Oil removal process for cobalt sulfate extraction waste liquid

A technology of cobalt sulfate and waste liquid, which is applied in metallurgical wastewater treatment, grease/oily substance/suspton removal devices, special treatment targets, etc. It can solve the problems of easy pollution of water bodies and failure to achieve adsorption, so as to achieve difficult desorption and improve The effect of adsorption capacity and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

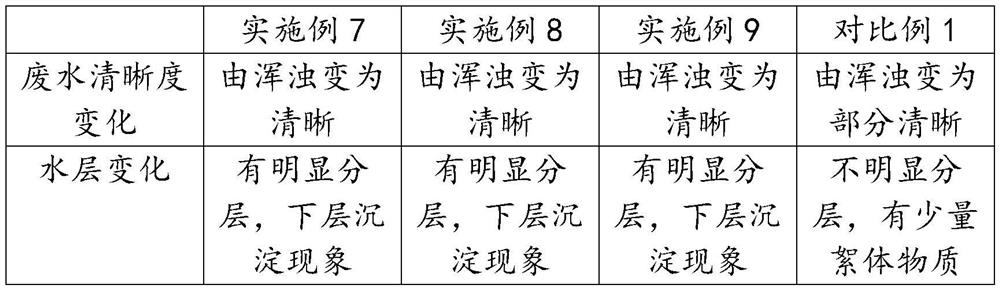

Examples

Embodiment 1

[0032] The modified flocculant is prepared by the following steps:

[0033] S1: Control the dosage ratio of sodium alginate, absolute ethanol, ethylene glycol, and calcium chloride to 4.56g: 60mL: 4mL: 5.0g, add sodium alginate to the absolute ethanol solution, stir with a magnetic stirrer, Control the rotation speed to 1000r / min, stir for 30min, then add sodium periodate into the water solution, control the sodium periodate: distilled water dosage ratio in the sodium periodate aqueous solution to be 2.35g: 50mL, react at room temperature for 3h, obtained Oxidized sodium alginate, then continue to add ethylene glycol and calcium chloride, filter out, wash twice with 75% ethanol, put the washed sodium alginate into distilled water, continue to stir for 10 minutes until it is completely dissolved, and obtain a mixed Liquid A;

[0034] S2: Control the dosage ratio of triethylenetetramine and sodium borohydride to 3.89g:0.45g, raise the temperature of the triethylenetetramine sol...

Embodiment 2

[0038] The modified flocculant is prepared by the following steps:

[0039] S1: Control the dosage ratio of sodium alginate, absolute ethanol, ethylene glycol, and calcium chloride to 4.56g: 60mL: 4mL: 5.0g, add sodium alginate to the absolute ethanol solution, stir with a magnetic stirrer, Control the rotation speed to 1100r / min, stir for 30min, then add sodium periodate into the water solution, control the sodium periodate: distilled water dosage ratio in the sodium periodate aqueous solution to be 2.35g: 50mL, react at room temperature for 4h, obtained Oxidized sodium alginate, then continue to add ethylene glycol and calcium chloride, filter out, wash twice with 75% ethanol, put the washed sodium alginate into distilled water, continue to stir for 15 minutes until it is completely dissolved, and obtain a mixed Liquid A;

[0040] S2: Control the dosage ratio of triethylenetetramine and sodium borohydride to 3.89g:0.45g, raise the temperature of the triethylenetetramine sol...

Embodiment 3

[0044] The modified flocculant is prepared by the following steps:

[0045] S1: Control the dosage ratio of sodium alginate, absolute ethanol, ethylene glycol, and calcium chloride to 4.56g: 60mL: 4mL: 5.0g, add sodium alginate to the absolute ethanol solution, stir with a magnetic stirrer, Control the rotation speed to 1200r / min, stir for 30min, then add sodium periodate into the water solution, control the sodium periodate in the sodium periodate aqueous solution: the ratio of distilled water is 2.35g: 50mL, react at room temperature for 5h, obtained Oxidized sodium alginate, then continue to add ethylene glycol and calcium chloride, filter out, wash twice with 75% ethanol, put the washed sodium alginate into distilled water, continue to stir for 20 minutes until it is completely dissolved, and obtain a mixed Liquid A;

[0046] S2: Control the dosage ratio of triethylenetetramine and sodium borohydride to 3.89g:0.45g, raise the temperature of the triethylenetetramine soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com