Cadmium-lead compound contaminated soil repairing agent and application thereof

A soil remediation agent and composite pollution technology, which is applied in the field of lead composite contaminated soil remediation agent and cadmium, can solve the problems of low remediation efficiency and high treatment cost, achieve high reduction performance, high adsorption value, and improve the effect of soil remediation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0038] Using the mixture of straw and calcium oxide as raw material, the mass ratio of straw and calcium oxide is 20:1, vacuum pyrolysis for 30min under the conditions of system pressure of 20kPa and pyrolysis temperature of 500°C, the pellets obtained by grinding Solid powder with a diameter of less than 3mm;

[0039] Described potassium humate, 13X molecular sieve, sodium dodecyl sulfonate, and iron powder are solid powders below 2mm respectively;

[0040] Weigh according to mass percentage:

[0041] Biochar 40%;

[0042] Potassium humate 15%;

[0043] 13X Molecular Sieve 15%;

[0044] Sodium Lauryl Sulfonate 15%;

[0045] Iron powder 15%;

[0046] Biochar, potassium humate, 13X molecular sieve, sodium dodecyl sulfonate, and iron powder were evenly mixed according to the above proportions to prepare a restoration agent.

preparation Embodiment 2

[0048] Using the mixture of straw and calcium oxide as raw material, the mass ratio of straw and calcium oxide is 20:1, vacuum pyrolysis for 30min under the conditions of system pressure of 20kPa and pyrolysis temperature of 500°C, the pellets obtained by grinding Solid powder with a diameter of less than 3mm;

[0049] Described potassium humate, 13X molecular sieve, sodium dodecyl sulfonate, and iron powder are solid powders below 2mm respectively;

[0050] Weigh according to mass percentage:

[0051] Biochar 50%;

[0052] Potassium humate 20%;

[0053] 13X Molecular Sieve 10%;

[0054] Sodium dodecyl sulfonate 10%;

[0055] Iron powder 10%;

[0056] Biochar, potassium humate, 13X molecular sieve, sodium dodecyl sulfonate, and iron powder were evenly mixed according to the above proportions to prepare a restoration agent.

preparation Embodiment 3

[0058] Using the mixture of straw and calcium oxide as raw material, the mass ratio of straw and calcium oxide is 20:1, vacuum pyrolysis for 30min under the conditions of system pressure of 20kPa and pyrolysis temperature of 500°C, the pellets obtained by grinding Solid powder with a diameter of less than 3mm;

[0059] Described potassium humate, 13X molecular sieve, sodium dodecyl sulfonate, and iron powder are solid powders below 2mm respectively;

[0060] Weigh according to mass percentage:

[0061] Biochar 30%;

[0062] Potassium humate 10%;

[0063] 13X Molecular Sieve 20%;

[0064] Sodium dodecyl sulfonate 20%;

[0065] Iron powder 20%;

[0066] Biochar, potassium humate, 13X molecular sieve, sodium dodecyl sulfonate, and iron powder were evenly mixed according to the above proportions to prepare a restoration agent.

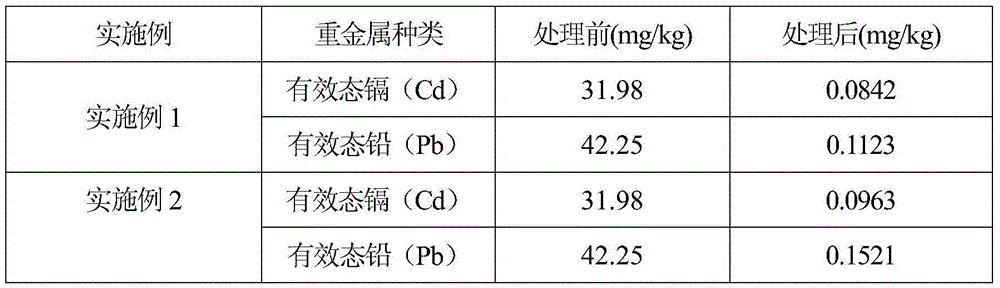

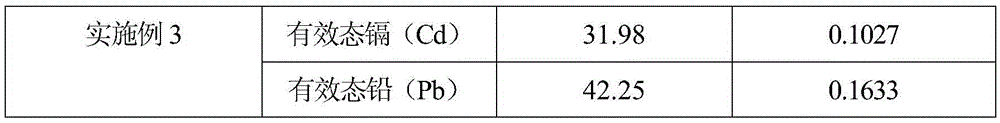

[0067] Embodiment 1-3 gained restorative agent application specific implementation and technical effect:

[0068] 300 kg of cadmium-lead compound con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com