Device and process for removing iron and silicon phases in primary aluminum-silicon alloy in one step

An aluminum-silicon alloy and aluminum alloy technology, which is applied in the field of electromagnetic metallurgy, can solve the problems of inability to optimize efficiency, reduce the content of alloy silicon, and take a long time, and achieve energy saving and resource utilization, low production cost, and resource utilization. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

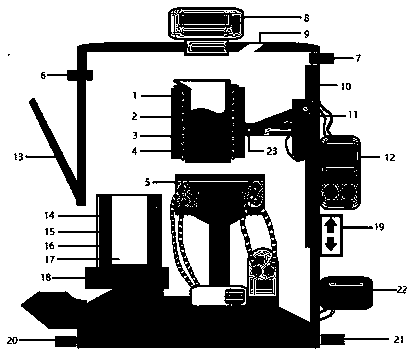

[0030] An electromagnetic separation furnace for removing iron and silicon phases in primary aluminum alloys in one step, including a furnace body, a material melting and solidification system, a material collection system, and a control system. The material melting and solidification system and the material collection system are placed in the furnace body, and the control system is placed in the furnace body. Outside the furnace;

[0031] The top of the furnace body is provided with an infrared thermometer 8 and an observation port 9; the upper part of the furnace body side wall is provided with a N 2 Inlet ports 6 and N 2 The outlet port 7 is provided with a discharge port 13 at the lower part;

[0032] Material melting and solidification system includes iron core 1, insulation cotton I2, magnetic stirring device 3, graphite heater 4, circulating water cooling heat exchange block 5, magnetic stirring-graphite heater fixing device chute 10 and magnetic stirring-graphite heat...

Embodiment 2

[0036] Get raw material primary aluminum-silicon alloy and metal Mn particles of iron remover: 100g primary aluminum-silicon alloy produced by industrial electrothermal method with silicon content of 35wt%, aluminum content of 60wt%, and iron content of 5wt%; 5g purity of 99.999% metal Mn particles.

[0037] The process steps are as follows:

[0038] Mix the above-mentioned primary aluminum-silicon alloy and metal Mn particles evenly, and place them in a graphite heater; vacuumize and fill the electromagnetic separation furnace in turn 2 After operation, adjust the power regulator, change the current and frequency to control the electromagnetic field and flow field of the alloy melt in the graphite heater, so that the furnace temperature rises slowly to 950~1150°C, and after holding at this temperature for 30 minutes, the metal elements Mn and The aluminum-silicon melt and the iron phase in the alloy fully react to form a multi-metal compound. Adjust the power regulator to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com