Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124results about How to "Recycle resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Volvaria volvacea cultivation method

InactiveCN101692771AMeet the nutritional requirements for growth and developmentFull of nutritionBio-organic fraction processingOrganic fertiliser preparationEcological environmentAdditive ingredient

The invention relates to a volvaria volvacea cultivation method and belongs to the edible mushroom cultivation technology. The ingredients of compost include 7-8 parts of fresh corn coating and 2-3 parts of fresh corn stigma. The method includes the steps of simultaneously processing the fresh corn coating and the fresh corn stigma with a grinding rubbing machine so that the corn coating is processed into soft threadiness and the corn stigma is cut short and snapped, meanwhile fully mixing the two processed raw materials and controlling the water content of the compost within 65-70 percent; and after processed, the compost can then be used for volvaria volvacea cultivation or filled in a container or a storage room to be compacted, sealed and stored. The method utilizes the waste materials after processing sweet corns to produce nuisanceless volvaria volvacea yearly, thus changing waste materials into things of value, recycling resources, saving water resource, reducing sewage discharge, protecting the ecological environment, reducing the production cost, improving the product quality and increasing economic benefit.

Owner:广州市白云区农业科学试验中心 +1

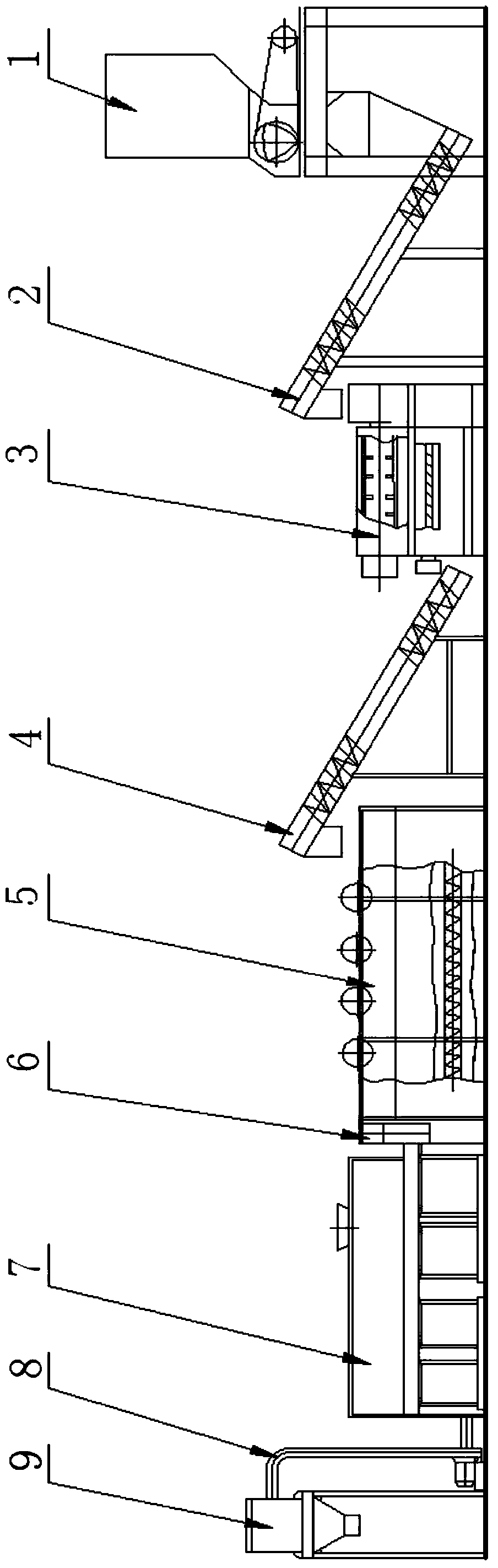

Method for recycling, cleaning and granulating waste mulching films

InactiveCN103640104AAvoid environmental pollutionRecycle resourcesPlastic recyclingPelletizingCrusher

The invention relates to a method for recycling, cleaning and granulating waste mulching films. The method comprises the steps of cleaning and granulating. In the cleaning step, the recycled waste mulching films are classified, sorted and pretreated, are conveyed into a thin film crusher for crushing, are conveyed into a frictional cleaner through a spiral conveyor I for cleaning, are conveyed to a rinsing tank through a spiral conveyor II for secondary cleaning, are conveyed to a squeezing machine through a spiral conveyor III, and are conveyed into a storage bin through a pneumatic conveying system I. In the granulating step, the waste mulching films are conveyed to a cutting compaction cylinder through a conveying belt for treatment, treated materials are automatically forced to be pushed into an SJ150 / 26 single-screw extruder, a melt is extruded through a hydraulic screen exchanger and is directly cut into uniform particles on a mold surface through a water ring granulator, the particles are conveyed into a centrifugal dehydrator for dehydration treatment, and the dehydrated particles are conveyed into the storage bin through a pneumatic conveying system II, and are bagged and stored at an outlet of the storage bin. According to an advanced method for recycling, cleaning and granulating the waste mulching films, the environment pollution is avoided, and resources are recycled.

Owner:甘肃宏鑫农业科技有限公司

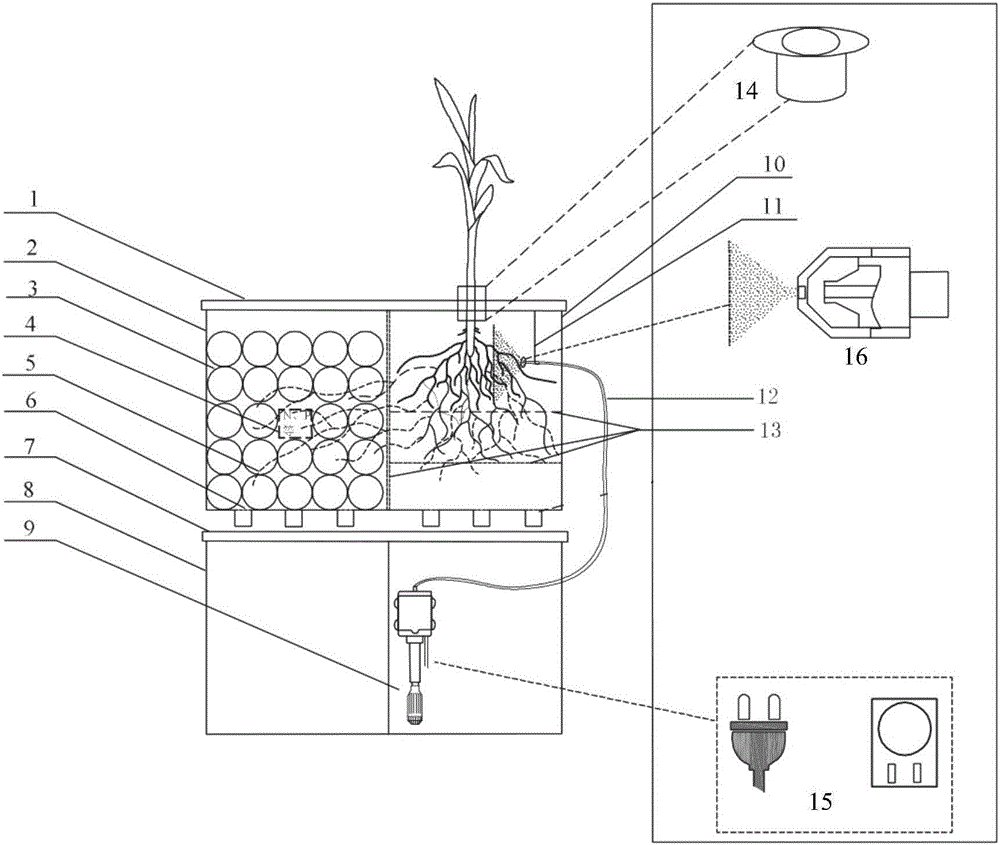

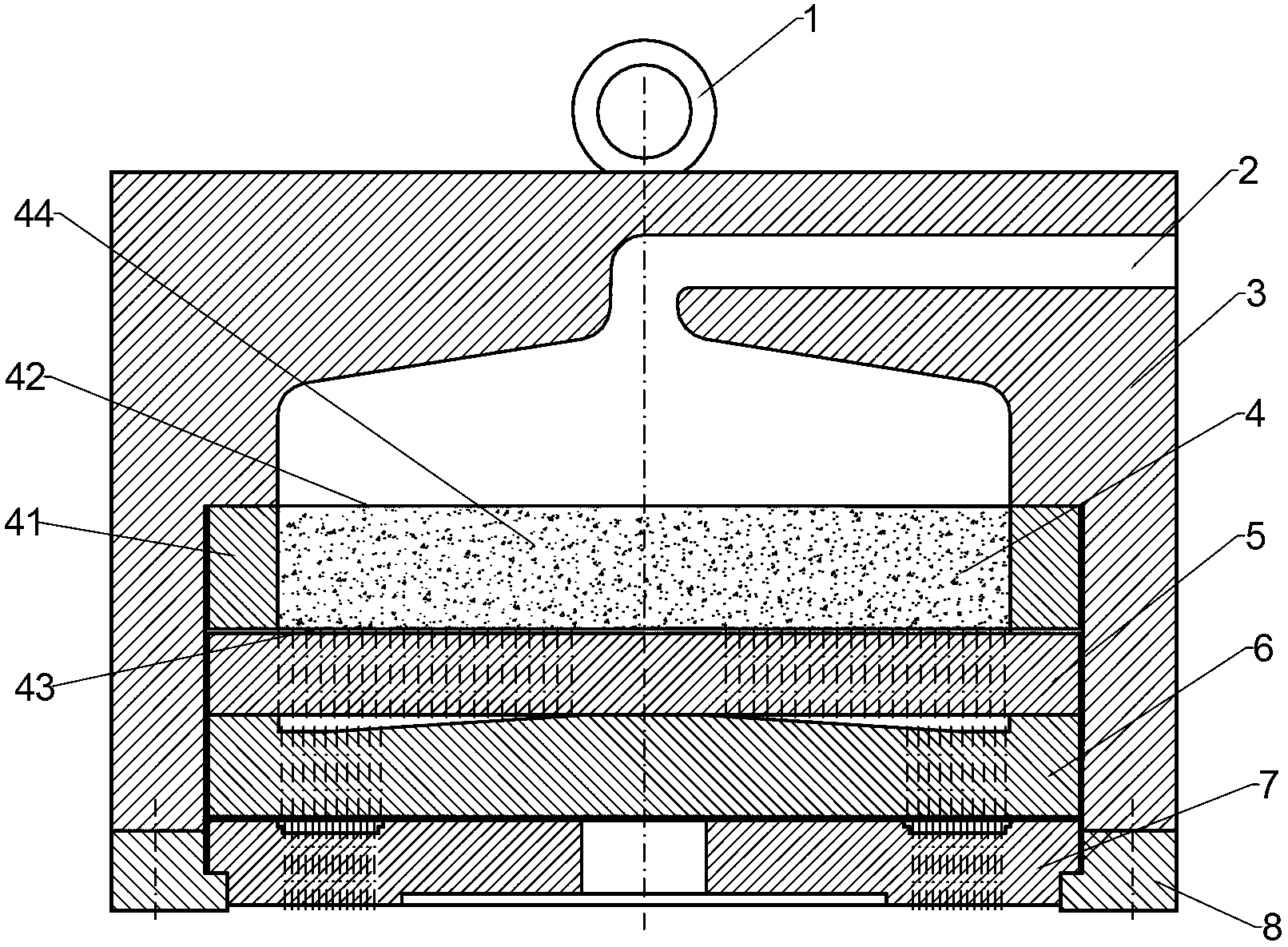

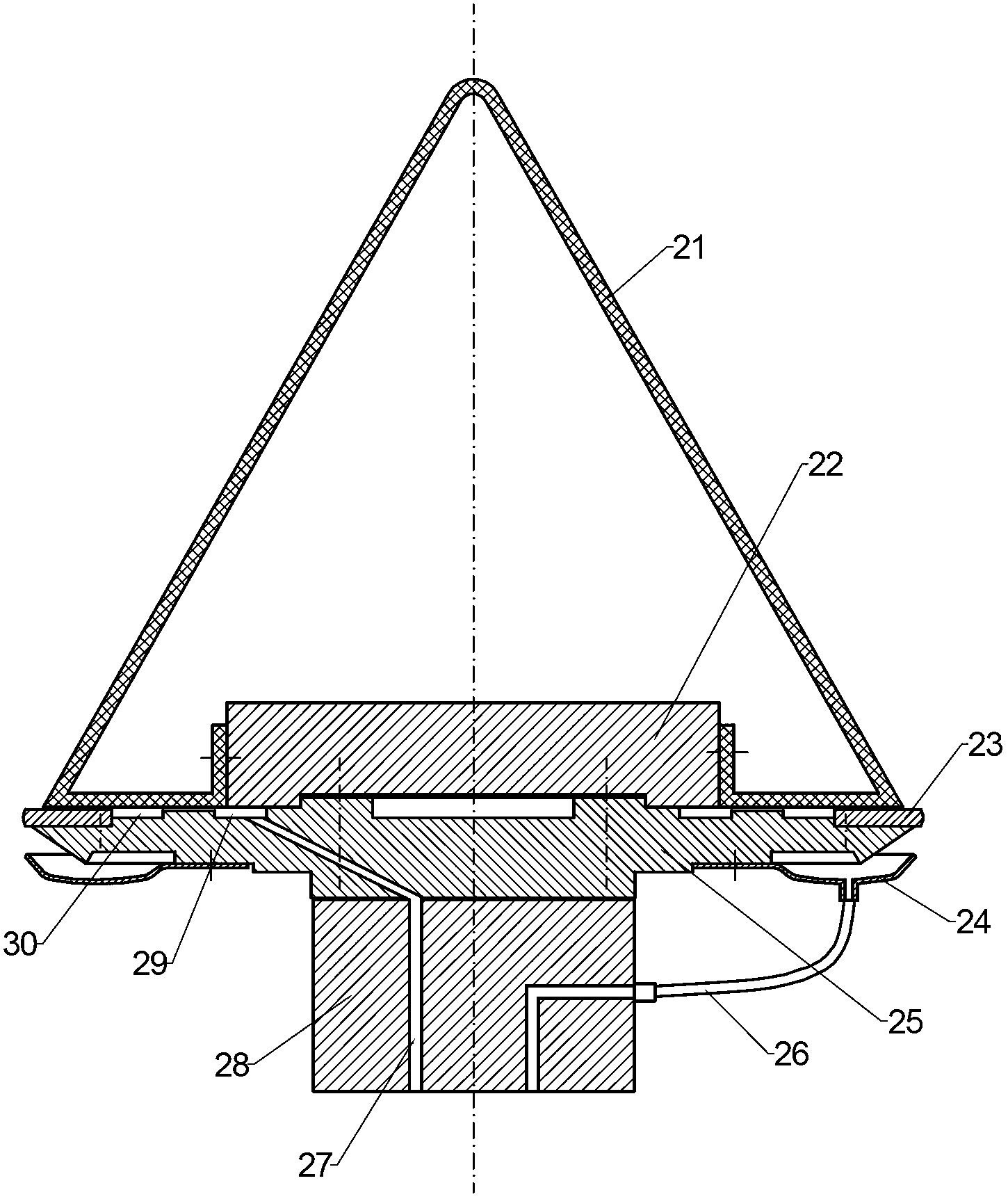

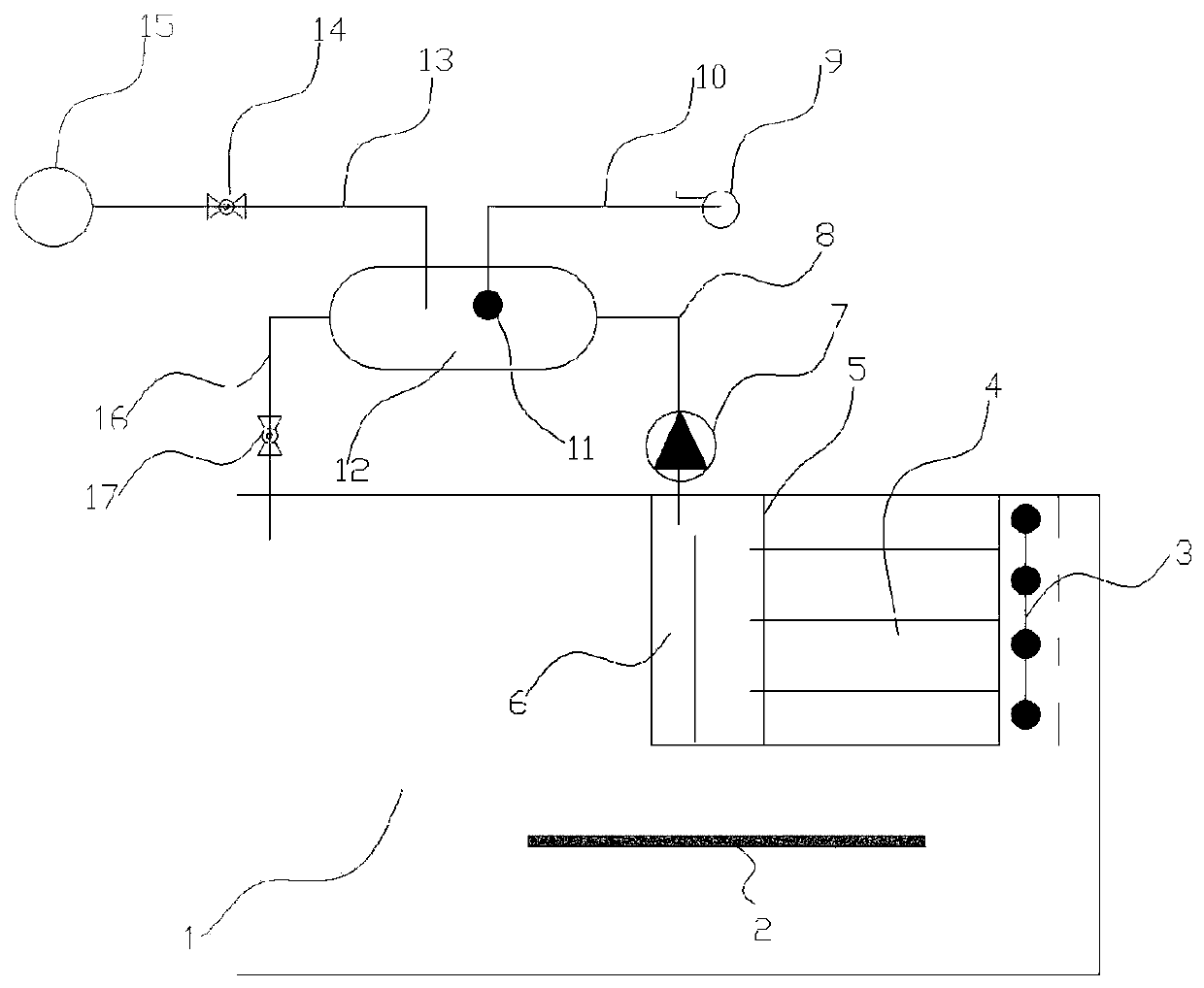

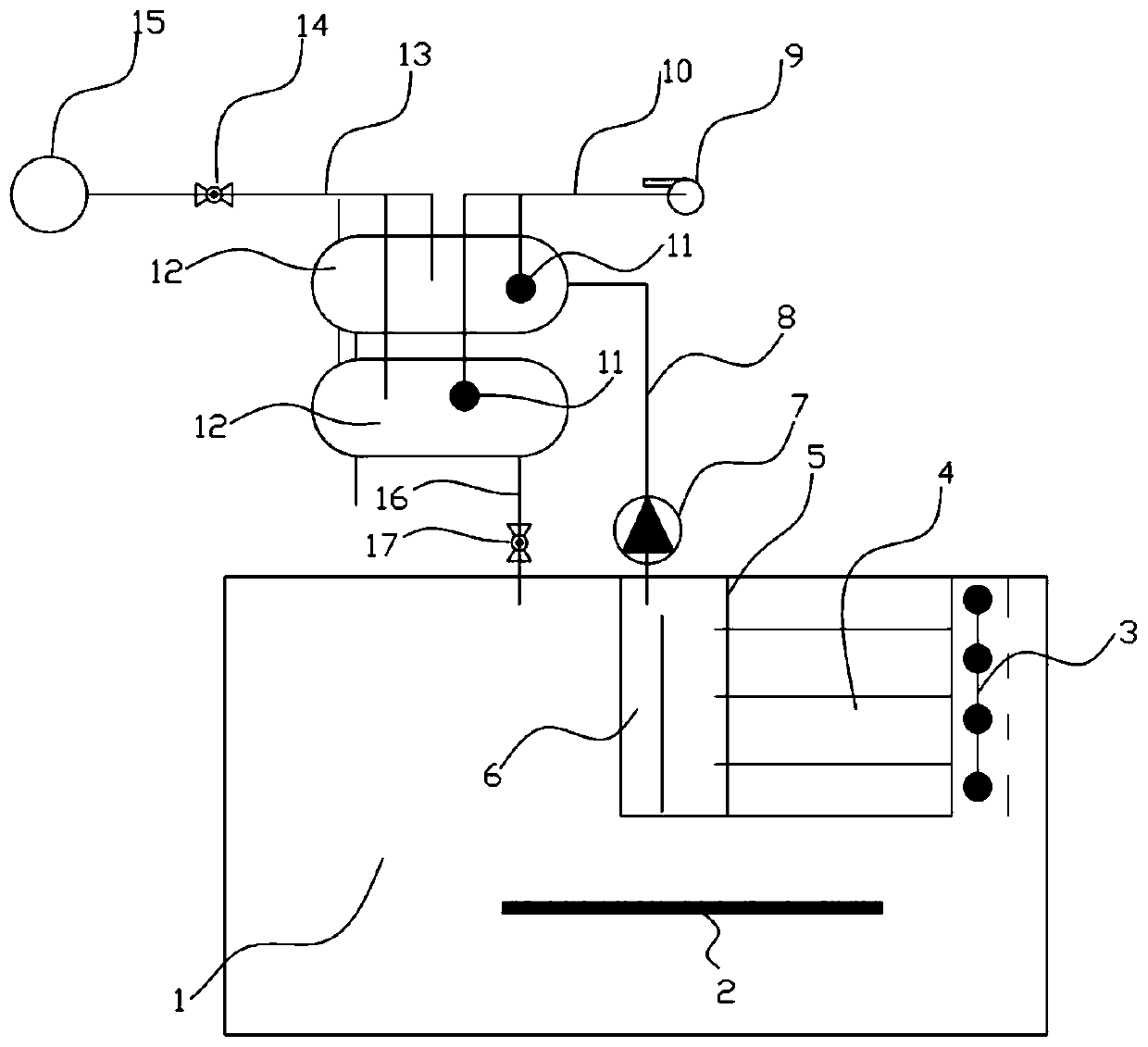

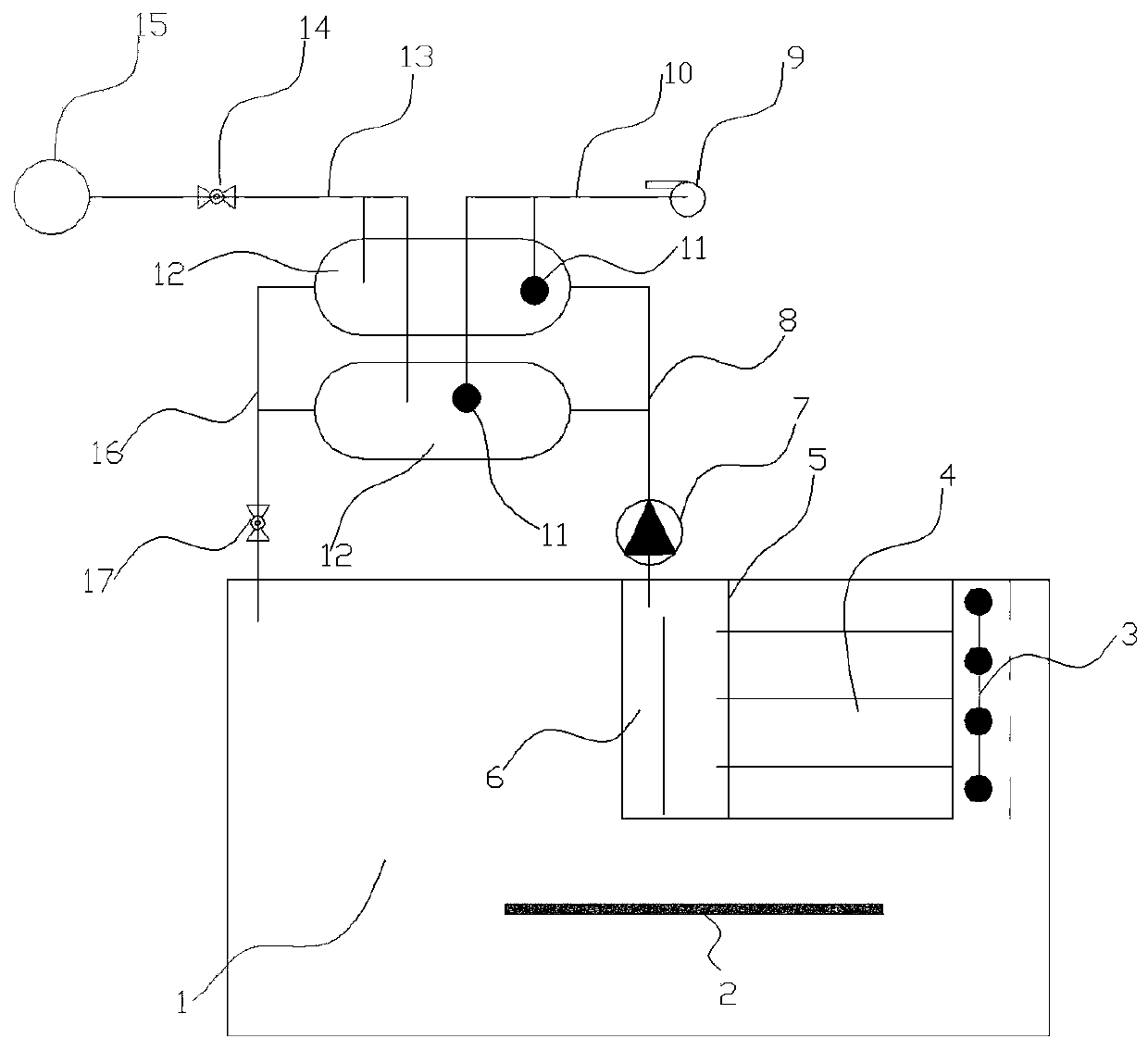

Timed and circulating AM (arbuscular mycorrhizal) fungus expanding propagation and functional experiment device and application method thereof

InactiveCN106834087AImprove cultivation efficiencySimple design and operationBioreactor/fermenter combinationsFungiMicroorganismGrowth plant

The invention provides a timed and circulating AM (arbuscular mycorrhizal) fungus expanding propagation and functional experiment device and relates to culture of soil microorganisms. The device is provided with an incubator cover, an incubator, a culture medium, a space for adding an isotope and the like, a hypha chamber, a water drainage tank cover, a water drainage tank, a filter pump, a plant growth chamber, a nozzle regulation and control hook and a nylon net, wherein the incubator cover covers the incubator, the incubator is divided into the hypha chamber and the plant growth chamber by virtue of a longitudinal net, the culture medium and the space for adding the isotope and the like are placed in the hypha chamber, and a water drainage hole is formed in the bottom of the incubator; the water drainage tank is arranged at the bottom of the incubator, the water drainage tank cover covers the water drainage tank, the filter pump is arranged in the water drainage tank, the nozzle regulation and control hook and the nylon net are arranged in the plant growth chamber, an atomizing nozzle is formed in the nozzle regulation and control hook, the atomizing nozzle and the filter pump are connected by virtue of a PVC hose, and a plant fixing device is arranged on the top of the plant growth chamber.

Owner:XIAMEN UNIV

Method for preparing spirit flavoring wine or spirit flavour liquid mainly with fragrance

InactiveCN101457190ASolve pollutionRecycle resourcesAlcoholic beverage preparationSodium acetateClostridium barati

The invention discloses a method for preparing a spirit flavoring spirit or a spirit flavoring liquor mainly aroma through liquid state fermentation and biological esterificaiton by using wastes produced from solid fermentation spirit production as culture mediums of composite bacteria. The composite bacteria comprise clostridium butyricum with a bacteria number of SICC1. 91, clostridium koseri with a bacteria number of SICC1. 13 and clostridium barati with a bacteria number of SICC1. 2; the composite bacteria fermentation mediums comprise yellow water, tail water, lees solution and pot-bottom water with a weight ratio of 7-8: 0. 5-1: 0. 5-1: 0. 5-1. Sodium acetate 1. 5and dibasic potassium phosphate 0. 04are added in the mixture solution, and ammonium bicarbonate is added to adjust pH value to 6. 5-7. 0, 95 degree ethanol 2 0s added after sterilization, then the mixture solution is sterilized at temperature 105 DEG C for 20min. The invention solves the pollution problem of the wastes to the water environment from the solid spirit production process. The added spirit body is more coordinate, which prevents the defect that the addition of monomer product easily generates float fragrant flavor. The spirit has strong nature feeling, and the recovered bacterial sludge and other residual nutritive matters can be recycled in the fermentation process and avoid secondary environment pollution.

Owner:SICHUAN YINFAN BIOTECH LTD

Method of preparing liquor seasoning wine or liquor seasoning liquid mainly to taste

InactiveCN101445776ASolve pollutionRecycle resourcesAlcoholic beverage preparationDipotassium hydrogen phosphateSodium acetate

The invention discloses a method of preparing liquor seasoning wine or liquor seasoning liquid mainly to taste by liquid state fermentation taking waste produced in solid-state fermentation liquor production as composite strain. The composite strain comprises Clostridium butyricum with strain number SICC1.91, Klinefelter Clostridium with strain number SICC1.13 and Pap Acetobacter with strain number SICC1.2; the composite strain fermentation medium is yellow water: tail water: groove liquid: spent wash=7-8:0.5-1:0.5-1:0.5-1, sodium acetate 1.5%, dipotassium hydrogen phosphate 0.04%, adjusting pH of ammonium bicarbonate to 6.5-7.0, adding 2% 95 degrees ethanol after sterilization; sterilizing 20 minutes under 105 degrees centigrade. The invention solves the pollution problem of the waste produced in solid-state fermentation liquor production process to the water environment, the added liquor being more coordinated, avoids the shortcomings that the added monomer products being easy to produce floating fragrance; the liquor has strong natural sense; the recovered strain mud and other residual nutrients are recycled in fermentation process, which avoids the secondary pollution.

Owner:SICHUAN YINFAN BIOTECH LTD

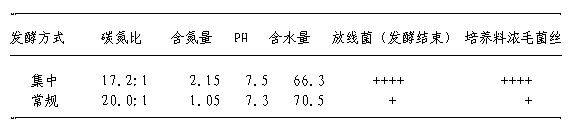

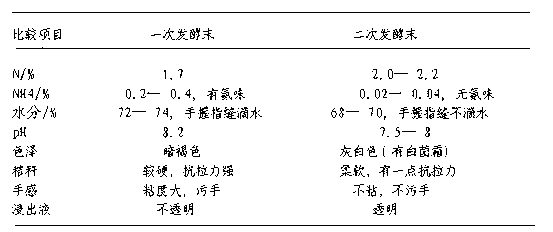

Centralized secondary fermentation method for agaricus bisporus

InactiveCN103319219AQuality productionHigh yield productionBio-organic fraction processingOrganic fertiliser preparationBiotechnologyAnimal Foraging

The invention discloses a centralized secondary fermentation method for agaricus bisporus. The culture medium comprises the following raw materials in parts by weight: 45-60 parts of forage, 35-50 parts of chicken manure, 2-8 parts of gypsum and 3-10 parts of oil cakes. The method comprises the following steps of: uniformly spreading forage in a pre-wetting pool for pre-wetting for 2-5 days; adding chicken manure, gypsum and oil cakes and uniformly and adequately mixing; filling the mixed fermentation material in a ventilating floor in a primary fermentation tunnel, and conveying fresh air to the fermentation material through a fan; fermenting for 4-6 days and transferring the fermentation material to another primary fermentation tunnel. The base material of the primary tunnel fermentation is uniformly stacked on the ventilating floor in a secondary fermentation tunnel, and the temperature of the fermentation material is controlled by operation of the fan. Secondary fermentation comprises the following steps: a balancing stage, a heating stage, pasteurization, cultivation at constant temperature and discharge at low temperature. According to the method, local wheat straw hoods, straws, chicken manure and the like are used as main raw materials to form the culture medium. Centralized scaled production cultivation materials are formed by the technology of pre-treatment of the raw materials, primary fermentation and secondary fermentation.

Owner:SICHUAN MAOSEN BIOLOGICAL SCI & TECH

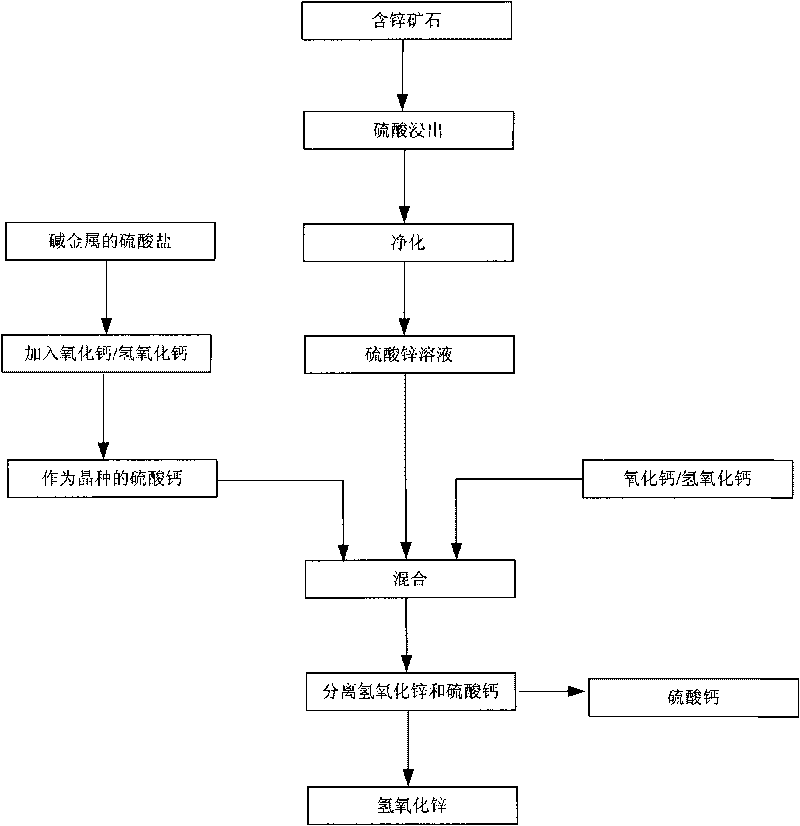

Method for leaching zinc-containing ores

ActiveCN101760613ALarge granularityReduce pollutionProcess efficiency improvementZinc hydroxidePregnant leach solution

The invention provides a method for leaching zinc-containing ores, comprising the following steps: A) mixing the zinc-containing ores with sulfuric acid solution to leach sulfuric acid so as to obtain leachate containing zinc sulfate; B) purifying the leachate to obtain zinc sulfate solution; C) mixing the zinc sulfate solution with calcium oxide and / or calcium hydroxide as well as calcium sulfate used as seed crystal to generate calcium sulfate precipitation and calcium hydroxide precipitation; and D) separating the calcium sulfate and the zinc hydroxide. The invention can recycle metallic elements from the zinc-containing ores with low cost and low pollution, recycle resources and additionally produce the calcium sulfate (gypsum), thereby reducing production cost and mitigating environmental pollution.

Owner:CHINA ENFI ENGINEERING CORPORATION

Method for spinning high-strength polyester staple fibers by using waste polyester

InactiveCN102703999AEliminate static electricityReduce the fineness of semi-finished productsFilament/thread formingArtificial filament heat treatmentBreaking strengthPolyester

The invention relates to a method for spinning high-strength polyester staple fibers by using waste polyester. The method is characterized in that on the basis of the conventional spinning process condition, a sea sand filter is added into a spinning assembly, and a molten material is filtered finely by using the sea sand filter, so that a melt of which the cleanliness is consistent with that of a raw material is obtained; a central oil feeding process is added after a circular air blow cooling process, and oil is fed to tows which are cooled by circular air blow through a central oil feeding device, so that the tows are further cooled after adsorbing oil, and static electricity is eliminated simultaneously; a tensioning and thermal setting device is partitioned into seventeen drums in four groups; a first group consists of five drums; each of the other groups consists of four drums; saturated steam is used for heating the insides of the drums; the heating temperature of the first group is 125-130 DEG C; the heating temperature of the second group is 145-150 DEG C; the heating temperature of the third group is 165-170 DEG C; and the heating temperature of the fourth group is 185-190 DEG C. The fiber linear density of the regenerated polyester staple fibers produced from waste polyester is below 1.2denier, the breaking strength is 6.0cN / dtex, the dry-hot shrinkage is 5-7 percent, and superior indexes of high tenacity and low elongation are achieved.

Owner:广东秋盛资源股份有限公司

Preparation method of fiber pervious recycled aggregate concrete

PendingCN109534744AHigh strengthAlleviate urban waterlogging problemsSolid waste managementCeramicwareBasaltBasalt fiber

The invention discloses a preparation method of fiber pervious recycled aggregate concrete. Specifically, waste C20 pavement is crushed by a jaw crusher, then artificial screening of recycled aggregate is conducted, and the fiber recycled aggregate pervious concrete meets that: in per cubic meter of chopped basalt fiber recycled aggregate pervious concrete, the ratio of aggregate to a cementing material is 4.5:1; the ratio of water to the cementing material is 0.3:1; and the content of chopped basalt fiber is 0.1%-0.3%. The invention designs and prepares the following 3 fiber situations: incorporation of chopped basalt fiber, chopped carbon fiber and polypropylene fiber, the incorporation of the 3 fibers has small influence on the permeability coefficient and porosity of recycled aggregatepervious concrete, but can effectively improve the splitting tensile strength and tension-compression ratio, has significant toughening and crack resistant effects, the comprehensive evaluation indexis the highest, and the pervious recycled aggregate concrete has the best overall performance.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

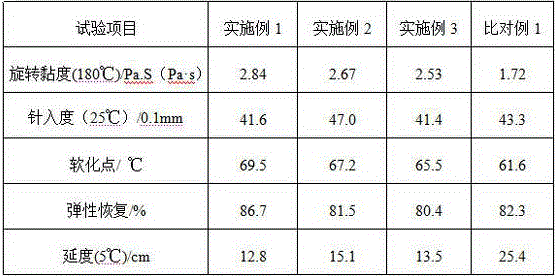

Environment-friendly rubber asphalt and preparation method thereof

The invention discloses environment-friendly rubber asphalt. The environment-friendly rubber asphalt is prepared from, by mass, 72-78% of matrix asphalt and 22-28% of waste tire rubber powder and modifier. The waste tire rubber powder and modifier is mainly prepared from, by mass, 82-92% of waste tire rubber powder, 2-4% of an activating agent, 2-5% of a binding agent, 2-4% of an active agent, 1-3% of a vulcanizing agent and 1-2% of an antioxidant. According to the environment-friendly rubber asphalt, the waste tire rubber powder, waste oil and other waste materials can be recycled, and the use performance of the asphalt can be improved. The invention further discloses a preparation method of the environment-friendly rubber asphalt. According to the preparation method, the mode of activating the waste tire rubber powder is simple, cost is low, and the process is simple.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD +1

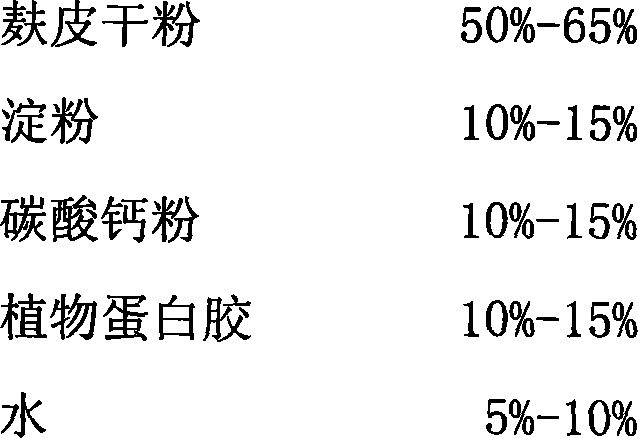

Dinnerware made from bran

The invention relates to dinnerware made from bran, belongs to novel environment-friendly material products, and provides dinnerware made from crop bran. The dinnerware avoids cross infection of diseases due to long-term use, enables crop resources to be recycled and is environment-friendly and comprises, by weight, 50-60% of dry bran powder, 10%-15% of starch, 10%-15% of calcium carbonate powder, 10%-15% of plant protein adhesive, and 5%-10% of water. A production process of the dinnerware includes: cleaning and drying bran, removing dust and decayed substances, grinding into fine powder by a grinder, adding the starch, the calcium carbonate powder and the plant protein adhesive according a certain proportion, adding mixture of the materials into a certain proportion of water, mixing to obtain mixed slurry, and extruding the mixed slurry under high temperature and high pressure by a hot-press forming machine to obtain the reusable dinnerware of bran.

Owner:SHANXI BAISHUN TECH CO LTD

AISI410SS martensite stainless steel for valve and preparation process of AISI410SS martensite stainless steel

The invention belongs to the technical field of metallurgy, and particularly relates to AISI410SS martensite stainless steel for a valve and a preparation process of the AISI410SS martensite stainless steel. By reasonably designing chemical components, the AISI410SS martensite stainless steel is composed of 0.10%-0.15% of C, 0.20%-0.50% of Si, 0.30%-0.60% of Mn, 11.0%-13.5% of Cr, 0-0.6% of Mo, 0.30%-0.60% of Ni, 0-0.020% of S, 0-0.020% of P, 0-0.20% of Cu, 0-0.050% of V, 0.010%-0.080% of Nb, 0-0.00016% of H, 0-0.0035% of O, and the balance Fe and impurity elements, wherein the total content of the impurity elements is smaller than or equal to 1.0%. In the smelting process, high-quality scrap steel, pig iron and sponge iron are selected as furnace charges, electric arc furnace EBT primary melting, LF refining, vacuum degassing (VD), mould casting of a steel ingot and hot charging of the steel ingot are adopted, through an oil and precision combined forging process of upsetting and drawing out of an oil press and forming of a precision forging machine, after a forge piece is subjected to overall conditioning, the strength meets the requirements that Rm is greater than or equal to 655 MPa, Rp 0.2 is greater than or equal to 517 MPa, A is greater than or equal to 18% and Z is greater than or equal to 35%, -29 DEG C impact energy averagely reaches 50 J, -46 DEG C impact energy averagely reaches 38 J, the requirement of API6A standard low temperature toughness AKv is met, the rejection rate of products is reduced, and labor efficiency is improved.

Owner:ZHONGYUAN SPECIAL STEEL

Separation and purification method of m-cresol

ActiveCN104230669AReduce dosageEfficient separationOrganic chemistryOrganic compound preparationAlkanePurification methods

The invention relates to a separation and purification method of m-cresol. The separation and purification method comprises the following steps: a) complexing: adding mixed cresol, urea and a mixed solvent formed by toluene and liquid alkane into a reactor, stirring, heating to increase the temperature to 65-90 DEG C, performing heat preservation for 1-2h, reducing the temperature to 40-60 DEG C, then cooling and crystallizing at the temperature of 0-20 DEG C for 1-2h, and filtering to obtain a complex solid and filtrate A; and b) decomplexing: adding the complex solid obtained in the step a) into an ether type solvent, stirring at the temperature of 10-60 DEG C, performing decomplexing reaction for 0.5-3h, and filtering to obtain urea and filtrate B; and performing decompression rectification on the filtrate B to obtain m-cresol. The method for separating m-cresol from mixed cresol is high in product purity, simple in process, low in solvent consumption, high in recovery rate and low in energy consumption and can operate at normal pressure, prevent the production of three wastes in a separation process and realize recycling of resources, so that the method is environment-friendly.

Owner:江苏富比亚化学品有限公司

Method for removing or inhibiting alga in eutrophic water

InactiveCN109626491AAvoid garbageRecycle resourcesOther chemical processesSpecific water treatment objectivesFertilizerChemistry

The invention discloses a method for removing or inhibiting alga in eutrophic water. The method is characterized in that clay and clayey soil are taken as primary raw materials to produce ceramsite, and the ceramsite is pre-processed; the pre-processed ceramsite is produced into phosphorous removal modified ceramsite and iron removal modified ceramsite; the phosphorous removal modified ceramsite and the iron removal modified ceramsite are filled into an alga removing device; the alga removing device is transported to the place where algal bloom takes place, the alga removing device in water issalvaged after soaking is conducted for 5-7 days, and the modified ceramsite which completely absorbed alga is poured out. The method has the advantages that on one hand sunlight can be shaded usingthe alga removing device so that the alga in the water cannot perform photosynthesis to inhibit the growth of the alga, on the other hand, the growth of alga cells is inhibited due to limited nutrients, the modified ceramsite which completely absorbed the alga can be used for producing fertilizers for potted flowers, the generation of rubbish is avoided, and resources are recycled, which is more environmentally friendly.

Owner:珠江流域水环境监测中心

A processing and recycling method for waste lithium ion battery of a mobile phone

InactiveCN101262082ARecycle resourcesReduce processing costsSolid waste disposalWaste accumulators reclaimingRecovery methodBatch processing

The invention provides a recovery method for waste lithium-ion batteries, which is characterized in that cutting processing is carried out first to the waste lithium-ion batteries under 10 to 60 percent of relative humidity. The recovery method of waste lithium-ion batteries of the invention has the advantages of safe and simple operation and easily realizing batch processing, thereby being capable of achieving environment protection and reutilization of resources.

Owner:张永祥

Thermal-decomposing pore-forming self-heat-insulating bearing sintered product and preparation method thereof

InactiveCN101644088ARecycle resourcesSave land resourcesSolid waste managementMixing operation control apparatusBrickMass ratio

The invention relates to a thermal-decomposing pore-forming self-heat-insulating bearing sintered product and a preparation method thereof. The thermal decomposing pore-forming self-heat-insulating bearing sintered product mainly comprises the following raw materials of powder solid waste, a binder and a thermal-decomposing pore-forming agent in a mass ratio of 1: (0.5-1.5): (0.1-0.4), wherein thepowder solid waste adopts one of fly ash, coal gangue and tailings; the binder adopts shale or sodium soil; and the thermal-decomposing pore-forming agent adopts one salt or a mixture of calcium oxalate, basic magnesium carbonate, powdered whiting and dolomite which can be decomposed to discharge a great amount of gases at 500-900 DEG C. The preparation method comprises the following steps: adding water to granulate; aging for 1-3 days; forming blank blocks by a porous block mold in a vacuum extruder; drying at a temperature of 45-55 DEG C for 2-4 days; and sintering at 1000-1100 DEG C for 5-8 hours before cooling. The invention has the advantages of solid waste utilization, soil saving, good heat-insulating effect, convenient and rapid construction, and the like.

Owner:WUHAN UNIV OF TECH

Technology for producing electrolytic metal manganese from low-grade manganese mine

InactiveCN104232889ASolve the separation problemAcid balance problem solvingPhotography auxillary processesProcess efficiency improvementElectrolysisDecomposition

The invention relates to a technology for producing electrolytic metal manganese from low-grade manganese mine. The technological flow comprises ore grinding, sulfuric acid pre-leach, combusting sulfur for preparing sulfur dioxide, sulfur dioxide reduction leaching, solid-liquid separation, purifying of a leaching liquid, separation of dithionate radical, production of electrolytic metal manganese, decomposition of dithionate radical, production of anhydrous sodium sulfate and recovery of production water. The technology is simple, resource is cycled for utilization, the reduction leaching rate of manganese is even up to 98%, and the recovery utilization efficiency is high.

Owner:无锡市森信精密机械厂

Complex water-based polymer waterproof coating and manufacturing method thereof

ActiveCN104194500AReduce pollutionGood material performanceConjugated diene hydrocarbon coatingsEpoxy resin coatingsWater basedFreeze thawing

The invention relates to a complex water-based polymer waterproof coating and a manufacturing method thereof. The manufacturing materials comprise the following components in parts by weight: A, organic liquid and B, inorganic fillers, wherein the organic liquid consists of 500-1000 parts of water-based latex, 100-150 parts of water-borne epoxy resin, 5-10 parts of wetting dispersant and 5-10 parts of antifoaming agent; and the inorganic fillers consist of 250-500 parts of inorganic low-cementitious material, 50-100 parts of silica fume, 100-300 parts of calcium carbonate, 100-250 parts of quartz powder, 50-100 parts of talcum powder and 50-100 parts of bentonite. The complex water-based polymer waterproof coating disclosed by the invention has the characteristics of good waterproof performance, durable weather resistance, stable performance, high temperature resistance, freeze thawing resistance, simplicity and convenience in construction, wide application range, utilization of industrial solid wastes and the like. In addition, the product is compounded into a pasty flowing slurry and is directly used on site, the cost is saved, and the defects such as dust pollution are avoided.

Owner:祁振君 +2

Novel red mud decorating and heat-insulation integrated light wall material

A novel red mud decorating and heat-insulation integrated light wall material is characterized by consisting of colored glass and a red mud iron reduction slag high-temperature melt foaming material. The colored glass consists of from 25 to 45 % of potash feldspar, from 20 to 40% of quartz, from 5 to 25% of calcite, from 4 to 8% of sodium borate, from 2 to 8% of barium carbonate, from 2 to 8% of zirconium silicate, from 2 to 6% of potassium nitrate and from 0 to 10% of ceramic color agent. The forming steps of the red mud iron reduction slag high-temperature melt foaming material include forming metallic iron and silicate slag by means of carbothermic reduction of red mud wastes; melting the metallic iron and silicate slag at high temperature; obtaining high-temperature melt of silicate slag after separation of molten iron; and foaming. The novel red mud decorating and heat-insulation integrated light wall material can be colorful after being added with the ceramic color agent, is a multifunctional high-grade interior and exterior wall decorating material with functions of decoration, heat insulation, sound insulation, seismic proofing and the like, is low in production cost, reduces environmental pollution, and is economical and environment-friendly. The wastes can be reused.

Owner:SHANDONG UNIV OF TECH

Treatment method of nickel wet method refining tailings based on high temperature reduction

ActiveCN111100992AImprove economyRecycle resourcesProcess efficiency improvementPregnant leach solutionSlag

The invention discloses a treatment method of nickel wet method refining tailings based on high temperature reduction. The method is characterized by comprising the steps of ore pulp forming pre-leaching, high-temperature leaching out, reduction for copper deposition and vulcanization for nickel and cobalt deposition. The step of reduction for copper deposition specifically comprises the steps that a reducing agent is added into high-temperature leaching liquid obtained in the high-temperature leaching step, after the reaction, filtering is carried out, and liquid after copper deposition is obtained. Through the cooperation manner of high-temperature leaching, reduction for copper deposition and vulcanization for nickel and cobalt deposition, nickel slag is treated and is converted, afterleaching toxicity is qualified, the slag is discharged, meanwhile, nickel and cobalt contained in the slag is recycled, resources are recycled, and economy is high.

Owner:JINGMEN GEM NEW MATERIAL +1

Magnetic response Janus nano-particles based on oil-in-water high internal phase emulsification and preparation method of magnetic response Janus nano-particles

ActiveCN112812760AImprove acid resistanceImprove antioxidant capacityDrilling compositionFerriferrous OxideOil in water

The invention discloses a magnetic response Janus nanoparticle based on oil-in-water high internal phase emulsification and a preparation method thereof. The nanoparticle has a shell-core structure, the core is a ferroferric oxide particle, the surface of ferroferric oxide is coated with a silicon dioxide layer to serve as a shell, and the front and back surfaces of the surface of the shell are respectively grafted with a hydrophilic group and a hydrophobic group. The preparation method of the magnetic response Janus nano-particle comprises the following steps: firstly, coating the surface of a ferroferric oxide particle with a silicon dioxide layer, and then respectively carrying out hydrophilic and hydrophobic modification on the front and back surfaces of the silicon dioxide layer to prepare the magnetic response Janus nano-particle. The Janus nano-particles synthesized by the method can be used for preparing a high internal phase emulsion with good stability under the conditions of low concentration and no auxiliary additive, and efficient oil-in-water emulsification oil displacement is realized.

Owner:SOUTHWEST PETROLEUM UNIV

Cooperative treatment method for waste incineration fly ash and copper-containing sludge

The invention relates to a cooperative treatment method for waste incineration fly ash and copper-containing sludge. The waste incineration fly ash and the copper-containing sludge are mixed uniformly and pelleted to obtain a ball material; the ball material, a fluxing agent and fuel are mixed to obtain a mixture; smelting is carried out to obtain molten slag and smoke; when the ball material is a high-chlorine material, the molten slag is subjected to water quenching, and glass tailings are obtained; soot in the smoke is collected, the soot is sequentially subjected to water washing and solid-liquid separation, supernatant is obtained, then alkali is added into the supernatant, and sediment rich in copper and nickel is obtained; and when the ball material is a low-chlorine material, dilution treatment is carried out on the molten slag to obtain a slag phase and matte, and then water quenching is carried out on the slag phase to obtain glass tailings. In the invention, a binder does not need to added for pelleting in the treatment of the waste incineration fly ash, additional drying equipment does not need to be added in the treatment of the copper-containing sludge, and the two materials are co-treated, so that the process flow and the investment cost are greatly reduced.

Owner:湖南锐异资环科技有限公司

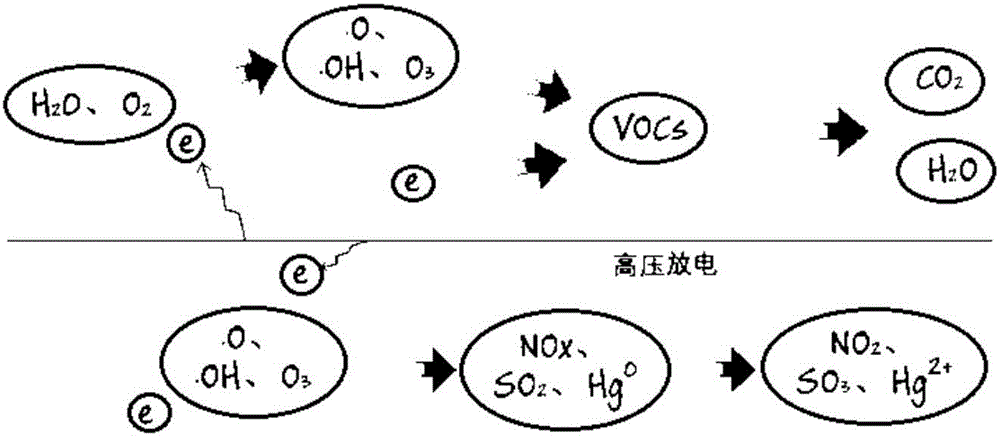

Flue gas pollutant treatment method based on wet plasma

InactiveCN106216096AMeet needsRecycle resourcesExternal electric electrostatic seperatorParticulatesPlasma technology

The invention discloses a flue gas pollutant treatment method based on wet plasma. By means of the flue gas pollutant treatment method based on the wet plasma, fine dust particles can be removed obviously and efficient desulfuration, denitration and demercuration on the flue gas can be realized. According to the method, first the fine dust particles in the flue gas are adsorbed and removed by using a wet electrostatic technology; and then the volatile organic compound in the flue gas is oxidized removed and elemental mercury, sulfur dioxide and nitrogen oxide in the flue gas are deeply oxidized by using a wet plasma technology; and after the flue gas is oxidized, the residual pollutants are absorbed and removed by using a bubble absorption method; and finally mercury, sulphur and nitre in the bubble absorption liquid are separated and extracted by cation exchange resin. The method has the characteristics of being efficient and capable of realizing energy conservation and recycle utilization of resources. The requirements of different factories can be met by controlling the index of each link flexibly in combination with the actual pollutant compositions in the flue gas.

Owner:XI AN JIAOTONG UNIV

Preparation method of ductile retarding fine aggregate concrete with initial setting time of 48-72 hours

ActiveCN111533512AImprove pore structureImprove early strengthReinforced concreteArchitectural engineering

The invention discloses a preparation method of ductile retarding fine aggregate concrete with initial setting time of 48-72 hours, belongs to the technical field of building construction, and particularly relates to a preparation technology of the ductile retarding fine aggregate concrete. Cement, fly ash, slag powder and a reinforcing compacting agent are adopted to form a cementing material, and the fly ash, the slag powder and the reinforcing compacting agent not only improve the performance of a concrete mixture, but also can improve the early-stage or later-stage strength of concrete, improve the pore structure and improve the compaction performance of the concrete; meanwhile, the effects of saving resources and protecting the environment are achieved. The concrete is suitable for pier wall reinforced concrete structures in the fields of construction engineering, water conservancy engineering, traffic engineering, water transportation engineering and the like, a layer of ductileretarding concrete is poured at the root of the pier wall, and the concrete can also be suitable for underground secant piles and structural construction joints needing to be poured by several times.

Owner:JIANGSU WATER CONSERVANCY SCI RES INST +5

Environment-friendly rubber asphalt and preparation method thereof

InactiveCN107916005AReduce environmental pollutionReduce manufacturing costBuilding insulationsWaste tiresActive agent

The invention discloses an environment-friendly rubber asphalt, which comprises matrix asphalt, waste tire rubber powder and a modifier, the mass percentage of the matrix asphalt is 73-77%, and the mass percentage of the waste tire rubber powder and modifier The percentage content is 23 ~ 27%; wherein said waste tire rubber powder and modifier are mainly made of the following raw materials in mass percentage content: waste tire rubber powder 82 ~ 92%, activator 2 ~ 4%, bonding Agent 2~5%, Active Agent 2~4%, Vulcanizing Agent 1~3%, Antioxidant 1~2%. The environmentally friendly rubber asphalt can not only recycle waste materials such as waste rubber powder and waste engine oil, but also improve the use performance of the asphalt. Also disclosed is a preparation method of the above-mentioned environment-friendly rubber asphalt, which has the advantages of simple activation of waste rubber powder, low cost and simple process.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

Method for preparing natural cellulose fiber by taking rice straws as raw material

InactiveCN103173870ASolve problems with fewer applicationsReduce pollutionVegetable materialResource utilizationCellulose fiber

The invention relates to a method for preparing a natural cellulose fiber by taking rice straws as the raw material, which comprises the following steps: pretreatment, mechanical rolling, alkali treatment, hydrogen peroxide treatment, softening treatment, humidifying, stewing, and carding. As the rice straws are used as the raw material for preparing the natural cellulose fiber, the problem of rare application of rice straws as the textile raw material in the textile industry is solved; furthermore, since the rice resources in China are rich and can be recycled, not only the problem of environmental pollution caused by improper utilization of rice straws in China can be reduced, but also the energy is saved, and the resource utilization ratio is higher.

Owner:DANYANG CHAOCHAO FASHION

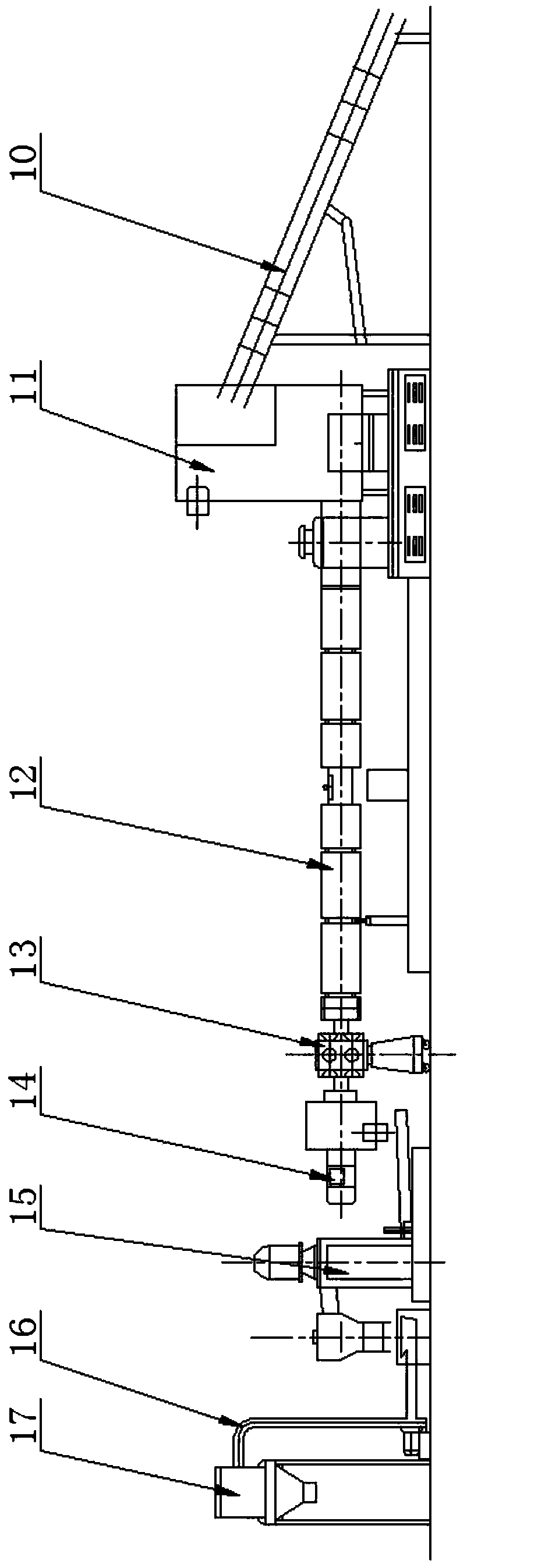

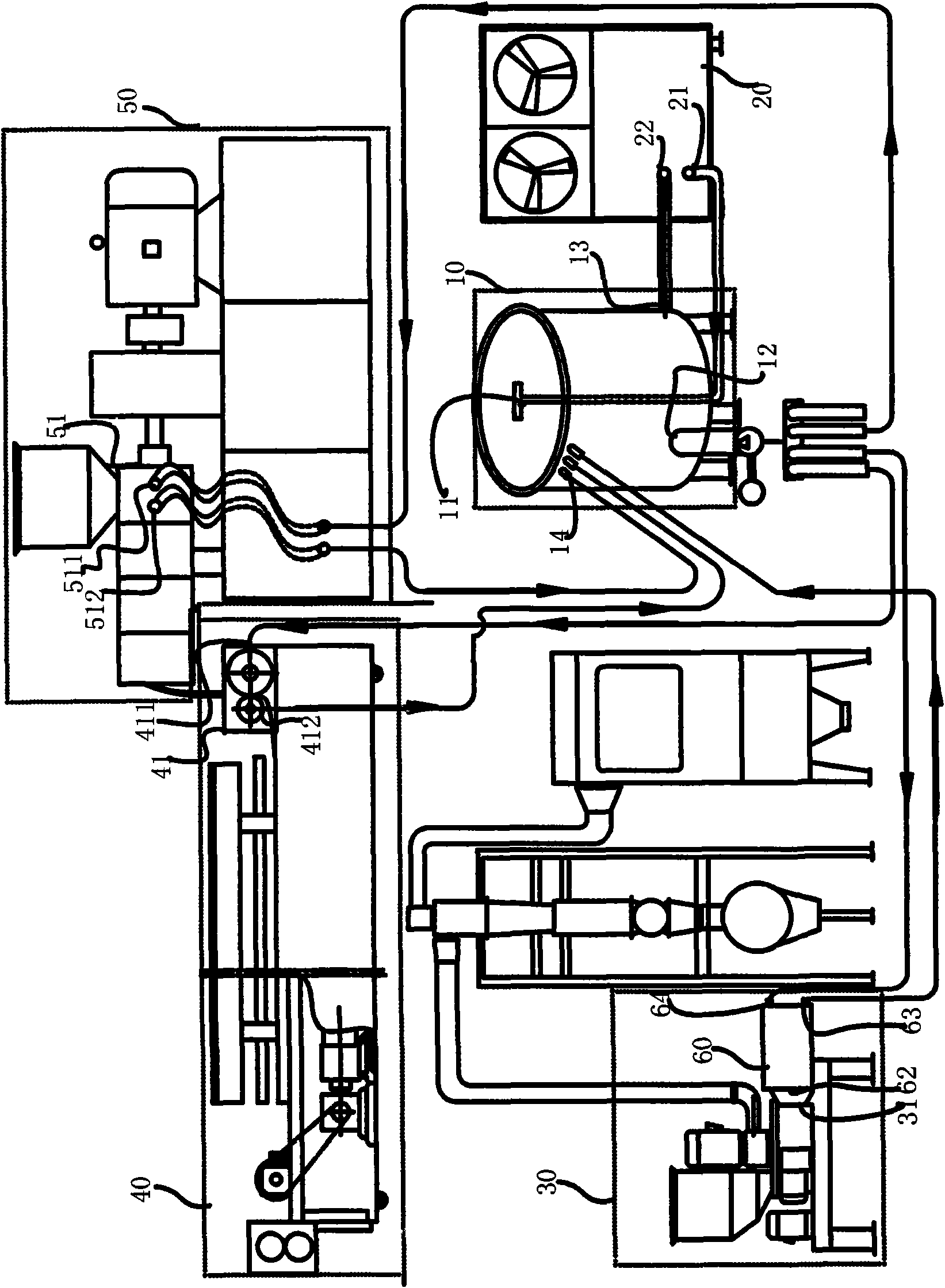

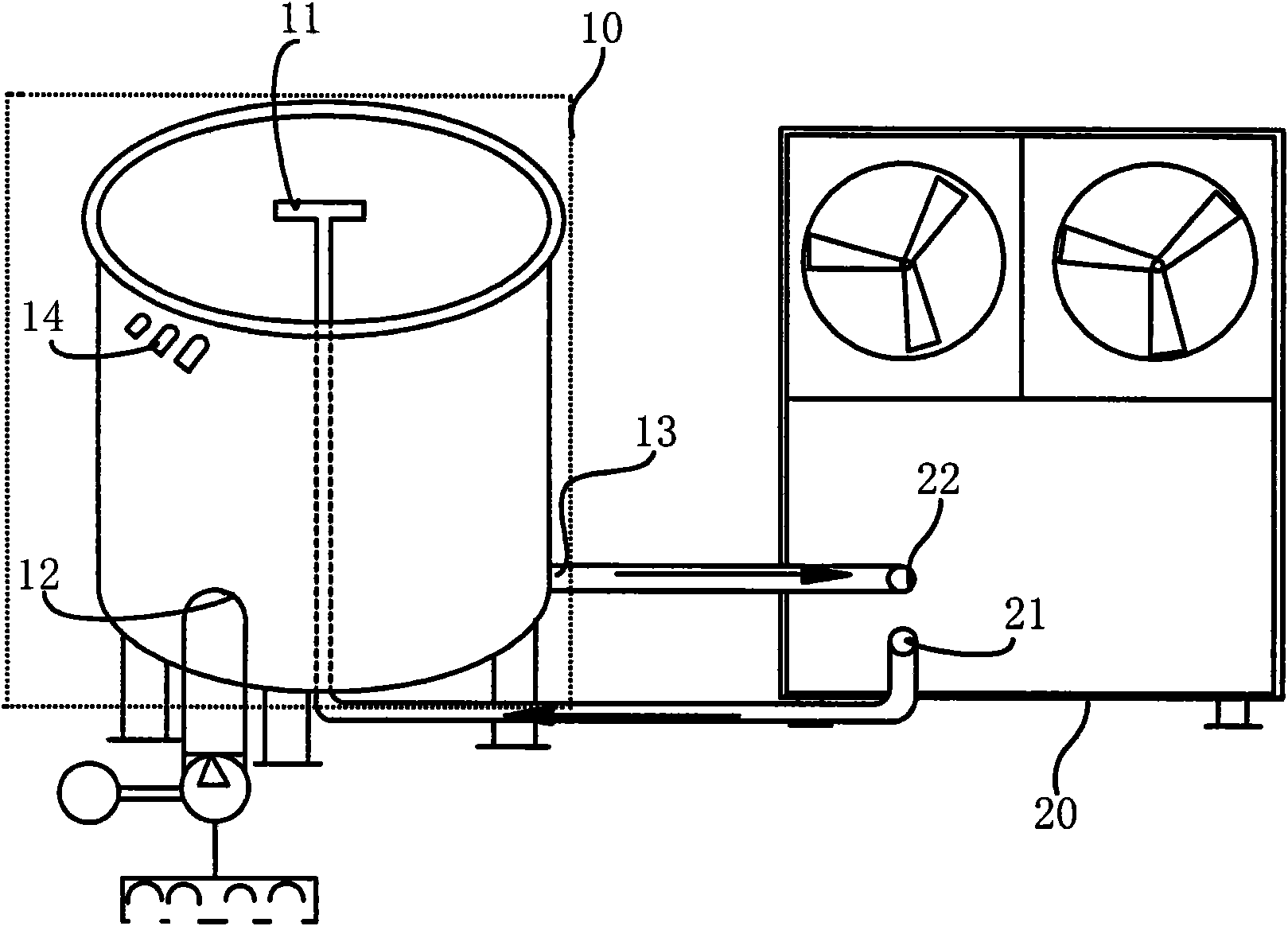

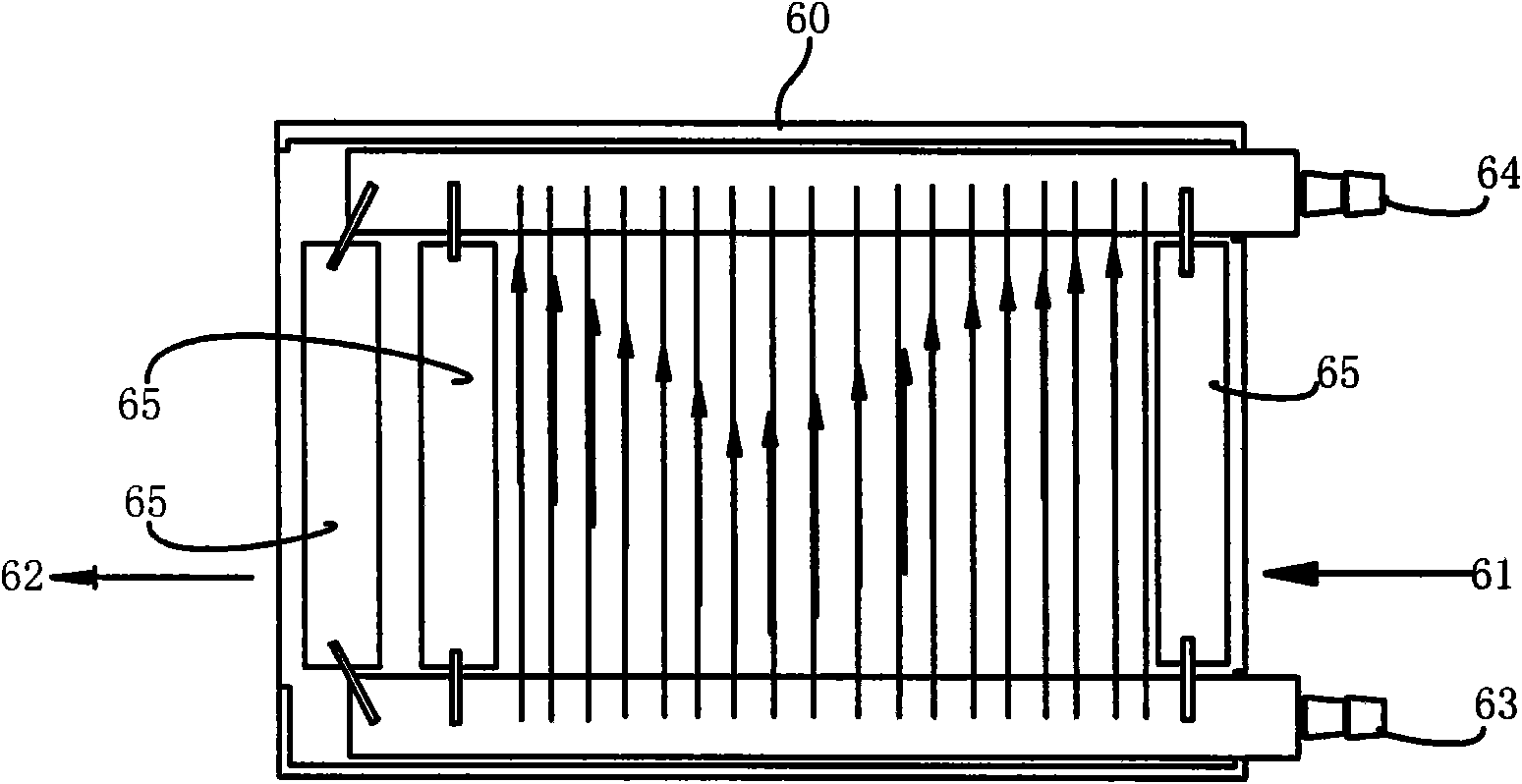

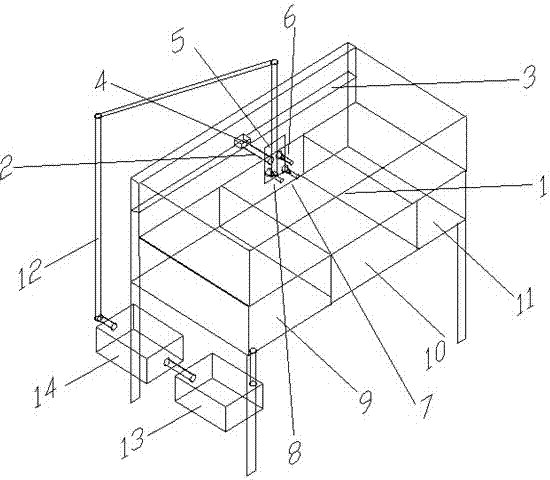

Production system of thermosetting powder coating

InactiveCN101613542AMeet production requirementsRecycle resourcesPowdery paintsWater storageWater resources

The invention relates to a production system, in particular to a production system of a thermosetting powder coating. A pulverizer, a sheeter and an extruder in the production system are connected with a cooling water circulation system which is divided into three paths; first, the cooling water circulation system is connected with a waterway tube of a heat exchanger positioned at a water inlet of the pulverizer and a cooling water outlet of a water storage device is connected with a water inlet of the waterway tube of the heat exchanger; second, the cooling water circulation system is connected with the sheeter and the cooling water outlet of the water storage device is connected with a water inlet of sheeting rolls of the sheeter; and third, the cooling water circulation system is connected with the extruder, the cooling water outlet of the water storage device is connected with a water inlet of a water tank of a raw material feed inlet of the extruder, and a water outlet of the waterway tube of the heat exchanger, the water outlet of the sheeting rolls and a water outlet of the water tank are connected with a backwater water inlet of the water storage device. The production system can meet the production requirements of the thermosetting powder coating and can help recycle cooling water resources.

Owner:张群

Multi-procedure efficient electroplating rinsing tank

InactiveCN106984576ARecycle resourcesEasy to disassembleCleaning using liquidsMachine partsBiochemical engineering

The invention discloses a multi-procedure efficient electroplating rinsing tank. The rinsing tank comprises a rinsing tank body. A guide rail is formed on the tank wall of the rinsing tank body. A sliding block is arranged on the guide rail. One end of a support is fixedly connected to the sliding block, and the other end of the support is fixedly connected with a clamp plate. The clamp plate is provided with a plurality of clamp bodies. The clamp bodies are evenly provided with first nozzles, second nozzles and third nozzles. The first nozzles, the second nozzles and the third nozzles are all connected with water concerting pipes. Two vertical partition plates are arranged inside a tank main body of the rinsing tank body, and the partition plates divide the rinsing tank body into a first tank body, a second tank body and a third tank body. A filter box and a liquid storage box are arranged below the first tank body, the second tank body and the third tank body. The bottom of the first tank body, the bottom of the second tank body and the bottom of the third tank body are all provided with draining openings. By the adoption of the mode, the multi-procedure efficient electroplating rinsing tank can be suitable for electroplating rinsing of multi-procedure machined parts.

Owner:WUXI MINGJI INTELLIGENT MACHINERY CO LTD

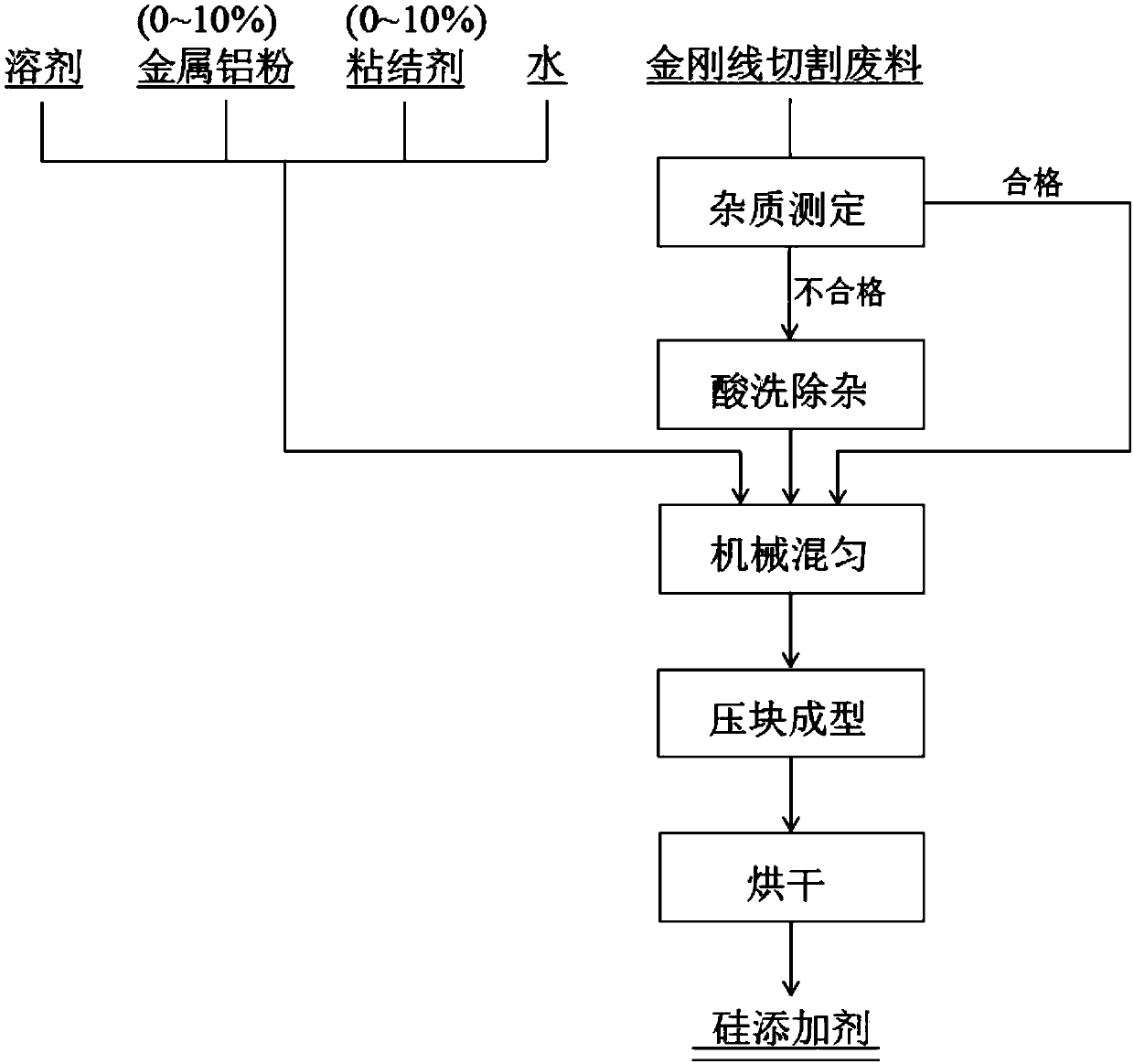

Silicon additive based on diamond wire cutting wastes of crystalline silicon, and preparation method thereof

The invention discloses a silicon additive based on diamond wire cutting wastes of crystalline silicon, and a preparation method thereof, and belongs to the technical field of recycling. The silicon additive comprises, by weight, 5-30 wt% of a solvent, 0-10 wt% of a binder, 0-10 wt% of metallic aluminum powder, and the balance of the diamond wire cutting wastes of crystalline silicon. The preparation method comprises the following steps: weighing the diamond wire cutting wastes of crystalline silicon, the solvent, the metallic aluminum powder and the binder in proportion, adding water, uniformly mixing above materials and the water, carrying out briquetting molding on the above obtained mixture in a briquetting machine, and drying the molded mixture to obtain the silicon additive based ondiamond wire cutting wastes of crystalline silicon. The silicon additive has the advantages of effective utilization of wastes generated in the silicon chip cutting process, realization of changing ofwastes into valuables, great shortening of the process flow for producing silicon-containing aluminum alloy, and reduction of the production cost.

Owner:NORTHEASTERN UNIV

Pond track-type recirculating fish-culture fecal treatment system and method

InactiveCN110604093AAchieve recyclingAvoid pollutionPisciculture and aquariaBiological sludge treatmentShrimpFeces

The invention discloses a pond track-type recirculating fish-culture fecal treatment system, comprising a filter-feeding fish culture pond, at least a fish pond, a residual bait and feces sedimentingtank and at least one biofloc culture tank. A micro-pore pneumatic water-pushing device is arranged at one side of the fish pond and a fish barrier is arranged at the other end; the fish pond is communicated with the filter-feeding fish culture pond through the micro-pore pneumatic water-pushing device, and is communicated with the residual bait and feces sedimenting tank through the fish barrier;the top of the residual bait and feces sedimenting tank is communicated with the filter-feeding fish culture pond, while a suction pump is arranged at the bottom of the residual bait and feces sedimenting tank ; the suction pump is connected with a water inlet pipe, the residual bait and feces sedimenting tank is communicated with one side of the biofloc culture tank through the suction pump andthe water inlet pipe; the other side of the biofloc culture tank is communicated with the filter-feeding fish culture tank through a discharging pipe. According to the system, the residual bait and feces can be collected and cultured into biofloc, which can be used as baits for fish, shrimp and crabs, and thus the circulation of resources is achieved while environmental pollution is avoided and culture cost is reduced.

Owner:HUZHOU TEACHERS COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com