Preparation method of nano magnetic beads for purifying histidine tagged protein

A nano-magnetic bead and histidine-labeled technology, which is applied in the field of nano-magnetic bead preparation, can solve the problems of complex steps in the synthesis process, difficulty in connecting to the surface of magnetic beads, and high requirements for sample solution, and achieve simple purification and separation , low cost, short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

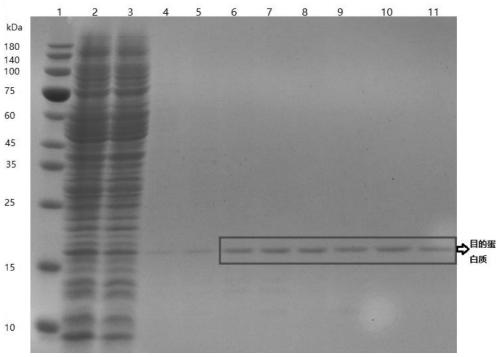

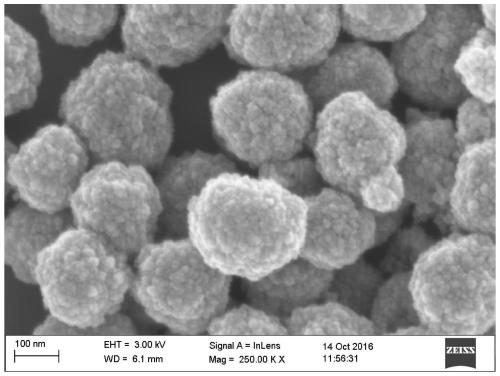

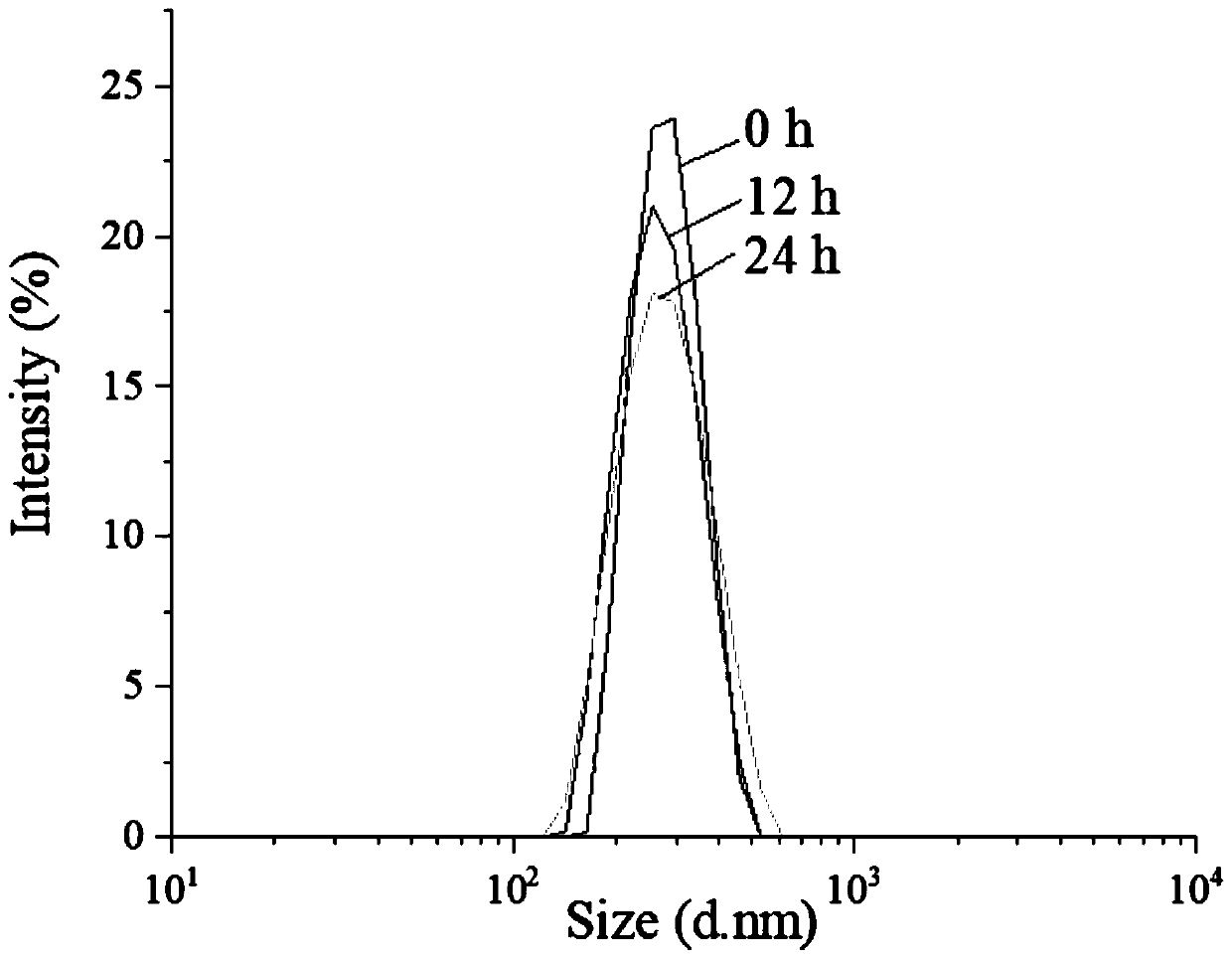

[0041] This example relates to the preparation and application of a new type of nano-magnetic beads for purifying histidine-tagged proteins.

[0042] The preparation method of magnetic beads comprises the following steps:

[0043] The first step, reactant 0.5 gram sodium alginate, 0.5 gram FeCl 3 ·6H 2 O, 1.5 g NaAc 3H 2 O. 1 milliliter of PEG (MW: 300-6000) and 1 milliliter of deionized water were mixed in 20 milliliters of ethylene glycol solvent, and mechanically stirred at 300 rpm until completely dissolved. Under the conditions of reaction for 25 hours, after cooling to room temperature, the reaction product was moved to a 50 ml centrifuge tube, washed with deionized water, collected with a magnet, and stored in vacuum to obtain black Fe 3 o 4 nanoparticles.

[0044] In the second step, cross-linked sodium alginate is coated on the surface of nanoparticles: 1 g of Fe 3 o 4 Nanoparticles, 1.2 grams of sodium alginate, 0.5 grams of sodium hydroxide, 2 milliliters of ...

Embodiment 2

[0057] This example relates to the preparation and application of a new type of nano-magnetic beads for purifying histidine-tagged proteins.

[0058] The preparation method of magnetic beads comprises the following steps:

[0059] The first step, reactant 0.1 gram sodium alginate, 0.05 gram FeCl 3 ·6H 2 O, 0.05 g NaAc 3H 2 O. 0.1 milliliters of PEG (MW: 300-6000) and 0.1 milliliters of deionized water were mixed in 20 milliliters of ethylene glycol solvents, mechanically stirred at 300 rpm until completely dissolved, then the above solution was transferred to a 50 milliliter reaction kettle, and heated at 100°C Under the conditions of reaction for 48 hours, after cooling to room temperature, the reaction product was moved to a 50 ml centrifuge tube, washed with deionized water, collected with a magnet, and stored in vacuum to obtain black Fe 3 o 4 nanoparticles.

[0060] In the second step, cross-linked sodium alginate is coated on the surface of nanoparticles: 0.5 g of F...

Embodiment 3

[0066] This example relates to the preparation and application of a new type of nano-magnetic beads for purifying histidine-tagged proteins.

[0067] The preparation method of magnetic beads comprises the following steps:

[0068] In the first step, reactant 1 gram of sodium alginate, 1 gram of FeCl 3 ·6H 2 O, 3 g NaAc 3H 2 O. 2 milliliters of PEG (MW: 300~6000) and 2 milliliters of deionized water are mixed in 20 milliliters of ethylene glycol solvents, and after mechanical stirring at 300 rpm until completely dissolved, the above-mentioned solution is transferred to a 50 milliliter reaction kettle and heated at 250° C. Under the conditions of reaction for 2 hours, after cooling to room temperature, the reaction product was transferred to a 50 ml centrifuge tube, washed with deionized water, collected with a magnet, and stored in vacuum to obtain black Fe 3 o 4 nanoparticles.

[0069] In the second step, cross-linked sodium alginate is coated on the surface of nanopartic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com