Copper-based methanol synthesis catalyst and preparation method thereof

A methanol synthesis and catalyst technology, which is applied in catalyst activation/preparation, chemical instruments and methods, hydroxyl compound preparation, etc., can solve the problems of short service life, poor thermal stability, etc., to improve the degree of dispersion and utilization, and improve catalytic activity. , the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

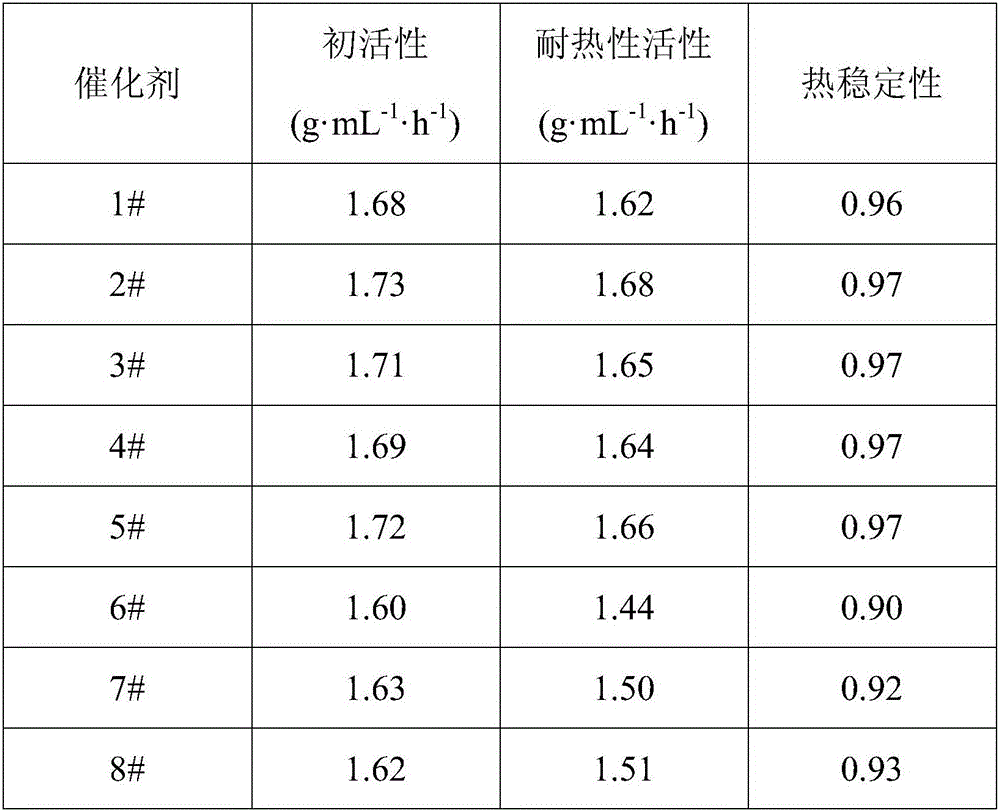

Examples

Embodiment 1

[0038] The preparation method of the copper-based methanol synthesis catalyst described in the present embodiment comprises the steps:

[0039] Prepare 2L of aqueous solution containing 126g sodium oxalate; 136g Cu(NO 3 ) 2 ·3H 2 O and 110gZn(NO 3 ) 2 ·6H 2 O was dissolved in 2L of water to form a copper-zinc mixed solution; the above two solutions were added to the reaction kettle in parallel under continuous stirring, and the pH value of the reaction system was controlled to be 7-8. ;

[0040] Formulated to contain 88g of NH 4 HCO 3 Aqueous solution 1L stand-by; 139g Al(NO 3 ) 3 9H 2 Dissolve O in 1L of water; slowly add the ammonium bicarbonate aqueous solution to the aluminum nitrate aqueous solution, and react under stirring, and control the pH value of the reaction system to 7-8, the temperature is 50°C, keep stirring for 30 minutes, and stand still after the addition is completed Aging for 1 hour to obtain slurry B;

[0041] Fully mix slurry A and slurry B, ...

Embodiment 2

[0045] The preparation method of the copper-based methanol synthesis catalyst described in the present embodiment comprises the steps:

[0046] Prepare 2L of aqueous solution containing 127g sodium oxalate; 140g Cu(NO 3 ) 2 ·3H 2 O and 101gZn(NO 3 ) 2 ·6H 2 O was dissolved in 2L of water to form a copper-zinc mixed solution; the above two solutions were added to the reaction kettle in parallel under continuous stirring, and the pH value of the reaction system was controlled to be 7-8. A;

[0047] Formulated to contain 81g of NH 4 HCO 3 Aqueous solution 1L stand-by; 128g Al(NO 3 ) 3 9H 2 Dissolve O in 1L of water; slowly add the ammonium bicarbonate aqueous solution to the aluminum nitrate aqueous solution, and react under stirring, and control the pH value of the reaction system to 7-8, the temperature is 50°C, keep stirring for 30 minutes, and stand still after the addition is completed Aging for 1 hour to obtain slurry B;

[0048] Fully mix slurry A and slurry B,...

Embodiment 3

[0052] The preparation method of the copper-based methanol synthesis catalyst described in the present embodiment comprises the steps:

[0053] Prepare 2L of aqueous solution containing 126g sodium oxalate; 144g Cu(NO 3 ) 2 ·3H 2 O and 89gZn(NO 3 ) 2 ·6H 2 O was dissolved in 2L of water to form a copper-zinc mixed solution; the above two solutions were added to the reaction kettle in parallel under continuous stirring, and the pH value of the reaction system was controlled to be 7-8. ;

[0054] Formulated to contain 72g of NH 4 HCO 3 Aqueous solution 1L stand-by; 113g Al(NO 3 ) 3 9H 2 Dissolve O in 1L of water; slowly add the ammonium bicarbonate aqueous solution to the aluminum nitrate aqueous solution, react under stirring, and control the pH value of the reaction system to 7-8, the temperature is 50°C, continue to stir for 30 minutes, and stand still after the addition is completed Aging for 0.5h to obtain slurry B;

[0055] Fully mix slurry A and slurry B, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com