Tantalum-containing cast nickel-based superalloy for 700 DEG C unit and preparation method thereof

A nickel-based high-temperature alloy and unit technology, applied in the field of heat-resistant alloys, can solve the problems of reducing the uniformity of the alloy structure, affecting the mechanical properties of the alloy, and slowing the diffusion rate, achieving high microhardness at room temperature, improving structure stability, and inhibiting The effect of coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Prepare raw materials according to the set composition; raw materials contain Ta 0.49%, Cr 22.21%, Co 12.00%, Mo 8.55%, Al 1.2%, Ti 0.34%, Al+Ti=1.54%, C 0.044%, B 0.004% by mass percentage , the balance being Ni, (Al+Ti) / Ta=1.54 / 0.49=3.14≥0.8; and Ti / Al=0.34 / 1.2=0.28≤0.8;

[0047] Put the raw materials into a vacuum induction furnace and melt under vacuum conditions; the melting temperature is 1530±25°C;

[0048] Refining and removing impurities of the smelted material under vacuum conditions, and then casting wax molds under vacuum conditions; the pouring temperature is 1460±25°C;

[0049] After the pouring is completed, keep the vacuum condition until the molten steel conjunctiva is released from the furnace, and then cooled to room temperature to make an ingot;

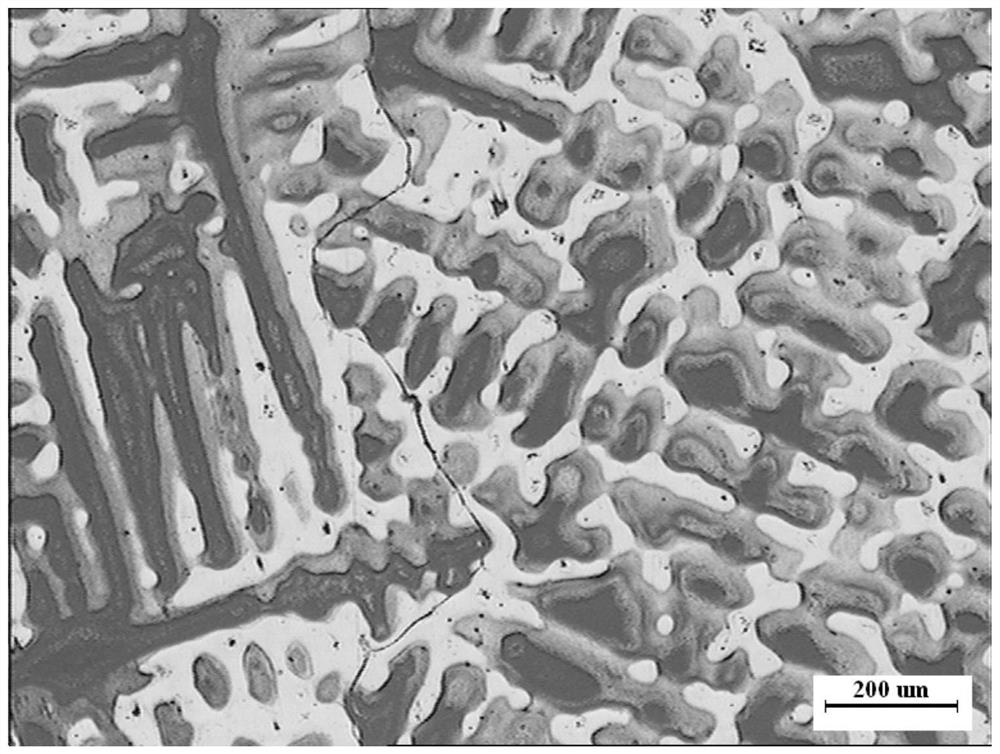

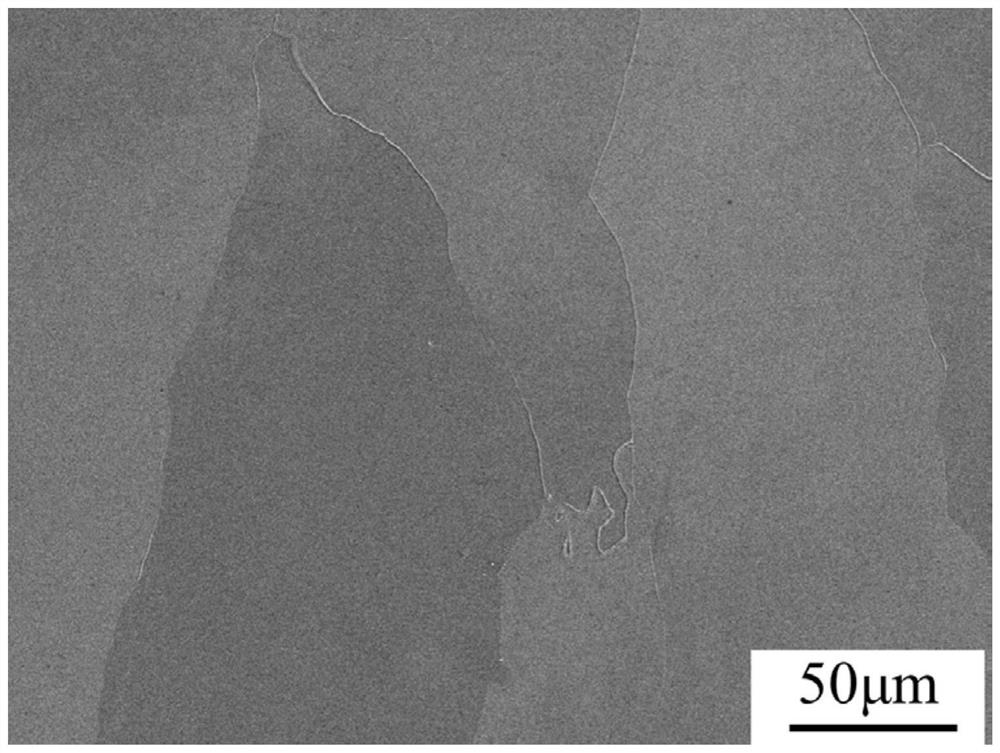

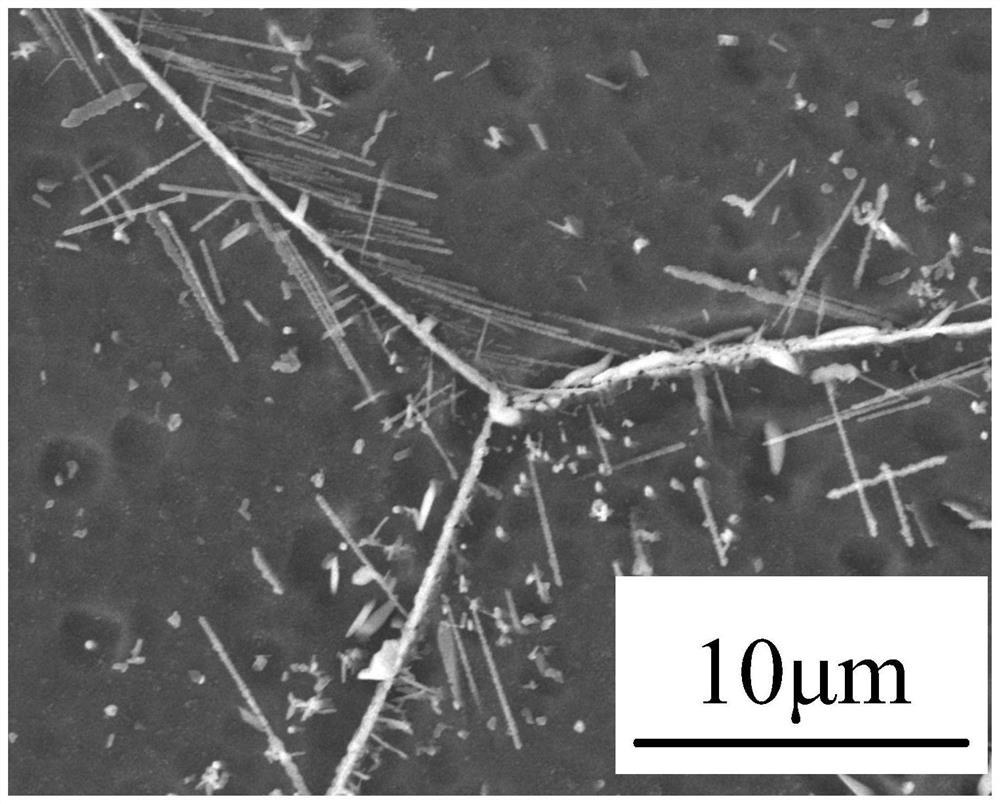

[0050] The as-cast microstructure of the ingot is as follows: figure 1 As shown in the figure, it can be seen that the structure is mainly composed of typical dendrites, in which the secondary dendrite sp...

Embodiment 2

[0060] Method is with embodiment 1, and difference is:

[0061] (1) The raw material contains Ta 0.5%, Cr 20.5%, Co 11.4%, Mo 8.5%, Al 1.15%, Ti 0.36%, Al+Ti=1.51%, C 0.057%, B 0.003%, and the balance is Ni, (Al+Ti) / Ta=1.51 / 0.5=3.02≥0.8; and Ti / Al=0.36 / 1.15=0.31≤0.8;

[0062] (2) Solid solution treatment is carried out when the temperature drops to 1200°C, and the time is 1.5h;

[0063] (3) Tensile strength at room temperature σ of cast nickel-base superalloy containing tantalum b 581MPa, yield strength σ 0.2 It is 269MPa, the elongation at break is 49%, and the reduction of area is 52%; the tensile strength σ at 700±1°C b 385MPa, yield strength σ 0.2 It is 138MPa, the elongation at break is 56%, and the reduction of area is 49%.

Embodiment 3

[0065] Method is with embodiment 1, and difference is:

[0066] (1) The raw material contains Ta 1.89%, Cr 22.5%, Co 12%, Mo 8.4%, Al 1.25%, Ti 0.34%, Al+Ti=1.59%, C 0.05%, B 0.004%, and the balance is Ni, (Al+Ti) / Ta=1.59 / 1.89=0.84≥0.8; and Ti / Al=0.34 / 1.25=0.272≤0.8;

[0067] (2) When the temperature drops to 1150°C, solid solution treatment is carried out for 2 hours;

[0068] (3) Tensile strength at room temperature σ of cast nickel-base superalloy containing tantalum b 590MPa, yield strength σ 0.2 It is 272MPa, the elongation at break is 47-51%, and the reduction of area is 55%; the tensile strength σ at 700±1°C b 390MPa, yield strength σ 0.2 It is 139MPa, the elongation at break is 60%, and the reduction of area is 49%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com