Resourceful treatment system for industrial rubber waste

A treatment system and waste technology, which is applied in the field of industrial rubber waste resource treatment system, can solve the problems of inability to fully remove iron, inability to guarantee rubber, and large total amount of rubber, etc.

Active Publication Date: 2019-02-01

遵义华清塑料制品有限公司

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention intends to provide a recycling treatment system for industrial rubber waste to solve the problem that since the total amount of rubber reprocessed in a single time is very large, it is impossible to ensure that the powder mixture of rubber can be close to or in contact with the iron removal device, so that The problem of insufficient iron removal

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

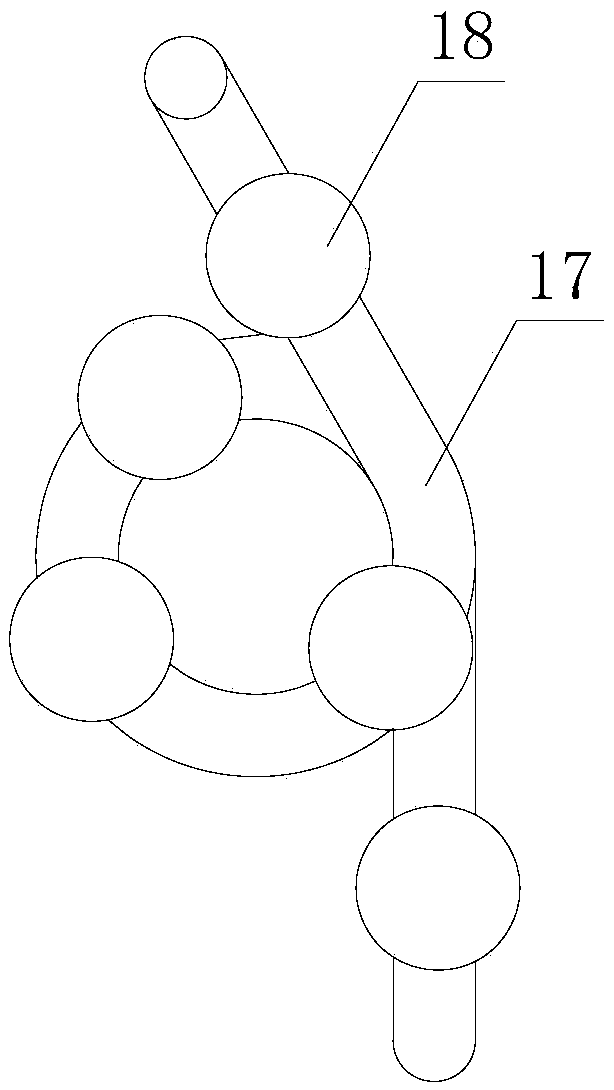

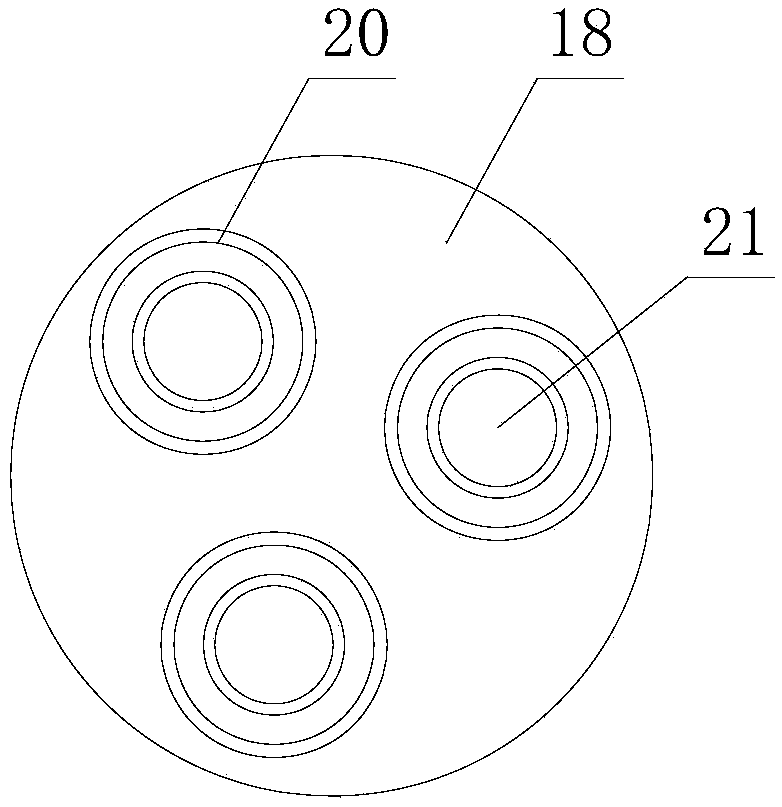

[0028] Such as figure 2 As shown, the difference from Embodiment 1 is that the rigid connecting rod 17 has a helical structure, and spherical first magnets 18 are uniformly arranged thereon. This can uniformly attract the spherical first magnets 18 in the mixture.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the field of plastic breaking, and discloses a resourceful treatment system for industrial rubber waste. The system comprises a slabbing machine, a smashing machine and a screening machine. The slabbing machine is connected with the smashing machine, and the smashing machine is connected with the screening machine. The screening machine comprises a first screening barrel,a second screening barrel and a third screening barrel which are horizontally and coaxially arranged in sequence from inside to outside, a first motor driving the first screening barrel to rotate is arranged below the first screening barrel, a first gear and a second gear are fixedly connected to an output shaft of the first motor in the longitudinal direction, the first gear is engaged with a first gear ring, the first gear ring is fixedly connected with the lower end edge of the third screening barrel, the second gear is engaged with a third gear, a second gear ring is arranged in the thirdgear, and the second gear ring is fixedly connected with the lower end edge of the second screening barrel. By means of the resourceful treatment system for the industrial rubber waste, a rubber mixture can be scattered, and iron-containing impurities in the mixture can be more comprehensively attracted.

Description

technical field [0001] The invention relates to the field of fragmented plastics, in particular to a resource recovery treatment system for industrial rubber waste. Background technique [0002] With the progress of society and the improvement of people's living standards, the number of vehicles in daily life is increasing year by year, so the amount of vehicle tire maintenance and scrapping is also increasing year by year. Replaced and scrapped tires can be processed and reused through the recycling system. The existing recycling system is mainly to disassemble the rubber tire and the rim, cut the rubber tire into pieces, then crush it into a fine powder state, and then process it into a product. In the existing recycling system, when the rubber tire and the rim are disassembled, iron fragments will appear on the rim, and the iron fragments and the rim will be mixed and then cut into pieces and crushed. Therefore, in the recycling system, we must put the iron particles or i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29B17/00B29B17/02B29B17/04

CPCB29B17/00B29B17/02B29B17/0412B29B2017/0021B29B2017/0224B29B2017/0272B29B2017/044Y02W30/52Y02W30/62

Inventor 丁云

Owner 遵义华清塑料制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com