Method for preparing high-purity magnesium oxide

A magnesia, high-purity technology, applied in the direction of magnesia, can solve the problems of easily decomposing hydrogen sulfide gas that pollutes the environment, is not conducive to large-scale industrial production, and the properties of sodium sulfide are unstable, so as to achieve small investment, stable operation, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

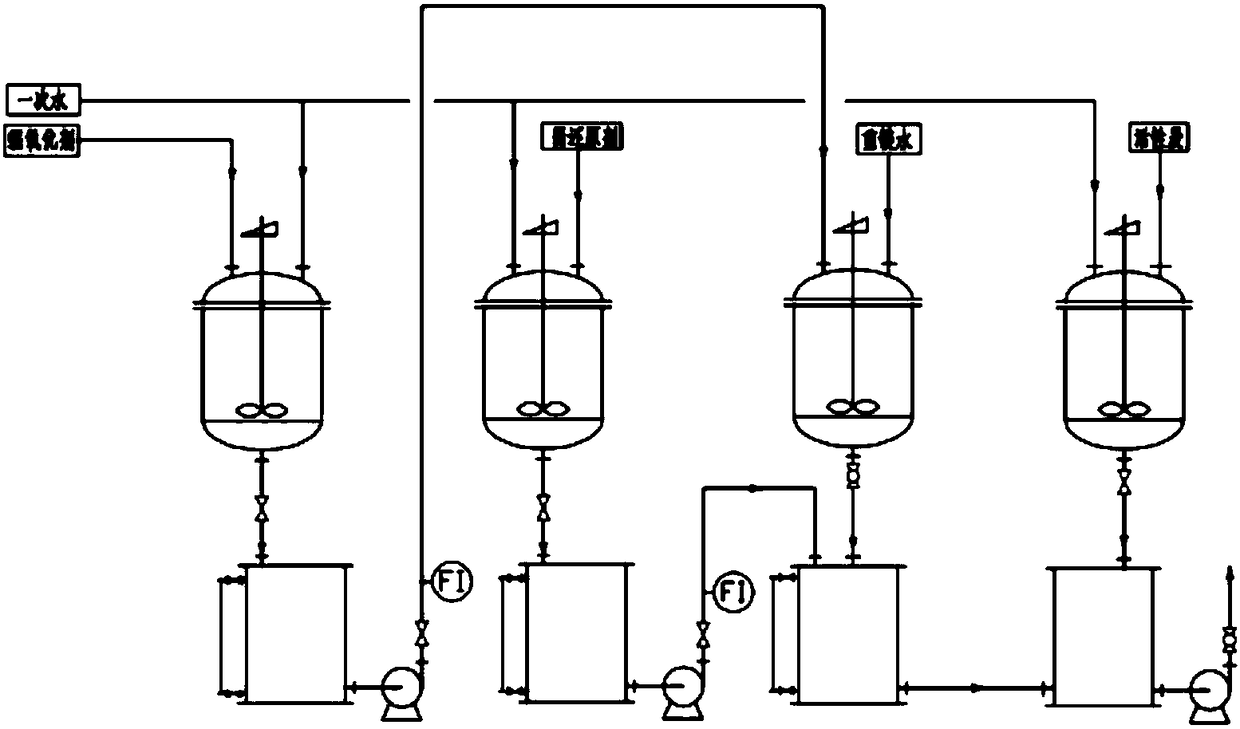

[0036] Such as figure 1 Shown, the invention provides a kind of method for preparing high-purity magnesium oxide, comprises the following steps:

[0037] (2) According to the analysis of GB / T3049-2006, the iron content in the heavy magnesium water is obtained, wherein the total iron is 15.4mg / L, Fe 2+ 9.2mg / L; the amount added is Fe 2+ 1.5 times the molar amount of ammonium persulfate, and add 3 drops of potassium ferricyanide solution as a reaction indicator, and then introduce CO into heavy magnesium water 2 Keep the pH of the mixed solution at 6, and oxidize for 20 minutes under the condition of this pH. When no dark blue precipitate is produced, all the Fe in the heavy magnesium water 2+ oxidized to Fe 3+ , precipitation of ferric hydroxide precipitates, and the oxidation reaction ends;

[0038](2) then according to the excessive value of strong oxidizing agent, add the sodium sulfite salt that addition is 0.7 times of strong oxidizing agent molar mass and carry out ne...

Embodiment 3

[0043] Such as figure 1 Shown, the invention provides a kind of method for preparing high-purity magnesium oxide, comprises the following steps:

[0044] (3) According to the analysis of GB / T3049-2006, the iron content in heavy magnesium water is obtained, wherein the total iron is 15.4mg / L, Fe 2+ 9.2mg / L; the amount added is Fe 2+ 2 times the molar amount of ammonium persulfate, potassium permanganate and potassium periodate mixed in any proportion, and add 2 drops of potassium ferricyanide solution as a reaction indicator, and then pass CO into heavy magnesium water 2 Keep the pH of the mixed solution at 8, and oxidize for 30 minutes under the condition of this pH. When no dark blue precipitate is produced, all the Fe in the heavy magnesium water 2+ oxidized to Fe 3+ , precipitation of ferric hydroxide precipitates, and the oxidation reaction ends;

[0045] (2) then according to the excessive value of strong oxidant, add the potassium thiosulfate that addition is 1.2 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com