High-silicon ceramic with quartz as base material and preparation method

A technology of matrix material and high-silicon ceramics, applied in the field of daily ceramics, can solve the problems of high weight, high cost, increased cost and difficulty, etc., to improve thermal stability, prevent product deformation, and solve the effects of frying porcelain defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

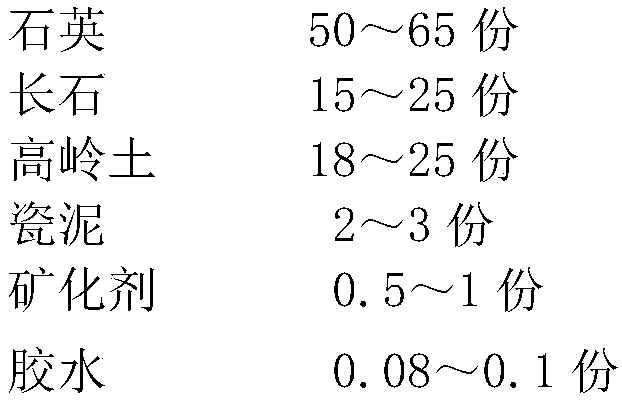

[0042] Components and content in the formula of the present invention are:

[0043]

[0044] The high-quality Guizhou soil is a kind of kaolin.

[0045] The mineralizer contains 10-20% by weight of calcium oxide and 10-20% by weight of magnesium oxide.

[0046] Described glue comprises polyvinyl alcohol, gum arabic and cellulose, and the weight ratio of described polyvinyl alcohol, gum arabic and cellulose is 0.6:0.5:0.4.

[0047] Accurately formulate the weight of each raw material in the above formula, make mud sticks according to the above mud making method, shape the green body, apply glaze, put it in a kiln at 1380°C for 15 hours and fire it, and test the water absorption and thermal stability of the obtained high-silicon ceramic products as follows:

[0048] Water absorption test:

[0049]

[0050] Thermal Stability Test:

[0051] Sample serial number

Embodiment 2

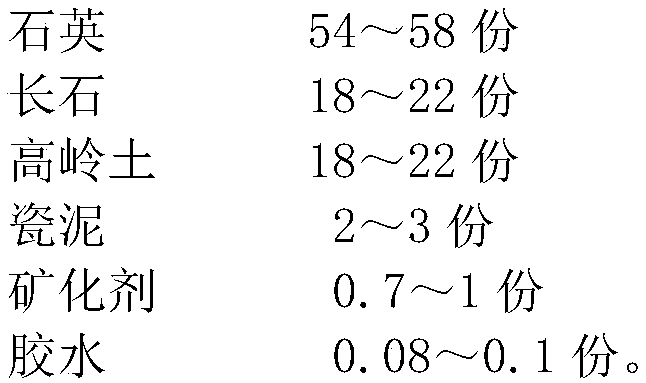

[0053] Components and content in the formula of the present invention are:

[0054]

[0055] The high-quality Guizhou soil is a kind of kaolin.

[0056] The mineralizer contains 10-20% by weight of calcium oxide and 10-20% by weight of magnesium oxide.

[0057] Described glue comprises polyvinyl alcohol, gum arabic and cellulose, and the weight ratio of described polyvinyl alcohol, gum arabic and cellulose is 0.7:0.2:0.1.

[0058] Accurately formulate the weight of each raw material in the above formula, make mud sticks according to the mud making method above, shape the green body, apply glaze, put it in a kiln at 1370°C for 15.5 hours and fire it, and test the water absorption and thermal stability of the obtained high-silicon ceramic products as follows:

[0059] Water absorption test:

[0060]

[0061] Thermal Stability Test:

[0062] Sample serial number

Embodiment 3

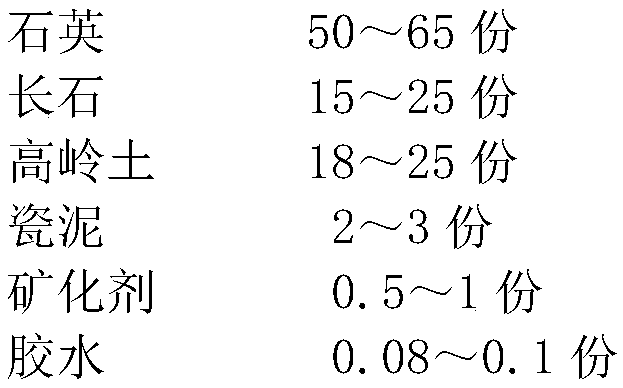

[0064] Components and content in the formula of the present invention are:

[0065]

[0066] The mineralizer contains 10-20% by weight of calcium oxide and 10-20% by weight of magnesium oxide.

[0067] Described glue comprises polyvinyl alcohol, gum arabic and cellulose, and the weight ratio of described polyvinyl alcohol, gum arabic and cellulose is 0.2:0.6:0.2.

[0068] Accurately formulate the weight of each raw material in the above formula, make mud strips according to the mud making method above, shape the green body, apply glaze, and put it in a kiln at 1360°C for 16 hours for firing. The water absorption test and thermal stability test of the obtained high-silicon ceramic products as follows:

[0069] Water absorption test:

[0070]

[0071] Thermal Stability Test:

[0072] Sample serial number

[0073] The present invention is based on the national standard (GB / T3532-2009) for testing the thermal shock resistance of daily-use ceramics in my country...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com