Lithium battery diaphragm and preparation method thereof

A lithium battery separator, lithium battery technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of porous membrane ion passage hindering, affecting battery capacity and efficiency, etc., to achieve stable heating and moisture absorption. The effect of uniformity, improving production efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

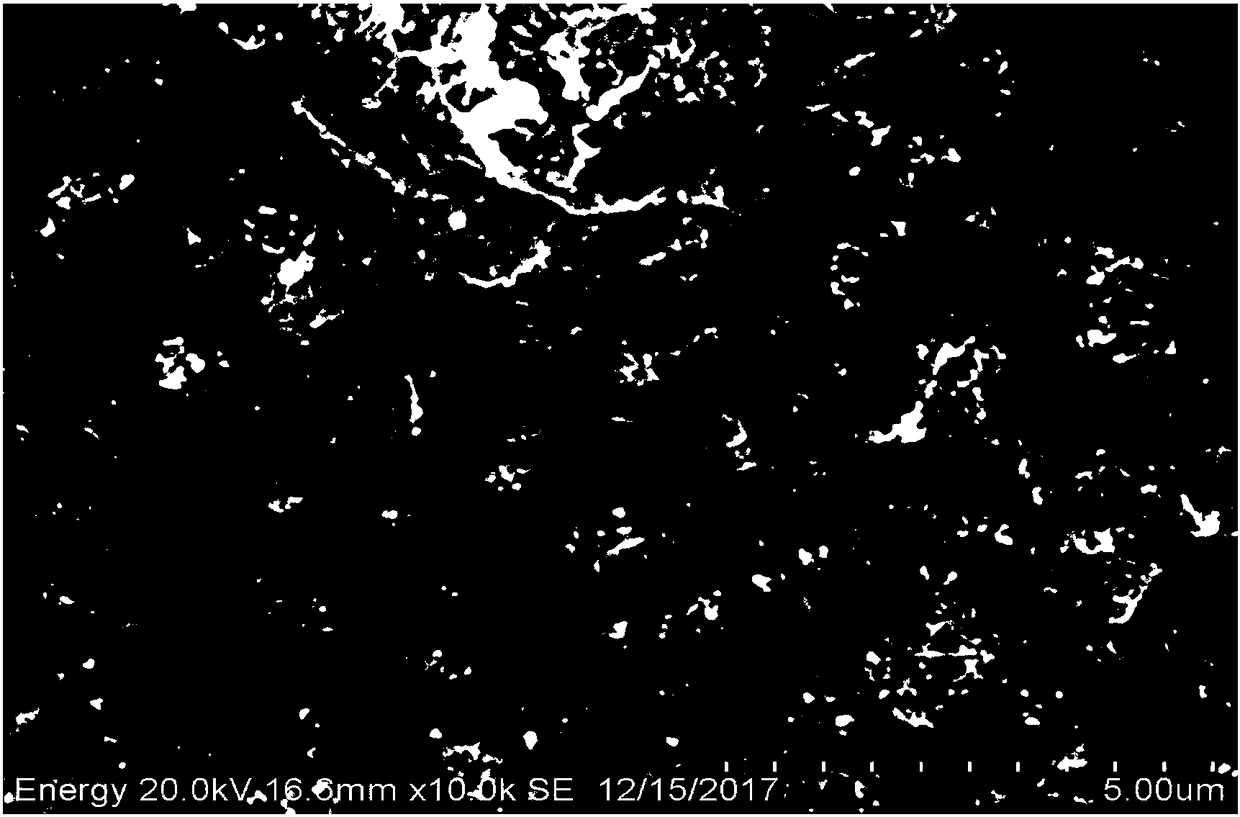

[0025] Usually aromatic polymers such as aromatic aromatic amide with excellent heat resistance are difficult to prepare a coating film with a stable structure, many mesh holes and uniformity due to improper molding process, and thus it is impossible to make the lithium battery separator have high heat resistance. It also has excellent breathability. In view of this, the present invention provides a lithium battery separator and a preparation method thereof, capable of stably manufacturing an aromatic polymer coated film lithium ion battery separator, ensuring heat resistance and having high air permeability.

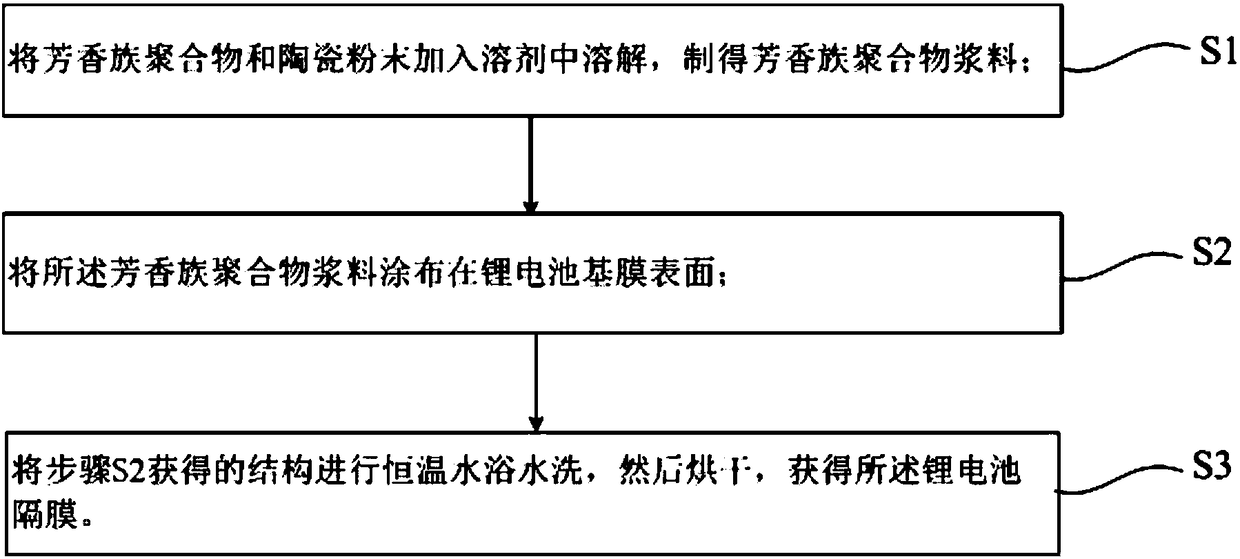

[0026] Such as figure 1 As shown, the present invention provides a kind of preparation method of lithium battery diaphragm, and described preparation method comprises at least:

[0027] Firstly, step S1 is performed, adding aromatic polymer and ceramic powder into a solvent to dissolve, so as to prepare an aromatic polymer slurry.

[0028] In this step, the aromatic p...

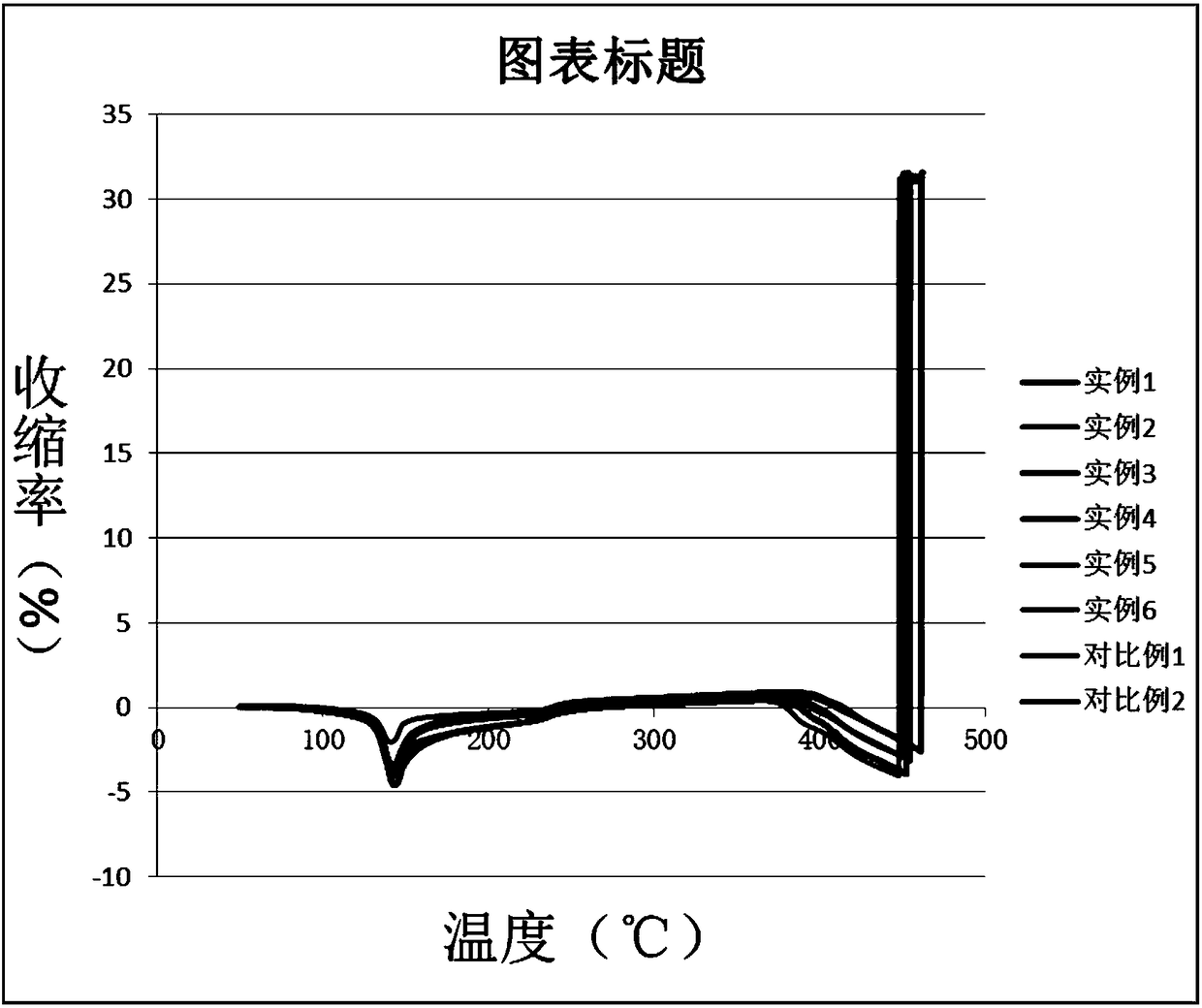

Embodiment 1

[0053] Take a lithium battery base film with a thickness of 14 μm, and use an automatic coating machine to evenly coat the prepared coating slurry on one side of the base film at a coating speed of 80 m / min. Put it in a constant temperature water bath at 30° C. for 2 minutes, then take it out and dry to obtain an aromatic polymer-coated lithium-ion battery separator, and the coating thickness of the lithium-ion battery separator is 4 μm.

Embodiment 2

[0055] The same operation as in Example 1 was performed except that the constant temperature water bath was 40°C. A lithium-ion battery separator coated with an aromatic polymer can be obtained, and the coating thickness of the lithium-ion battery separator is 4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com