Quartz ore powder treatment system

A powder processing and quartz ore technology, applied in solid separation, chemical instruments and methods, magnetic separation, etc., can solve the problems of water resource waste, high processing cost, low iron removal from quartz powder, etc., to reduce unnecessary waste, The effect of increasing the iron removal rate and saving the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0024] In addition, the following terms are defined based on the functions in the present invention, and may be different according to the user's or operator's intention or practice. Therefore, these terms are defined based on the entire content of this specification.

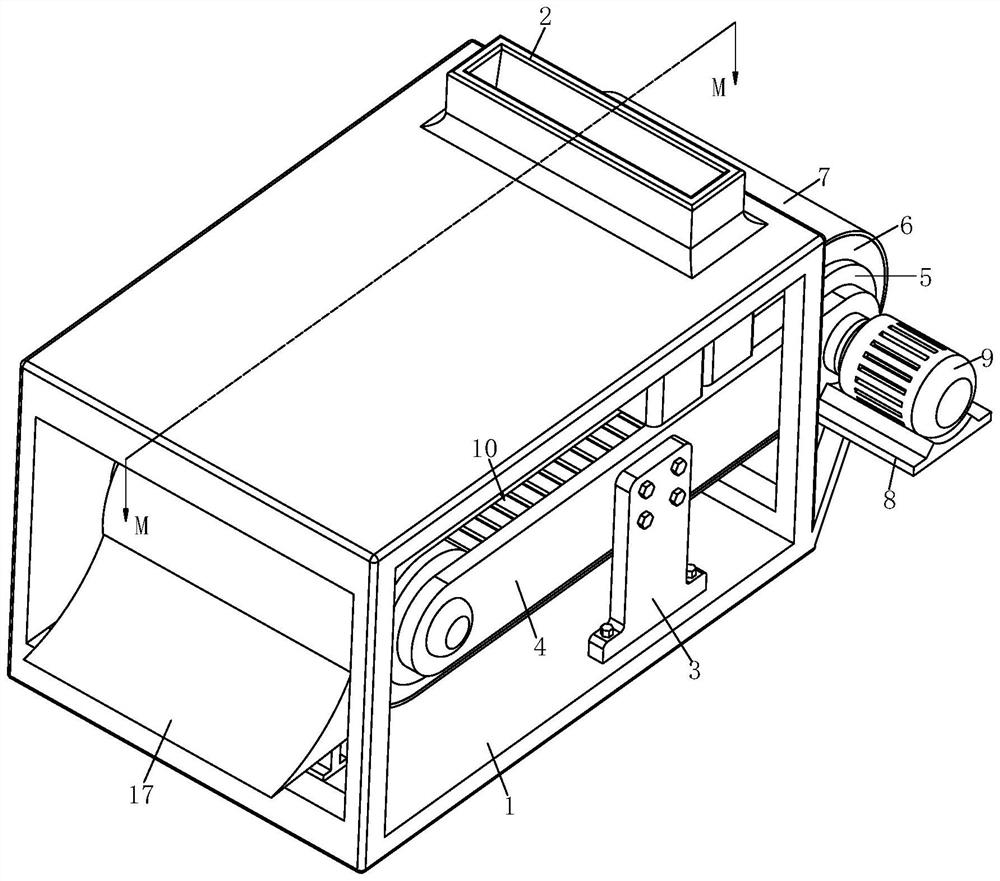

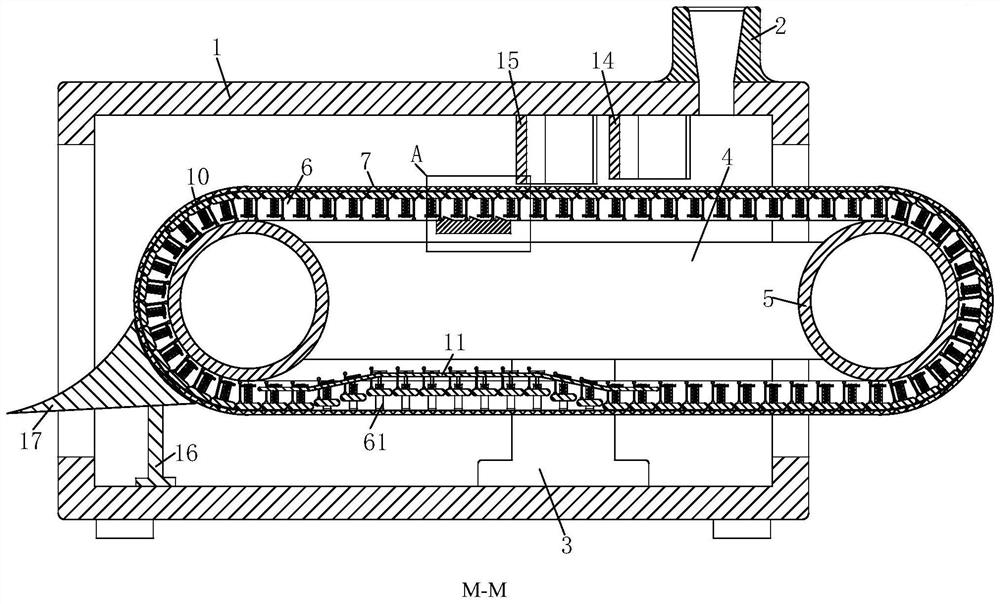

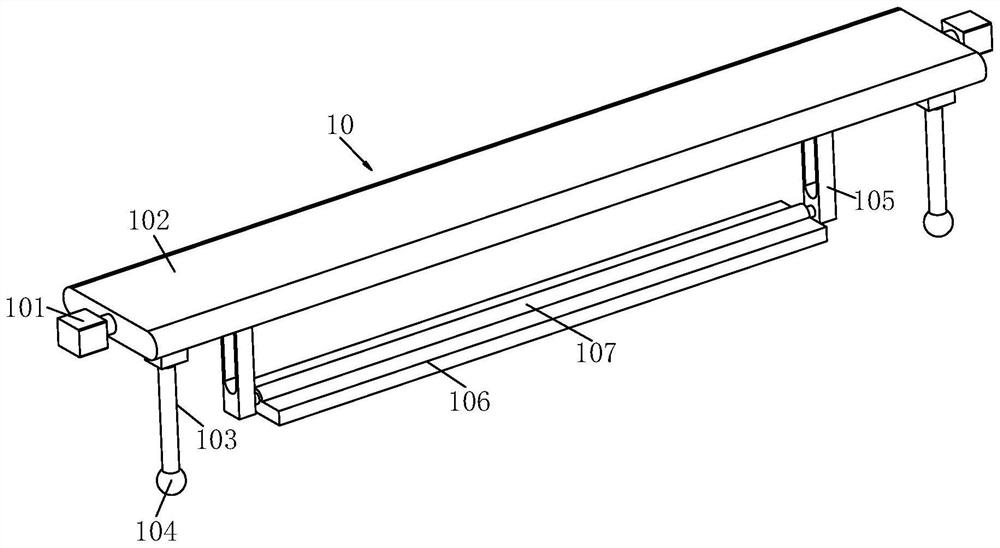

[0025] refer to figure 1 , a quartz ore powder processing system according to the present invention comprises a fixed frame 1, a feed port 2, a supporting side plate 3, a positioning side plate 4, a rotating roller 5, a motor frame 8 and a drive motor 9, the fixed The inner bottom of the frame 1 is symmetrically installed with support side plates 3 through bolts, the side walls of the two support side plates 3 are fixed with positioning side plates 4 through bolts, and a rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com