Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "High iron removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient magnetic separation method for quartz sand

InactiveCN102626668AIncrease production capacityReduce unit energy consumptionWet separationPurification methodsNo production

The invention discloses an efficient purification method for quartz sand. In the method, two-section smashing (rough smashing and fine smashing) and ore milling with a rod mill are adopted, so that the production capacity is increased greatly, unit energy consumption is lowered, and the method is suitable for large-scale production. A method for removing weakly-magnetic minerals and intergrowth quartz with high iron content from quartz sand through advanced ore washing and weakly magnetic-high gradient strongly magnetic combined magnetic separation before ore milling is adopted, so that the purity of quartz sand is increased greatly. The method has the advantages of simple process flow, easiness for operating, low cost, high purification efficiency, stable performance and environmental friendliness of a produced product, no use of any chemical substance in an entire production process, no production of any waste water, waste residues and waste gas, true realization of zero emission, no production of waste and prevention of pollution. The method is not limited by the production scale, various quartz sand products of low, medium and high grades can be produced, the enterprise profit can be maximized, and the method has a wide application prospect on the aspect of purification of quartz sand.

Owner:赣州金环磁选科技装备股份有限公司

Method for melting copper by using waste copper and concentrate of copper sulfide as raw materials

The invention discloses a method for melting copper by using waste copper and concentrate of copper sulfide as raw materials. The method comprises the following steps of: in a mass ratio of the copper content of waste copper to the copper content of the concentrate of copper sulfide of 1:1.3-10, mixing the waste copper and the concentrate of copper sulfide, adding a raw material containing silicon dioxide into the mixture, recycling, continuously putting the mixture into a melting pond, adding fuel and controlling the temperature of the melt to be between 1,100 and 1,300 DEG C, charging oxygen-enriched air, of which the volume concentration is 23 to 85 percent, in the melting pond, and stirring and melting the materials in an oxidizing atmosphere in the melting pond until slag and copper matte are separated by melting; transferring the separated copper matte to an air refining procedure for air refining to obtain raw copper products; transferring the slag to a common electric furnace for melting to further lower the copper content of the slag to below 0.5 percent, and performing water quenching of the slag; and transferring smoke to an acid-making procedure for preparing sulfuric acid. By the method, a large amount of waste copper can be treated, and simultaneously due to the adoption of the waste copper, the slag type of the concentrate of copper sulfide in melting is improved.

Owner:XIZHI ELECTRONICS MATERIALS BRANCH YUNNAN COPPER IND GRP +3

Method for jarosite precipitation and deironization by pressure acid leaching of high-iron zinc-sulphide concentrate in kettle

ActiveCN101591733ALarge amount of slagShort processProcess efficiency improvementSolid phasesJarosite

The invention discloses a method for jarosite precipitation and deironization by pressure acid leaching of high-iron zinc-sulphide concentrate in a kettle, which comprises the following steps: conveying the high-iron zinc-sulphide concentration and zinc oxide ore in a mixing ratio of 23:1 into an autoclave; in the zinc leaching process, controlling the acidity to convert most of iron into a slag phase; converting a solid phase of a small amount of leached iron into a water phase in leachate; making the leachate enter an adjusting tank, and adding low-grade zinc oxide ore or zinc precipitation residue for neutralization to make the iron generate hydrolytic precipitation and become the slag phase; and discharging the iron along slag through filter pressing, and performing purification treatment on generated qualified supernatant directly. Because the deironization is carried out in the kettle, the method has the advantages of short flow, simple and convenient operation, low treatment cost, high deironization rate, low zinc content in the slag, high zinc recovery rate and the like. The zinc leaching reaches over 98 percent, and the Fe contained in the leachate is less than or equal to 20 mg / l.

Owner:云南永昌铅锌股份有限公司

Metal remover

ActiveCN1982413ARaw materials are easy to getLow costRefining with acid-containing liquidsAfter treatmentSulfur

A metal remover consists of organic carboxylic acid 30-99wt% and organic phosphoric acid 1-70wt%. It can eliminate iron element and various metal elements. It doesn't consist of nitrogen, sulfur, chlorine and metal elements so it's cheap, simple, convenient and no after treatment harm.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing middle supernatant solution by carrying out two-step pressure acid leaching on high-iron zinc sulfide concentrate

ActiveCN101974683AHigh recovery rateHigh iron removal rateProcess efficiency improvementPregnant leach solutionFilter press

The invention discloses a method for producing a middle supernatant by carrying out two-step pressure acid leaching on high-iron zinc sulfide concentrate, comprising the following steps: one-step pressure acid leaching: mixing and matching the high-iron zinc sulfide concentrate and the leached residue generated in the two-step pressure acid leaching; adding into a size mixing groove for mixing size; adding a proper amount of surfactant lignin; pumping the surfactant lignin and dilute sulphuric acid into a pressurizing kettle; controlling the temperature of the kettle; introducing industrial pure oxygen into the pressurizing kettle; controlling the pressure of the kettle; controlling the final concentration of the sulfuric acid to be 0.2-0.36mol / L in an ore pulp after the one-step pressure leaching; and filter pressing to obtain a supernatant as leaching agent of the two-step pressure leaching; two-step pressure acid leaching: pumping the high-iron zinc sulfide concentrate and the surfactant obtained in the one-step pressure acid leaching into the pressurizing kettle; controlling the temperature, introducing the industrial pure oxygen into the pressurizing kettle; controlling the pressure; and controlling the final pH value to be 4.8-5.2 in the ore pulp after the two-step pressure acid leaching to obtain middle supernatant of which the leachate contains more than or equal to 20mg / l of Fe for follow-up purifying and removing impurities, and the obtained leaching residue is returned to the one-step pressure acid leaching procedure.

Owner:云南永昌铅锌股份有限公司

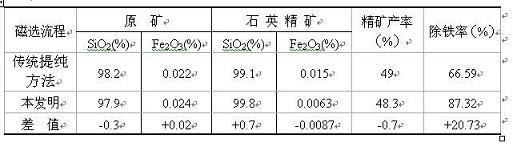

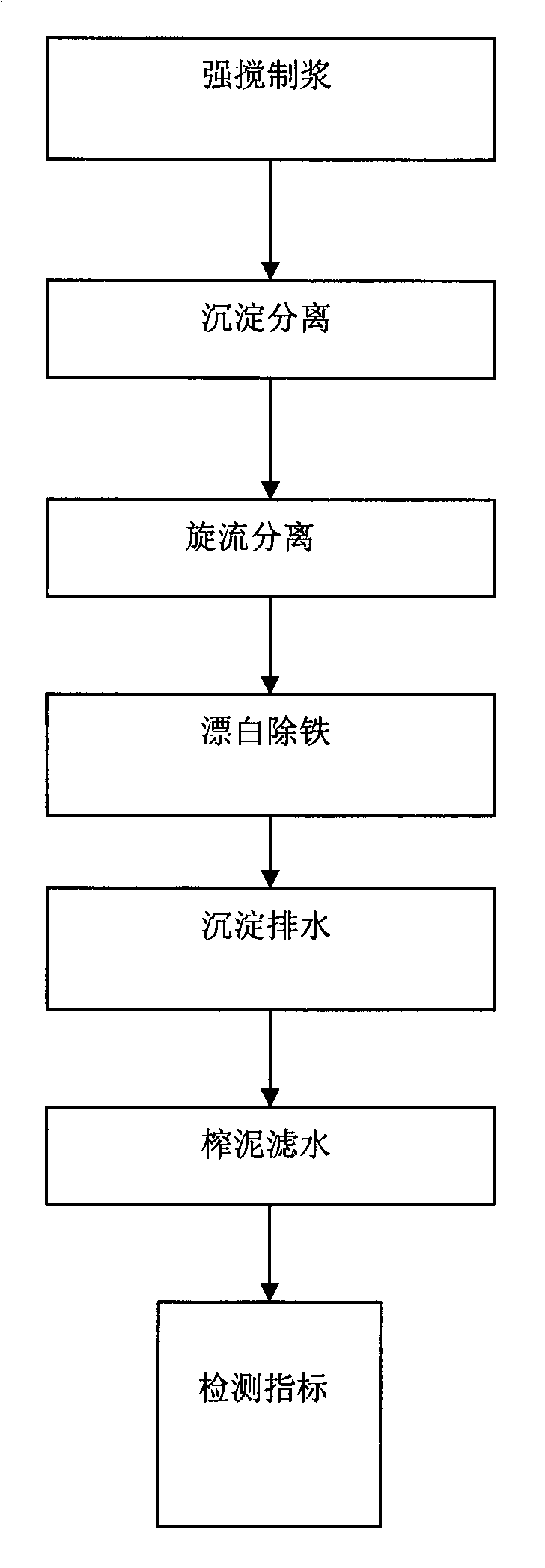

Preparation method of non-pickling raw kaolin ore

InactiveCN101987480AImprove reducibilityCan control the effect of reductionClay processing apparatusIron removalSlurry

The invention relates to a preparation method of non-pickling raw kaolin ore. The method comprises the following steps of: (A) grinding and screening raw kaolin ore to obtain a raw screening material; (B) pouring the raw screening material into a special proportioning device and a container; and (C) sequentially carrying out the following steps in the container: forcefully stirring to prepare slurry; precipitating and separating; eddying and separating; blanching to remove iron; precipitating and dewatering; pressing the slurry and filtering water; detecting indexes; and obtaining kaolin concentrate. The former three steps (A), (B) and (C) form a necessary process for obtaining the kaolin concentrate, a strong reducing agent used in the step (C) has higher reduction potential compared with the traditional hydrosulfite and low declination speed of the reduction potential to be only 1 / 5 the declination number of the reduction potential of the traditional hydrosulfite, and the step enhances the effect of removing coloring impurities in the kaolin. Moreover, the reducing agent has the action of controlling reduction and has the advantages of good safety performance, pollution-free production and use, high iron-removal rate, and the like.

Owner:施永义

Technology for preparing manganese carbonate from silver-manganese ores

The invention relates to a technology for preparing manganese carbonate from silver-manganese ores. The manganese leaching rate of the technology is greater than 98%, and the later stage silver leaching rate can reach 95%; Fe in a manganese leaching liquid can be completely removed through pre-oxidation and an E.Z. goethite process, and the Fe content in the iron removed liquid is less than 1mg / L, so the iron removal rate reaches 99.99%; heavy meal impurities in the manganese leaching liquid can be removed through a sulfuration process, and the removal rates of Co, Ni and Zn reach 97.19%, 99.84% and 72.10% respectively, so the purifying effect is good; and a manganese carbonate product is successfully prepared, and the quality of the product reaches requirements of one-grade products.

Owner:无锡永发电镀有限公司

Preparation method of high-purity quartz sand

The invention discloses a preparation method of high-purity quartz sand, and belongs to the technical field of mineral refining, and the preparation method comprises the following steps: crushing: crushing quartz sand crude ore into quartz sand particles; ultrasonic scrubbing: performing ultrasonic scrubbing on quartz sand particles; magnetic separation: selecting high gradient magnetic separatorfor three times magnetic separation of quartz sand fine sand; acid leaching: performing microwave heating quartz sand after flotation, then stirring and soaking with a 10% oxalic acid solution; flotation: mixing the quartz sand after acid leaching with water and putting into a flotation machine, adjusting the pH value in three steps, and using different collectors for flotation at the same time; drying and bagging: drying in a vacuum drying oven, and vacuum bagging after cooling. The preparation process is simple, reasonable and efficient in design; iron impurities in the quartz sand can be removed by ultrasonic scrubbing, multiple magnetic separation, microwave heating and acid leaching and flotation; the iron impurities in the prepared high-purity quartz sand are reduced to below 0.35 mg / kg; and the product has stable quality and high efficiency, and is suitable for large-scale popularization and application.

Owner:SICHUAN QINGCHUAN HONGYUAN STONE IND

Process for producing mineral water

InactiveCN107585932ASimple production processIncrease oxygen contentMultistage water/sewage treatmentActivated carbon filtrationWater velocity

The invention relates to a process for producing mineral water. The process comprises the following steps: (1) selecting spring water of a main peak of Dabie Mountain, filtering the spring water withcocoanut shell activated charcoal, and filtering the water again by using sandstone and activated charcoal; (2) carrying out reverse osmosis filtering on the water treated in the step (1) to remove colloidal microbes from the water; (3) carrying out iron removal by using a manganese sand filtering device, wherein a water velocity is 18m<3> / h to 20m<3> / h during iron removal; (4) carrying out sterilization by using ozone, and then, carrying out disinfection by ultraviolet rays; (5) introducing clean carbon dioxide into the water; (6) introducing clean mixed gas into the water so as to enable theoxygen content of water of 25 DEG C to reach 65mg / L; (7) carrying out sterile filling on the water. The process provided by the invention is simple, the amount of chemical additives is small, and themineral water is good in taste and high in oxygen content and has very good health-care value.

Owner:ANHUI YELING BEVERAGE & FOOD

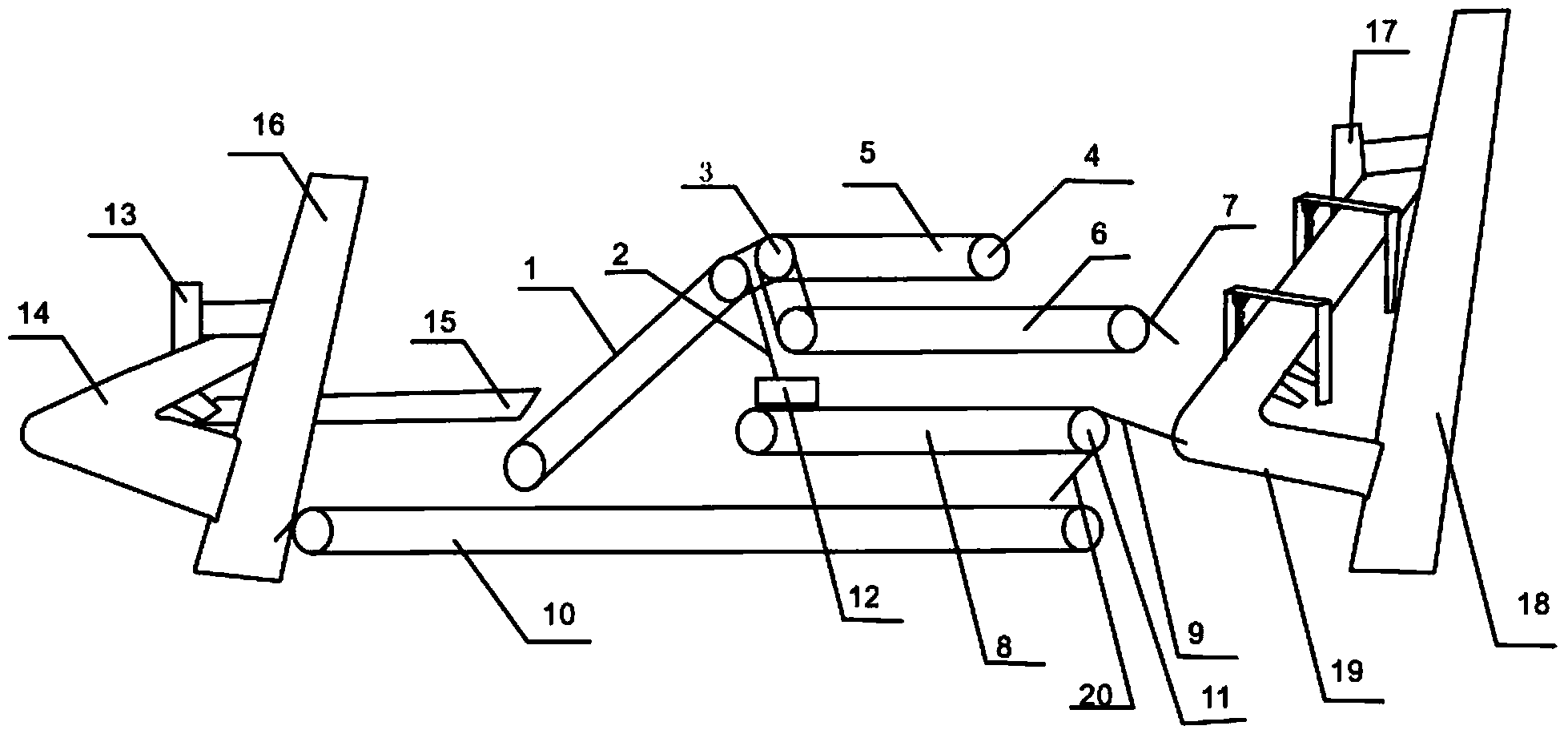

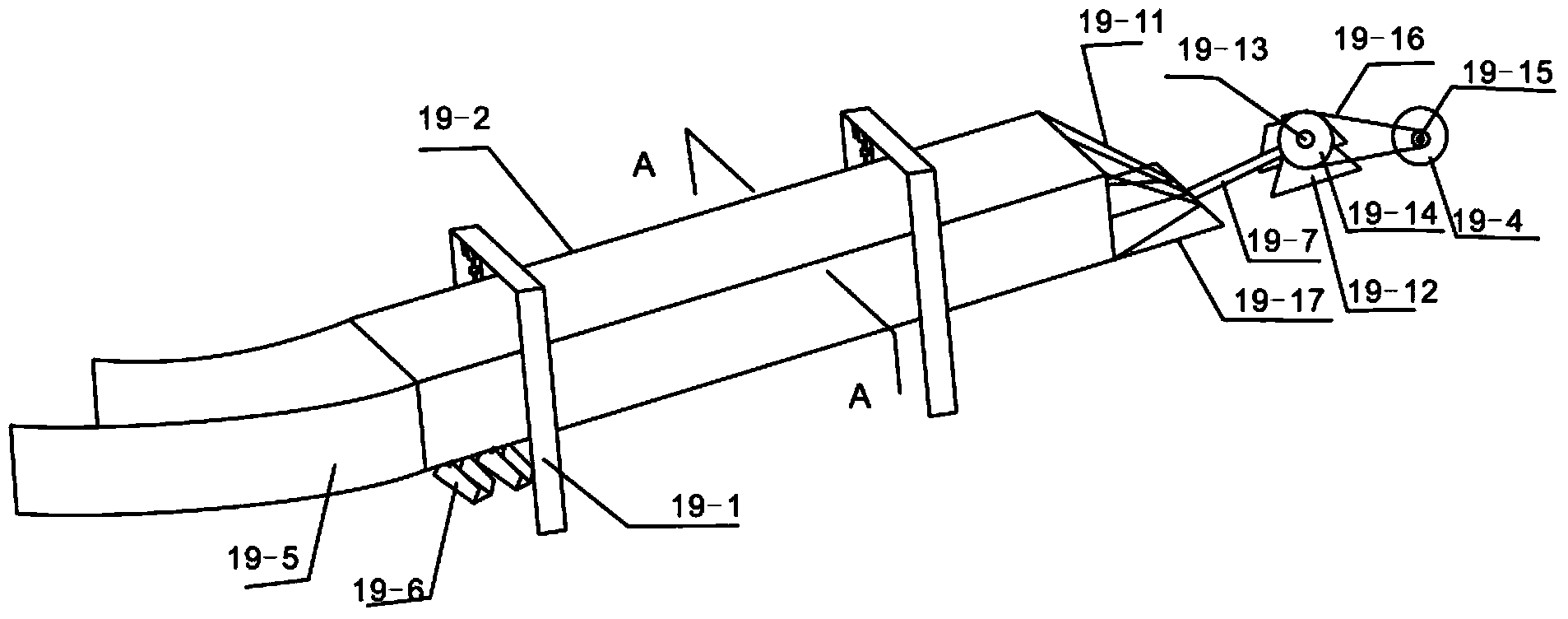

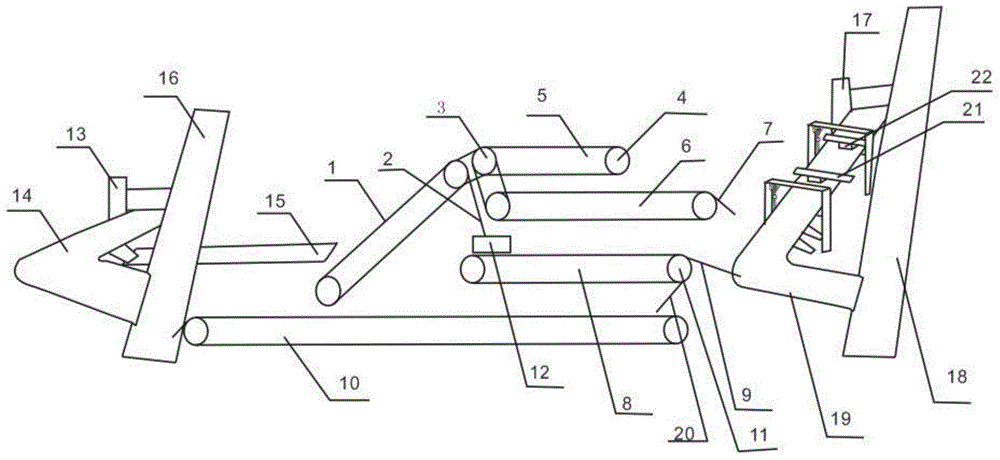

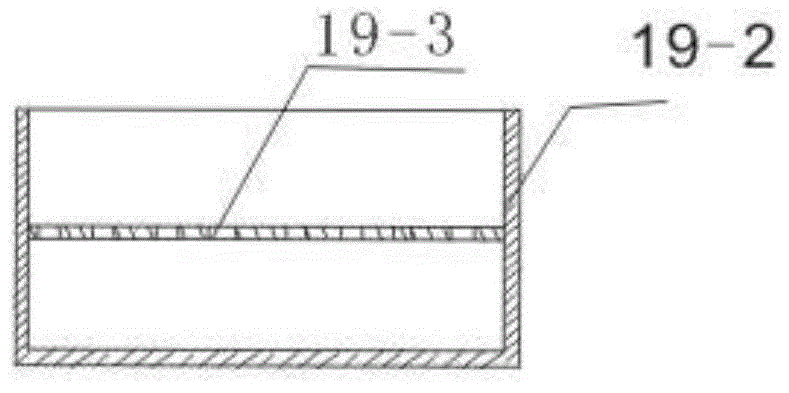

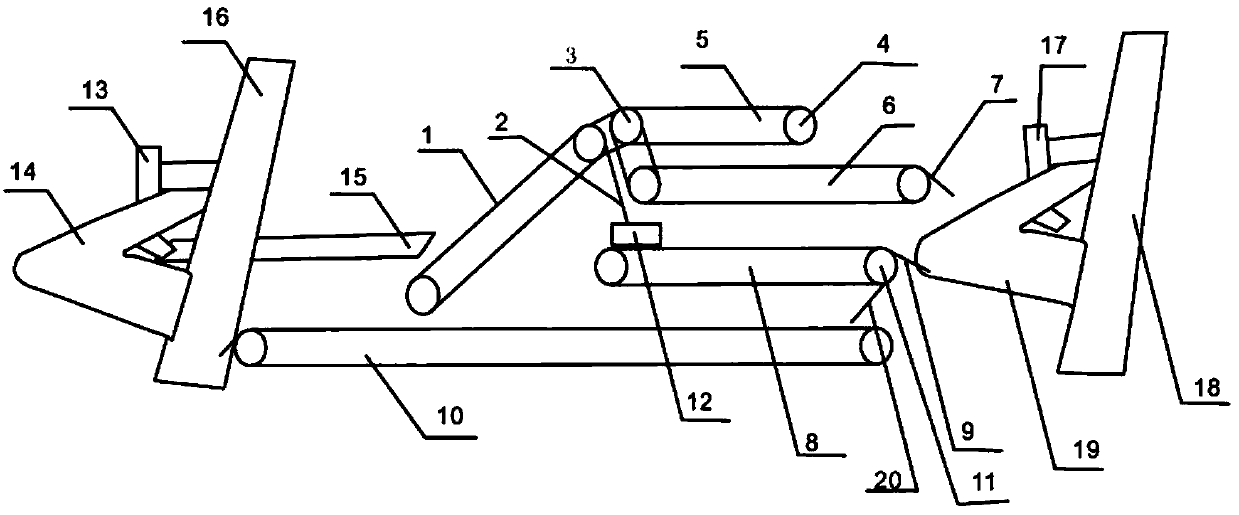

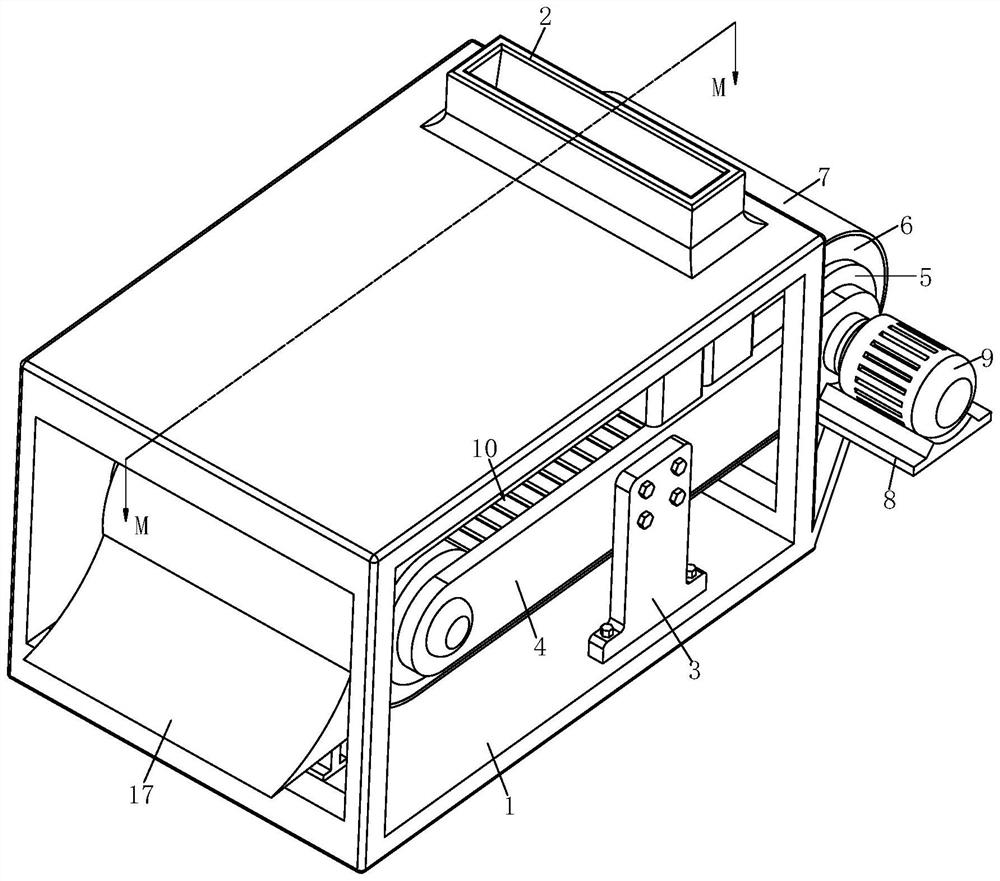

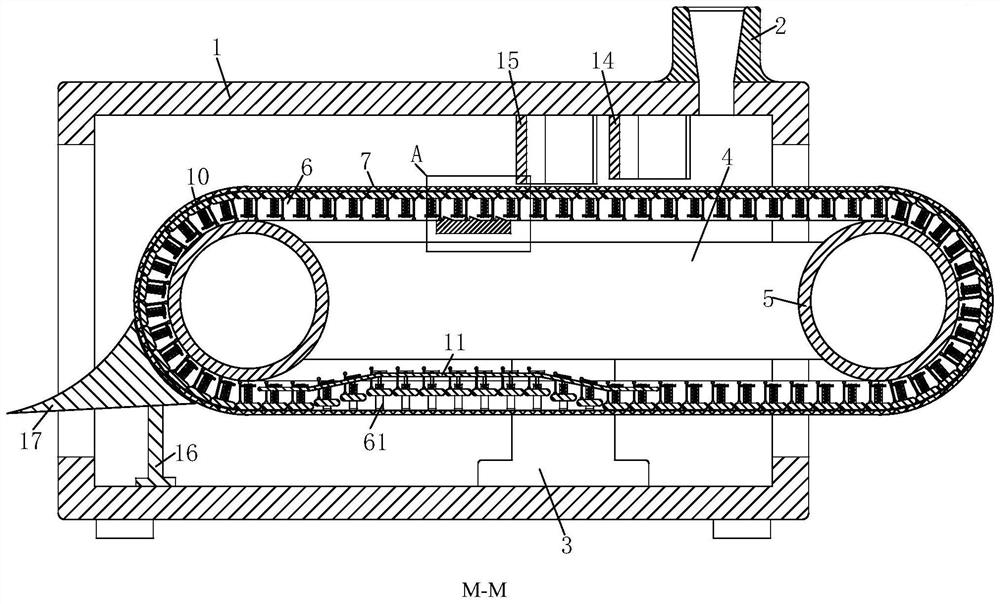

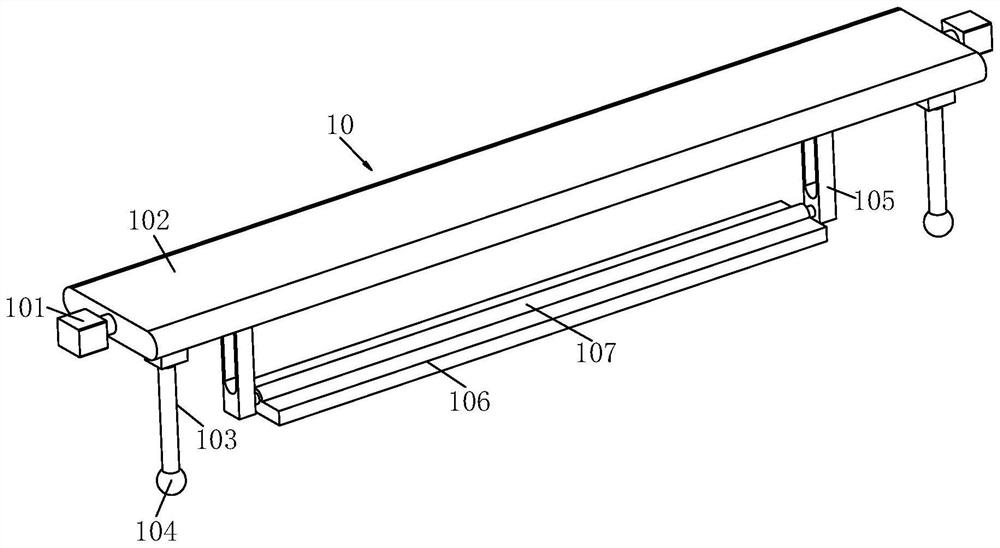

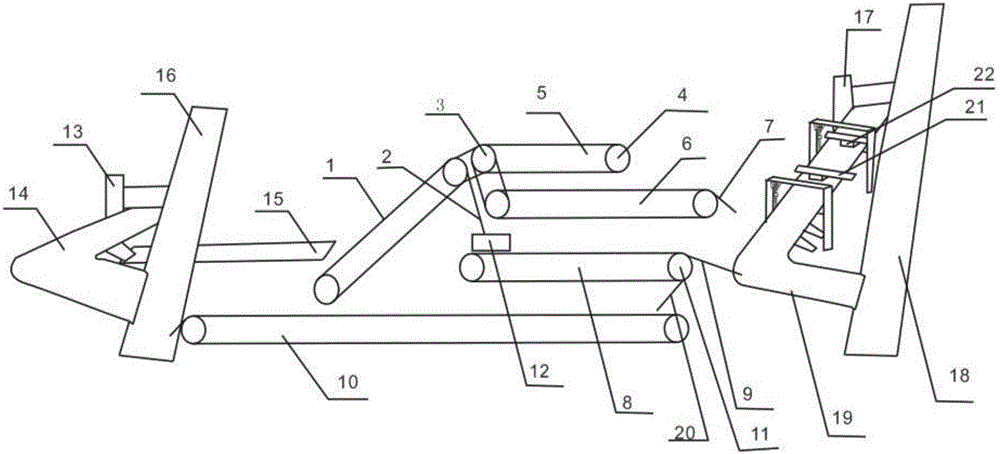

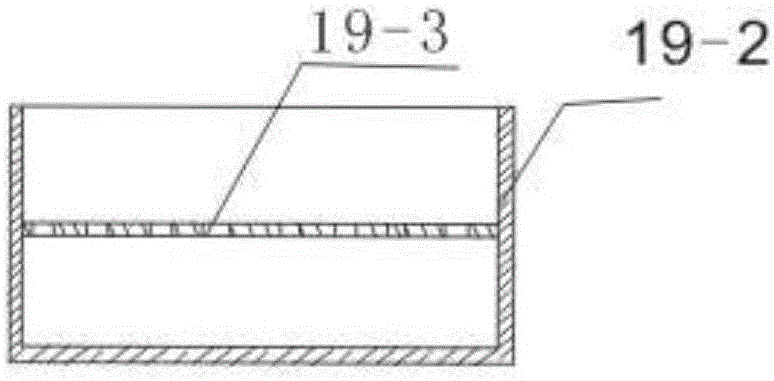

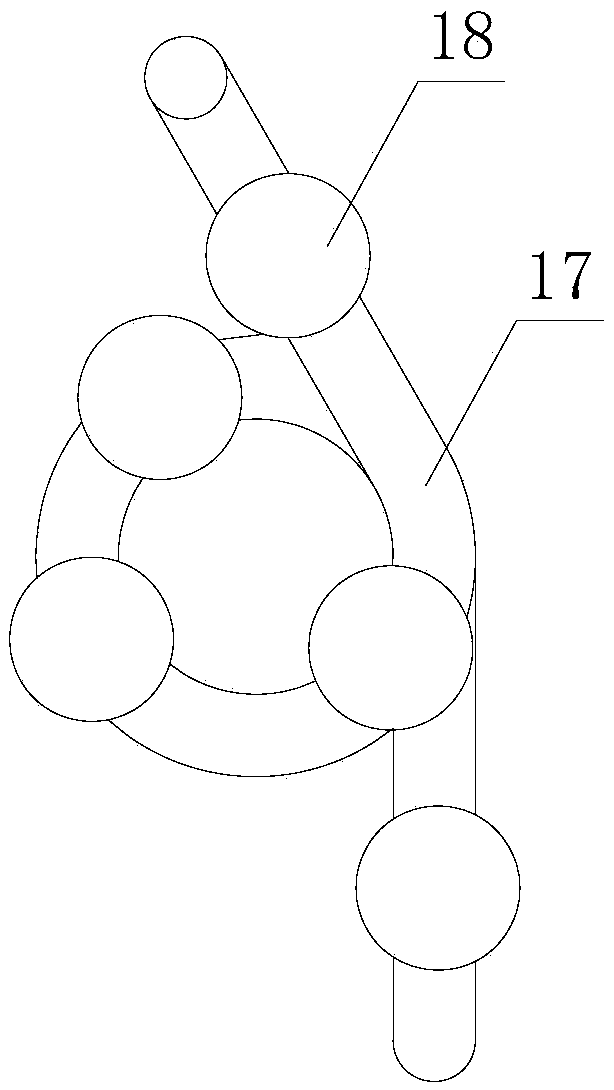

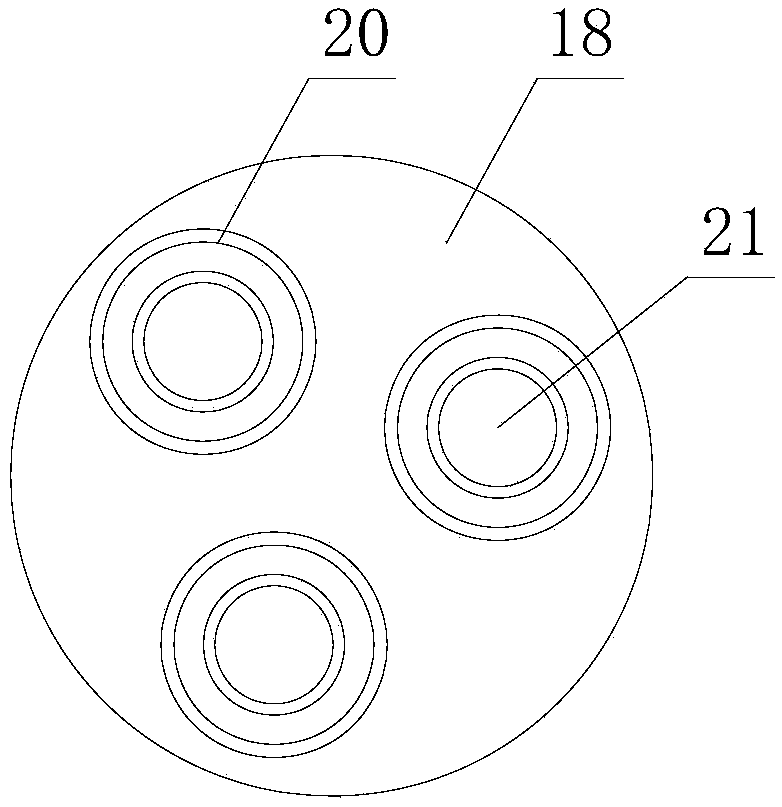

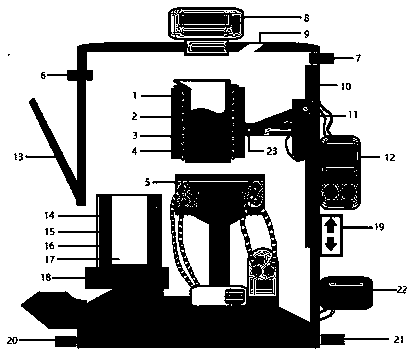

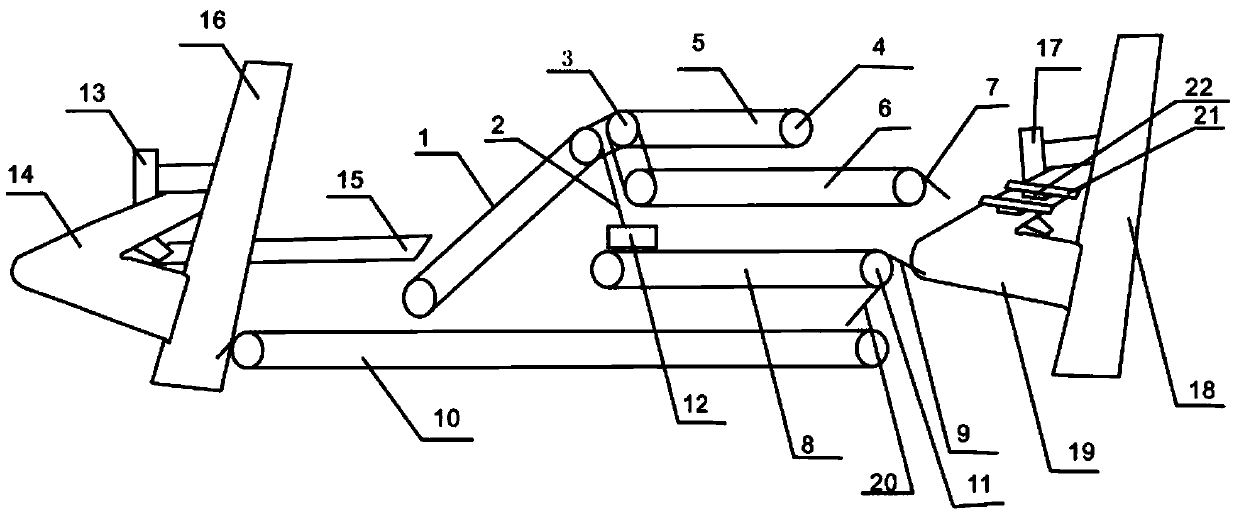

Regenerated rubber powder production device

ActiveCN104002398AHigh efficiency of magnetic separationHigh iron removal rateSievingScreeningIron powderCoarse particle

The invention discloses a regenerated rubber powder production device. The regenerated rubber powder production device is characterized in that tyre blocks formed through rough crushing of a tyre are crushed into coarse particles through a rubber coarse crushing pulverizer firstly, and the coarse particles are subjected to magnetic separation. Compared with the method that rubber is crushed into powder are then subjected to magnetic separation, a mode adopted by the device has the advantages that a steel wire is not fully smashed into iron powder, the efficiency of magnetic separation is high, and the iron removing ratio is high; before the coarse particles are delivered to a rubber powder crushing pulverizer, the coarse particles are subjected to the magnetic separation through an all-magnetic roller, so that iron-containing rubber particles are completely removed, and the iron-containing rubber can be crushed by the rubber coarse crushing pulverizer, therefore, through two-time coarse crushing pulverizer by the all-magnetic roller, the removing ratio of steel wire can reach above 99%, consequently, the content of iron powder is finished rubber powder is greatly reduced, and the production efficiency is high; an elastic part of a second moving sieve is replaced by an oscillating structure which is composed of an oscillating arm and a door-shaped frame, so that the screening efficiency is high, and the service life is greatly prolonged.

Owner:CHONGQING JUYI RUBBER PROD

Production device of rubber powder

ActiveCN103977874AHigh efficiency of magnetic separationHigh iron removal rateMagnetic separationGrain treatmentsIron powderIron removal

The invention discloses a production device of rubber powder. Tires which are cut into blocks by coarse crushing are firstly ground into coarse particles by a rubber coarse crusher, and then magnetic separation is carried out on the coarse particles. Compared with an existing device which directly grinds the rubber into powder before magnetic separation, the production device of the rubber powder is capable of grinding a steel wire which is incompletely ground into powder, so that the magnetic separation efficiency is high, and iron removal rate is high. Furthermore, before reaching the rubber crusher, the coarse particles are subjected to magnetic separation through an all-magnetic drum, so that the iron-containing rubber particles are thoroughly removed and can return to the rubber coarse crusher to be crushed. After the magnetic separation is carried out by the all-magnetic drum for twice, the steel wire removal rate reaches up to more than 99%. After the rubber particles are ground into the rubber powder in the next step, little iron powder in the rubber powder is removed by an iron powder collection box, so that the content of the iron powder in the finished rubber powder product is greatly reduced, and the production efficiency is high. An elastic part in a second movable screen is replaced by a swing type structure formed by a swing arm and a portal frame, so that the screening efficiency is high, and the service life is greatly prolonged.

Owner:CHONGQING JUYI RUBBER PROD

Vanadium iron separation method for vanadium-containing solution

InactiveCN108531729AAchieve separationLow costProcess efficiency improvementPotassium nitratePotassium ions

The invention relates to a vanadium iron separation method for vanadium-containing solution. According to the technical scheme, according to the potassium ion in potassium salt, specifically, the ratio of substance iron ion in the vanadium-containing solution is (1-6):1, the potassium salt is added into the vanadium-containing solution and is stirred for 1-3 hours at 80-95 DEG C, and reaction solution is obtained. The reaction solution is stationary for 3-24 hours at 0-10 DEG C and under light-proof conditions, the solid-liquid separation is carried out, the solution after the vanadium iron separation and filter cake are obtained; and the solution after the vanadium iron separation is used for further purification and enrichment, and the filter cake is used for further purification of (K3[Fe (C2O4) 3].3H2O). According to the vanadium-containing solution, the vanadium concentration is 1-4 g / L, the iron concentration is 3-10 g / L, the oxalate concentration is 10-30 g / L, and the pH valueis 0-5. The potassium salt is more than one of potassium chloride, potassium sulfate, potassium oxalate and potassium nitrate. The vanadium iron separation method for the vanadium-containing solutionhas simple process and low cost, and has the characteristics of good vanadium iron separation effect, high comprehensive utilization rate of resources and remarkable environmental protection benefit.

Owner:WUHAN UNIV OF SCI & TECH

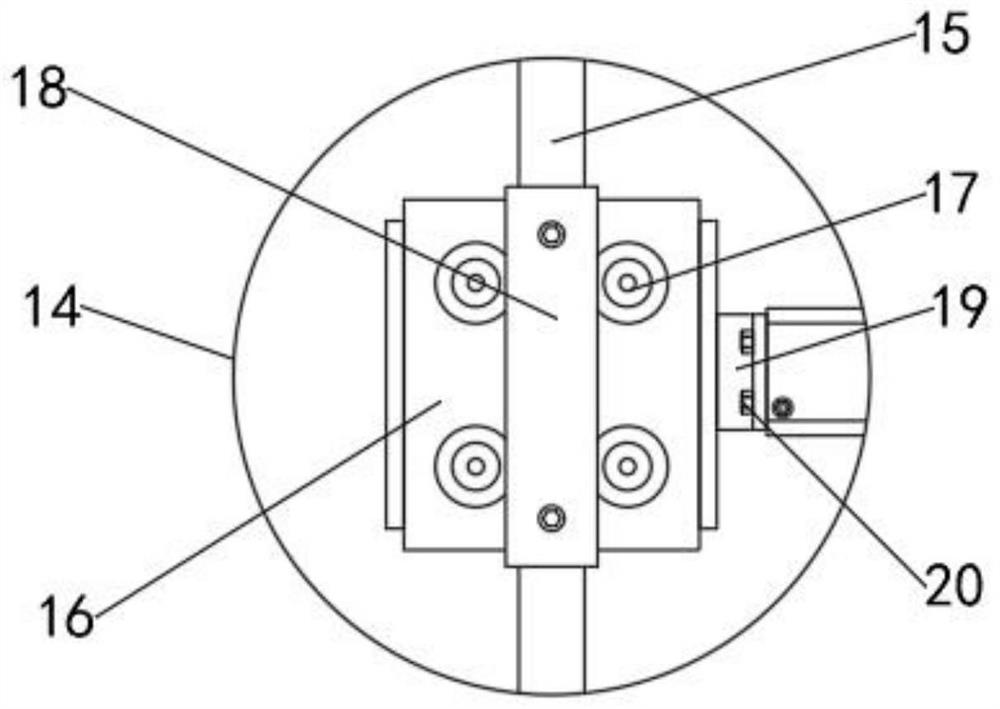

A recycling system for crushing and removing iron from recycled rubber

ActiveCN103991149BHigh efficiency of magnetic separationHigh iron removal ratePlastic recyclingMagnetic separationIron powderIron removal

The invention discloses a system for circularly grinding and deironing reclaimed rubber. The system has the beneficial effects that firstly, tires coarsely ground into blocks are firstly ground into coarser particles by a rubber coarse grinder, and then magnetic separation is carried out; compared with existing systems for directly grinding rubber into powder and then carrying out magnetic separation, the system has the advantages that steel wires are not completely ground into iron powder, the magnetic separation efficiency is high, and the iron removal rate is high; secondly, the coarse particles are subjected to magnetic separation in full-magnetic rollers before reaching a rubber powder grinder, the rubber particles containing iron are completely removed, and the rubber containing iron can return to the rubber coarse grinder to be ground. Therefore, through two-time magnetic separation in the full-magnetic rollers, the steel wire removal rate can be more than 99%. The system greatly reduces the content of iron powder in a finished rubber powder product and has high production efficiency.

Owner:CHONGQING JUYI RUBBER PROD

System for circularly grinding and deironing reclaimed rubber

ActiveCN103991149AHigh efficiency of magnetic separationHigh iron removal ratePlastic recyclingMagnetic separationIron powderIron removal

The invention discloses a system for circularly grinding and deironing reclaimed rubber. The system has the beneficial effects that firstly, tires coarsely ground into blocks are firstly ground into coarser particles by a rubber coarse grinder, and then magnetic separation is carried out; compared with existing systems for directly grinding rubber into powder and then carrying out magnetic separation, the system has the advantages that steel wires are not completely ground into iron powder, the magnetic separation efficiency is high, and the iron removal rate is high; secondly, the coarse particles are subjected to magnetic separation in full-magnetic rollers before reaching a rubber powder grinder, the rubber particles containing iron are completely removed, and the rubber containing iron can return to the rubber coarse grinder to be ground. Therefore, through two-time magnetic separation in the full-magnetic rollers, the steel wire removal rate can be more than 99%. The system greatly reduces the content of iron powder in a finished rubber powder product and has high production efficiency.

Owner:CHONGQING JUYI RUBBER PROD

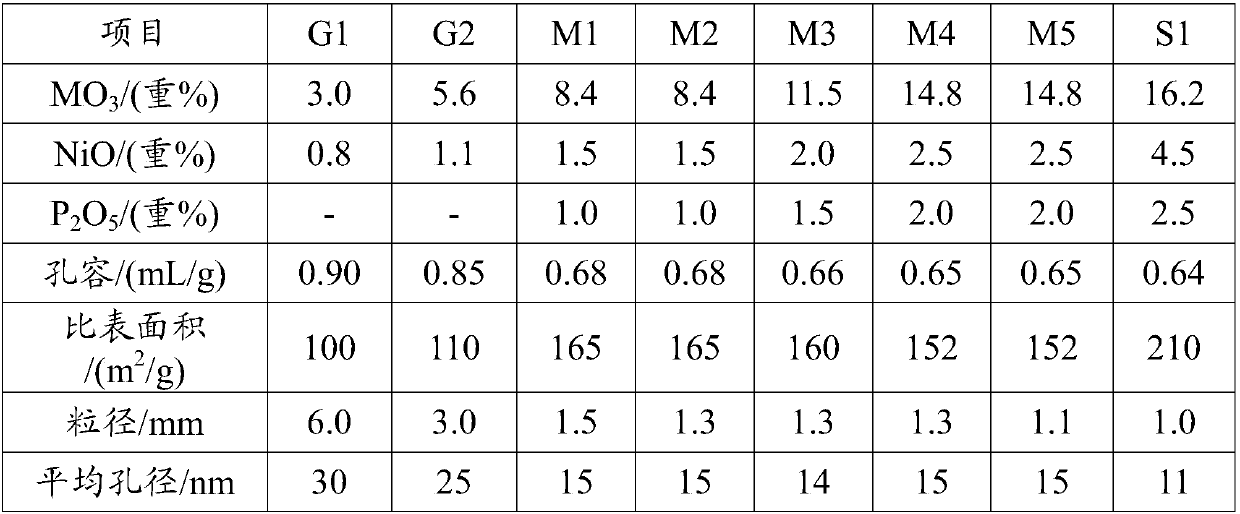

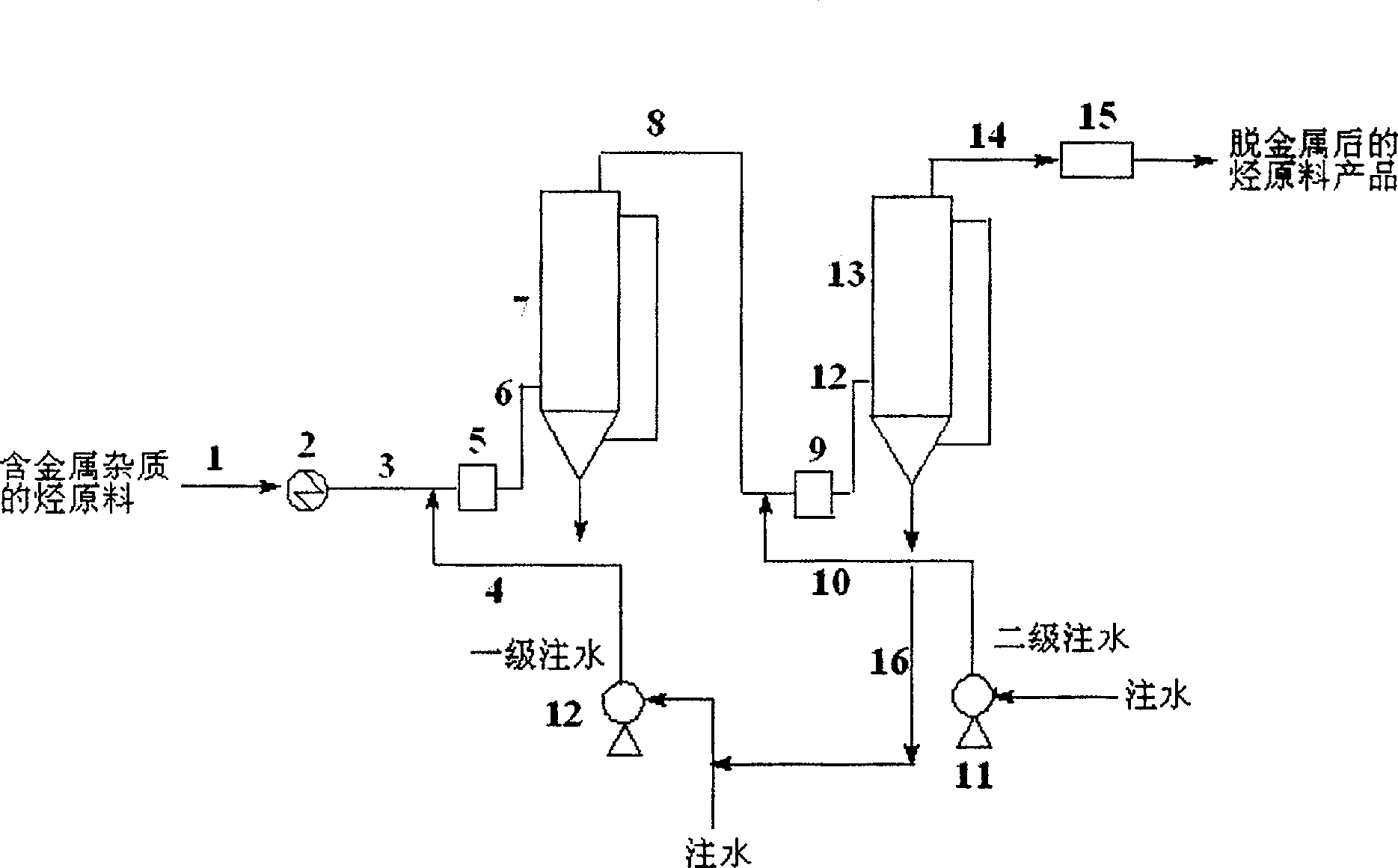

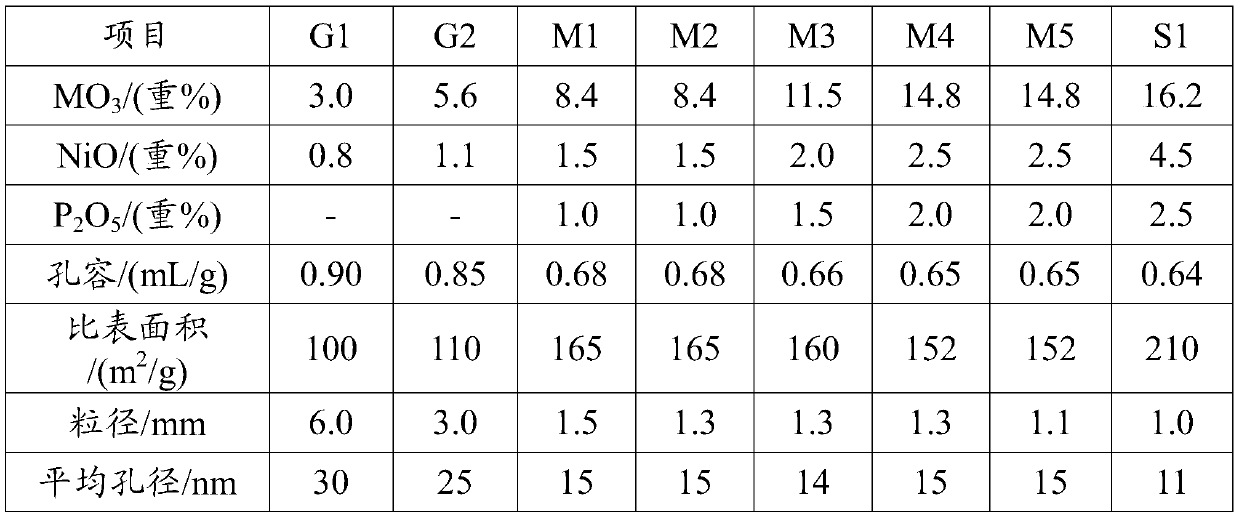

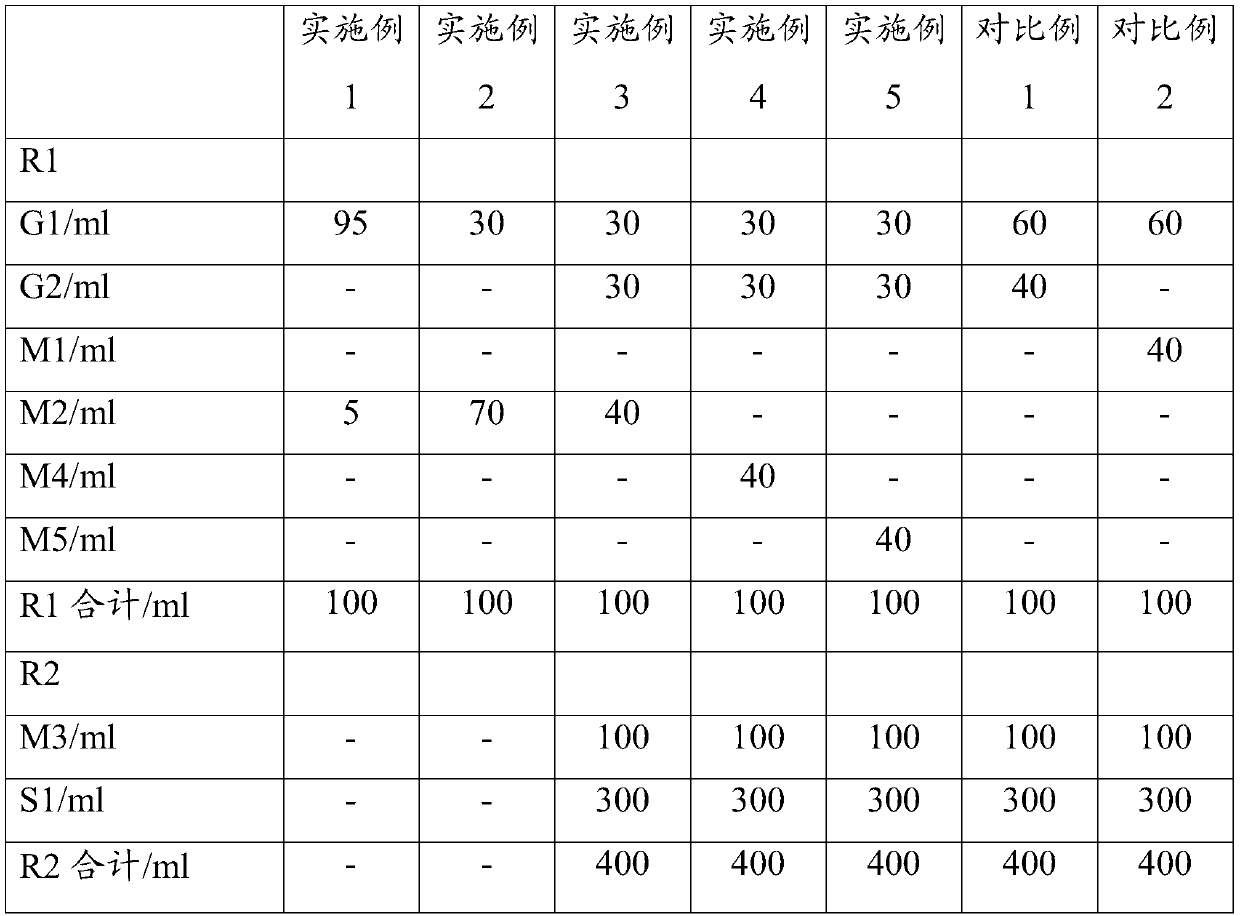

Hydrogenation system for iron containing hydrocarbon raw material and method thereof

ActiveCN107794084AOvercoming the problem of insufficient interception abilityHigh iron capacityTreatment with hydrotreatment processesChemical compoundHydrodesulfurization

The invention provides a hydrogenation system for an iron containing hydrocarbon raw material and a method thereof. The hydrogenation system comprises a pretreatment reaction zone, a first gas-liquidseparation zone, a main reaction zone and a second gas-liquid separation zone, wherein the interior of the pretreatment reaction zone is provided with at least one fixed bed reactor; the interior of the fixed bed reactor along a material flowing direction is successively filled with at least one hydrogenation protective agent and at least one first hydrodemetallization agent; the interior of the main reaction zone is provided with at least one fixed bed reactor; and the interior of the fixed bed reaction along a material flowing direction is successively filled with at least one second hydrodemetallization agent and at least one hydrodesulfurization agent. The system provided by the invention has high iron tolerant capacity and iron intercepting capacity in the pretreatment reaction zone,and overcomes the problem of insufficient capacity of intercepting an iron containing compound during long-period operation of the pretreatment reaction zone in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

Iron removal device for garbage pretreatment

PendingCN113967534ASmooth liftEnhanced magnetic forceMagnetic separationMagnetic tension forceThermodynamics

The invention discloses an iron removal device for garbage pretreatment, and belongs to the technical field of garbage treatment. The iron removal device is characterized by comprising a conveying belt, an iron removal device body and a collecting box, the iron removal device body is located above the end of the conveying belt, the collecting box is located on the right side of the end of the conveying belt, and theiron removal device body comprises a rack. When a steel wire rope is wound, the iron removal device body is driven to ascend, and on the contrary, when the steel wire rope is slowly released, the iron removal device body is driven to descend. When the iron removal device body descends, the distance between the iron removal device body and the conveying belt is closer, namely, the magnetic force of an excitation system is improved. When the iron removal device body ascends, the magnetic force of the excitation system is reduced, so that the overall adsorption capacity of the iron removal device is conveniently controlled, adjustment can be conveniently carried out according to actual conditions, the iron removal rate is improved, and the interior of the incinerator operates stably. The invention solves the problems that: an existing iron removal device is generally fixedly installed, the height of a suspended iron remover is inconvenient to adjust, part of magnetic metal at the upper end of a conveying belt cannot be effectively removed, and then stable operation of the boiler is affected.

Owner:山西荣光能源有限公司

Method for producing middle supernatant solution by carrying out two-step pressure acid leaching on high-iron zinc sulfide concentrate

ActiveCN101974683BHigh recovery rateHigh iron removal rateProcess efficiency improvementPregnant leach solutionFilter press

The invention discloses a method for producing a middle supernatant by carrying out two-step pressure acid leaching on high-iron zinc sulfide concentrate, comprising the following steps: one-step pressure acid leaching: mixing and matching the high-iron zinc sulfide concentrate and the leached residue generated in the two-step pressure acid leaching; adding into a size mixing groove for mixing size; adding a proper amount of surfactant lignin; pumping the surfactant lignin and dilute sulphuric acid into a pressurizing kettle; controlling the temperature of the kettle; introducing industrial pure oxygen into the pressurizing kettle; controlling the pressure of the kettle; controlling the final concentration of the sulfuric acid to be 0.2-0.36mol / L in an ore pulp after the one-step pressureleaching; and filter pressing to obtain a supernatant as leaching agent of the two-step pressure leaching; two-step pressure acid leaching: pumping the high-iron zinc sulfide concentrate and the surfactant obtained in the one-step pressure acid leaching into the pressurizing kettle; controlling the temperature, introducing the industrial pure oxygen into the pressurizing kettle; controlling the pressure; and controlling the final pH value to be 4.8-5.2 in the ore pulp after the two-step pressure acid leaching to obtain middle supernatant of which the leachate contains more than or equal to 20mg / l of Fe for follow-up purifying and removing impurities, and the obtained leaching residue is returned to the one-step pressure acid leaching procedure.

Owner:云南永昌铅锌股份有限公司

Quartz ore powder treatment system

PendingCN114471942AHigh iron removal rateReduce use costMagnetic separationMining engineeringIron removal

The invention relates to the field of quartz ore treatment equipment, in particular to a quartz ore powder treatment system which comprises a fixing frame, a feeding port, supporting side plates, positioning side plates, a rotating roller, a motor frame and a driving motor. Positioning side plates are fixedly installed on the side walls of the two supporting side plates through bolts, a rotating roller is installed between the two positioning side plates, the outer wall of the rotating roller is symmetrically sleeved with silicon rubber cases, elastic cloth adheres to the outer walls of the silicon rubber cases, a motor frame is welded to the outer side wall of the fixing frame, and a driving motor is installed on the upper end face of the motor frame; an output shaft of the driving motor is connected to the center of the side wall of one rotating roller through a connecting shaft, the top of the feeding opening is welded with the feeding opening used for conveying quartz powder, the inner section of the feeding opening is in a V shape, the inner wall of the fixing frame is welded with a limiting guide plate, and the iron removal device has the characteristics of being high in iron removal rate and low in use cost.

Owner:周士博

A kind of production equipment of rubber powder

ActiveCN103977874BHigh efficiency of magnetic separationHigh iron removal rateMagnetic separationGrain treatmentsIron powderIron removal

The invention discloses a production device of rubber powder. Tires which are cut into blocks by coarse crushing are firstly ground into coarse particles by a rubber coarse crusher, and then magnetic separation is carried out on the coarse particles. Compared with an existing device which directly grinds the rubber into powder before magnetic separation, the production device of the rubber powder is capable of grinding a steel wire which is incompletely ground into powder, so that the magnetic separation efficiency is high, and iron removal rate is high. Furthermore, before reaching the rubber crusher, the coarse particles are subjected to magnetic separation through an all-magnetic drum, so that the iron-containing rubber particles are thoroughly removed and can return to the rubber coarse crusher to be crushed. After the magnetic separation is carried out by the all-magnetic drum for twice, the steel wire removal rate reaches up to more than 99%. After the rubber particles are ground into the rubber powder in the next step, little iron powder in the rubber powder is removed by an iron powder collection box, so that the content of the iron powder in the finished rubber powder product is greatly reduced, and the production efficiency is high. An elastic part in a second movable screen is replaced by a swing type structure formed by a swing arm and a portal frame, so that the screening efficiency is high, and the service life is greatly prolonged.

Owner:CHONGQING JUYI RUBBER PROD

Resourceful treatment system for industrial rubber waste

ActiveCN109291310AHigh iron removal rateHigh iron removal efficiencyPlastic recyclingMechanical material recoveryMotor driveToxic industrial waste

The invention relates to the field of plastic breaking, and discloses a resourceful treatment system for industrial rubber waste. The system comprises a slabbing machine, a smashing machine and a screening machine. The slabbing machine is connected with the smashing machine, and the smashing machine is connected with the screening machine. The screening machine comprises a first screening barrel,a second screening barrel and a third screening barrel which are horizontally and coaxially arranged in sequence from inside to outside, a first motor driving the first screening barrel to rotate is arranged below the first screening barrel, a first gear and a second gear are fixedly connected to an output shaft of the first motor in the longitudinal direction, the first gear is engaged with a first gear ring, the first gear ring is fixedly connected with the lower end edge of the third screening barrel, the second gear is engaged with a third gear, a second gear ring is arranged in the thirdgear, and the second gear ring is fixedly connected with the lower end edge of the second screening barrel. By means of the resourceful treatment system for the industrial rubber waste, a rubber mixture can be scattered, and iron-containing impurities in the mixture can be more comprehensively attracted.

Owner:遵义华清塑料制品有限公司

Device and process for removing iron and silicon phases in primary aluminum-silicon alloy in one step

Owner:KUNMING UNIV OF SCI & TECH

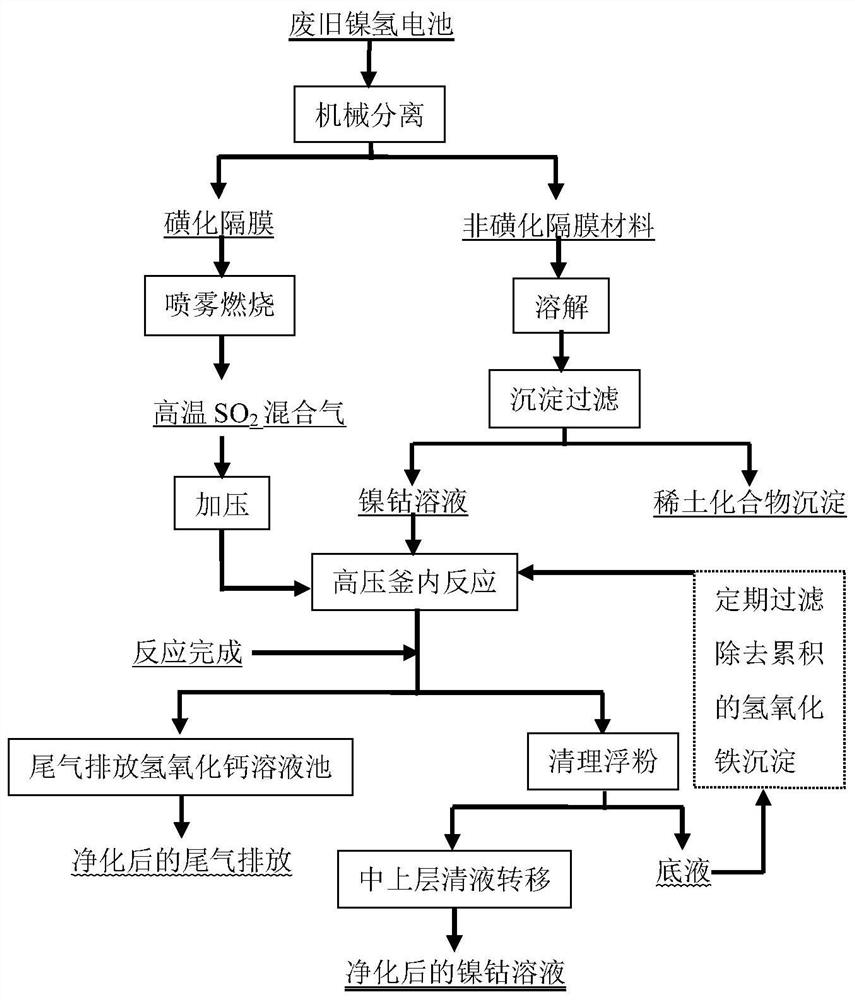

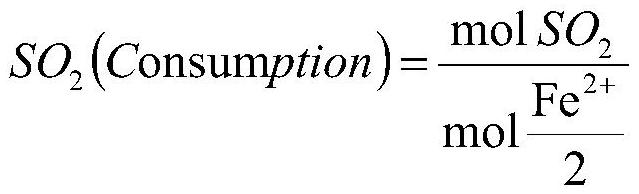

Method for removing iron in waste nickel-metal hydride battery

ActiveCN111847528AAchieve reuseEasy to handleWaste accumulators reclaimingProcess efficiency improvementIron removalPhysical chemistry

The invention belongs to the technical field of waste material retreatment, and particularly relates to a method for removing iron in a waste nickel-metal hydride battery. The method comprises the steps of: separating a sulfonated diaphragm material and a non-sulfonated diaphragm material from a waste nickel-metal hydride battery; dissolving the non-sulfonated diaphragm material, and separating out rare earth compound precipitates to obtain a nickel-cobalt solution; finely crushing the sulfonated diaphragm, spraying the crushed sulfonated diaphragm into a combustion furnace through a sprayingdevice, and carrying out combustion in an oxygen-enriched air atmosphere; pressurizing mixed gas generated by combustion, and mixing and reacting the pressurized mixed gas with the nickel-cobalt solution in a high-pressure kettle; and after the reaction is finished, transferring middle-upper-layer clear liquid to obtain a deeply purified nickel-cobalt solution, and directly entering a subsequent ternary precursor synthesis process. The method is simple in process, sulfur in the sulfonated diaphragm can enter a nickel-cobalt solution pool in the form of a mixture of sulfur dioxide and air for iron removal, the removal rate is larger than 99.5%, and sulfur reutilization is achieved; and the product obtained after SO2 oxidation is SO4<2->, other impurity ions are not introduced, the iron removal cost is low, and the method has great industrial value.

Owner:包头昊明稀土新电源科技有限公司

Technology for producing mineral water

InactiveCN108911303ASimple production processIncrease oxygen contentWater/sewage treatment by irradiationSpecific water treatment objectivesBrickMetasilicate

The invention discloses a technology for producing mineral water. The technology comprises the following steps: selecting mountain spring water in the Dabie Mountain region as raw water, filtering themountain spring water by an ultrasonic filter, filtering the mountain spring water by an activated carbon filter, removing iron by a manganese sand filtering device, and sterilizing the mountain spring water by ultraviolet rays; sterilizing the mountain spring water by ozone; performing an UH reverse osmosis technology; introducing a clean mixed gas, and filtering the mountain spring water by a titanium filter; and performing aseptic filling by a blowing and filling integration machine to obtain the mineral water. The technology has the advantages of effectiveness in filtration, excellent adsorption effect on organic matters, and good interlayer exchange, adsorption and polymerization effects; and an auxiliary filler layer structure is designed by the applicant according to the structureof existing grass-planting bricks in order to effectively fix a main filler layer and effectively prevent the main filler layer from being obstructed, so the main filler layer has a good hydraulic load, and mineral substance elements beneficial for human bodies, such as potassium, lithium, zinc and metasilicate ions, are well reserved.

Owner:安徽迎驾山泉股份有限公司

Pretreatment method of precious metal-containing iron alloy

InactiveCN112501439ASimple processHigh silicon removal rateProcess efficiency improvementPregnant leach solutionPretreatment method

The invention relates to the field of comprehensive utilization of precious metal secondary resources, in particular to a pretreatment method of a precious metal-containing iron alloy. The pretreatment method of the precious metal-containing iron alloy sequentially comprises the following steps: A, pulverizing, B, conducting pressure alkaline leaching, C, carrying out liquid-solid separation, D, removing iron by acid dissolution, and E, performing liquid-solid separation. In the step A, the precious metal-containing iron alloy is processed into powder with the particle size of 30-300 meshes; in the step B, alkali is added into ferroalloy powder containing precious metal obtained in the step A, heating is conducted, and silicon in the alloy is subjected to pressure leaching; In the step C,feed liquid is cooled and filtered after the pressurized alkaline leaching reaction in the step B to obtain a silicon-containing leachate and alkaline leaching residues; in the step D, hydrochloric acid is added into the alkaline leaching residues obtained in the step C, and then water is added to enable the liquid-solid ratio to be 10: 1 so to be dissolved for 4 hours at normal temperature; and in the step E, the feed liquid is filtered after the acid dissolution iron removal reaction in the step D to obtain an iron-containing leachate and a precious metal-containing enriched material. According to the pretreatment method, the process is simple, the silicon removal rate is high, the iron removal rate is high, and the precious metal content in the precious metal-containing enriched material is increased.

Owner:GUIYAN RESOURCE YIMEN

Method for removing metal impurities from hydrocarbon raw material

ActiveCN100537716CEfficient removalHigh iron removal rateRefining with acid-containing liquidsSulfurMetal impurities

A method for removing metal impurities in hydrocarbon raw materials, the method comprises contacting the hydrocarbon raw materials containing metal impurities with a metal removal agent, wherein the metal removal agent contains organic carboxylic acid and organic phosphonic acid. Because the method provided by the invention contains organic carboxylic acid and organic phosphonic acid, it can effectively remove the iron element in the hydrocarbon raw material, and the iron removal rate is as high as 95%. The demetallization method provided by the invention also has the advantages of low cost, readily available raw materials and simple operation, and can effectively remove various metal impurity elements. In addition, since the demetallization agent used in the present invention does not contain nitrogen, sulfur, chlorine, or metal elements, it will not cause harm to subsequent treatment processes such as catalytic hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

A recycling crushing iron removal device for reclaimed rubber powder

ActiveCN103990536BImprove clearanceHigh efficiency of magnetic separationMagnetic separationGrain treatmentsIron powderIron removal

The invention discloses a device for circularly grinding and deironing reclaimed rubber powder. The device has the beneficial effects that firstly, tires coarsely ground into blocks are firstly ground into coarser particles by a rubber coarse grinder, and then magnetic separation is carried out. Compared with existing devices for directly grinding rubber into powder and then carrying out magnetic separation, the device has the advantages that steel wires are not completely ground into iron powder, the magnetic separation efficiency is high, and the iron removal rate is high; secondly, the coarse particles are subjected to magnetic separation in full-magnetic rollers before reaching a rubber powder grinder, the rubber particles containing iron are completely removed, and the rubber containing iron can return to the rubber coarse grinder to be ground. Therefore, through two-time magnetic separation in the full-magnetic rollers, the steel wire removal rate can be more than 99%; after the rubber particles enter the next procedure of finely grinding the rubber particles into rubber powder to be ground, little iron powder in the rubber powder is removed via an iron powder collecting box. The device greatly reduces the content of iron powder in the finished rubber powder product and has high production efficiency.

Owner:CHONGQING JUYI RUBBER PROD

System and method for hydrogenation of iron-containing hydrocarbon feedstock

ActiveCN107794084BEffective interceptionEasy feedingTreatment with hydrotreatment processesHydrogenHydrodesulfurization

The invention provides a hydrogenation system for an iron containing hydrocarbon raw material and a method thereof. The hydrogenation system comprises a pretreatment reaction zone, a first gas-liquidseparation zone, a main reaction zone and a second gas-liquid separation zone, wherein the interior of the pretreatment reaction zone is provided with at least one fixed bed reactor; the interior of the fixed bed reactor along a material flowing direction is successively filled with at least one hydrogenation protective agent and at least one first hydrodemetallization agent; the interior of the main reaction zone is provided with at least one fixed bed reactor; and the interior of the fixed bed reaction along a material flowing direction is successively filled with at least one second hydrodemetallization agent and at least one hydrodesulfurization agent. The system provided by the invention has high iron tolerant capacity and iron intercepting capacity in the pretreatment reaction zone,and overcomes the problem of insufficient capacity of intercepting an iron containing compound during long-period operation of the pretreatment reaction zone in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of regenerated rubber powder production device

ActiveCN104002398BHigh efficiency of magnetic separationHigh iron removal rateSievingScreeningIron powderCoarse particle

The invention discloses a regenerated rubber powder production device. The regenerated rubber powder production device is characterized in that tyre blocks formed through rough crushing of a tyre are crushed into coarse particles through a rubber coarse crushing pulverizer firstly, and the coarse particles are subjected to magnetic separation. Compared with the method that rubber is crushed into powder are then subjected to magnetic separation, a mode adopted by the device has the advantages that a steel wire is not fully smashed into iron powder, the efficiency of magnetic separation is high, and the iron removing ratio is high; before the coarse particles are delivered to a rubber powder crushing pulverizer, the coarse particles are subjected to the magnetic separation through an all-magnetic roller, so that iron-containing rubber particles are completely removed, and the iron-containing rubber can be crushed by the rubber coarse crushing pulverizer, therefore, through two-time coarse crushing pulverizer by the all-magnetic roller, the removing ratio of steel wire can reach above 99%, consequently, the content of iron powder is finished rubber powder is greatly reduced, and the production efficiency is high; an elastic part of a second moving sieve is replaced by an oscillating structure which is composed of an oscillating arm and a door-shaped frame, so that the screening efficiency is high, and the service life is greatly prolonged.

Owner:CHONGQING JUYI RUBBER PROD

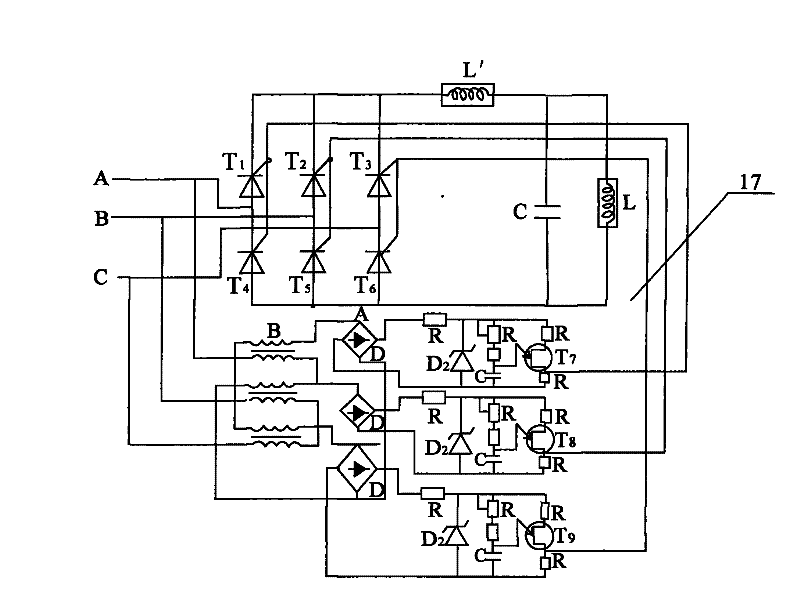

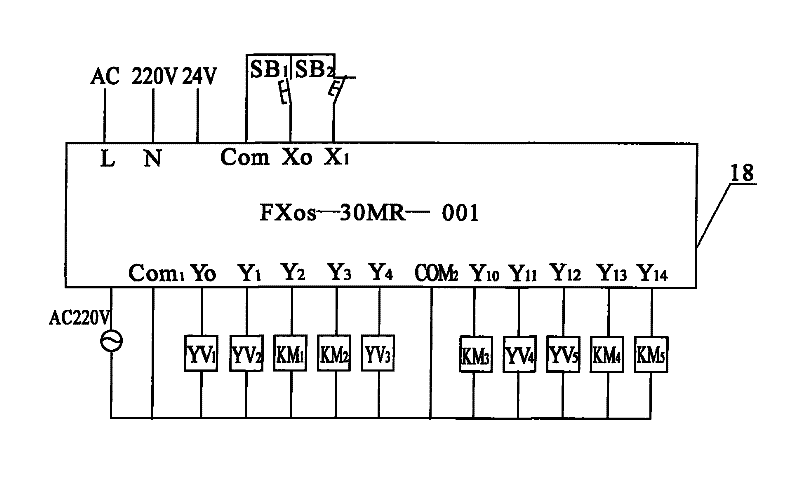

Powerful electromagnetic iron removing machine

InactiveCN101537389BIncrease the magnetic field strengthHigh iron removal rateAc-dc conversionMagnetic separationLithiumIron removal

The invention relates to an electromechanical integration powerful electromagnetic iron removing machine which has compact and reasonable structure and high electromagnetic intensity and ensures that the iron removing separation fine powder grade can meet standard requirements. The powerful electromagnetic iron removing machine consists of a base, a shell, a motor, a coil, a magnetic pole, a magnetic tube, a tube, a vibrator, a cooler, a feed port, a discharge port, an iron discharge port, a feed back port and electromagnetic valves. A magnetic pole net is excited by heavy direct current. Thepowerful electromagnetic iron removing machine is controlled by a PLC, and the electromagnetic valves are connected to corresponding pipelines respectively. The powerful electromagnetic iron removingmachine is used for the iron removal and purification of wet potassium feldspar powder, natrium feldspar powder, lithium feldspar powder, kaolin powder, figuline slurry, quartz sand powder and glaze.

Owner:张全喜 +1

Device for circularly grinding and deironing reclaimed rubber powder

ActiveCN103990536AHigh efficiency of magnetic separationHigh iron removal rateMagnetic separationGrain treatmentsIron powderPolymer science

The invention discloses a device for circularly grinding and deironing reclaimed rubber powder. The device has the beneficial effects that firstly, tires coarsely ground into blocks are firstly ground into coarser particles by a rubber coarse grinder, and then magnetic separation is carried out. Compared with existing devices for directly grinding rubber into powder and then carrying out magnetic separation, the device has the advantages that steel wires are not completely ground into iron powder, the magnetic separation efficiency is high, and the iron removal rate is high; secondly, the coarse particles are subjected to magnetic separation in full-magnetic rollers before reaching a rubber powder grinder, the rubber particles containing iron are completely removed, and the rubber containing iron can return to the rubber coarse grinder to be ground. Therefore, through two-time magnetic separation in the full-magnetic rollers, the steel wire removal rate can be more than 99%; after the rubber particles enter the next procedure of finely grinding the rubber particles into rubber powder to be ground, little iron powder in the rubber powder is removed via an iron powder collecting box. The device greatly reduces the content of iron powder in the finished rubber powder product and has high production efficiency.

Owner:CHONGQING JUYI RUBBER PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com