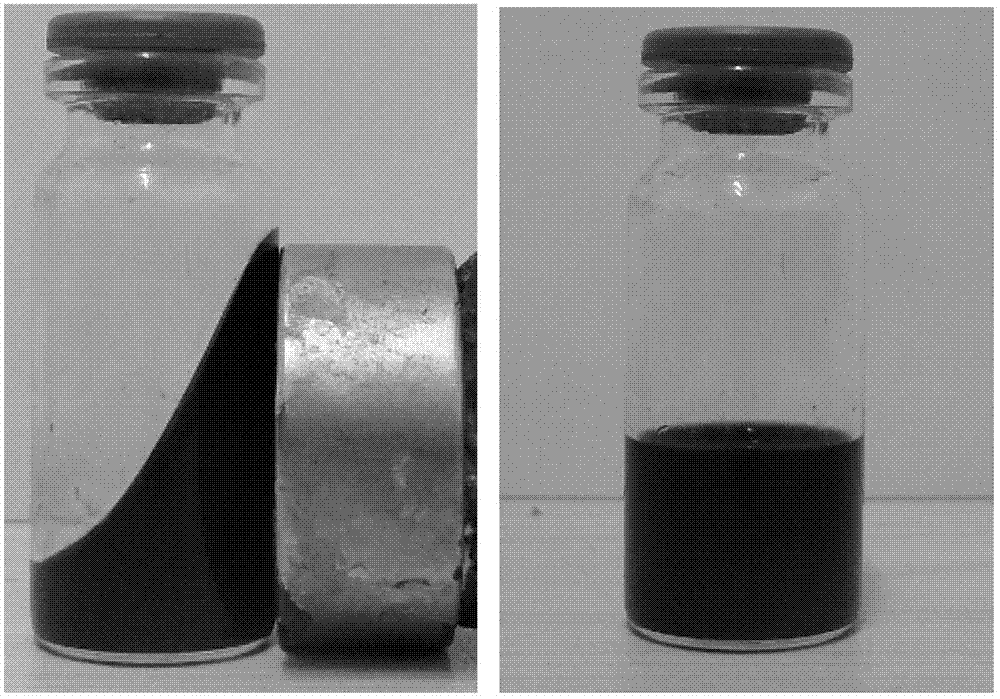

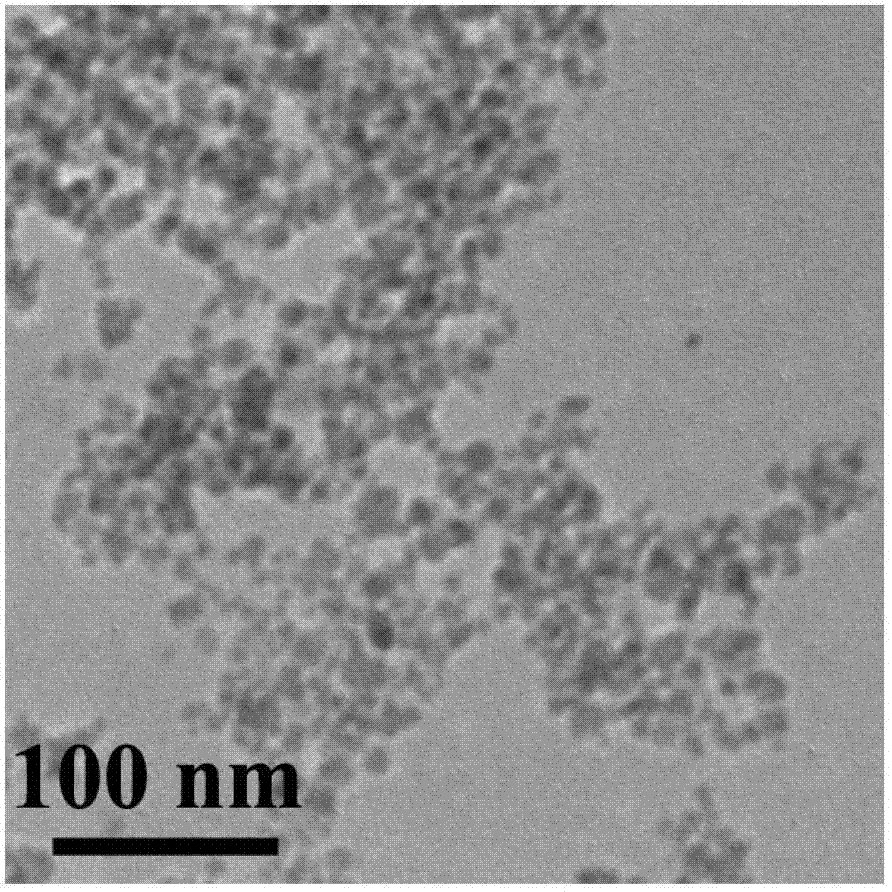

Polyamino acid coated nano-magnetic fluid composite material and preparation method for same

InactiveCN102881398AImprove magnetic propertiesStrong magnetismMaterial nanotechnologyMagnetic liquidsSignal responsePolyaspartic acid

The invention discloses a polyamino acid coated nano-magnetic fluid composite material and a preparation method for the same, and belongs to the technical field of magnetic fluids. A polyaspartic acid obtained by the hydrolysis of polysuccinimide is coated on the surface of a magnetic ferroferric oxide nano-particle, a part of carboxyl groups are coupled with the ferroferric oxide nano-particle, and a part of carboxyl groups are free outside the particle. The polyamino acid coated nano-magnetic fluid composite material can be obtained by reacting a 6,000-molecular weight mixed solution of the polysuccinimide and a solution of sodium hydroxide with FeCl3 and Fe(NH4)2(SO4)2 in a Teflon reaction kettle, and performing separation and washing. The material synthesized by the method is high in crystallinity and magnetism and quick in T2 weighted signal response.

Owner:BEIJING UNIV OF CHEM TECH

Method for decolorizing heparin sodium and lowering dermatan sulfate content

The invention discloses a method for decolorizing heparin sodium and lowering dermatan sulfate content, belonging to the technical field of heparin sodium purification. The method comprises the following steps: (1) dissolving heparin sodium in a sodium acetate solution; (2) regulating the pH value of the solution obtained in the step (1) to an acidic state with acetic acid (3) heating the solution obtained in the step (2) to 60 DEG C, adding ethanol accounting for 0.7-1.0 time by weight of the solution while stirring, keeping the solution at 60 DEG C for 1 hour, and stopping stirring; (4) cooling the solution obtained in the step (3) to room temperature in a gradient cooling mode; and (5) after finishing the gradient cooling in the step (4), removing the supernate containing waste ethanol, and dehydrating and drying the subnatant precipitate solid to obtain the purified heparin sodium. The method for treating heparin sodium can effectively remove the color and lower the dermatan sulfate content in the heparin sodium.

Owner:NANJING KING FRIEND BIOCHEM PHARMA CO LTD

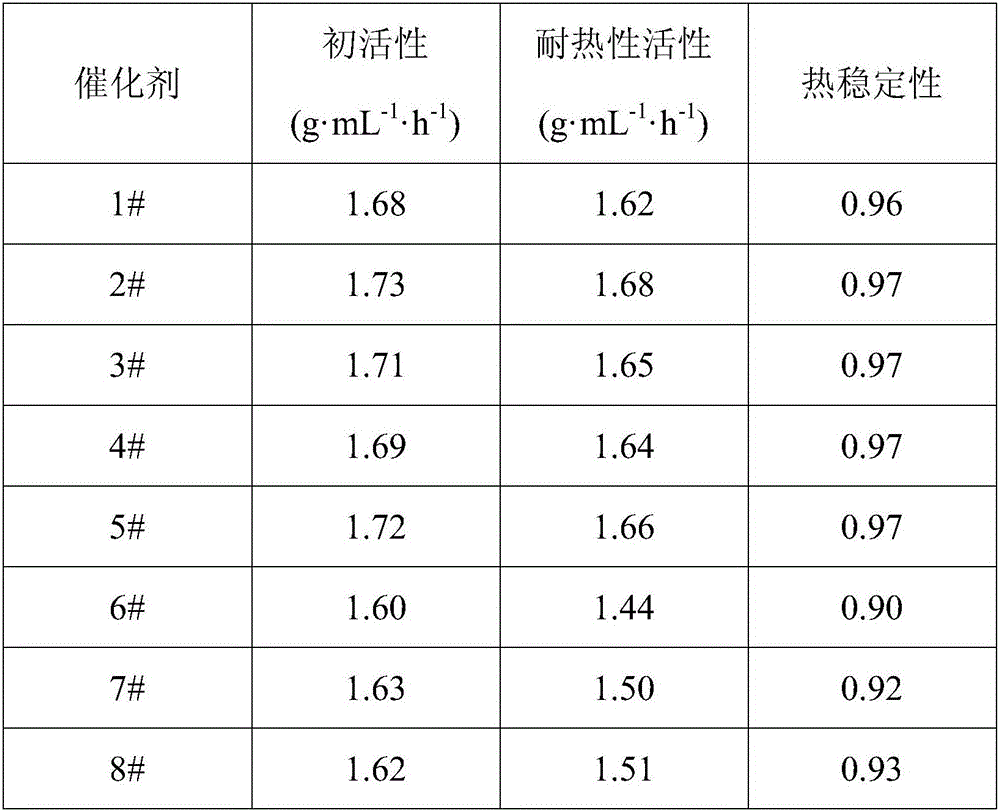

Copper-based methanol synthesis catalyst and preparation method thereof

ActiveCN105964267AEnsure activity stabilityEnsure thermal stabilityOrganic compound preparationHydroxy compound preparationSyngasHeat stability

The invention provides a copper-based methanol synthesis catalyst and a preparation method thereof. The method includes the steps that copper-zinc mixed liquor is mixed with a first precipitator aqueous solution in a parallel flow mode, the pH is controlled to be 7-8, standing is performed for ageing, and slurry A is formed; a second precipitator aqueous solution is added into a soluble aluminum salt aqueous solution, the pH is controlled to be 7-8, the temperature is controlled to be 40-50 DEG C, standing is performed for ageing, and slurry B is obtained; the slurry A and the slurry B are mixed and filtered, a solid phase is washed, dried, roasted and formed, and the copper-based methanol synthesis catalyst is obtained. According to the preparation method, the steps are simple, the controllability is high, the raw material source is wide, and industrialization is easy to achieve; by the adoption of the preparation method, the copper-based methanol synthesis catalyst with high catalytic activity and heat stability can be obtained and is suitable for producing methanol with synthesis gas containing CO, CO2 and H2 under the low temperature and low pressure conditions; besides, the catalyst does not need reduction before use and can be conveniently applied and popularized on a large scale.

Owner:SHENYANG SANJUKAITE CATALYST +1

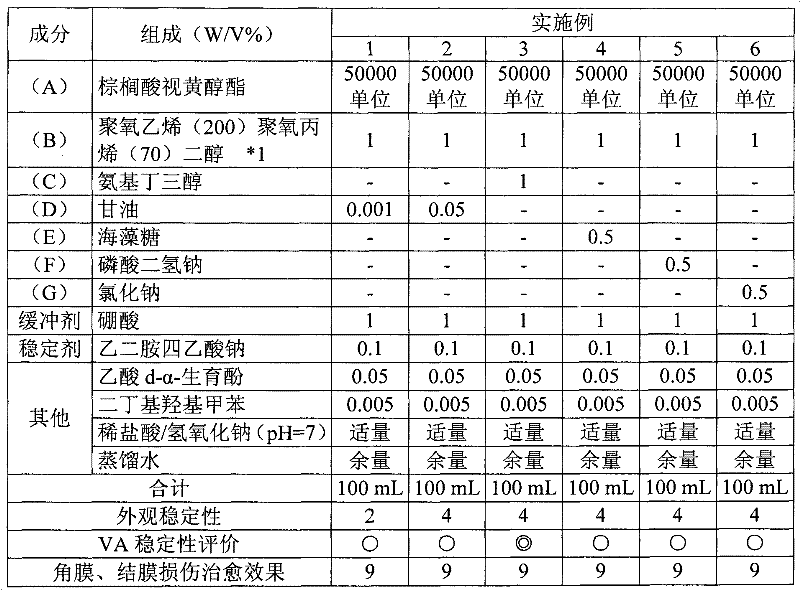

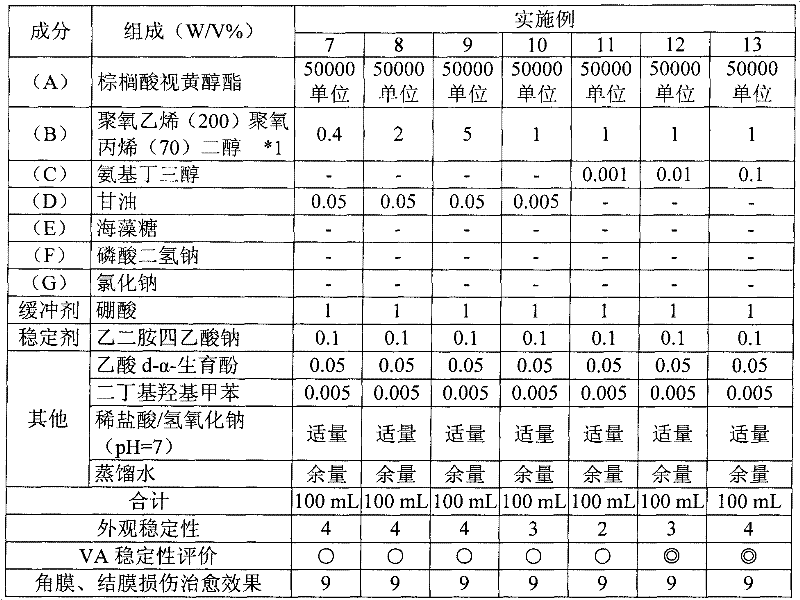

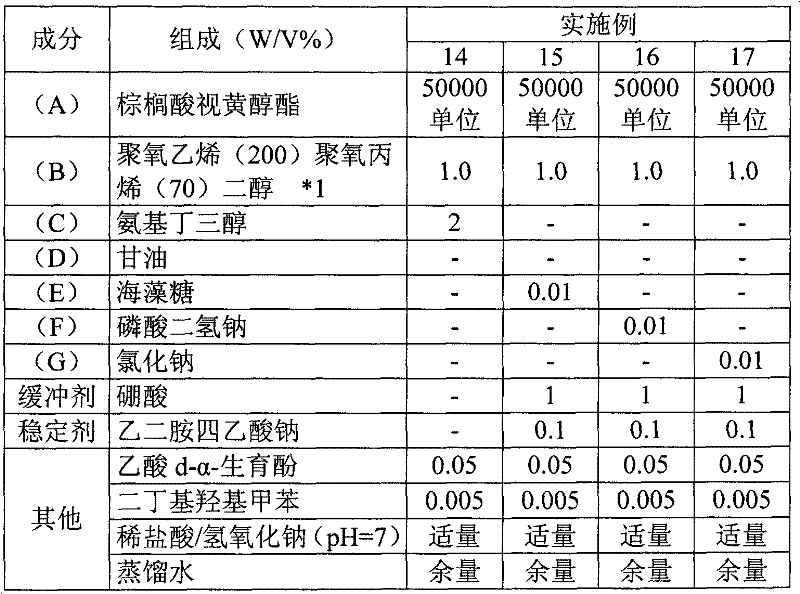

Ophthalmic composition and method for prevention of cloudiness/precipitation

ActiveCN102481268AStable mixStable appearanceSenses disorderHydroxy compound active ingredientsAlcoholVitamin A Alcohol

An ophthalmic composition characterized by comprising (A) vitamin A, (B) a polyoxyethylene polyoxypropylene glycol, and at least one component selected from (C) trometamol, (D) polyhydric alcohols, (E) saccharides, (F) phosphoric acid and salt thereof and (G) monovalent neutral salts.

Owner:LION CORP

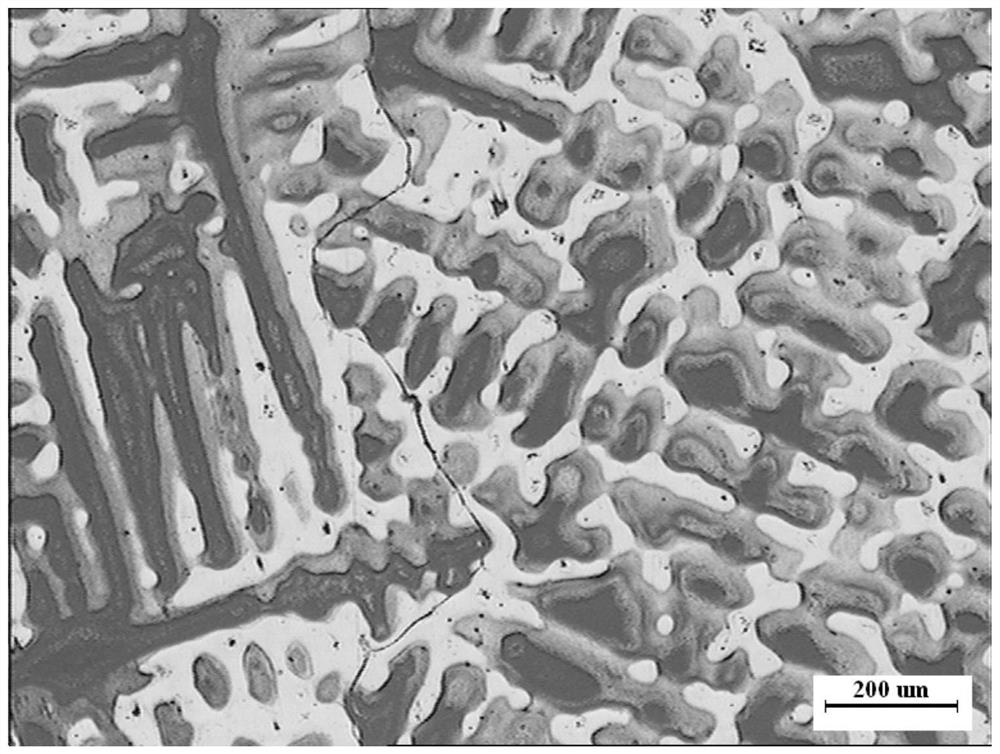

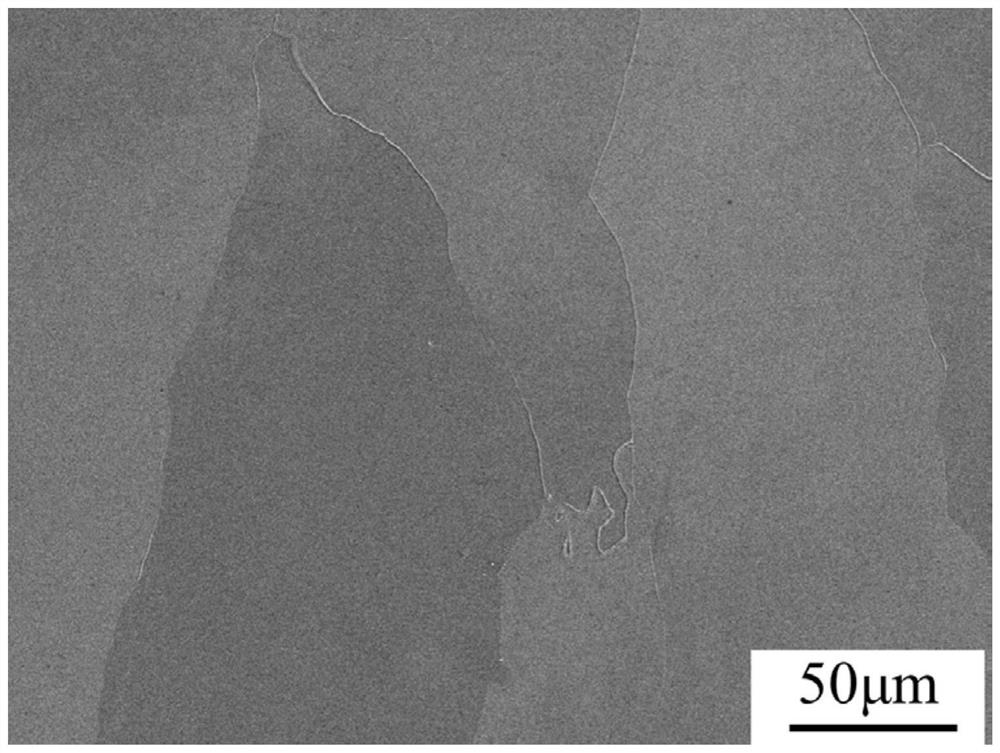

Tantalum-containing cast nickel-based superalloy for 700 DEG C unit and preparation method thereof

The invention discloses a tantalum-containing cast nickel-based high-temperature alloy for a 700 DEG C unit and a preparation method thereof. The alloy comprises the following components in percentage by mass: 0.2-2.0% of Ta, 20-23% of Cr, 11-13% of Co, 8-9% of Mo, 1.2-2.4% of Al + Ti, less than or equal to 1% of Nb, less than or equal to 0.06% of C, less than or equal to 0.004% of B and the balance of Ni. The method comprises the following steps: (1) preparing raw materials according to set components; (2) smelting under a vacuum condition; (3) refining and removing impurities, and then carrying out vacuum pouring; (4) keeping the vacuum condition until the molten steel forms a film, and discharging to prepare a cast ingot; and (5) preserving heat at 1150-1200 DEG C for 1-2 hours, carrying out solution treatment, and carrying out water cooling. According to the invention, the strength of the solid solution is ensured by utilizing the matching of several elements including the Ta element, meanwhile, a more stable precipitated phase is formed, the coarsening of a grain boundary is inhibited, and meanwhile, the optimal chemical component range, the optimal element adding proportion and the optimal heat treatment process system are determined.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Oil removal process for cobalt sulfate extraction waste liquid

PendingCN113620534AAchieve reuseImprove adsorption capacityFatty/oily/floating substances removal devicesSpecific water treatment objectivesWastewaterPolymeric adsorbent

The invention relates to an oil removal process for cobalt sulfate extraction waste liquid, and belongs to the technical field of waste liquid treating, DA201-A resin is used for effectively adsorbing oil in waste water, after the DA201-A resin is saturated in adsorption, the oil is decomposed and adsorbed in a steam blowing mode, and the oil is recycled in a condensation mode, so that waste of oil resources is avoided, And dilute alkali is added to regenerate the activity of the DA201-A resin so as to realize the reuse of the DA201-A resin, an unrecyclable oil component C is introduced into a biochemical tank to obtain a waste liquid B, a modified flocculantis added into the waste liquid B, filtering is performed to obtain recyclable wastewater and wastewater containing flocculate, and the waste of resources can be effectively reduced.

Owner:科立鑫(珠海)新能源有限公司

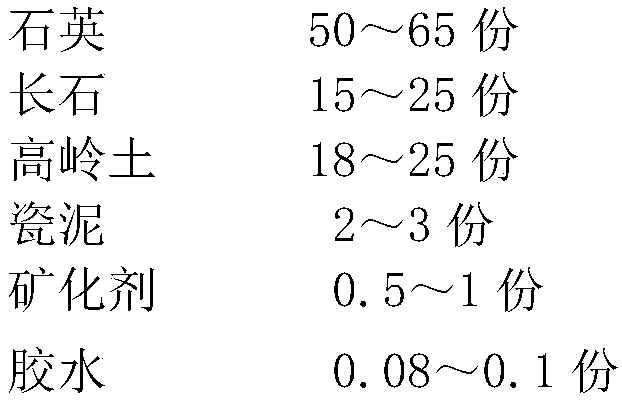

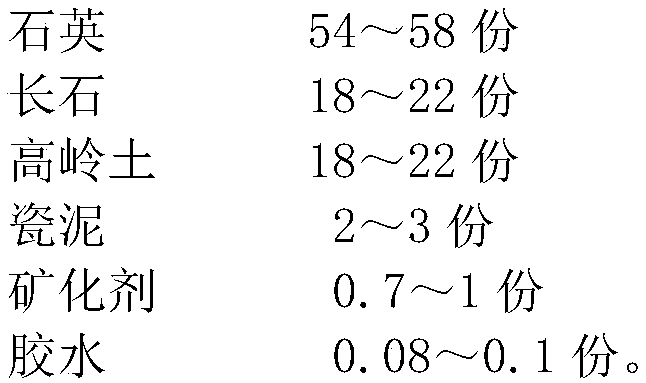

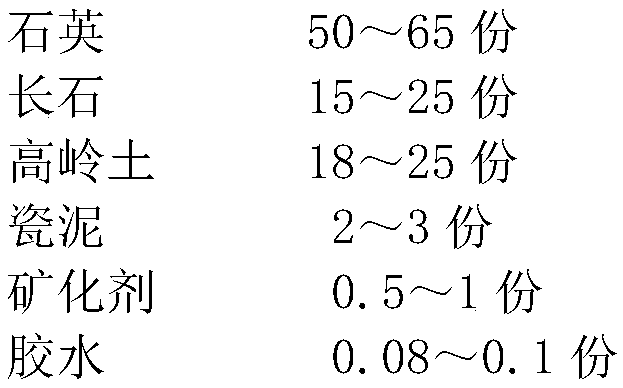

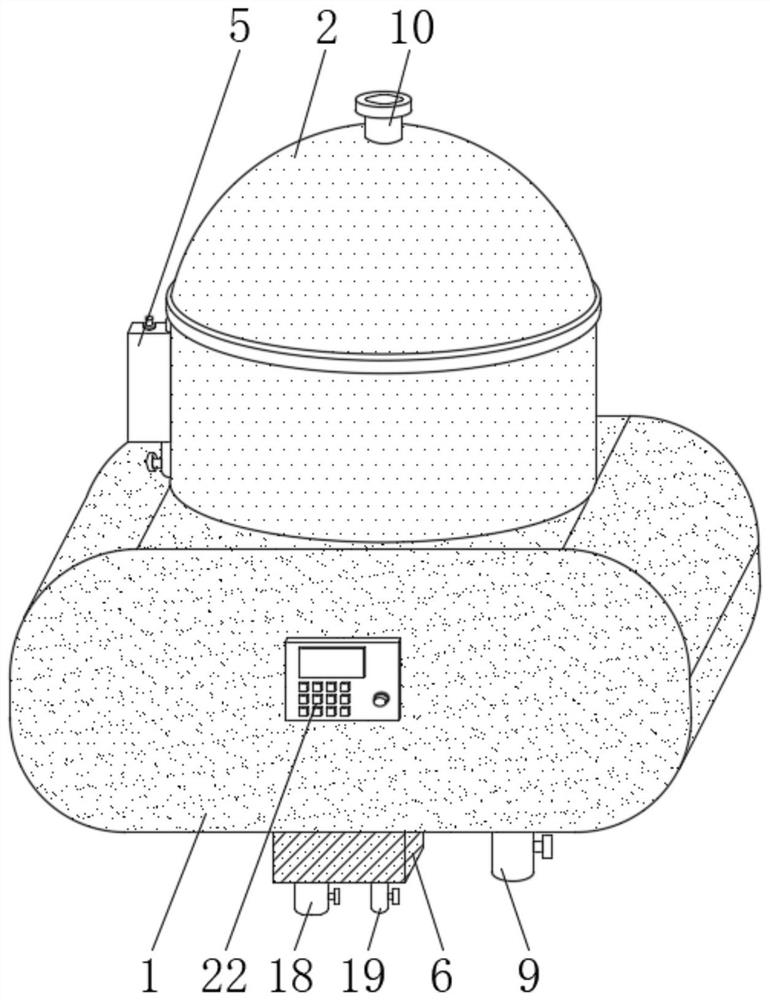

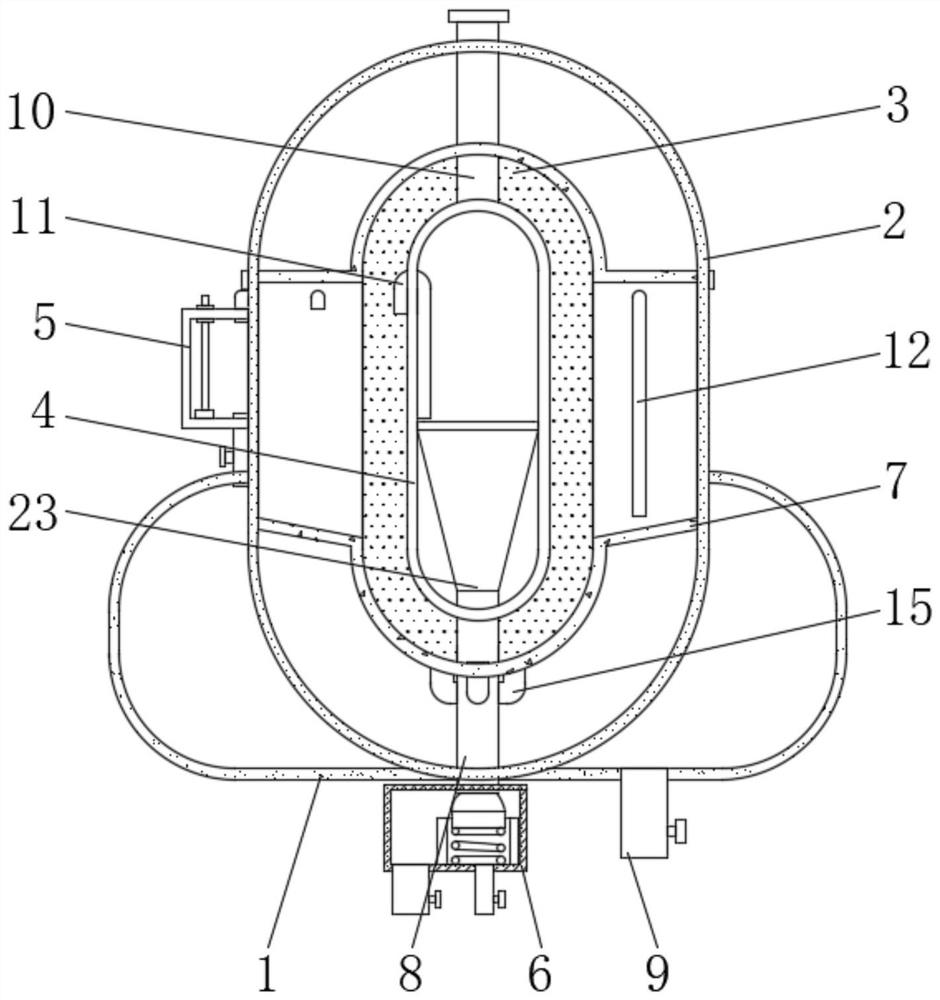

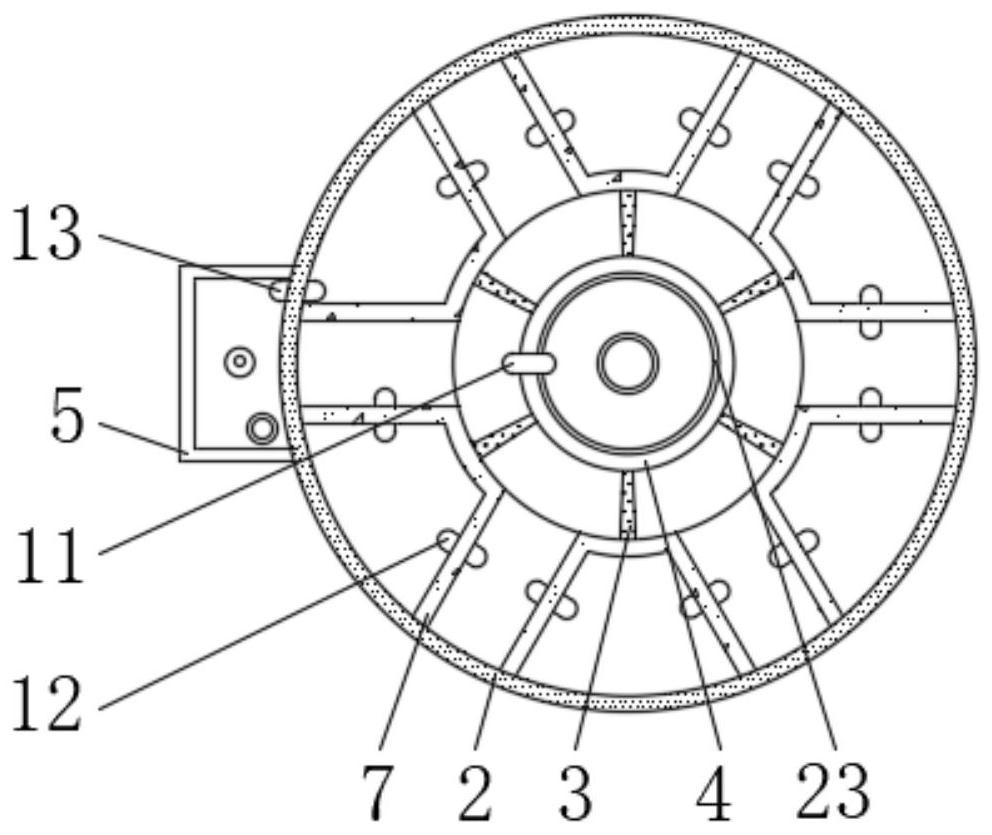

High-silicon ceramic with quartz as base material and preparation method

InactiveCN109095907ASolve the defects of fried porcelainImprove thermal stabilityBreaking strengthHeat stability

Owner:HUNAN HUALIAN CHINA IND

Sewage treatment device provided with anti-blocking mechanism and used for environmental protection

ActiveCN112320912AAvoid dischargeStable cleaningTreatment involving sedimentationWater/sewage treatment by flocculation/precipitationWater dischargeSludge

The invention discloses a sewage treatment device provided with an anti-blocking mechanism and used for environmental protection, and belongs to the technical field of sewage treatment. The sewage treatment device comprises a box body, the upper and lower surfaces of the inner wall of the box body are fixedly connected with the surface of a shell, and the inner wall of the shell is fixedly connected with the surface of a sub-sink bin; the inner wall of the sub-sink bin is clamped with a plurality of partition plates. According to the sewage treatment device provided with the anti-blocking mechanism and used for environmental protection, by arranging a sludge discharge pipe and a flow collecting pipe, when internal sediments and sludge need to be discharged, a water discharge pipe is opened, and then the sludge is discharged through the sludge discharge pipe; then a floating block blocks the bottom end of the flow collecting pipe under the action of the elastic force and buoyancy of a spring, sewage discharging can be completed, meanwhile, automatic closing is conducted after sewage discharging is completed, then the sludge discharge pipe is closed, in this way, stable cleaning of internal sludge can be kept, and meanwhile, internal stable discharging can be kept in cooperation with the counterclockwise circulating sedimentation mode; and meanwhile, the device can automaticallystop to prevent internal sewage from flowing out after sewage discharge is finished.

Owner:江西益洁环保技术有限公司

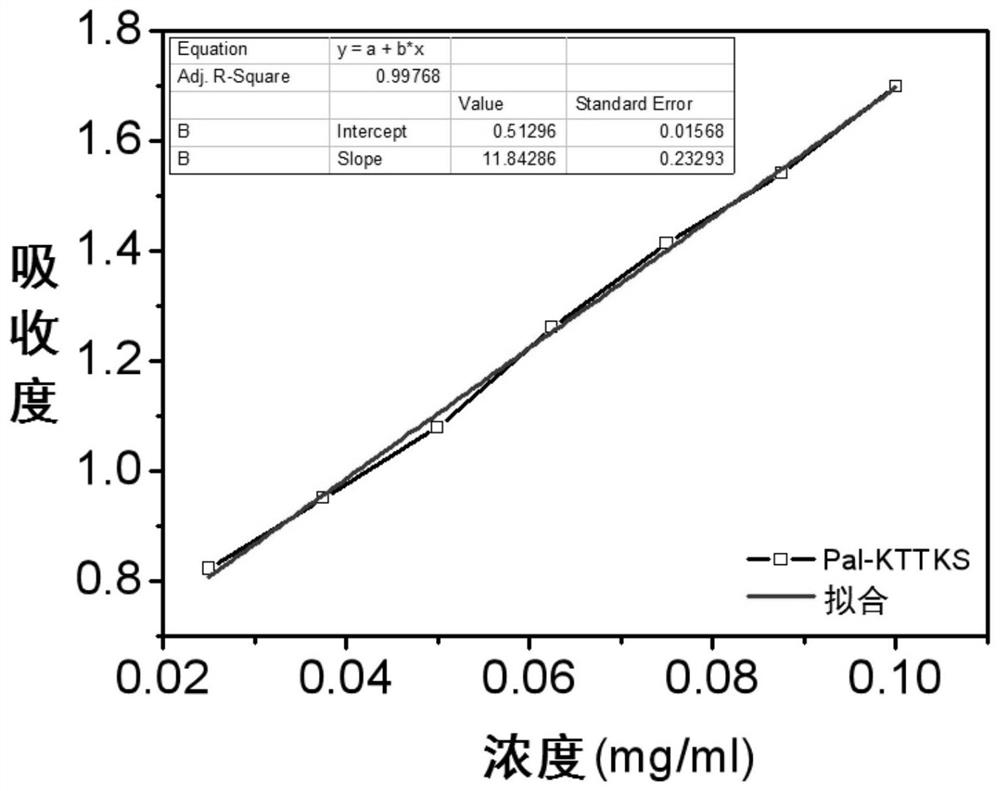

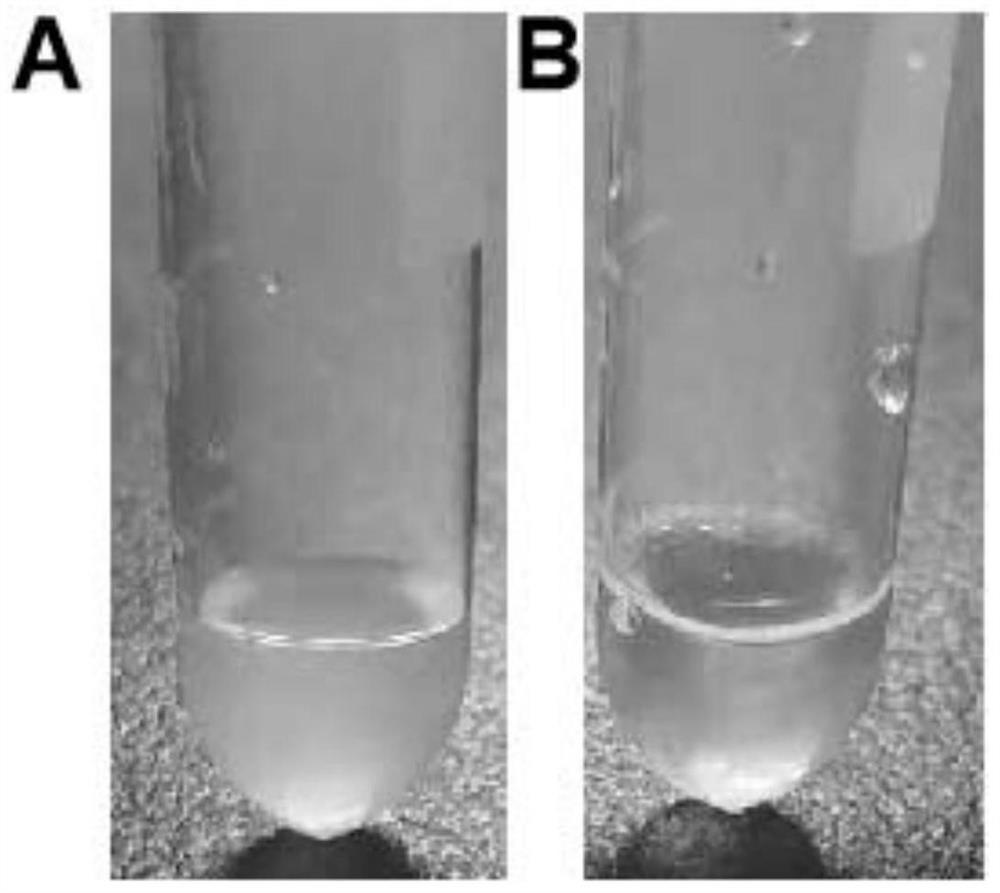

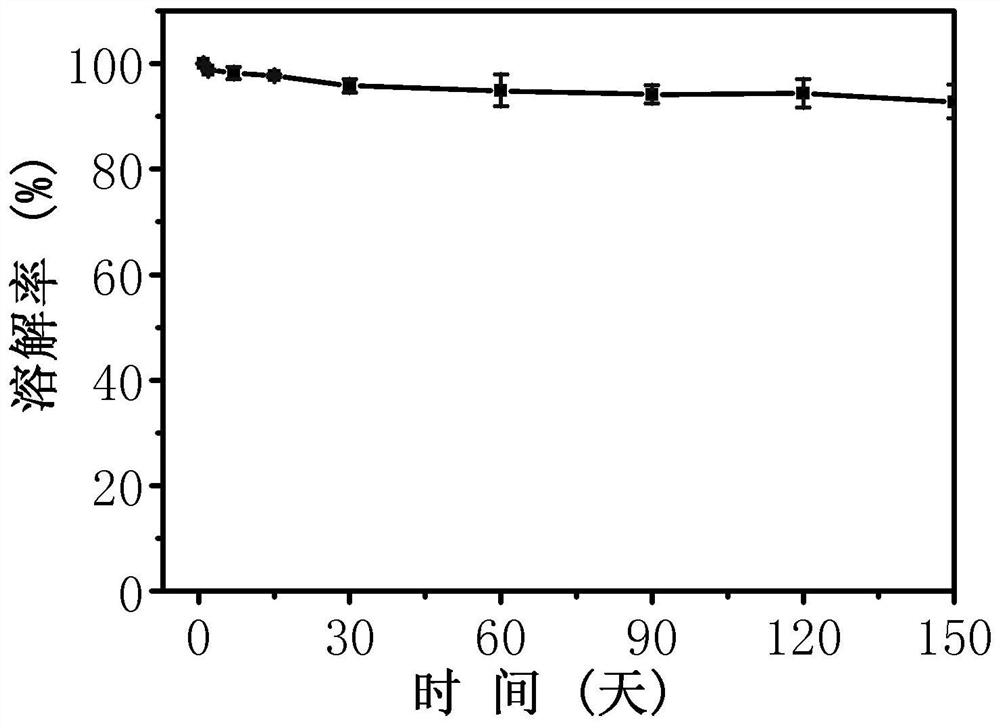

Peptide-containing water-soluble solution and application

InactiveCN111714405AEffective dissolutionDissolution applicableCosmetic preparationsToilet preparationsOligopeptideCastor oil

The invention discloses a peptide-containing water-soluble solution and a preparation method thereof. The water-soluble solution comprises hydrogenated castor oil and / or PEG modified hydrogenated castor oil; and peptide comprises one or a mixture of two or more of palmitoyl tripeptide-1 / palmitoyl oligopeptide, palmitoyl tripeptide-5 / collagen peptide, copper peptide / tripeptide-1 copper / prezatide copper acetate, palmitoyl tetrapeptide-7 / palmitoyl tetrapeptide-3, acetyl tetrapeptide-9, acetyl tetrapeptide-5,palmitoyl pentapeptide-4 / M-based peptide, pentapeptide-18, myristoyl pentapeptide-17, palmitoyl hexapeptide / palmitoyl hexapeptide-12, acetyl hexapeptide-8, acetyl octapeptide / acetyl glutamyl heptapeptide-3, hexapeptide-2, hexapeptide-9, hexapeptide-10, acetyl hexapeptide-38, nonapeptide-1and decapeptide-12. The water-soluble solution disclosed by the invention can still be clear and transparent under the high concentration, and no impurity is separated out. The prepared peptide solution is stable in property, mild and non-irritant, and the preparation method is green, controllable and low in consumption. In addition, the water-soluble solution provided by the invention has excellent compatibility, and can be compatible with a variety of humectants, thickeners, functional molecules, plant essences and the like and has wide application prospects in the fields of cosmetics, skincare products, daily use chemicals and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High efficiency stabilizing agent and method for combined contaminated soil with arsenic and manganese

ActiveCN110373202AFacilitate desorptionFacilitated releaseContaminated soil reclamationOrganic fertilisersPollution soilManganese

The invention discloses a high efficiency stabilizing agent and method for combined contaminated soil with arsenic and manganese. The high efficiency stabilizing agent includes silicate, magnesium oxide, an oxidant, and a ferric salt and / or a ferric salt. The high efficiency stabilizing agent can simultaneously and efficiently stabilize the manganese and the arsenic in the soil, the high efficiency stabilizing agent is wide in raw material source and low in cost, and can be widely promoted and applied.

Owner:长沙工研院环保有限公司

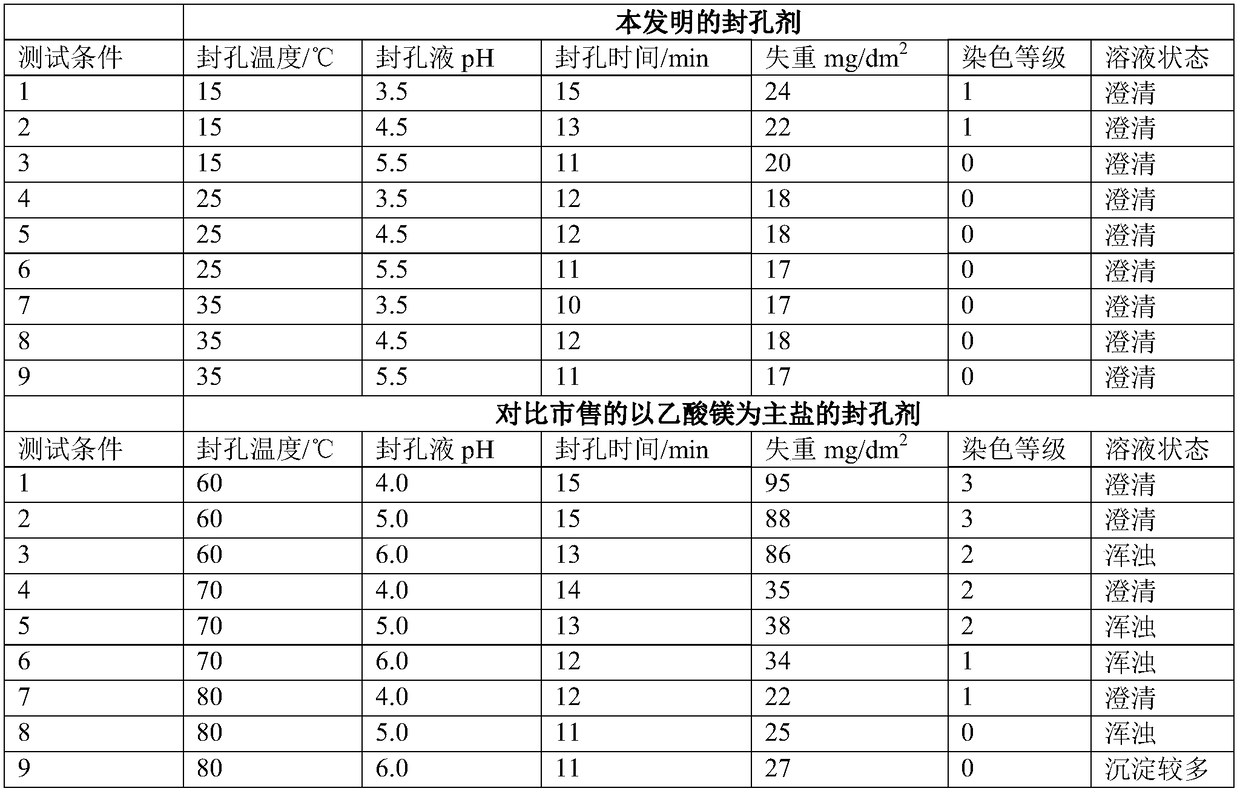

Nickel-free hole sealing agent for aluminum alloy anode oxide film and preparation method

InactiveCN109440162ALower working temperatureWide pH rangeSurface reaction electrolytic coatingEnvironmental resistanceOxide

The invention provides a nickel-free hole sealing agent for an aluminum alloy anode oxide film and a preparation method. The nickel-free hole sealing agent for the aluminum alloy anode oxide film is prepared from the following raw materials in mass percent: 3.0 to 6.0 percent of zinc series main salt compound, 2.0 to 4.0 percent of complexing agent, 2.0 to 4.0 percent of hole sealing accelerant, 4.0 to 10.0 percent of stabilizer, 5.0 to 15.0 percent of anti-gray brightener and the balance water. The hole sealing agent provided by the invention is low in working temperature and wide in pH (potential of hydrogen) range, and has a good hole sealing effect under the conditions that concentration is 2 to 6 percent, pH is 3 to 6 and temperature is 15 to 35 DEG C; the hole sealing agent is environmentally friendly and is free of nickel, so that the harm to the human body and the environment is avoided; the working temperature is low, energy resources are saved, and the process is stable; andthe hole sealing performance of a hole sealing groove can be kept only by supplementing the hole sealing agent periodically.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

Water-based long-acting antirust agent

A water-based long-acting antirust agent, which is composed of C8~C10 carboxylate (sodium, potassium or ammonium salt, 5.0~30.0%), ethanolamine (one, two or triethanolamine, 5.0~15.0%), boric acid (boric acid or ammonium borate, 3.0-8.0%) polyethylene glycol (8-10 ethylene glycol polymerization degree, 0.0-5.0%). The product is light yellow transparent viscous liquid. The antirust agent can dissolve the raw material in water at normal temperature or under heating. The antirust agent has a good protective effect on general carbon steel and cast iron. When used, no white spots will be formed on the metal surface, no flow marks and the original color of the metal surface will be maintained; there will be no change in the damp heat test period of more than 4 weeks. The anti-rust agent has good stability and can remain stable under high and low temperature conditions without stratification or precipitation. The product and raw materials are safe, and it has no harm to the human body and no pollution to the environment when it is prepared and used. It is an environmentally friendly and pollution-free long-term metal rust inhibitor.

Owner:DALIAN SANDAAOKE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com