Roller kiln low-temperature sintered colorful halo crystal glaze and preparation method thereof

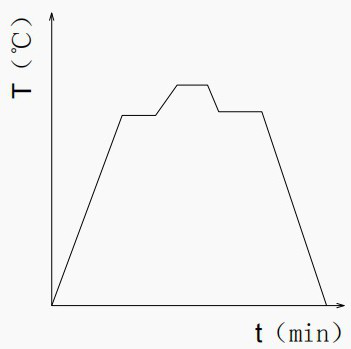

A technology of low-temperature firing and roller kiln, which is applied to clay products, other household utensils, and other applications. It can solve the problems of single glaze effect, high firing temperature, and long holding time, and achieve lower viscosity and lower firing rate. Effect of temperature, increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing colorful halo crystalline glaze fired at low temperature in a roller kiln of the present invention comprises the following steps:

[0037] S1. Preparation of bottom glaze:

[0038] First weigh the raw materials according to the composition weight of the bottom glaze; then put them into the ball mill, and add 1-4wt‰ of dispersant and 2-5wt‰ of debonding agent at the same time, wherein: the dispersing agent is sodium hydroxymethyl cellulose, degumming The agent is sodium tripolyphosphate, add water and grind for 4-6 hours to obtain the bottom glaze glaze slurry, the specific gravity of the bottom glaze slurry is 1.65-1.70, and the fineness of the glaze slurry is 0.1-0.2% of the million-hole sieve; finally, the bottom glaze The glaze slurry is filtered through a 100-mesh double-layer sieve, and after removing iron, it is pumped to the slurry tank to stave, and the colorful halo crystal underglaze is obtained;

[0039] S2. Preparation of top glaze: ...

Embodiment 1

[0045] The low-temperature fired colorful halo crystalline glaze of the roller kiln of this embodiment includes a bottom glaze and a surface glaze, wherein: the composition of the bottom glaze is calculated by weight: 80 parts of lead-zinc frit, 1 part of cobalt blue, and 10 parts of cobalt black The composition of the surface glaze is calculated by weight: 50 parts of high boron frit, 5 parts of titanium dioxide, 10 parts of zinc oxide, 5 parts of talc, 15 parts of manganese dioxide, 1 part of alum pentoxide, and 1 part of copper oxide.

[0046] The preparation method of the roller kiln low-temperature firing colorful halo crystalline glaze of this embodiment comprises the following steps:

[0047] S1. Preparation of bottom glaze:

[0048] First weigh the raw materials according to the composition weight of the bottom glaze; then put them into a ball mill, add 2wt‰ of dispersant and 2wt‰ of debonding agent at the same time, add water and grind for 5 hours to obtain the bottom...

Embodiment 2

[0054] The roller kiln low-temperature firing colorful halo crystalline glaze of this embodiment includes a bottom glaze and a top glaze, wherein: the composition of the bottom glaze is calculated by weight: 90 parts of lead-zinc frit, 3 parts of cobalt blue, and 16 parts of cobalt black The composition of the surface glaze is calculated in parts by weight: 70 parts of high boron frit, 10 parts of titanium dioxide, 20 parts of zinc oxide, 15 parts of talc, 10 parts of calcite, 20 parts of manganese dioxide, 5 parts of alum pentoxide, copper oxide 5 servings.

[0055] The preparation method of the roller kiln low-temperature firing colorful halo crystalline glaze of this embodiment comprises the following steps:

[0056] S1. Preparation of bottom glaze:

[0057] First weigh the raw materials according to the composition weight of the bottom glaze; then put them into a ball mill, add 3wt‰ of dispersant and 3wt‰ of debonding agent at the same time, add water and grind for 6 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com