Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Inhibition of microcracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

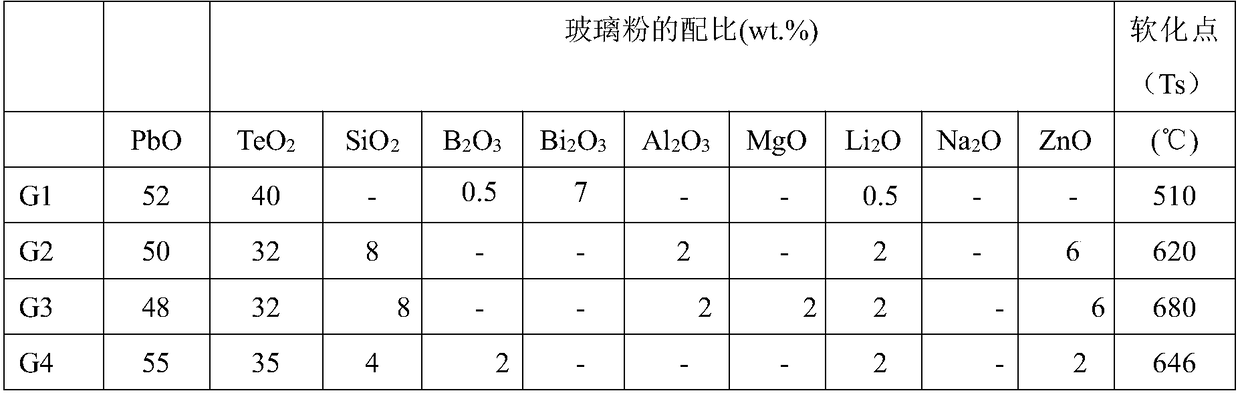

Crystalline silicon solar cell front silver paste and preparation method thereof

InactiveCN108766618AGood ink permeabilityEasy to fillNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteSilver electrode

The invention discloses a crystalline silicon solar cell front silver paste and a preparation method thereof. The front silver paste comprises the following components in percentage by weight: 85-90%of silver powder, 5-10% of an organic carrier, 5-10% of an organic carrier, 1.5-5% of composite glass powder, and 0.05-1% of a silver paste additive. The silver powder in different particle size distribution is cooperatively used, the slurry is good in ink permeability, and the silver powder particles in the grid line are more uniformly and tightly filled, so that the sintering density of the gridline is facilitated, the resistance of the grid lines is reduced, and the photoelectric conversion efficiency is improved. The preparation process of the glass powder is simple, the control is facilitated; the glass powder with different components is compounded and used, so that a series of particles are uniform, the softening temperature is low, and the composite glass powder has good wettability to the silver powder and the silicon substrate, a front silver paste prepared from the composite glass powder is sintered on the front surface of the cell, the silver electrode and the silicon havegood ohmic contact and welding performance, and the adhesion strength of the electrode is high.

Owner:湖南省国银新材料有限公司

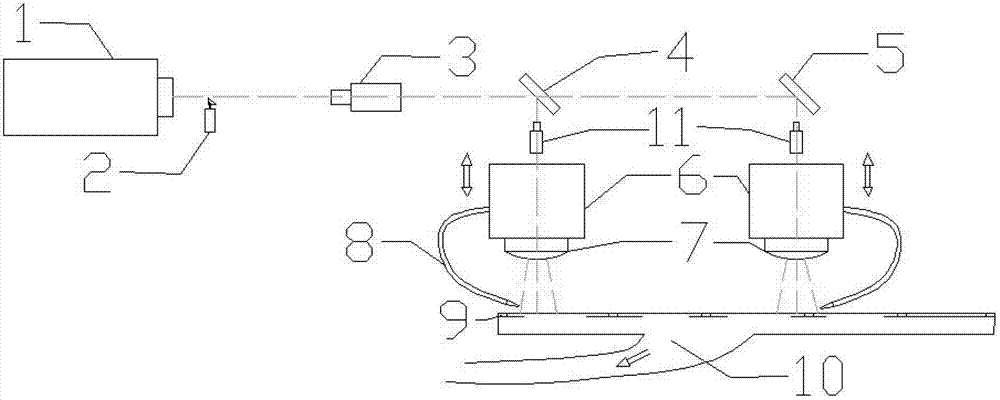

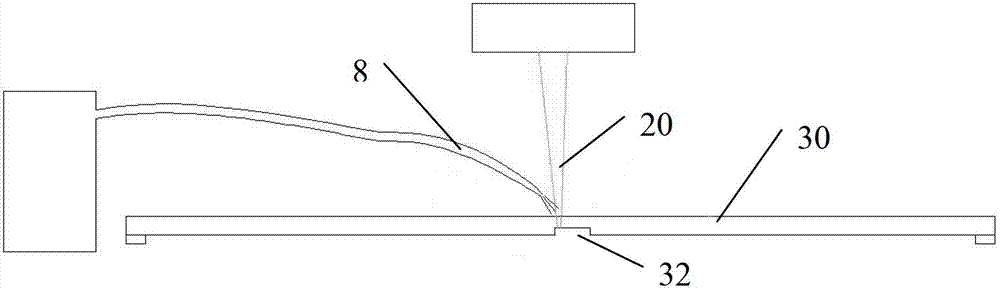

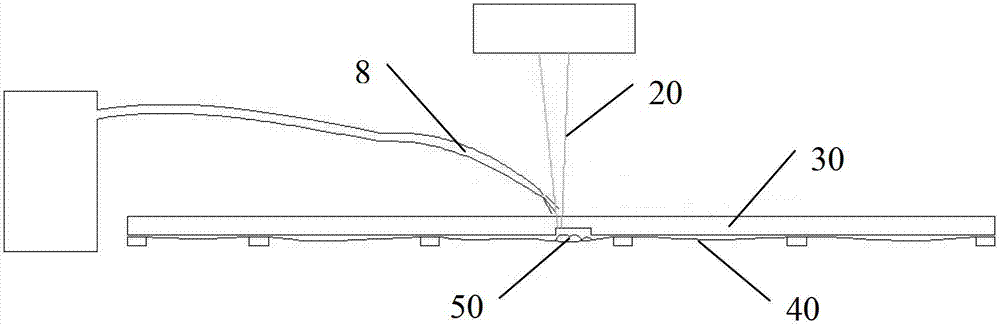

Laser processing method and laser processing equipment

ActiveCN102814591AAvoid FragmentationImprove stabilityLaser beam welding apparatusMaterials scienceLaser

The invention provides a laser processing method and laser processing equipment. The laser processing method comprises the steps as follows: radiating the laser through an incident surface of a material to be processed, and colleting the light on the initial cutting surface of or close to the material to be processed so as to gasify and / or melt the material to be processed at a light collecting point and / or in an area close to the light collecting point; forming an initial thermal removing area on the initial cutting surface; continuously distributing the initial thermal removing areas on the initial cutting face along a preset path so as to form an initial thermal removing line; irradiating the laser to collect the light on the surface of or close to the material to be processed formed in the thermal removing step so as to gasify and / or melt the material to be processed at the light collecting point and / or the area close to the light collecting point, thereby forming a follow-up thermal removing area; and continuously distributing the follow-up thermal removing areas along the preset path so as to form a follow-up thermal removing line.

Owner:SUZHOU DELPHI LASER

Zero-VOC (volatile organic compound) cement-based water-proof material copolymer emulsion and preparation method thereof

The invention discloses zero-VOC (volatile organic compound) cement-based water-proof material copolymer emulsion and a preparation method thereof. The preparation method adopts a zero-VOC copolymer emulsion component A and an inorganic powder component B, the zero-VOC copolymer emulsion component A is prepared from deionized water, alkyl acrylate, styrene, acrylic acid functional monomers, emulsifying agents, initiators, a buffer agents, polymerization inhibitors, oxidizing agents, reducing agents, sterilizing agents and defoaming agents through polymerization of pre-emulsification semi-continuous seed emulsion, and the inorganic powder component B comprises ordinary portland cement, quartz sand and water reducers. The prepared emulsion is high in solid content, low in viscosity, uniformin particle size and good in stability and has excellent rheological property and coating water absorption, the content of a residual monomer in an emulsion product is lower than 300ppm and meets national zero-VOC emulsion standards, the emulsion is environmentally friendly and free from toxicity and pollution, the compatibility of the emulsion and cement is good, and a prepared polymer cement waterproof coating is excellent in water resistance, good in low-temperature flexibility and low in water absorption.

Owner:SOUTH CHINA UNIV OF TECH

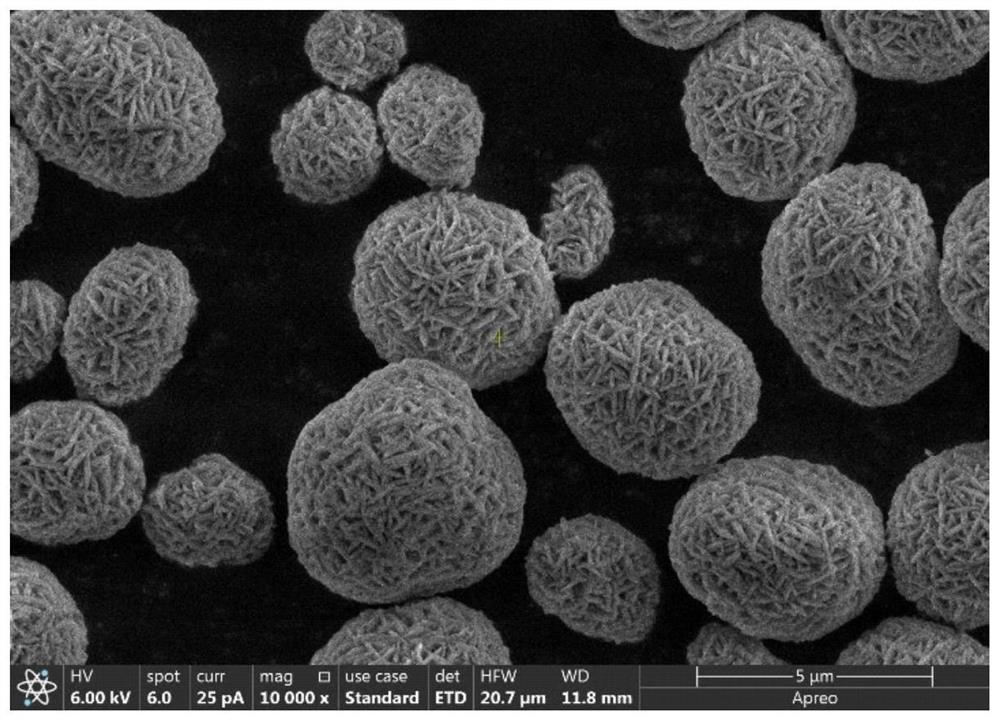

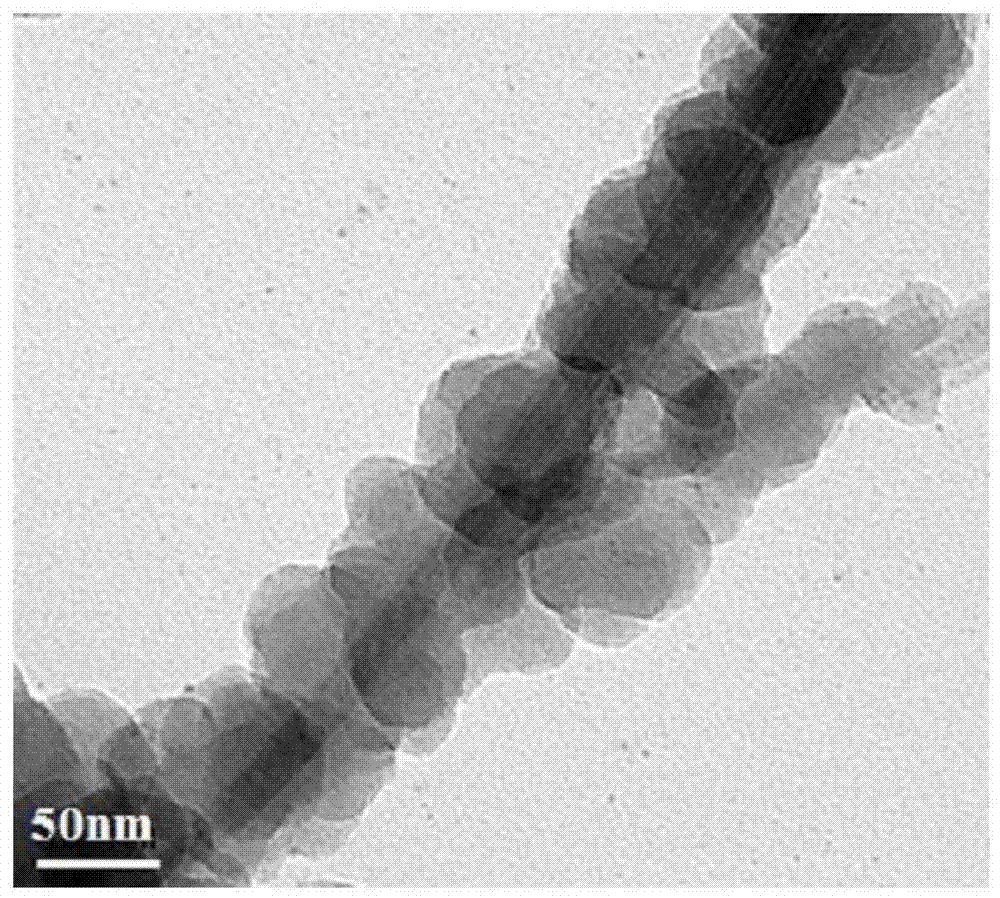

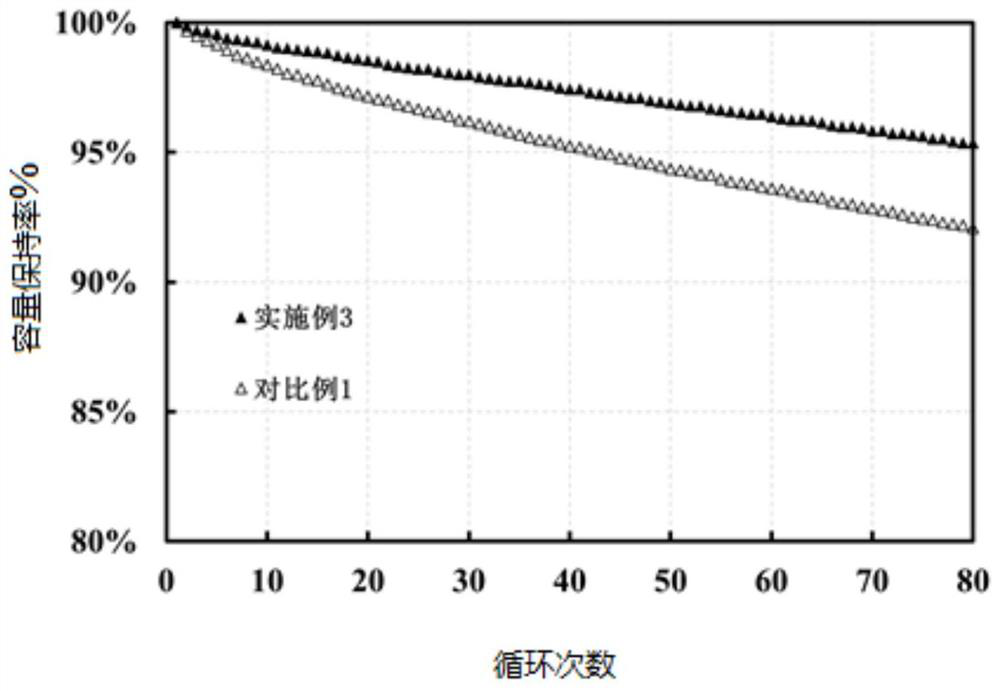

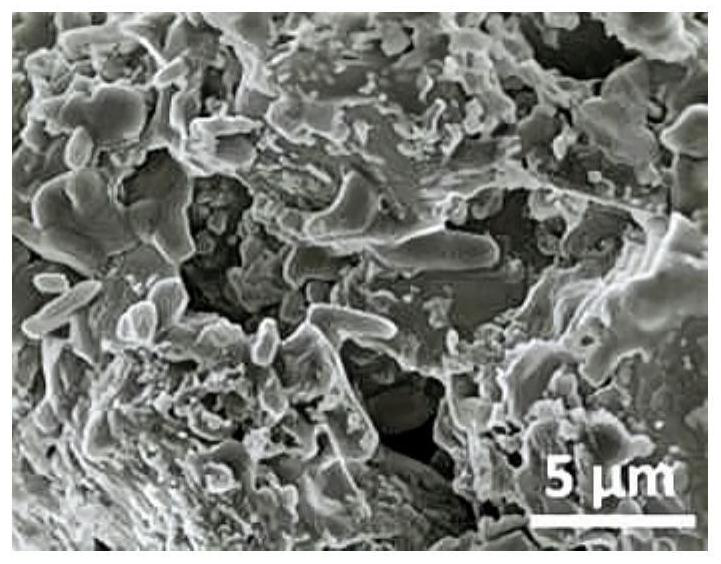

Preparation method of high-nickel ternary NCM622-nanowire material

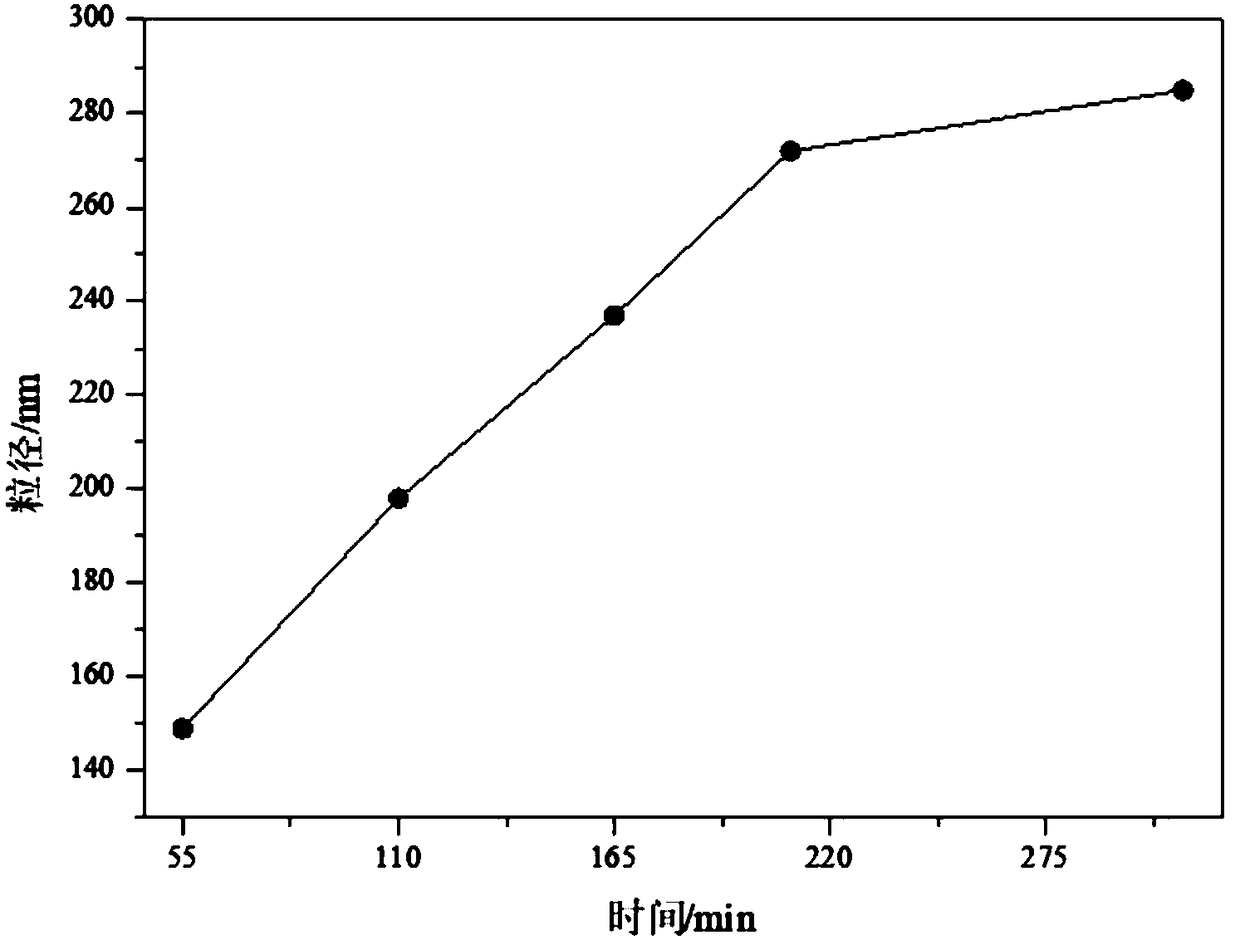

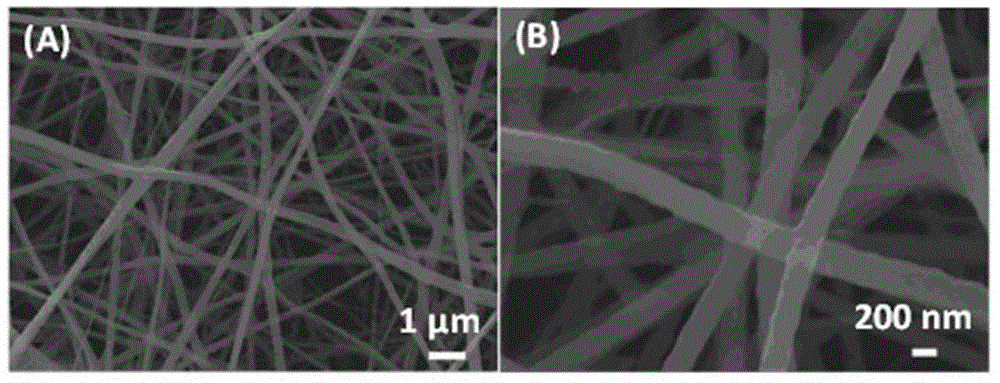

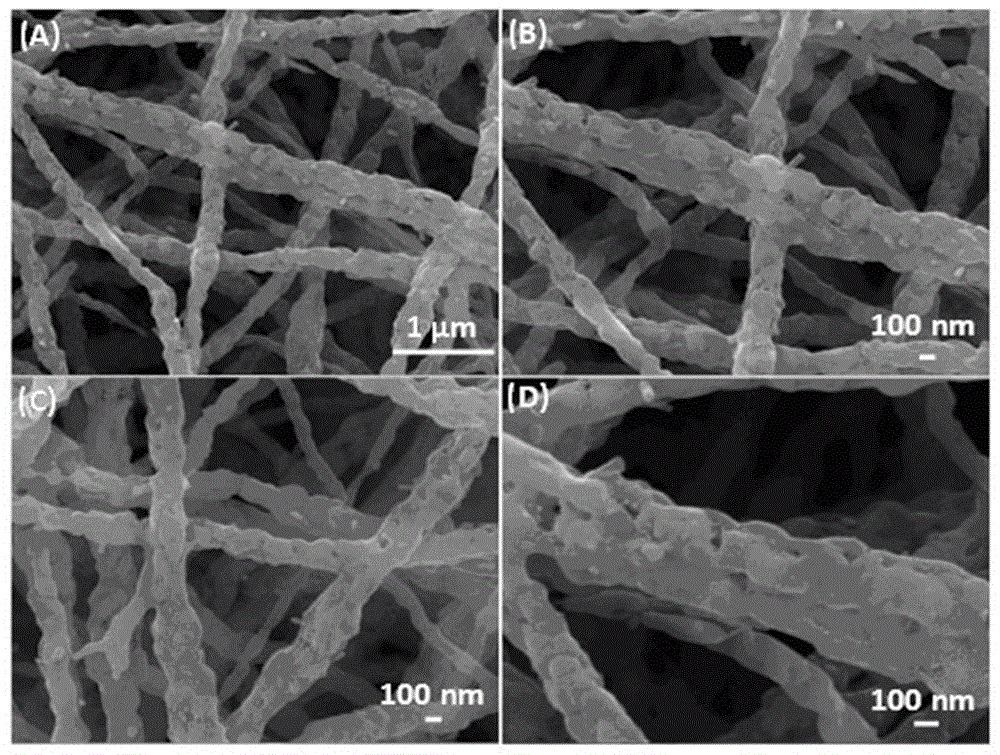

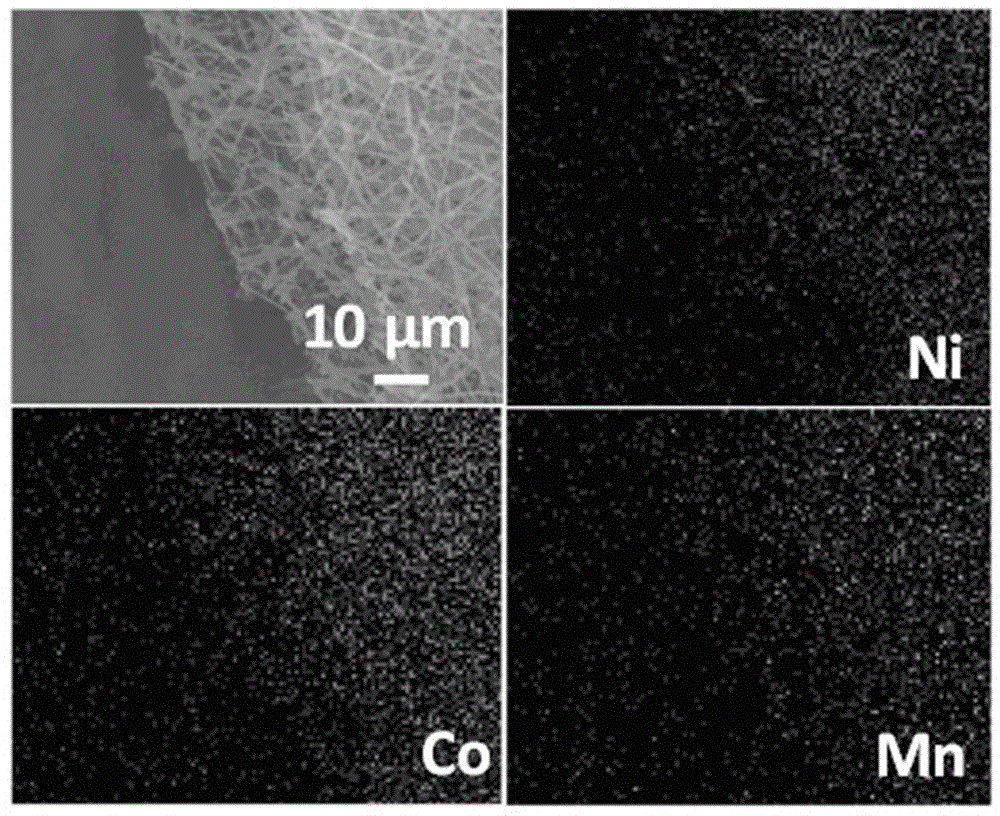

The invention discloses a preparation method of a high-nickel ternary NCM622-nanowire material. The method comprises the following steps: weighing certain amounts of a lithium source, a nickel source, a cobalt source and a manganese source according to a certain element mole ratio, adding the weighed sources into ethanol in order to a uniform and transparent solution; weighing a certain amount of polyvinylpyrrolidone, adding the polyvinylpyrrolidone into the above solution, and magnetically stirring the polyvinylpyrrolidone and the solution to completely dissolve the polyvinylpyrrolidone; weighing a certain amount of organic sugar used as a water absorption inhibitor into the above solution, and continuously stirring the organic sugar and the solution to completely dissolve the organic sugar; transferring the obtained solution into a syringe, carrying out electrostatic spinning, and receiving nano-fibers by aluminum foil; sintering the above obtained product in air; and carrying out high temperature calcination on the sintered product in an argon atmosphere to obtain the high-nickel ternary NCM622-nanowire material. The finally obtained product is made of nanowires formed by interconnecting LiNi0.6Co0.2Mn0.2O2 particles, has a high specific capacity and a good structure stability as alithium ion battery positive electrode active material, and improves the cycle stability and the rate performances of the lithium ion battery positive electrode active material.

Owner:广东迈纳科技有限公司

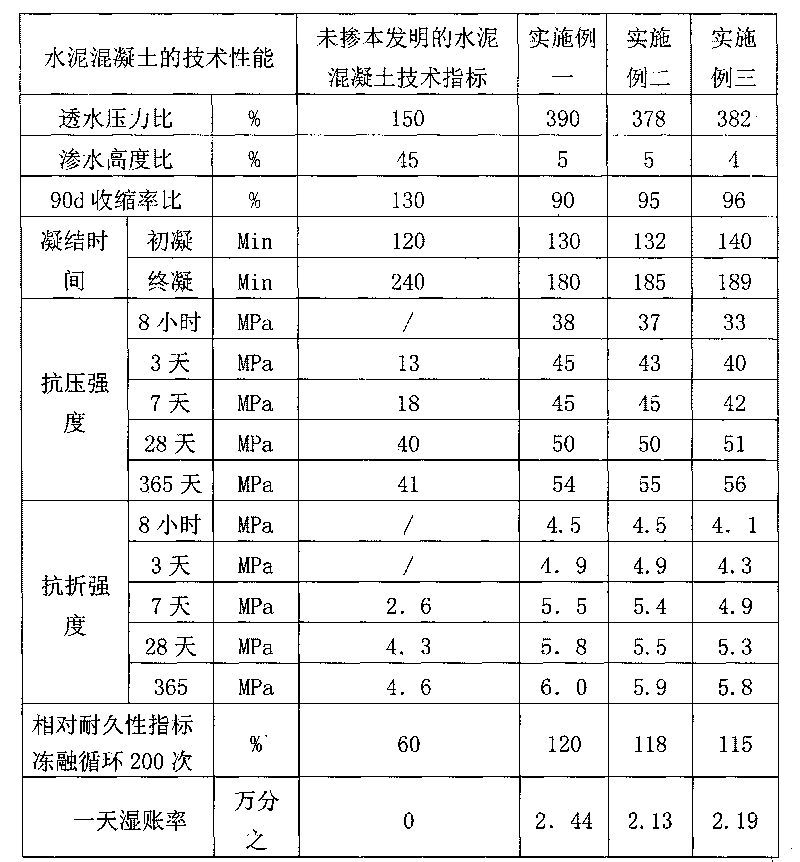

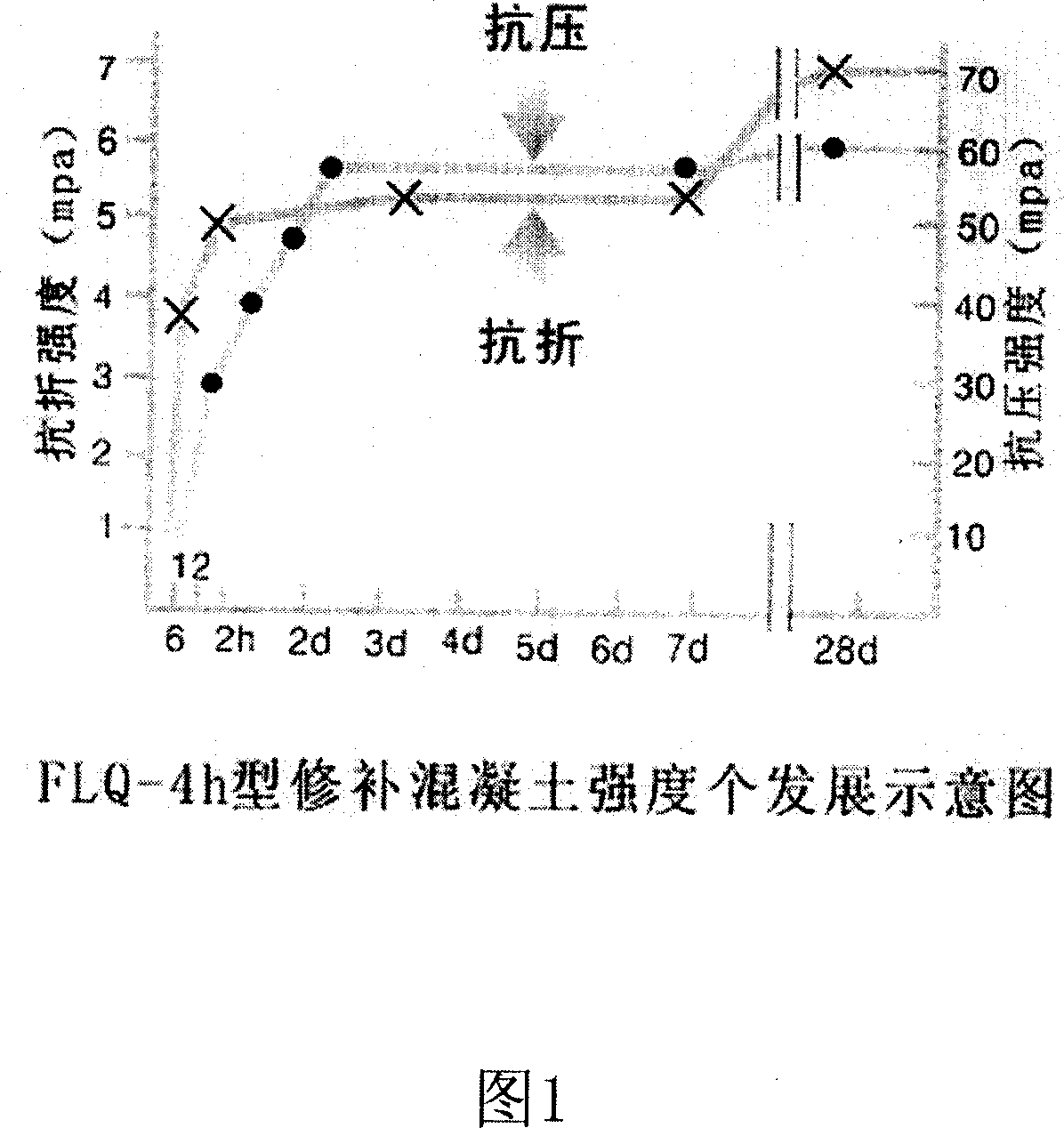

Cement concrete admixture for quickly repairing cement concrete roads

InactiveCN101708969ARapid early strength developmentReduce maintenance traffic timeRoad surfaceMaterials science

The invention belongs to the technical field of cement concrete admixtures. A cement concrete admixture for quickly repairing cement concrete roads consists of the following components in percentage by weight: 70 to 90 percent of inorganic basis material, 10 to 30 percent of early strength admixture, 5 to 20 percent of water reducing agent, 0 to 20 percent of cement-coagulation agent and 0 to 5 percent of rust inhibitor. The admixture can ensure that the traffic opening time of the maintenance of cement concrete pavements is shortened to 8 hours, has the characteristics of high early strength, no shrinkage at later stages, adjustable hardening and setting time, wide applicable temperature range, low mixing amount and the like, and is mainly applicable to the quick construction of engineering maintenance such as various airport runways, concrete pavements of highways, bridges, culverts, tunnels and the like.

Owner:惠州市富力新技术有限公司

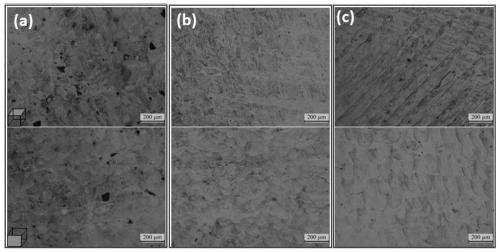

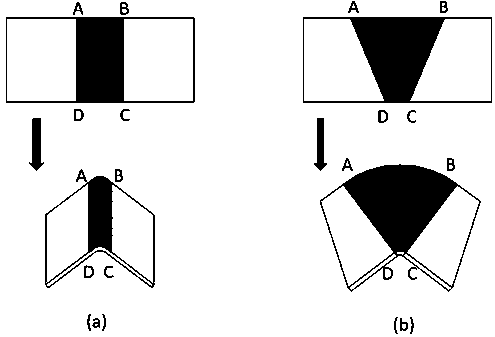

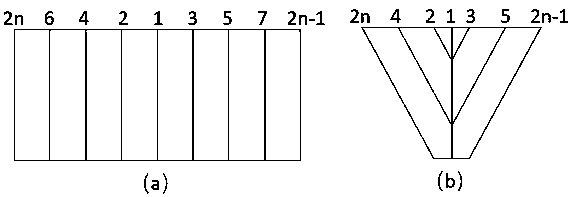

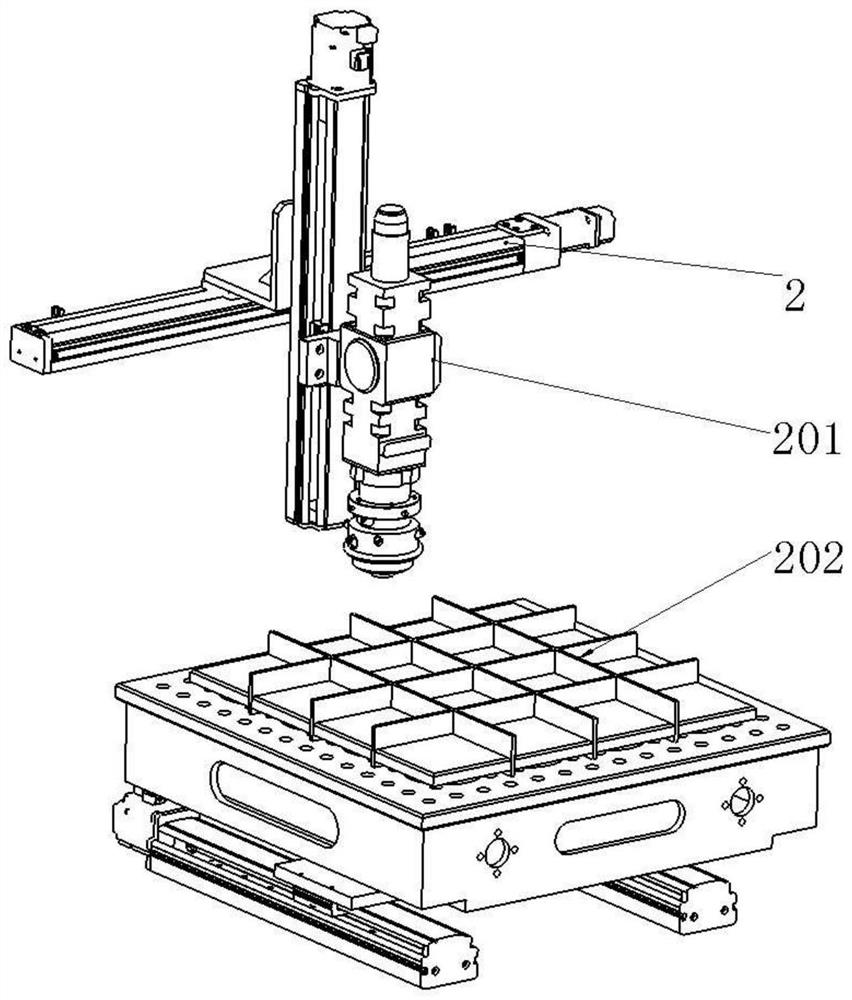

Laser additive manufacturing shear type phase change crack resistance method

ActiveCN111151753AInhibition of microcracksAdditive manufacturing apparatusIncreasing energy efficiencyMartensite transformationCrack resistance

The invention discloses a laser additive manufacturing shear type phase change crack resistance method. The method comprises the steps of adopting a laser additive manufacturing technology and takinghigh-entropy alloy powder with FCC-HCP martensite phase change as additive manufacturing special powder; drying the metal powder in a vacuum drying oven for 12 hours at a drying temperature of 120 DEGC; and carrying out additive manufacturing and printing on the dried high-entropy alloy powder, wherein the printing parameters are as follows: the laser power is 400 W, the scanning speed is 800-1600 mm / s, the scanning distance is 0.09 mm, the powder laying thickness is 0.03 mm, and the substrate preheating temperature is 100 DEG C. The problem of metallurgical defects such as thermal crack deformation and the like are caused by high temperature and high stress gradient in a molten pool in the traditional laser additive manufacturing process is solved. On the basis of the study, the idea ofsuppressing hot cracks in additive manufacturing alloys by stress-induced martensitic transformation is extended to other additive manufacturing alloy systems, and a new method is provided for additive manufacturing of crack-free alloys.

Owner:CENT SOUTH UNIV

Ternary material, preparation method and battery

ActiveCN113363497AChange propertiesSimple structureSecondary cellsPositive electrodesElectrolytic agentElectrical battery

The invention provides a ternary material, a preparation method and a battery. The chemical general formula of the ternary material is Li (Ni<x>Co<y>A )MO2, wherein M is a modifying element and comprises one or a combination of at least two of boron, tungsten, thallium, strontium, niobium or phosphorus, A is Al or Mn, x is more than 0.5 and less than 1, y is more than 0 and less than 0.5, z is more than 0 and less than 0.5, x + y + z = 1, a is more than or equal to 0.95 and less than or equal to 0.99, and a + b = 1. Special element modifiers are introduced into crystal lattices and the surfaces of the crystal lattices, so that the crystal face energy of the ternary material is regulated and controlled, the grain size and the growth direction are controlled, the structure, the size and the arrangement mode of primary particles in the material are optimized, generation of micro-cracks in the particles caused by anisotropic changes of the volume of the crystal lattices is relieved, the interface side reaction of the electrolyte is inhibited, and the electrochemical stability of the material is improved. Excellent grain orientation arrangement is beneficial to diffusion of lithium ions and improvement of the dynamic performance of the material.

Owner:EVE ENERGY CO LTD

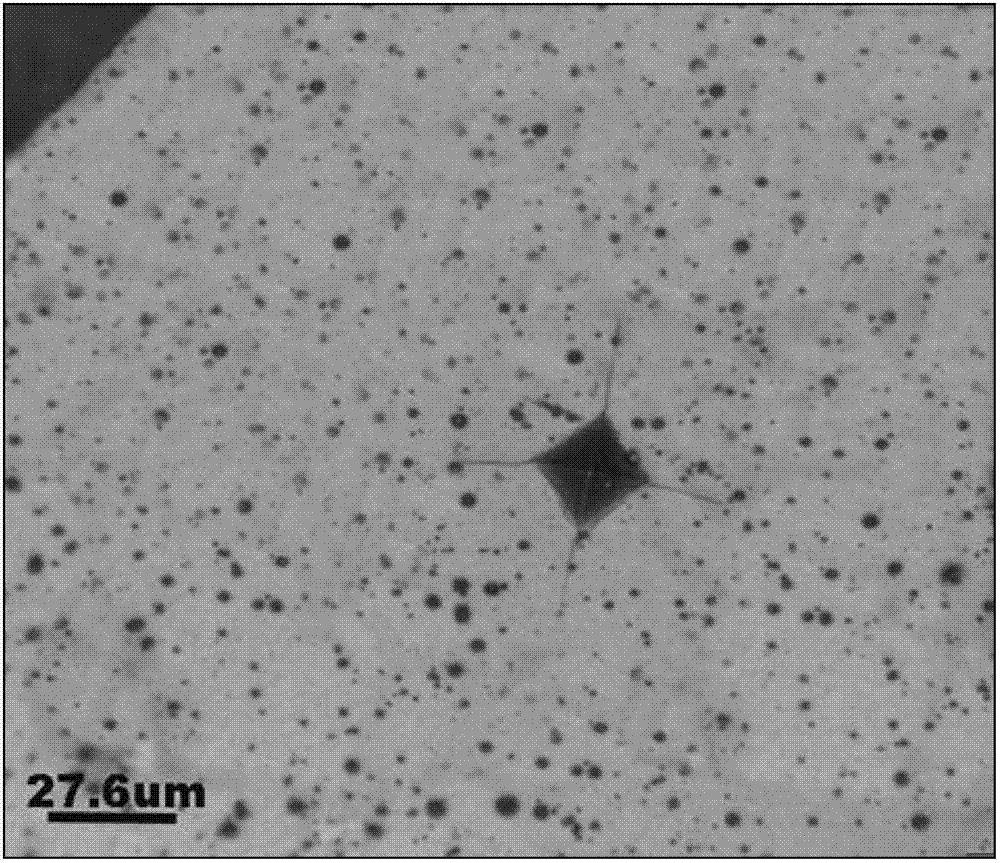

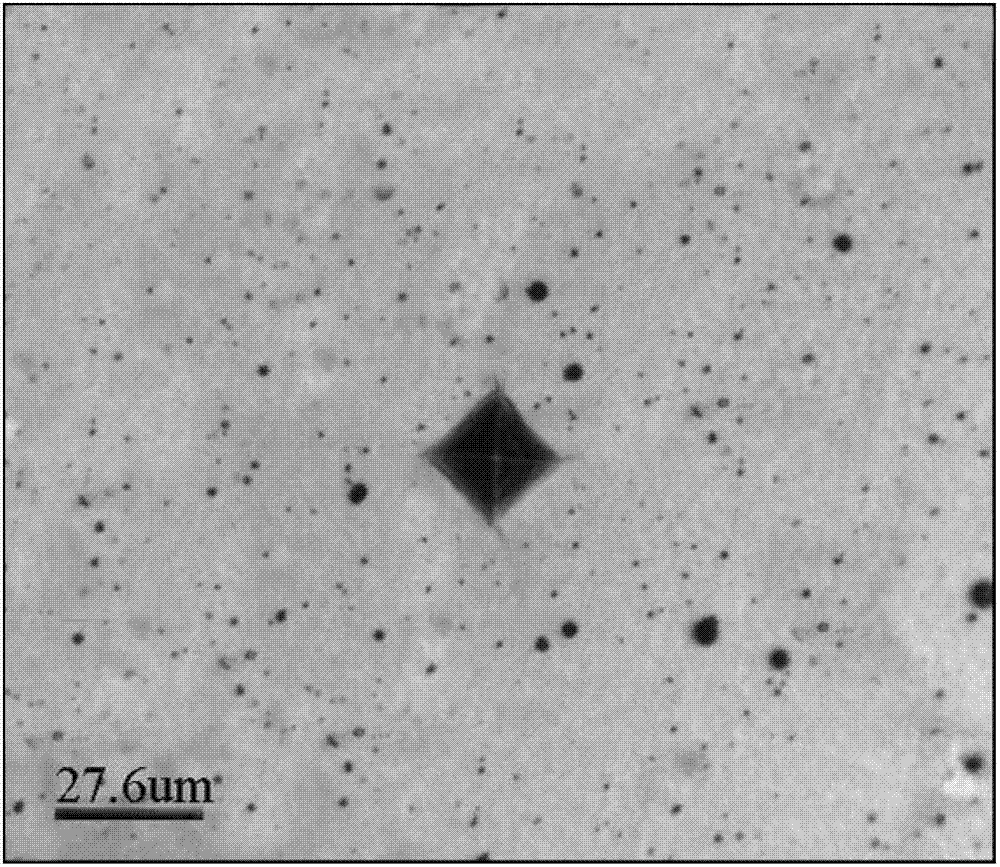

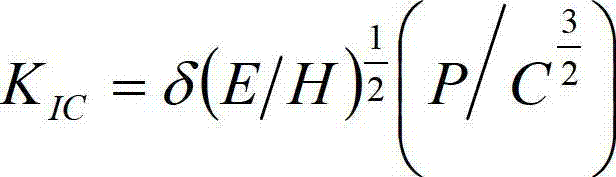

Magnetic toughening method for inhibiting machinery damage of hard and brittle materials

ActiveCN109534690AEfficient precision machiningImprove machined surface qualityCoatingsSurface layerLiquid state

The invention provides a magnetic toughening method for inhibiting machinery damage of hard and brittle materials and belongs to the technical field of quality control of machinery process. Accordingto the method, a hard and brittle material is immersed in a clamping mold filled with a magnetorheological fluid, and then the magnetorheological fluid infiltrates into pores, cracks and other defectson the surface layer of the hard and brittle material and liquid-state encapsulation is formed around workpieces; and during machining, a controllable magnetic field is applied such that the magnetorheological fluid is affected by the magnetic force to generate a magnetorheological effect and a high-viscosity elastic film having high yield strength is formed. Thereby, the magnetorheological fluidin the defects on the surface layer of the hard and brittle material is solidified to form a hole-sealed toughening mechanism. The magnetorheological fluid around the material is solidified to form three-dimensional circumferential compressive pre-stress encapsulation, and impact vibration and energy applied by cutters such as a grinding wheel, etc. on the workpieces can be absorbed, and it is helpful for inhibiting the cracks from extending in the deep radial direction or towards side edges. Thereby, defects such as cracks, surface fracture, breaking of edges, etc. are reduced, and machiningquality is improved.

Owner:中国人民解放军火箭军工程大学

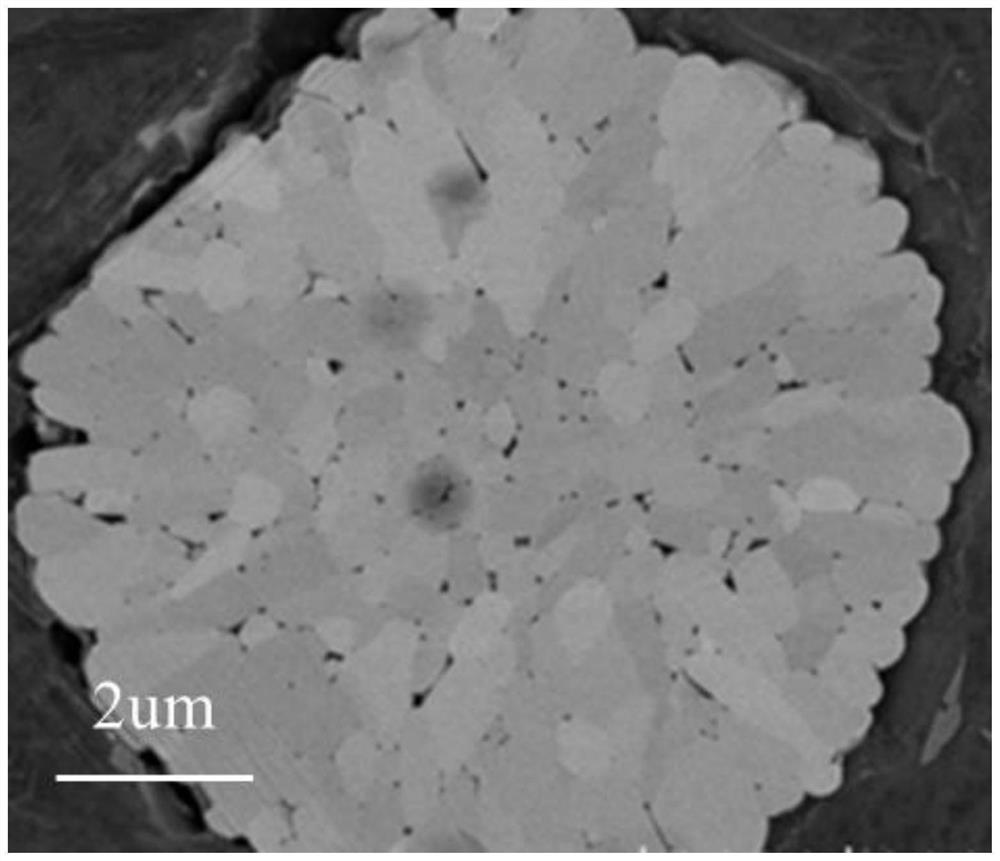

Double-layer -coated modified high-nickel cobalt-free single crystal ternary positive electrode material and preparation method thereof

ActiveCN113488634AHigh mechanical strengthGuaranteed stabilitySecondary cellsPositive electrodesLithiumPhysical chemistry

The invention discloses a double-layer-coated modified high-nickel cobalt-free single crystal ternary positive electrode material and a preparation method thereof, the chemical formula of the positive electrode material is LiNixMnyWzO2@TMO2@C, in the formula, x is greater than or equal to 0.9 and less than 1, y is greater than 0 and less than 0.06, z is greater than 0 and less than 0.04, x + y + z = 1, and TMO2 is one or more of oxides of Al, Mg, Cu and Ti. The preparation method comprises the following steps: (1) carrying out coprecipitation reaction on a nickel source, a manganese source, a tungsten source, a NaOH solution and an ammonia water solution to obtain a precursor; (2) uniformly mixing the precursor with a lithium source, and calcining to obtain a ternary positive electrode material; (3) mixing a TM source with the cobalt-free ternary positive electrode material, and calcining to obtain a single-layer coated ternary positive electrode material; and (4) mixing the single-layer coated ternary positive electrode material with a carbon source, and calcining to obtain the single-layer coated ternary positive electrode material. The double-layer -coated modified high-nickel cobalt-free single crystal ternary positive electrode material is good in electrochemical performance, the preparation method is simple, and the production cost is low.

Owner:ZHUJI PAWA NEW ENERGY

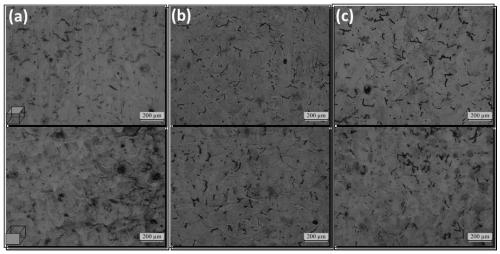

Method of controllable growth of graphene covering film on surface of copper plated steel fiber

InactiveCN106927705AHigh strengthAccelerated corrosionChemical vapor deposition coatingHydration reactionCopper plating

The invention provides a method of controllable growth of a graphene covering film on the surface of a copper plated steel fiber.The method mainly comprises the following technical steps: 1) cleaning the copper plated steel fiber, 2) performing high-temperature annealing treatment on the copper plated steel fiber, 3) adjusting a chemical vapor deposition technical parameter and a position of the copper plated steel fiber, and 4) growing graphene on the surface of the copper plated steel fiber to form uniform covering and controllable thickness graphene film.The technical flow is simple and easy to operate; the graphene on the surface of the copper plated steel fiber is stable in chemical property; the strength and corrosion resistance of the copper plated steel fiber in a cement-based composite can be effectively improved; the copper plated steel fiber can serve as a nucleation point of cement hydration reaction so as to profitably promote the cement hydration reaction; cement forms a dense structure; finally, crack formation is effectively avoided; and the strength of the cement-based composite is improved.The method has a wide application prospect in the field of the cement-based composite.

Owner:SOUTHEAST UNIV

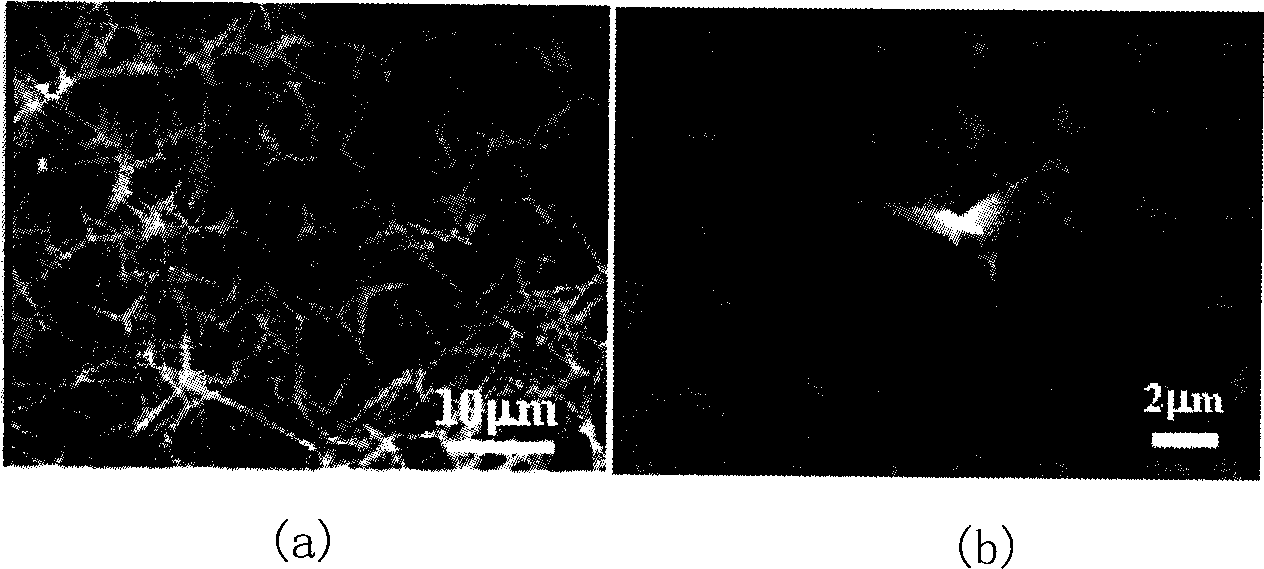

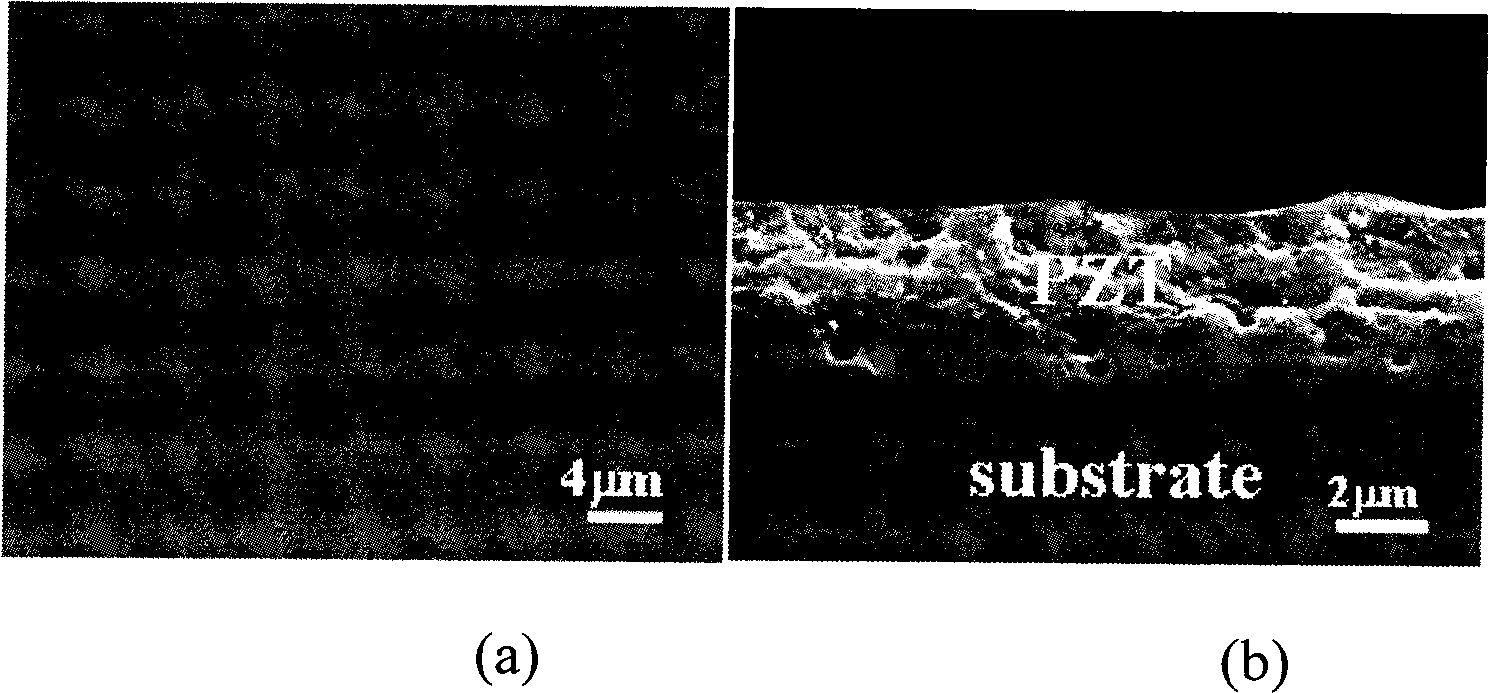

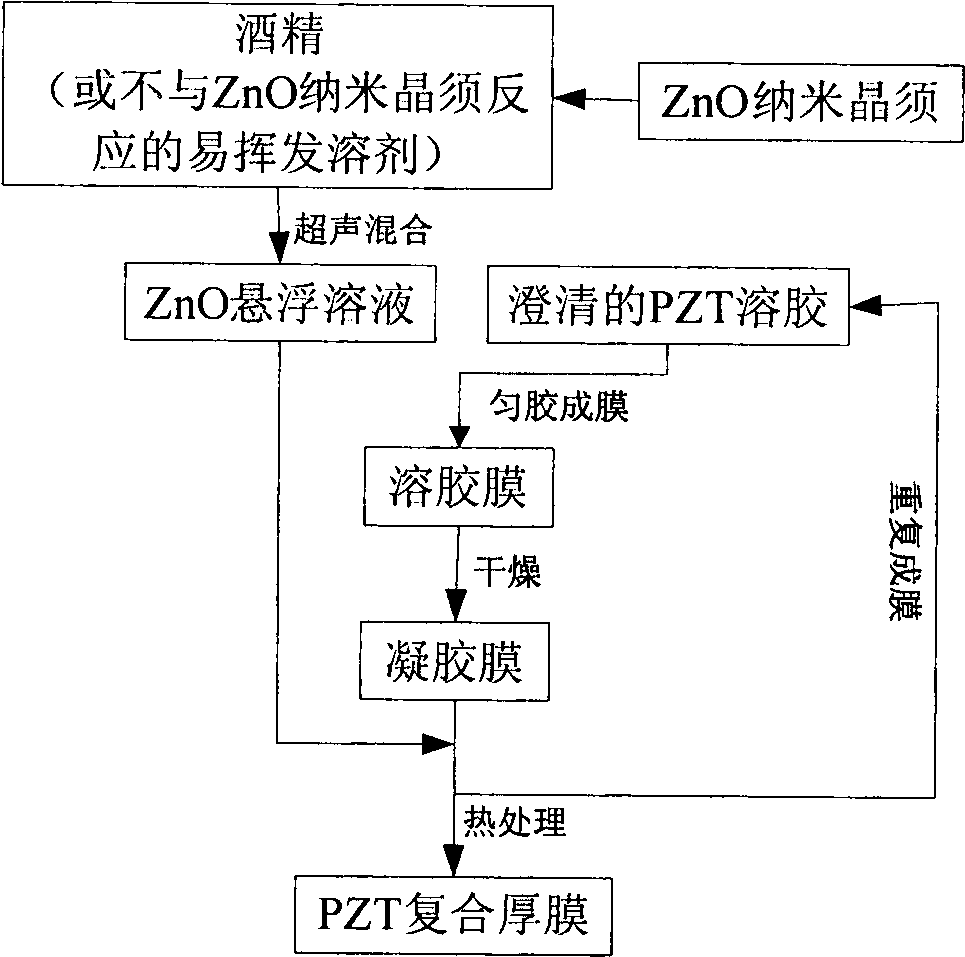

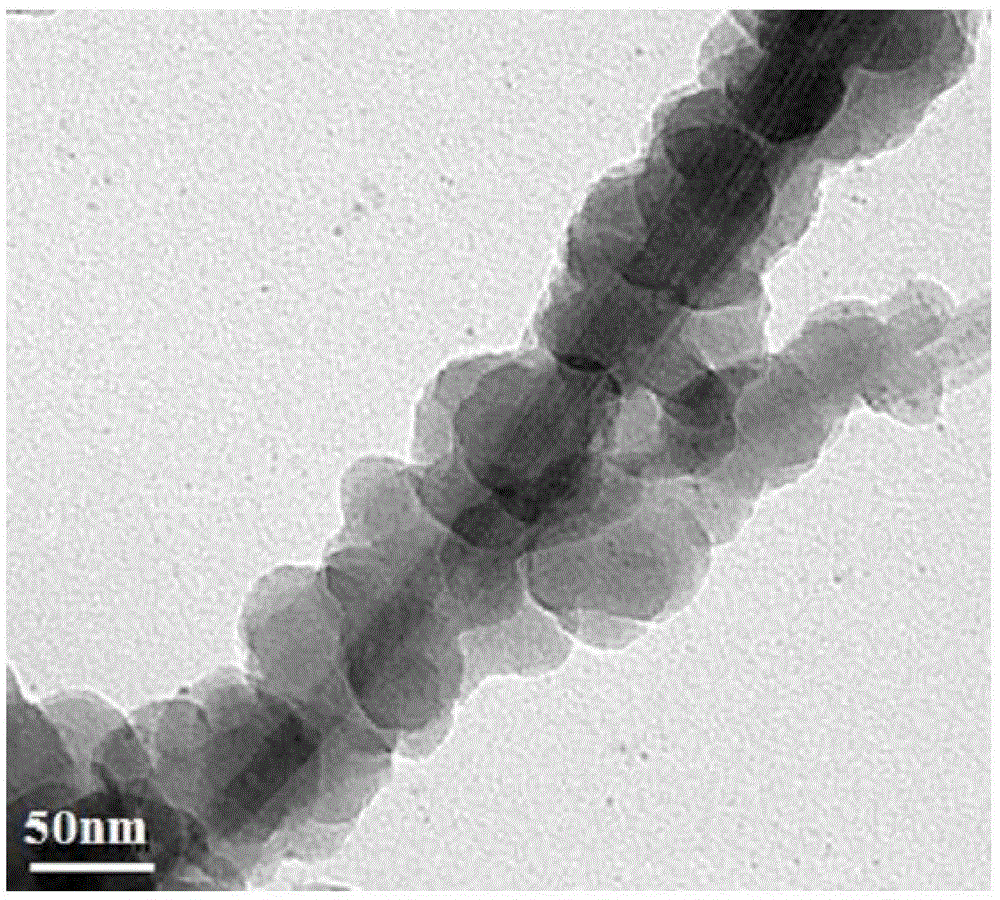

Preparation method of ZnO nano crystal whisker reinforced silicon-based lead zirconate titanate piezoelectric composite thick film

InactiveCN101533889AInhibition of microcracksExcellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyLead zirconate titanatePiezoelectric composite

The invention relates to a preparation method of ZnO nano crystal whisker reinforced silicon-based lead zirconate titanate piezoelectric composite thick film and belongs to the field of electronic material. The method of the invention comprises the steps of adding ZnO nano crystal whisker to alcohol to be prepared into ZnO suspension with a certain concentration, alternately coating clear PZT sol and ZnO suspension on a Pt / Cr / SiO2 / Si substrate by a spin coating method to form film, alternately coating for plural times until a desired thickness is obtained, and finally thermally processing the obtained thick film in a high-temperature tube furnace to obtain the silicon-based PZT piezoelectric composite thick film. The PZT piezoelectric composite thick film prepared by the method has smooth surfaces, uniform components and a film thickness more than 1 micron, and has no cracks. The PZT piezoelectric composite thick film prepared by the invention meets the actual requirements of MEMS ferro-electricity and piezoelectric device on the thick film, and can be widely applied to the high-tech fields of aviation, spaceflight, weapon, ship, information and communication.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

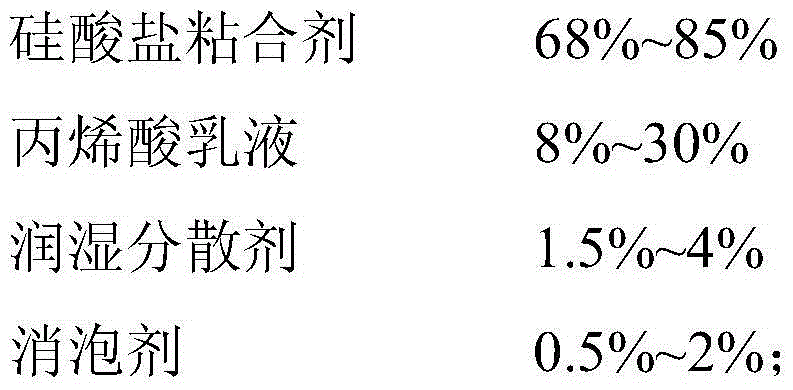

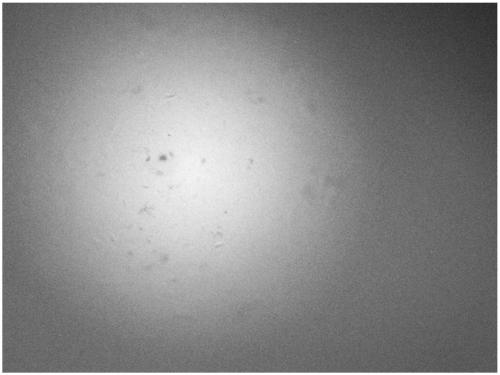

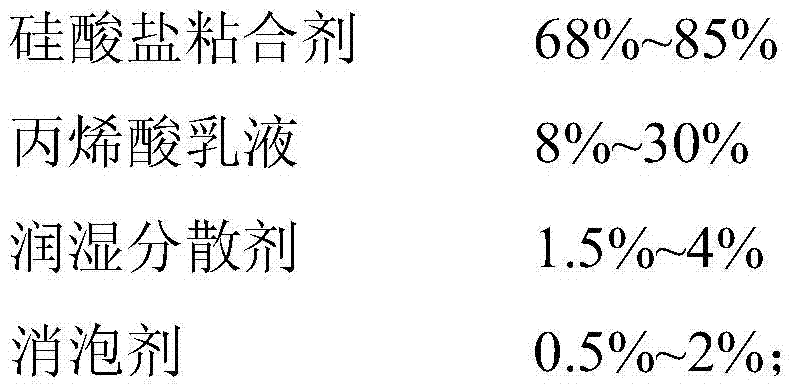

Nanometer inorganic zinc-rich composite anticorrosive coating and preparation method thereof

ActiveCN105273454AImprove solubilityImproved scratch corrosion resistanceAlkali metal silicate coatingsAnti-corrosive paintsAdhesivePolyaniline composite

The invention discloses a nanometer inorganic zinc-rich composite anticorrosive coating and a preparation method thereof. The anticorrosive coating is prepared through mainly mixing a component A with a component B, wherein the component A comprises a silicate adhesive, an acrylic emulsion, a wetting dispersant and an antifoaming agent; and the component B comprises flake zinc powder and nano-modified polyaniline, and the nano-modified polyaniline is a fibrous core-shell structured attapulgite-polyaniline composite material. The preparation method of the coating comprises the following steps: uniformly mixing the silicate adhesive, the acrylic emulsion, the wetting dispersant and the antifoaming agent to obtain the component A; and adding the component A to the component B, and uniformly mixing to obtain the anticorrosive coating. The nanometer inorganic zinc-rich composite anticorrosive coating has the advantages of strong combination force with a metal base material, salt spray resistance, scrape corrosion resistance and impact resistance, and can be used in various different situations; and the preparation method has the advantages of simplicity, good controllability, easy operation, low production cost and easy industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

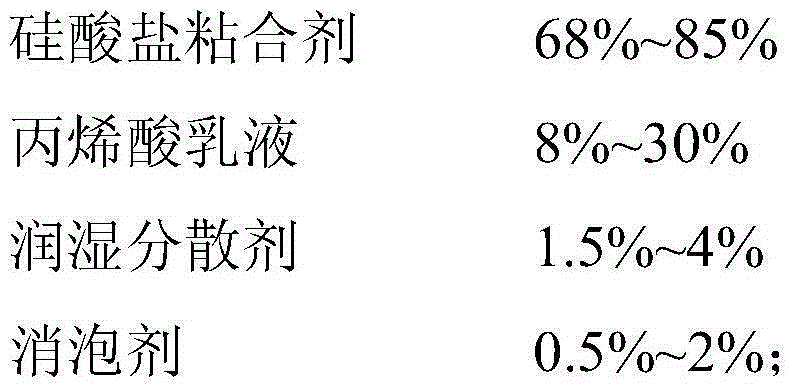

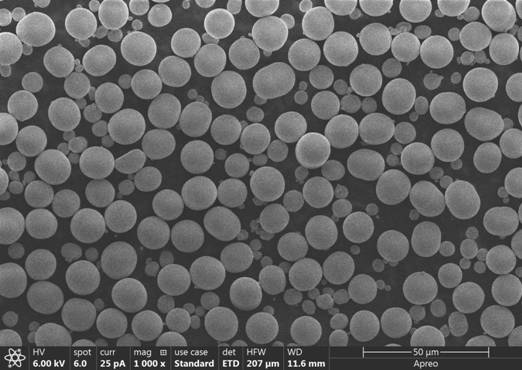

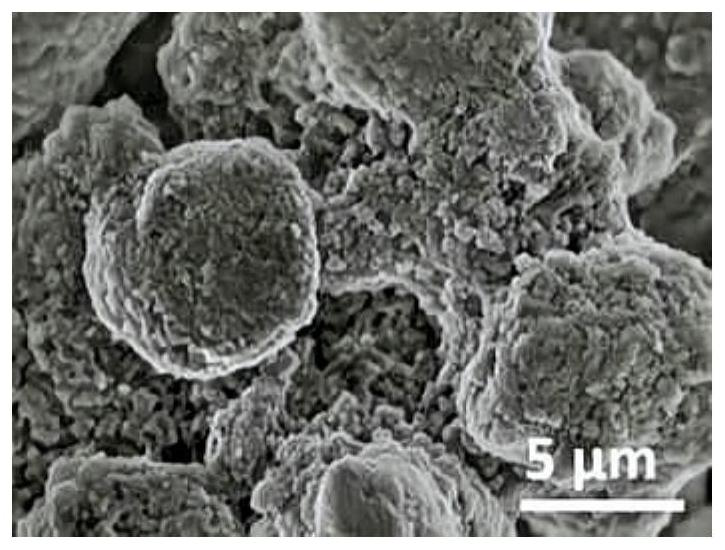

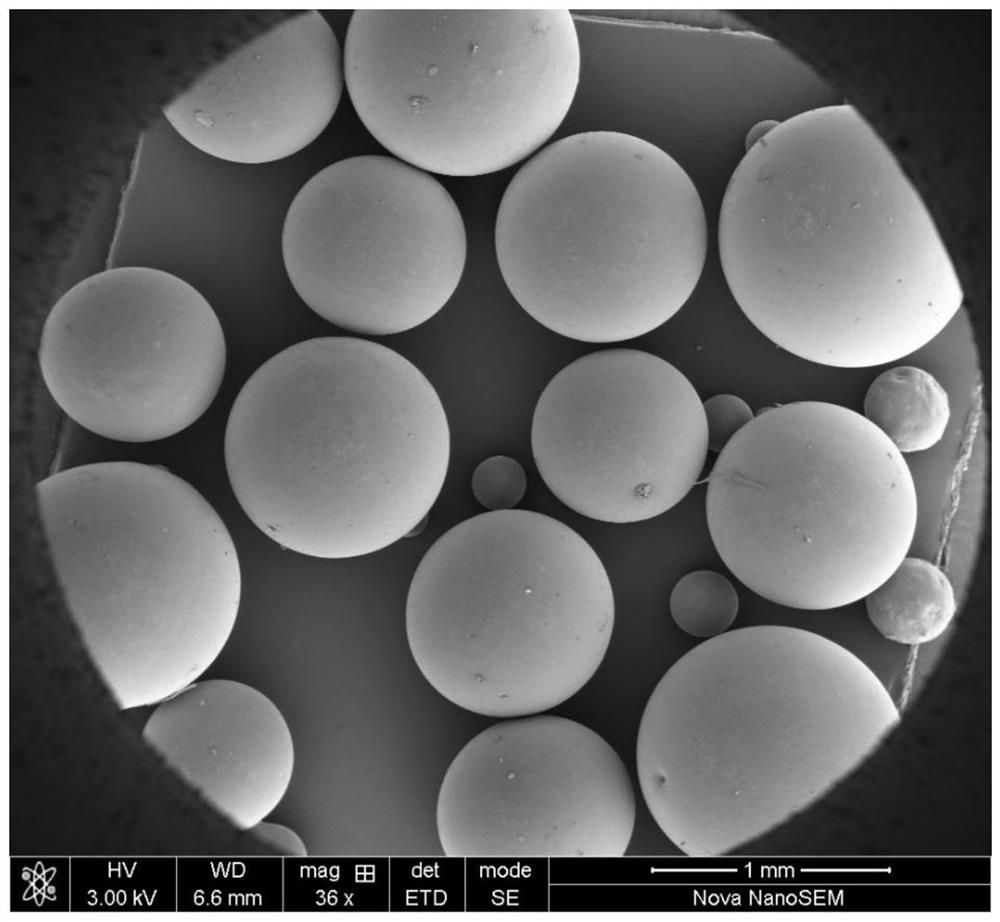

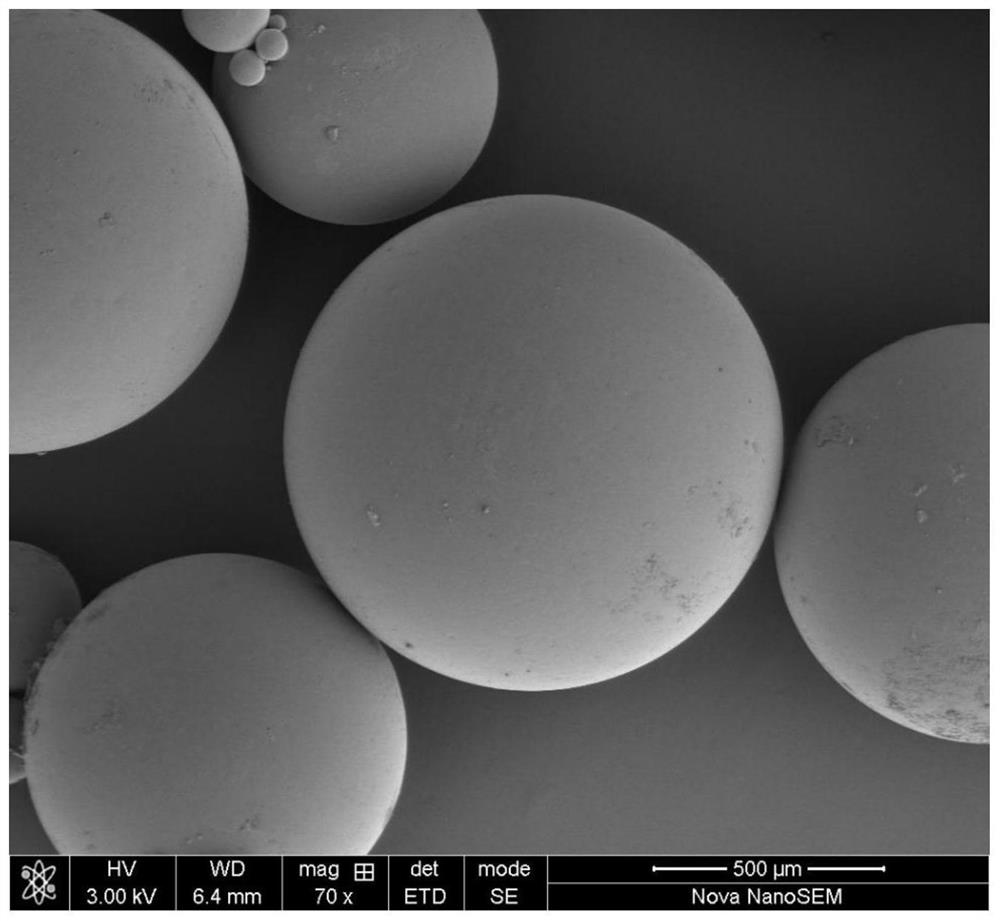

Method for preparing low-cost asphalt-based spherical activated carbon with hierarchical porouse structure

The invention discloses a low-cost asphalt-based spherical activated carbon with hierarchical porouse structure. According to the invention, asphaltic coal with softening point of 130-230 DEG C is used as a raw material, a low-temperature decomposable organic matter is used as a pore forming agent, after mixing, crushing, spheroidizing, air oxidation, liquid phase oxidation, charring, steam activation, and pickling, the asphalt-based spherical activated carbon is prepared.Regarding the asphalt-based spherical activated carbon, sphere diameter is 0.4-1.5 mm, density is 0.5-0.85 g / cm<3>, ratiospecific surface area is 800-1,500 m<2> / g, vibration strength is greater than 95%, microporous content is 60-83%, mesoporous content is 30-5%, macroporous content is 10-12%, and sphericity is greater than 99%.The invention has significant important significance for promoting the engineering of asphaltpitch-based spherical activated carbon and promoting the application of spherical activated carbon in civil, industrial, aerospace and other fields.

Owner:湖南曦威新材料有限公司

Multi-element microalloyed high-efficiency extruded magnesium alloy and preparation method thereof

The invention relates to the field of metal materials, and provides a multi-element microalloying efficient extrusion magnesium alloy and a preparation method thereof. The alloy is prepared from the following components in percentage by mass: 0.4 to 1.1 percent of aluminum, 0.4 to 0.6 percent of manganese, 0.01 to 0.05 percent of calcium, 0 to 1.6 percent of additive elements, less than or equal to 0.05 percent of inevitable impurities and the balance of magnesium, the additive element is one or any combination of zinc or rare earth, the content of zinc is 0-1.0%, the content of rare earth is one or combination of cerium or neodymium, the content of cerium is 0-0.3%, the content of neodymium is 0-0.3%, and the total content of alloying elements is less than or equal to 3.4%. The preparation method comprises the steps of smelting, gravity casting and efficient extrusion forming. The yield strength of the obtained alloy ranges from 212 MPa to 222 MPa, the tensile strength ranges from 275 MPa to 285 MPa, the ductility ranges from 12% to 17%, and the ratio of the yield strength to the total content of elements ranges from 86 MPa / wt.% to 206 MPa / wt.% and is 3-15 times of the ratio of the yield strength to the total content of the elements of existing commercial magnesium alloy.

Owner:JILIN UNIV

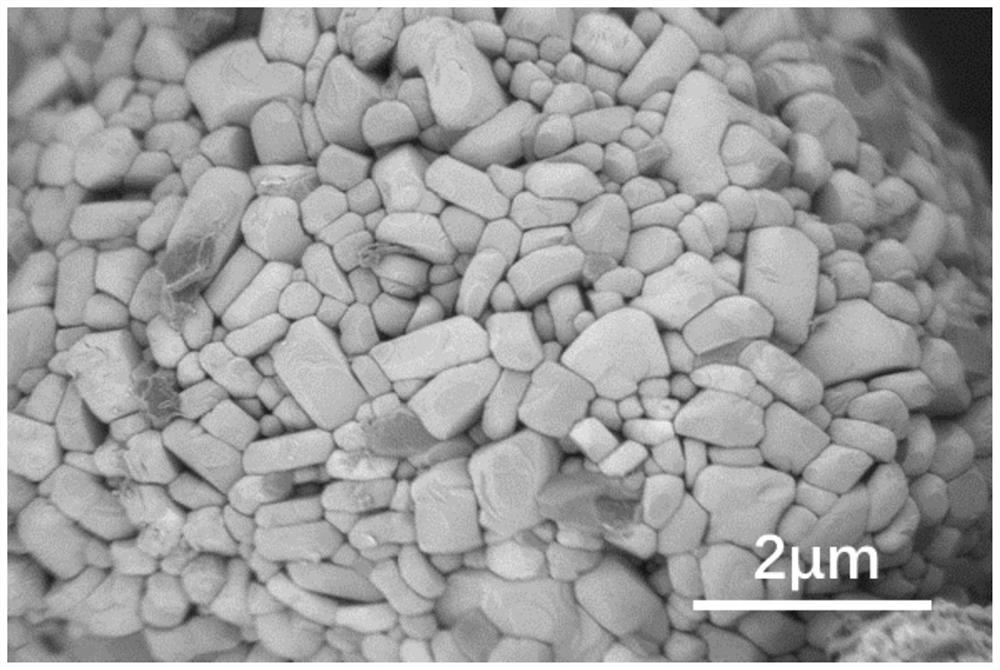

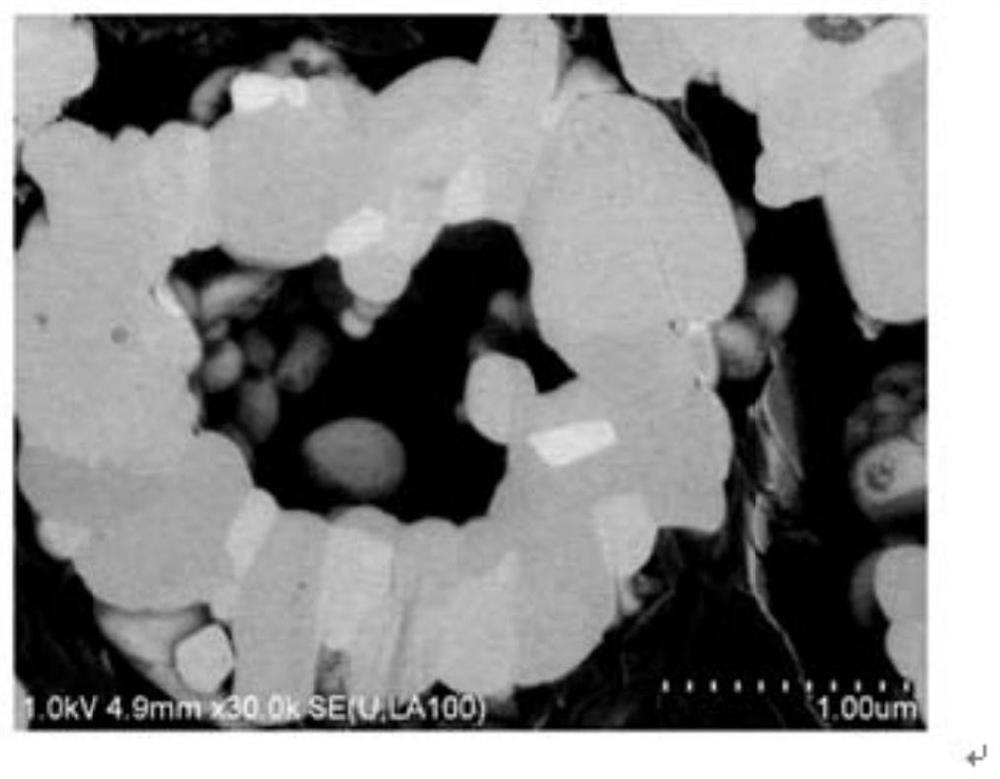

High-nickel ternary positive electrode material as well as preparation method and application thereof

InactiveCN112614991AImprove cycle stabilityReduce stressPositive electrodesLi-accumulatorsElectrical batteryManganese

The invention belongs to the technical field of lithium ion batteries, and provides a high-nickel ternary cathode material and a preparation method and application thereof, the chemical formula of the high-nickel ternary cathode material is LiNixCoyMnzBiO2, B is at least one of diboron trioxide, boric acid, lithium tetraborate, ammonium pentaborate, ammonium fluoborate or boron carbide, x > / = 0.9, y>0, z>0, i is not smaller than 0.001 and is not greater than 0.1, and x+y+z+i=1. The preparation method comprises the following steps of ball-milling and mixing a nickel-cobalt-manganese hydroxide precursor, a lithium source and a boron source, sintering and sieving to obtain the high-nickel ternary positive electrode material. Primary particles of the high-nickel ternary positive electrode material of the lithium battery are slender, interiors of secondary particles are looser, the high-nickel ternary positive electrode material of the lithium battery has higher first-circle capacity and better cycling stability, and the loose internal structure can reduce stress in the material in the cycling process, inhibit generation of microcracks, enhance the structural stability of the material and prolong the service life of the material; thus, a material having excellent cycle stability is obtained.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Processing method for improving toughness of hard film

ActiveCN102965635AImprove brittle fracture resistanceInhibition of microcracksVacuum evaporation coatingSputtering coatingHardnessBrittle fracture

The invention provides a processing method for improving toughness of a hard film, and the method comprises the following step of: injecting ions into the hard film by adopting an ion injecting machine, wherein energy of injected ions is 10-150kev, dosage of the injected ions is 1*10<11>-6*10<16>ions / cm<2>, the injected ions are one or more than one components of the hard film, and the hard film is a metal nitride film with Vickers hardness of no less than 20GPa. According to the processing film provided by the invention, ions are injected into the hard film by adopting an ion injecting technology, and the pinning effect and the pressure stress effect can be formed, so that initiation of a micro crack on the surface of the hard film is inhibited; and crest truncation on the micro crack of the hard film is realized, and the micro crack is prevented from expanding inside the film, so that brittle fracture resistance of the film is improved, the toughness of the hard film is obviously improved, and the problem that the brittleness of the hard film is invalid in a using process is solved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for controlling surface micro crack of pitch-based spherical activated carbon

ActiveCN109052398AImprove performancePromote the engineering processCarbon compoundsActivated carbonApplication areas

The invention relates to a method for controlling surface micro cracks of pitch-based spherical activated carbon. The method comprises the following steps: carrying out modification with high softening point coal tar pitch, improving pelletizing conditions of naphthalene-containing pitch granules, and changing a removal method for naphthalene in the naphthalene-containing pitch granules, thereby obtaining the pitch-based spherical activated carbon which is smooth in surface, free of surface micro crack and high in sphericity degree, wherein the pitch-based spherical activated carbon has a density of 0.5-0.85g / cm<3>, a specific surface area of 800-1300m<2> / g, vibration strength greater than 95% and a micro pore content greater than 83%. By adopting the method, while the pitch-based spherical activated carbon is prepared, the problem of micro cracks on the surface of the pitch-based spherical activated carbon can be effectively solved, the mechanical properties of the material are improved, and the method has great significances for promoting engineering progress of the material and widening the application range of the material.

Owner:湖南曦威新材料有限公司

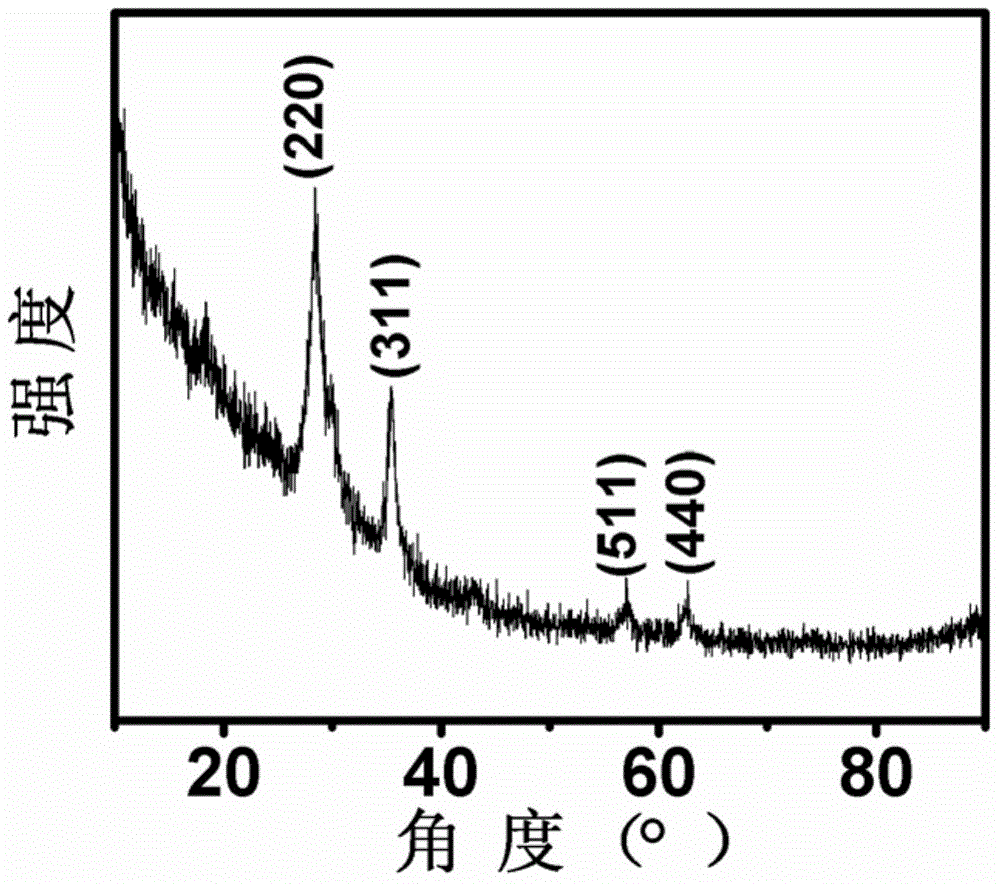

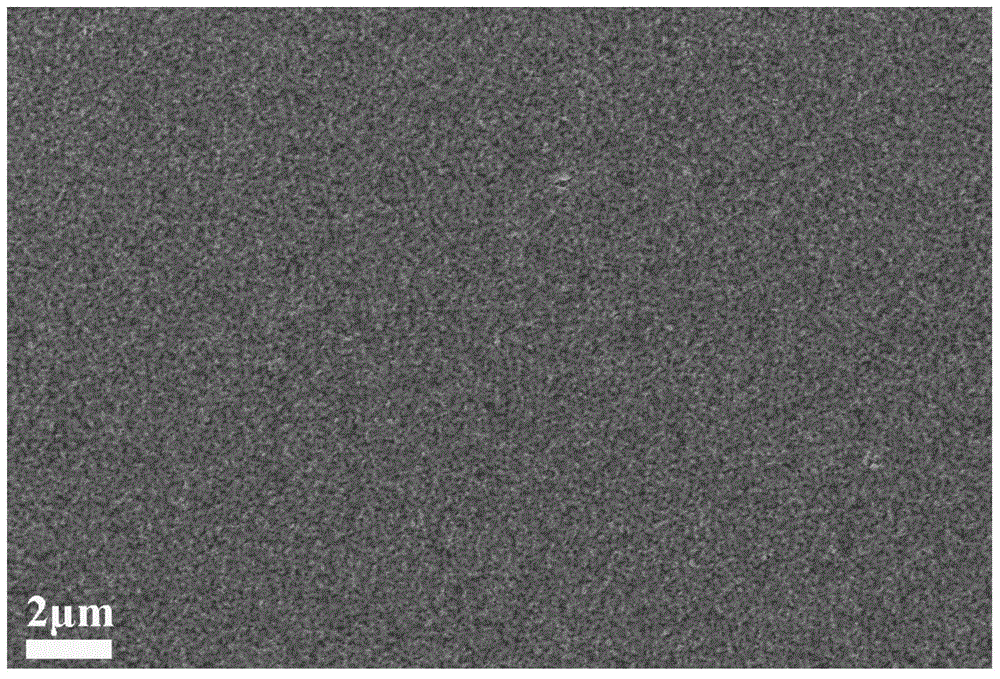

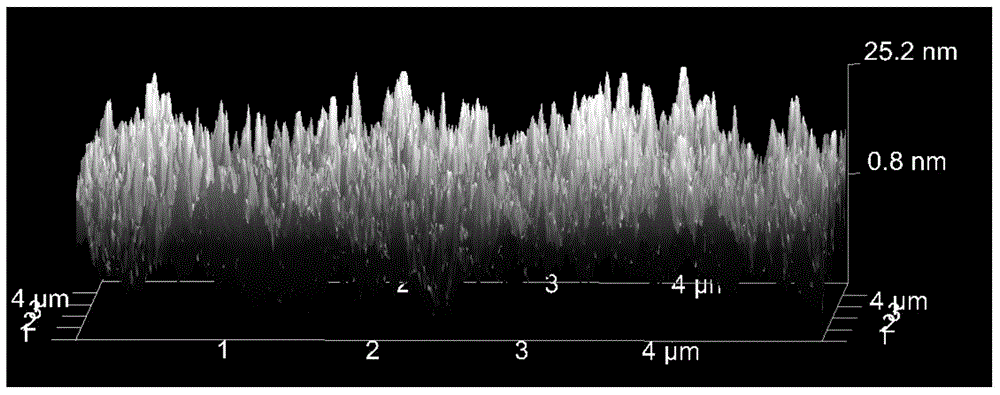

Method for manufacturing manganese zinc ferrite film through sol-gel method

ActiveCN104599807ASimple processLow costLiquid applicationSolid/suspension decomposition chemical coatingFurnace temperatureZinc nitrate

Disclosed is a method for manufacturing a manganese zinc ferrite film through a sol-gel method. The method comprises the steps that 1, ferric nitrate and zinc nitrate are weighed according to the Mn<0.5>Zn<0.5>Fe<2>O<4> stoichiometric proportion, and the two raw materials are dissolved in deionized water; 2, a manganous nitrate solution is added to a solution obtained in the step 1, citric acid is added as a complexing agent, and a mixed solution is obtained; 3, ammonia water is added to the mixed solution obtained in the step 2, the pH value of the solution is adjusted to range from six to seven, sol is obtained, and then polyvinylpyrrolidone is added in the sol; 4, a silicon substrate is washed through a hydrochloric acid and hydrofluoric acid mixed aqueous solution and is blow-dried through nitrogen; 5, the manganese zinc ferrite sol obtained in the step 3 is dropped on the silicon substrate washed in the step 4, a KW-4A spin coater is used for whirl coating by 2,000-3,000 r / min, the sol is evenly distributed on the surface of the silicon substrate, then after the silicon substrate is placed in a muffle furnace of 250 DEG C to 300 DEG C for heat treatment for 20-30 min, the silicon substrate is heated to 500 DEG C along with the furnace, and the silicon substrate is taken out after heat preservation is kept for 20-30 min. the temperature rise rate along with the furnace is 10-20 DEG C / min, and the furnace temperature change is within + / -5 DEG C.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

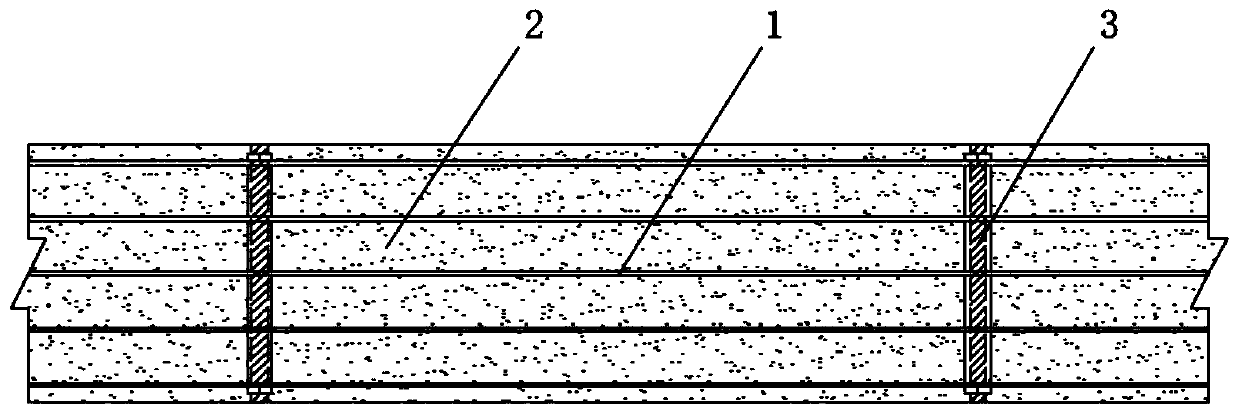

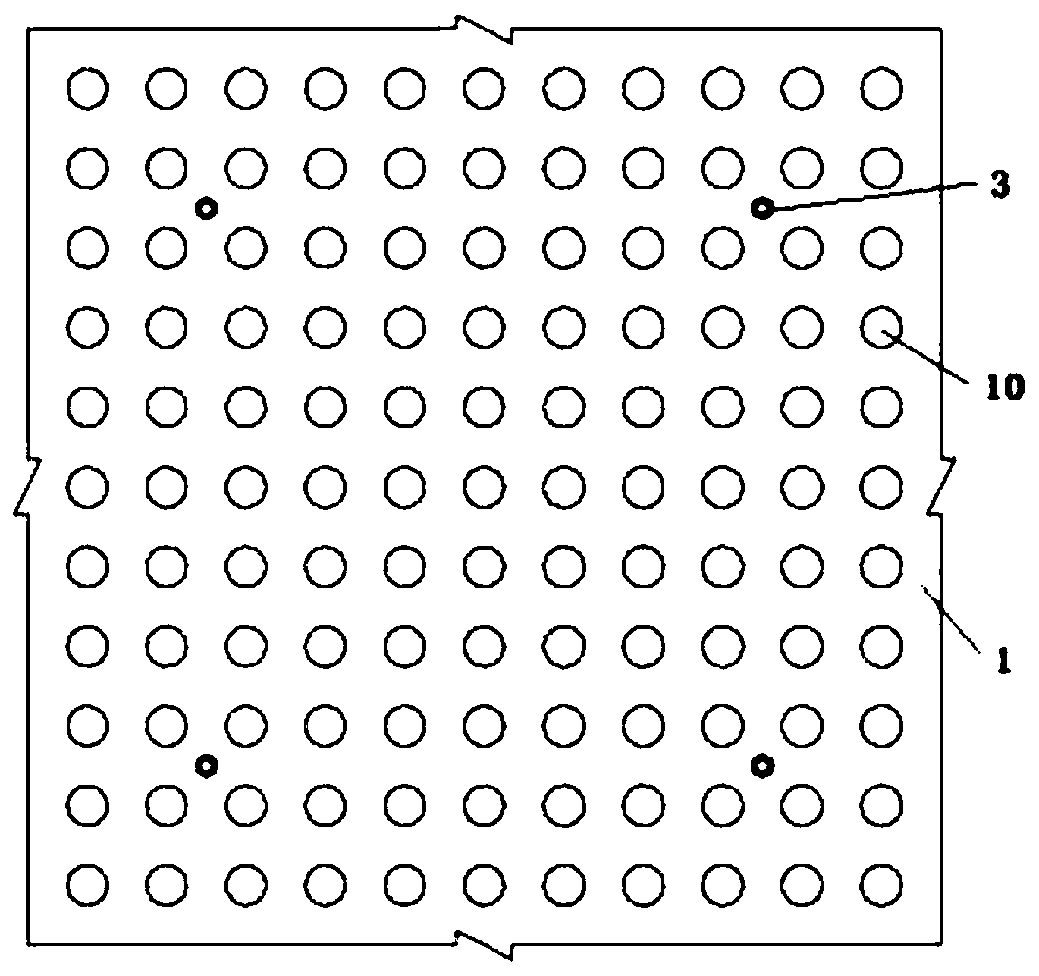

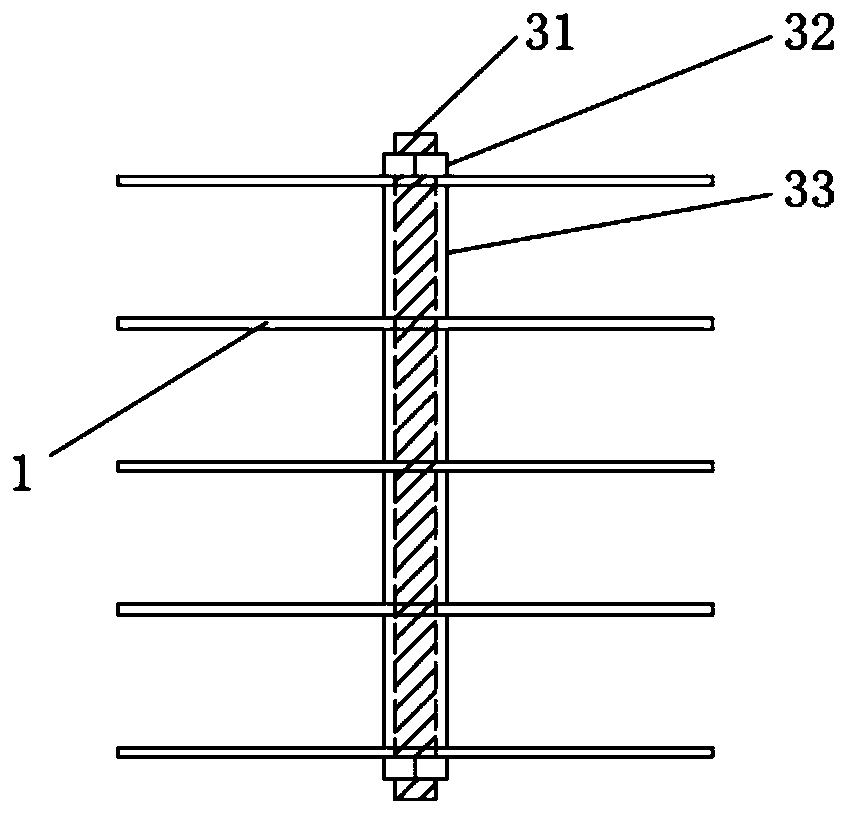

Open-hole thin steel plate and ultra-high-performance concrete composite structure and construction method thereof

PendingCN110258910AImprove crack resistanceIncrease contact areaConstruction materialSheet steelProjection plane

The invention discloses an open-hole thin steel plate and ultra-high-performance concrete composite structure. The open-hole thin steel plate and ultra-high-performance concrete composite structure comprises a plurality of thin steel plates distributed at intervals, three or more limiting parts and ultra-high-performance concrete, wherein a filling space is formed by all the thin steel plates, the height of the filling space is equal to the distance between the two thin steel plate located on the outermost sides, and the projection plane of the filling space is equal to the union set of frontal projection planes of all the thin steel plates; and meanwhile, each thin steel plate is provided with a plurality of small holes located in the filling space; each limiting part is arranged on the corresponding thin steel plate in a penetrating mode, the projection of every three limiting parts on the same thin steel plate is not collinear, and the filling space is filled with the ultra-high-performance concrete. The open-hole thin steel plates have the orientation constraint effect and the cracking resisting effect on disorderly-distributed steel fiber in the ultra-high-performance concrete, so that the cracking strength and ductility of the open-hole thin steel plate and ultra-high-performance concrete composite structure are improved by a large margin.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

Nano-inorganic zinc-rich composite anti-corrosion coating and preparation method thereof

ActiveCN105273454BImprove solubilityImproved scratch corrosion resistanceAlkali metal silicate coatingsAnti-corrosive paintsAdhesivePolyaniline composite

The invention discloses a nanometer inorganic zinc-rich composite anticorrosive coating and a preparation method thereof. The anticorrosive coating is prepared through mainly mixing a component A with a component B, wherein the component A comprises a silicate adhesive, an acrylic emulsion, a wetting dispersant and an antifoaming agent; and the component B comprises flake zinc powder and nano-modified polyaniline, and the nano-modified polyaniline is a fibrous core-shell structured attapulgite-polyaniline composite material. The preparation method of the coating comprises the following steps: uniformly mixing the silicate adhesive, the acrylic emulsion, the wetting dispersant and the antifoaming agent to obtain the component A; and adding the component A to the component B, and uniformly mixing to obtain the anticorrosive coating. The nanometer inorganic zinc-rich composite anticorrosive coating has the advantages of strong combination force with a metal base material, salt spray resistance, scrape corrosion resistance and impact resistance, and can be used in various different situations; and the preparation method has the advantages of simplicity, good controllability, easy operation, low production cost and easy industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

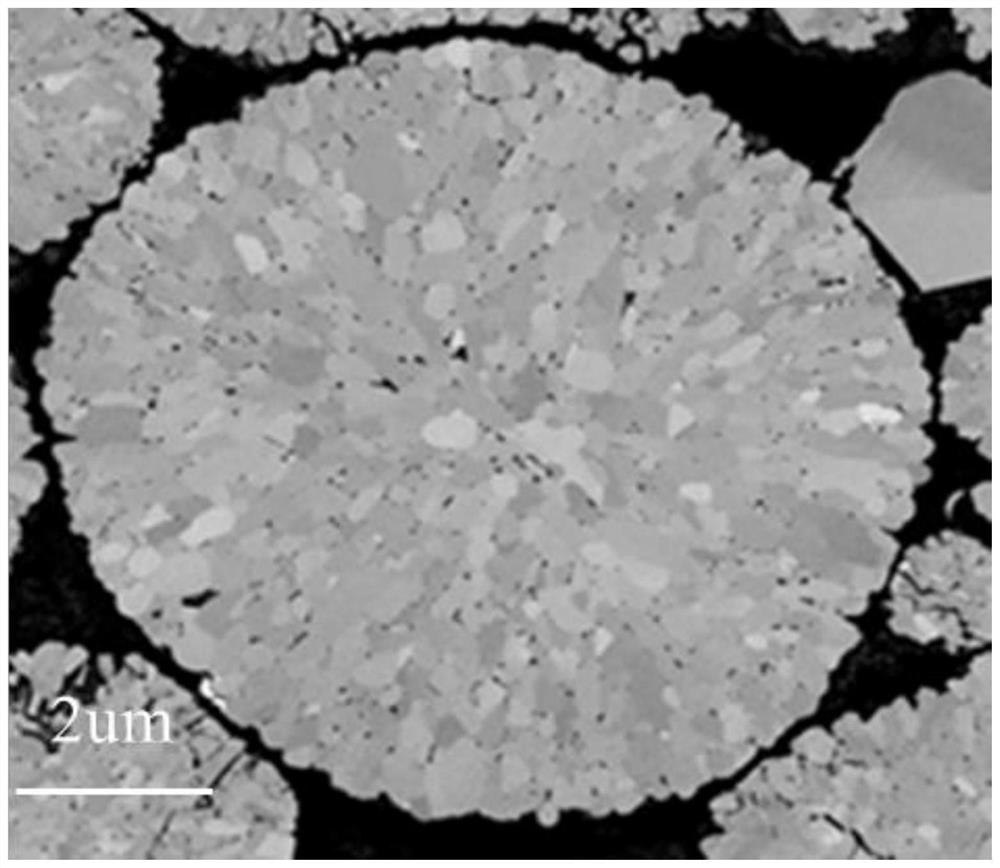

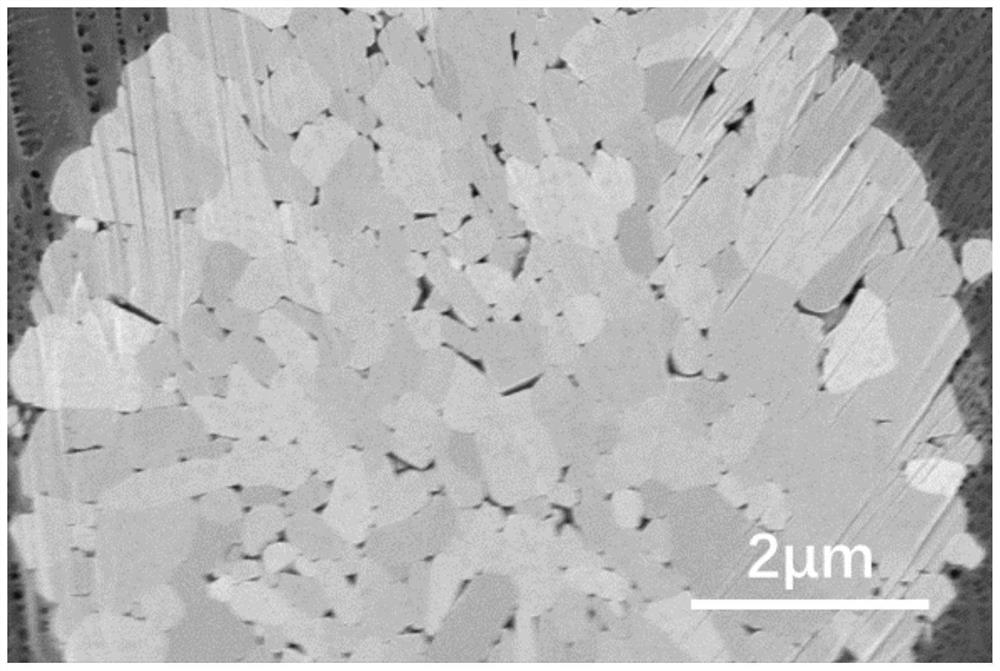

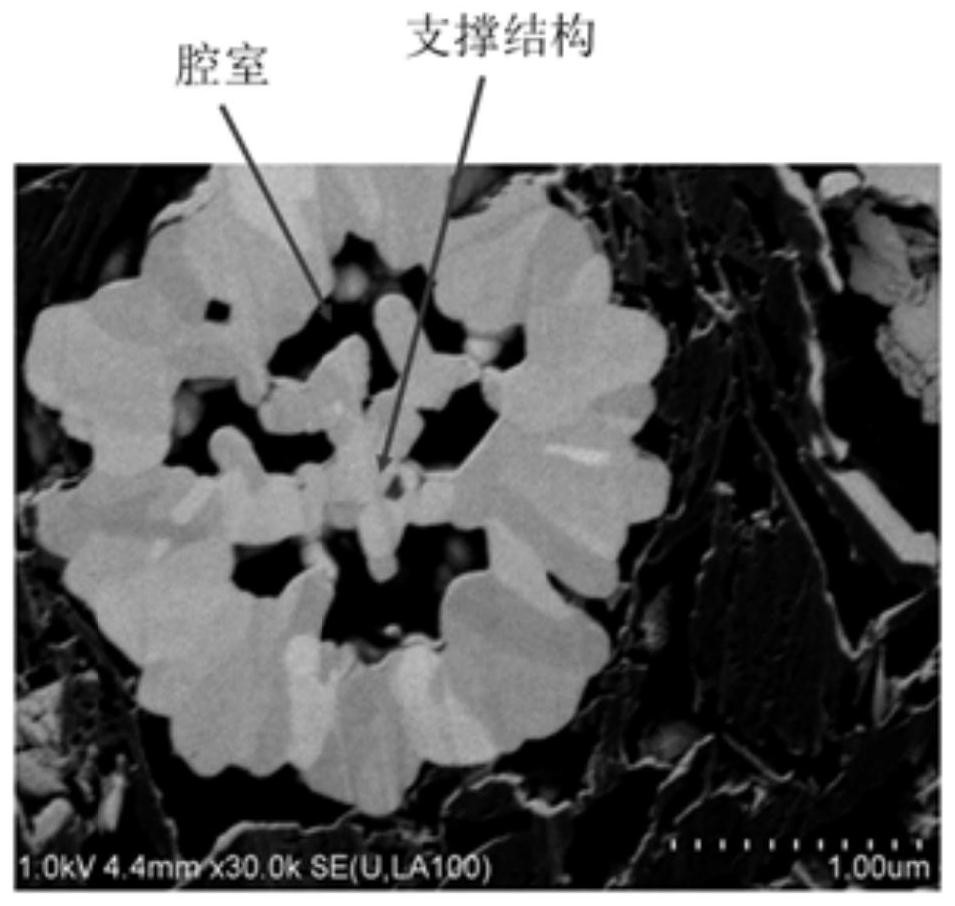

Positive electrode material with multi-cavity structure, preparation method of positive electrode material and lithium ion battery

PendingCN114678519ALower impedanceImprove power performancePositive electrodesLi-accumulatorsLithium-ion batteryBattery cell

The invention relates to the technical field of lithium ion battery positive electrode materials, and discloses a positive electrode material with a multi-cavity structure, a preparation method of the positive electrode material and a lithium ion battery. The positive electrode material is formed by gathering a plurality of primary particles, part of the primary particles grow in an oriented mode to form supporting structures, and the supporting structures are overlapped with one another to form a plurality of cavities in the positive electrode material. The particle strength of the positive electrode material is remarkably improved, so that the positive electrode material has the advantage of long service life; in addition, the impedance of the positive electrode material is reduced, so that the power performance of the positive electrode material is improved.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Cement concrete additive for repairing cement concrete road

InactiveCN101134650AReduced shrinkage performanceHigh impermeability levelSolid waste managementRebarSlag

The present invention relates to one kind of cement concrete admixture for repairing cement concrete road. The cement concrete admixture consists of industrial slag 70-80 wt%, bentonite 10-15 wt% and silica powder 8-15 wt%, and is produced through mixing the materials and grinding to specific surface area greater than 500 sq m / kg. It is added into cement concrete, with the weight ratio between cement and the admixture being 1 to 0.025-0.035. It has the features of high early strength, slight early expansion, no after shrinkage, anticracking and antiseepage, no corrosion to reinforcing bar, etc. It is especially suitable for use in the repair engineering of cement concrete road, bridge, culvert, tunnel, etc.

Owner:邬桂林

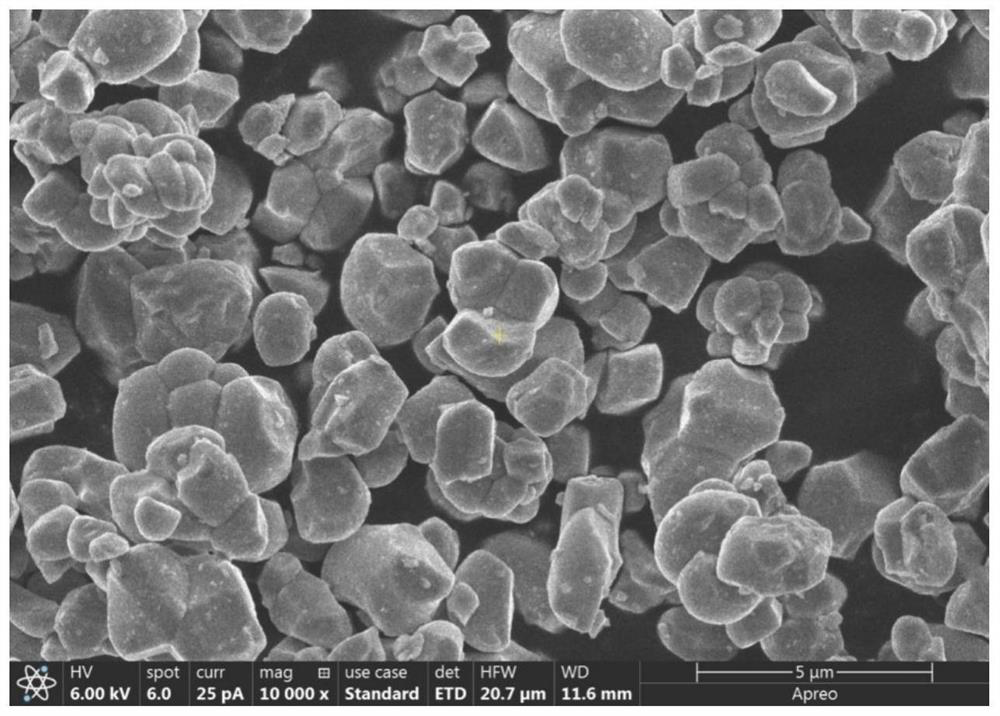

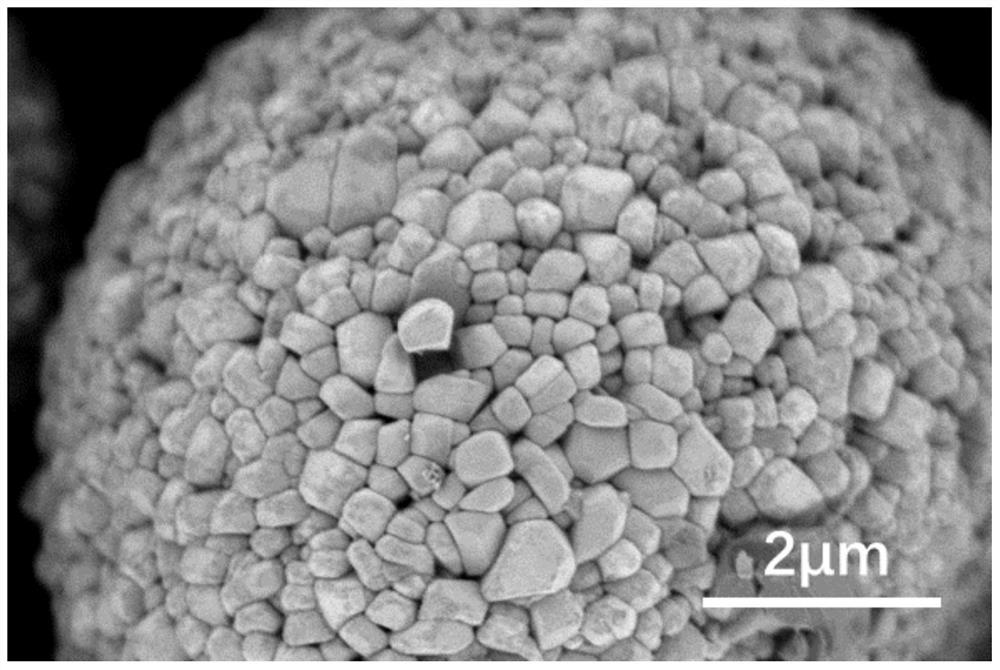

Nickel-cobalt-boron precursor material, preparation method and nickel-cobalt-boron positive electrode material

ActiveCN114105156AImprove cycle performanceInhibition of microcracksSecondary cellsPositive electrodesElectrically conductiveIndium

The invention belongs to the technical field of lithium ion battery materials, and discloses a nickel-cobalt-boron precursor material, a nickel-cobalt-boron positive electrode material and a preparation method. The chemical formula of the nickel-cobalt-boron precursor material is NixCoyBz (OH) 2, and the surface energy of the (003) crystal face of the precursor material is calculated to be 1.1-2.5 J / m < 2 > by using CASTEP software. In the process of preparing the nickel-cobalt-boron precursor material through coprecipitation, the temperature of a reaction system is controlled to be 30-90 DEG C, the pH value is 11-12.8, the concentration of a complexing agent is 5-8 g / L, the stirring speed is 300-450 rmp, and the solid content is 150-400 g / L. The nickel-cobalt-boron precursor material is mixed with lithium and calcined to obtain the positive electrode material, and the positive electrode material can be further coated with an indium coating with conductive ions. The positive electrode material prepared by the method is excellent in electrochemical performance.

Owner:ZHUJI PAWA NEW ENERGY

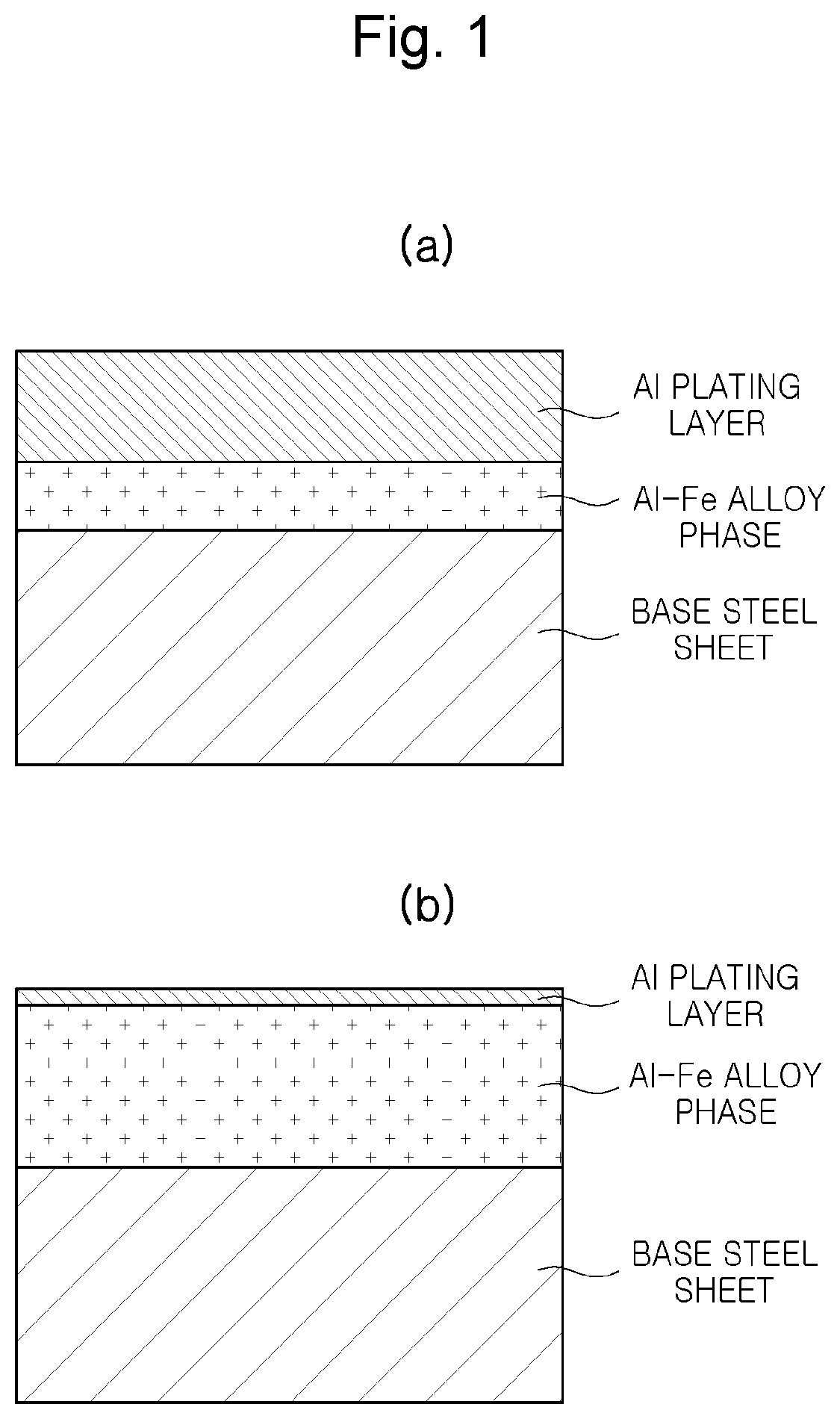

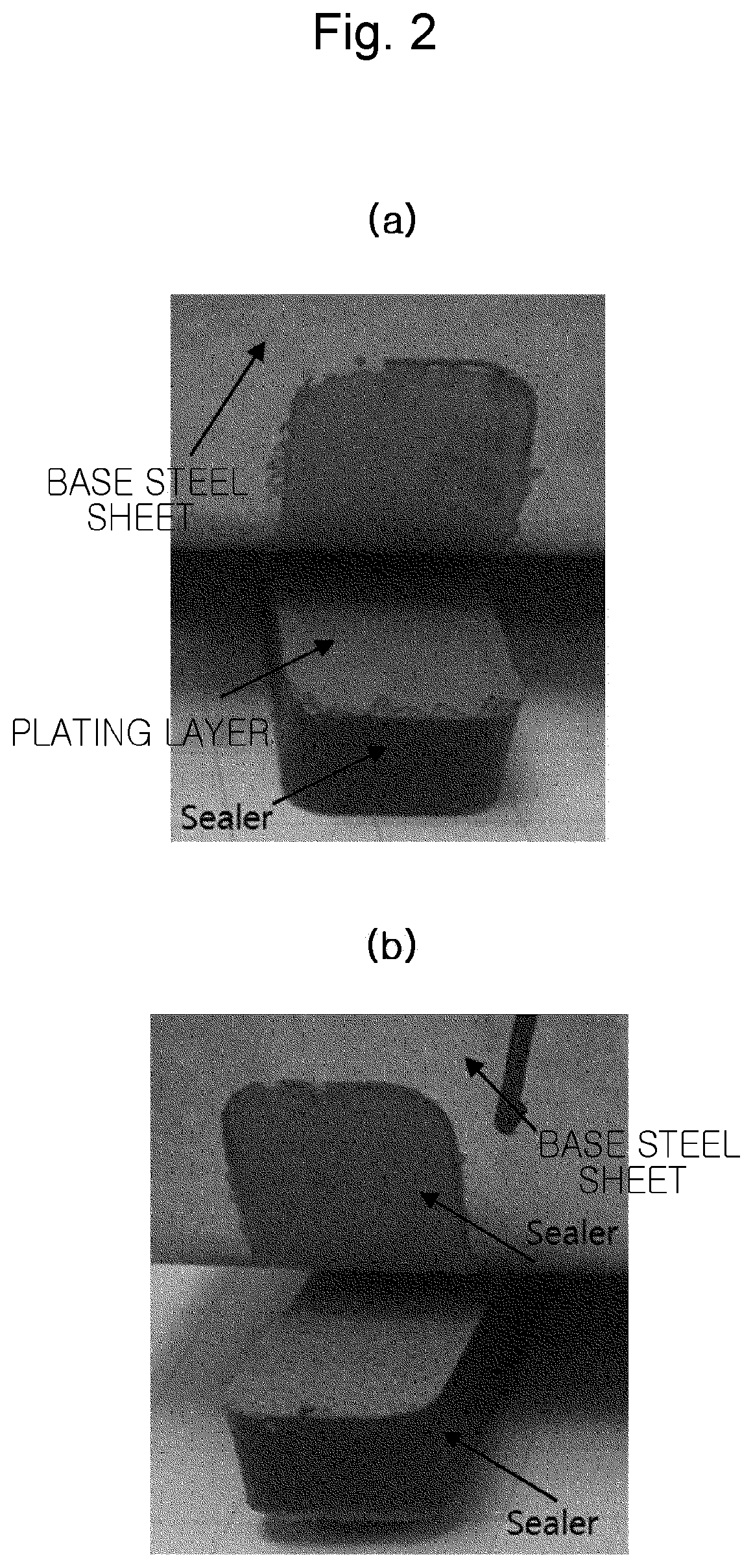

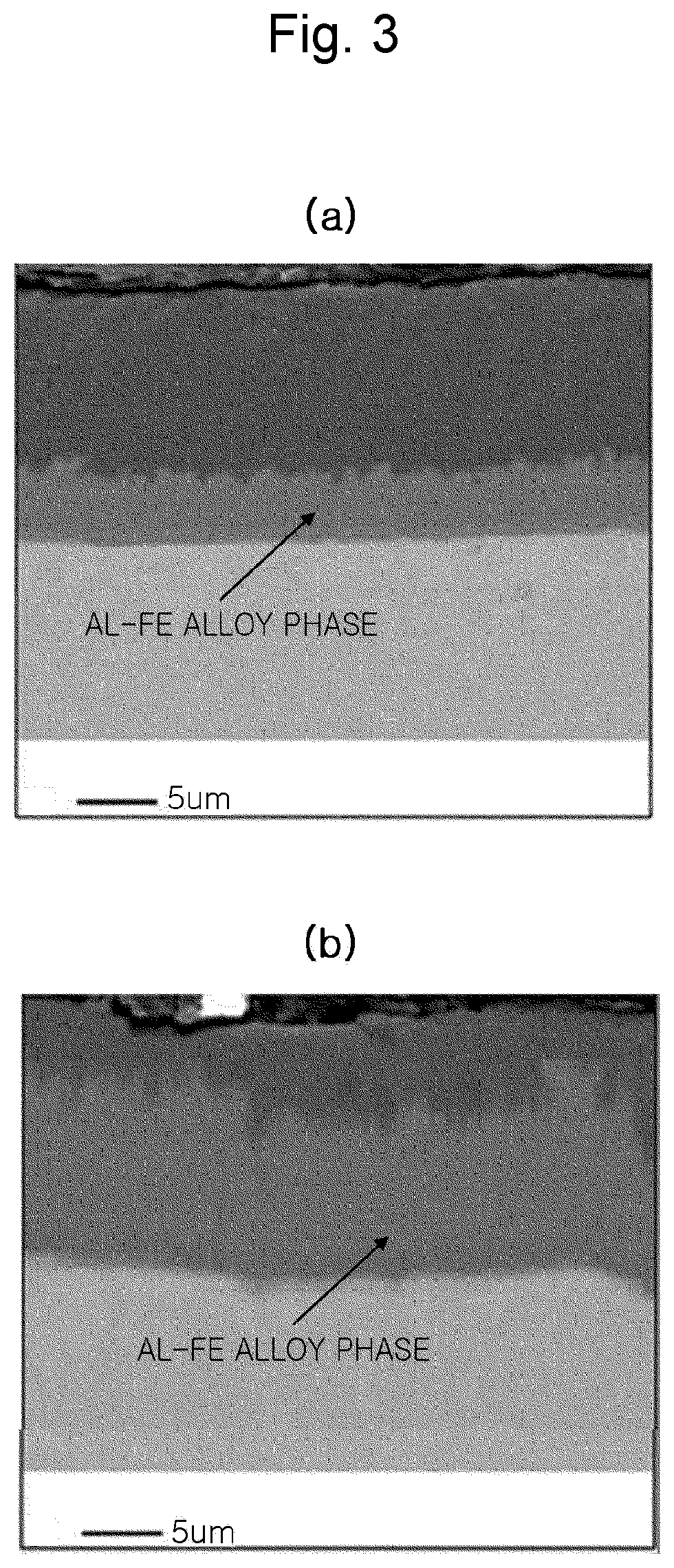

Aluminum-zinc alloy plated steel sheet having excellent hot workability and corrosion resistance, and method for manufacturing same

PendingUS20210348257A1Inhibition of microcracksImprove corrosion resistanceHot-dipping/immersion processesSuperimposed coating processAlcladZinc alloys

Provided are an aluminum-zinc alloy plated steel sheet having excellent hot workability and corrosion resistance, and a method for manufacturing same. The plated steel sheet has an Al—Zn hot-dip aluminized coating layer on a base steel sheet, wherein: the coating layer is composed of a lower layer part and an upper layer part; the lower layer part comprises 40-50% of Fe, 50-60% of Al, 1% or less of Si, and other unavoidable impurities, on the basis of wt % of the lower layer part itself; the upper layer part comprises 10-30% of Zn, the balance of Al, and 0.05% or less of at least one of Cr, Mo, and Ni as an impurity, on the basis of wt % of the upper layer part itself; and the thickness of the upper layer part accounts for 30% or less of the total thickness of the coating layer.

Owner:POHANG IRON & STEEL CO LTD

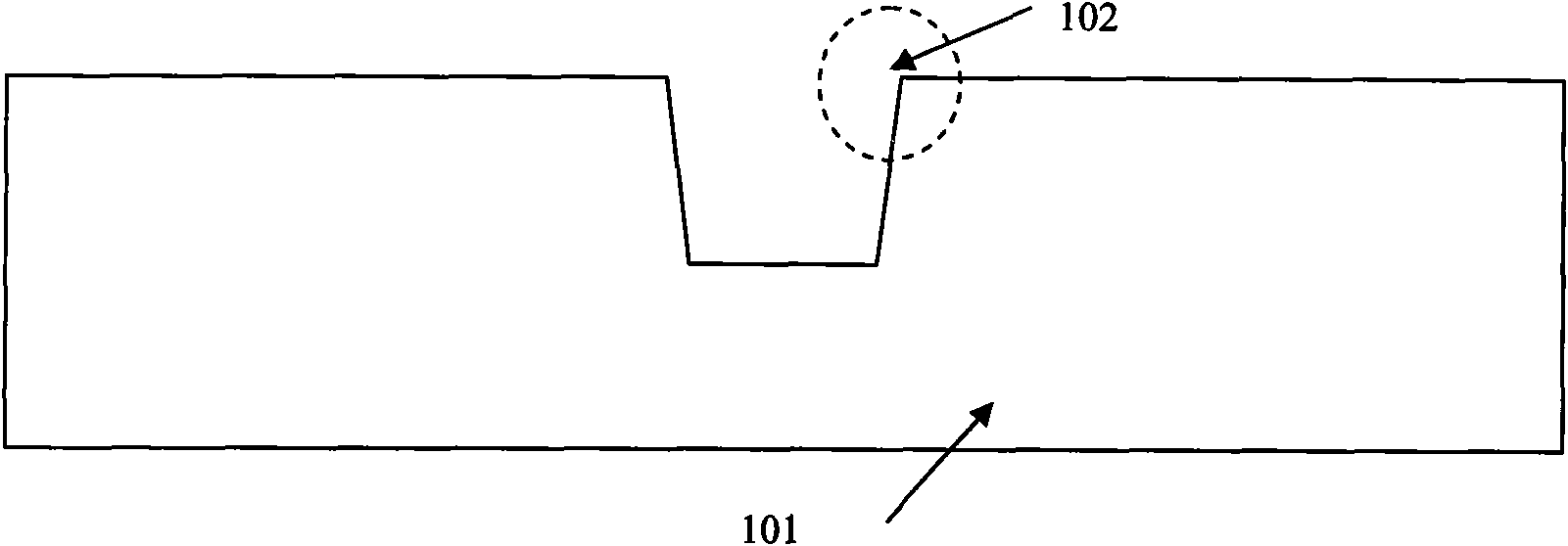

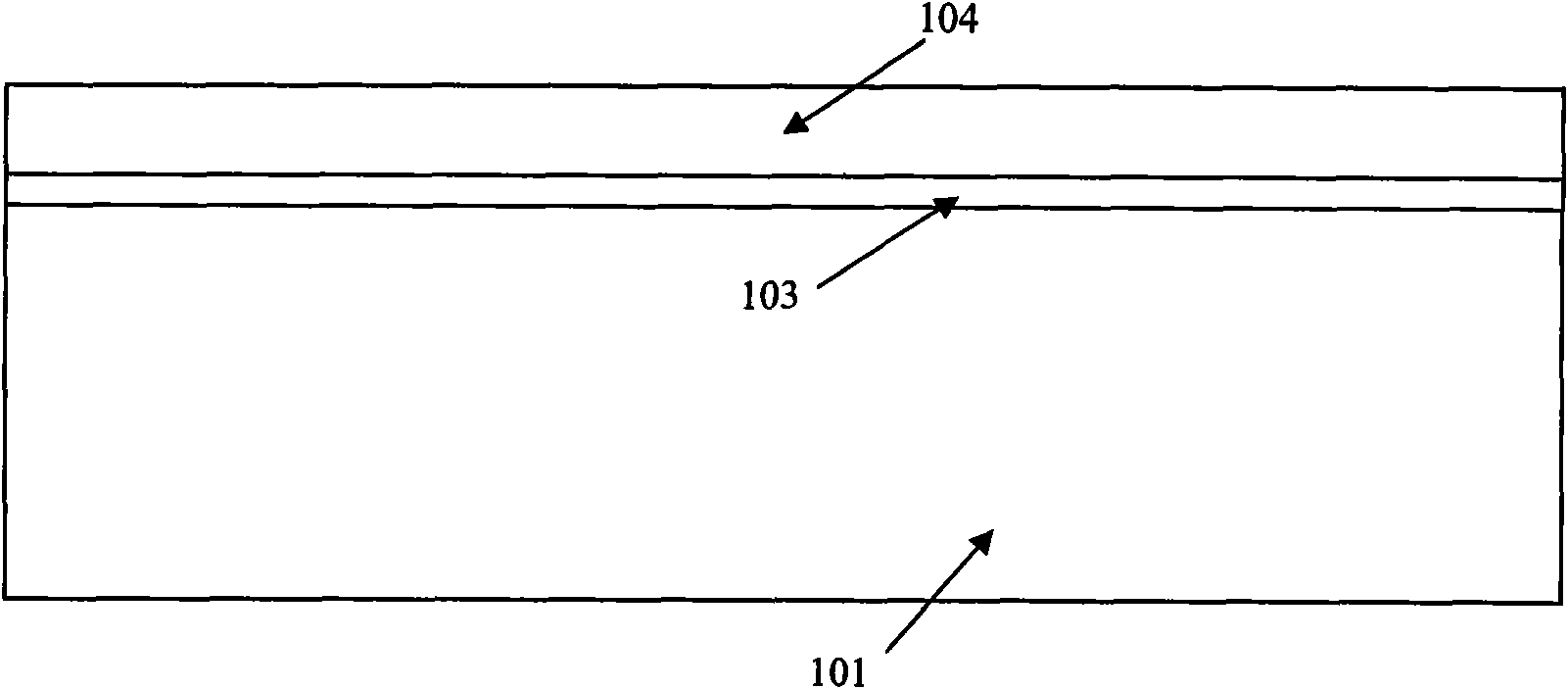

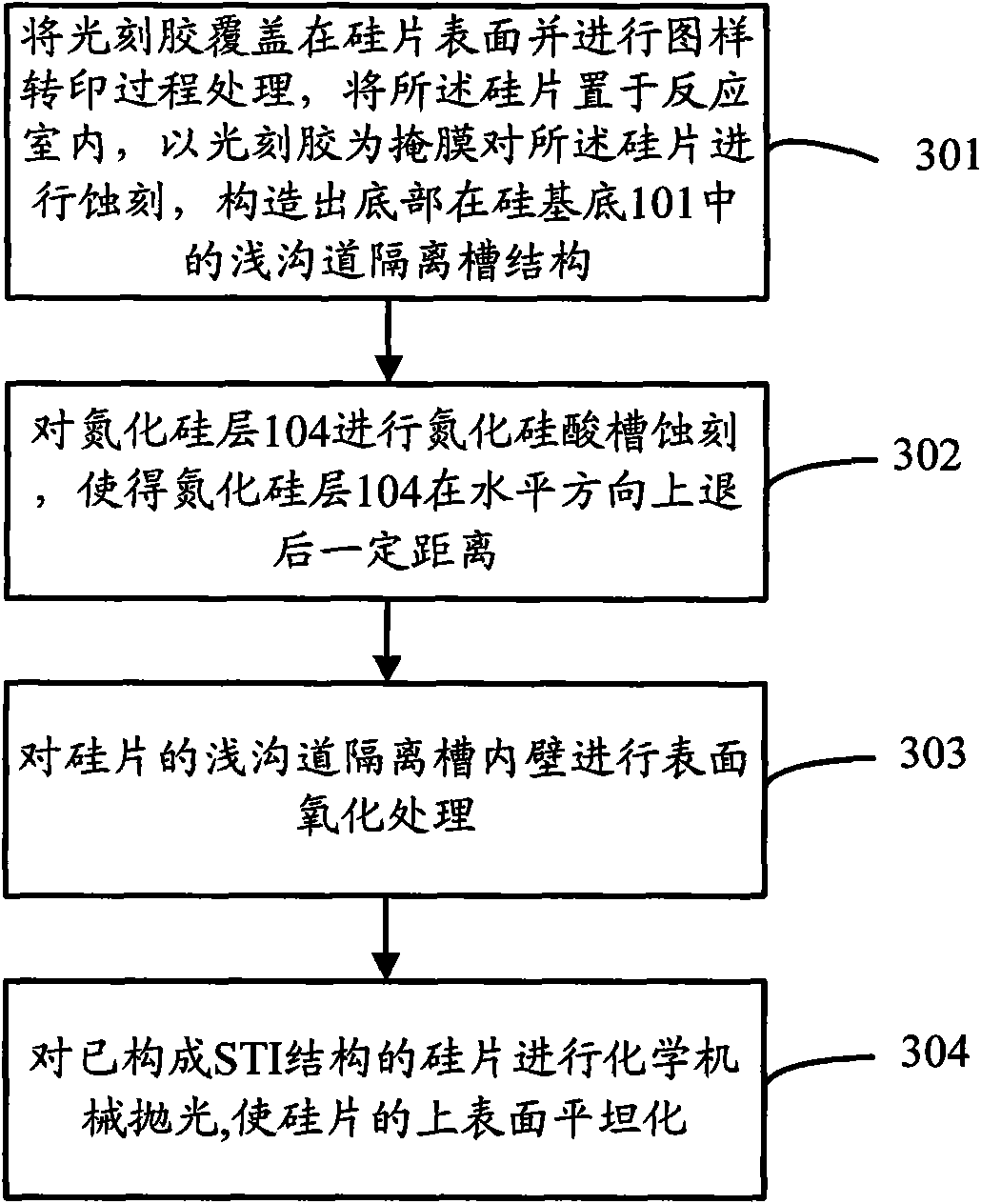

Method for overcoming defects of silicon chip with STI and method for constructing STI on silicon chip

InactiveCN101958266AEliminate internal stressInhibition of microcracksSemiconductor/solid-state device manufacturingSilicon chipPhotoresist

The invention discloses a method for overcoming defects of a silicon chip with STI (Shallow Trench Isolation). A method for constructing STI on the silicon chip comprises the following steps of: depositing a pad oxides layer (103) and a silicon nitride layer (104) on a silicon substrate (101) of the silicon chip sequentially, covering the surface of the silicon chip by using photoresist, performing pattern transferring, and etching silicon nitride, pad oxide and the silicon chip by using the photoresist as a mask to construct an STI structure of which the bottom part is positioned in the silicon substrate. The method is characterized in that: After the silicon nitride layer (104) is deposited on the silicon chip and before the surface of the silicon chip is covered by the photoresist and pattern transferring is performed, the method comprises following step of: performing first annealing on the silicon chip to remove the internal stress of the silicon. The invention also discloses other methods for overcoming the defects of silicon chip with STI and methods for constructing the STI on the silicon chip. The technical scheme can effectively remove the internal stress of the silicon chip, thereby avoiding micro cracks in corners of the STI caused by internal stress and overcoming the defects of the surface of the silicon substrate.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

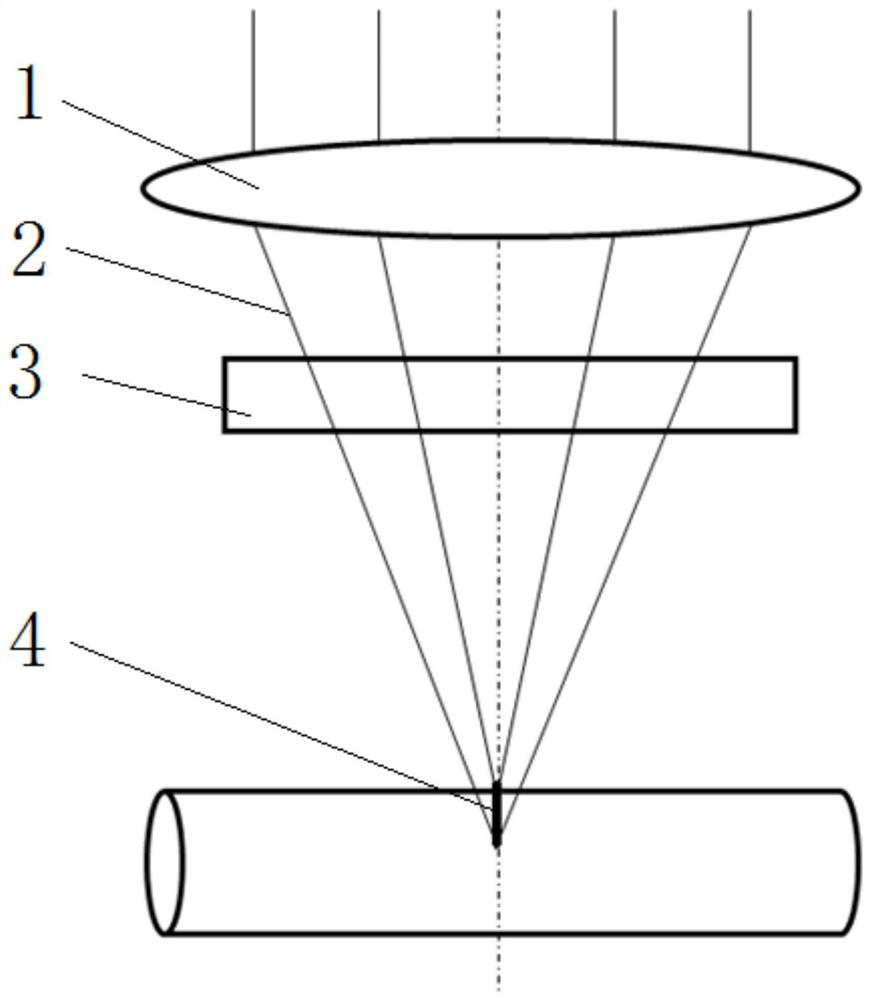

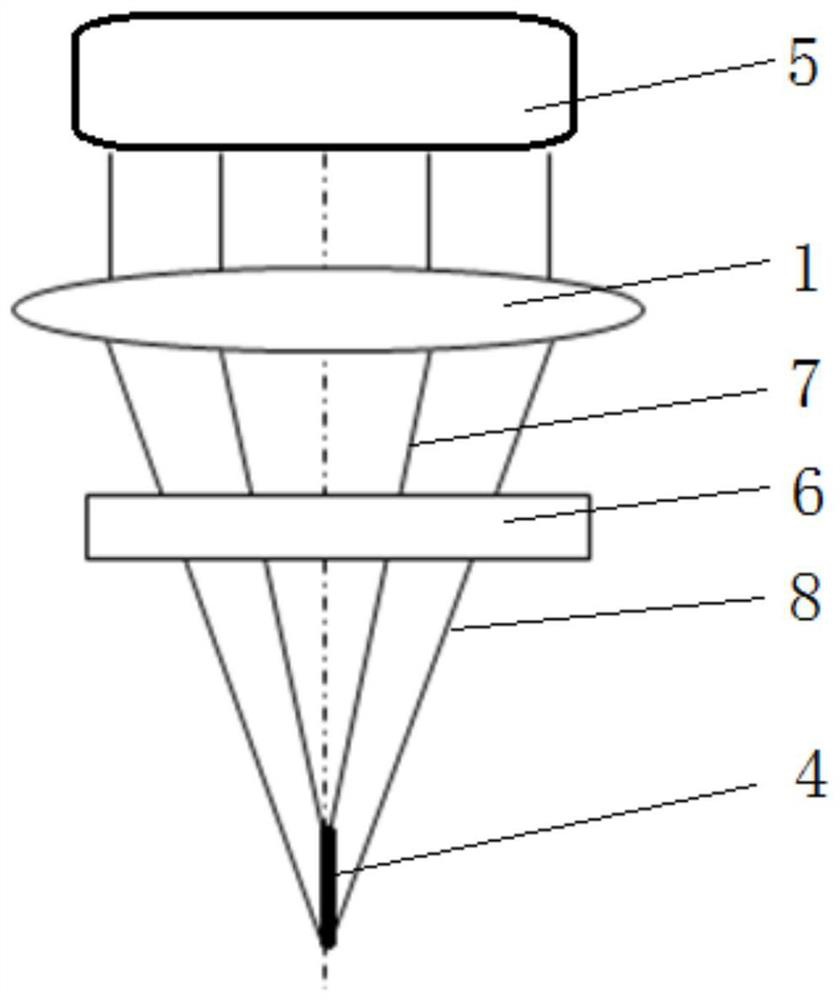

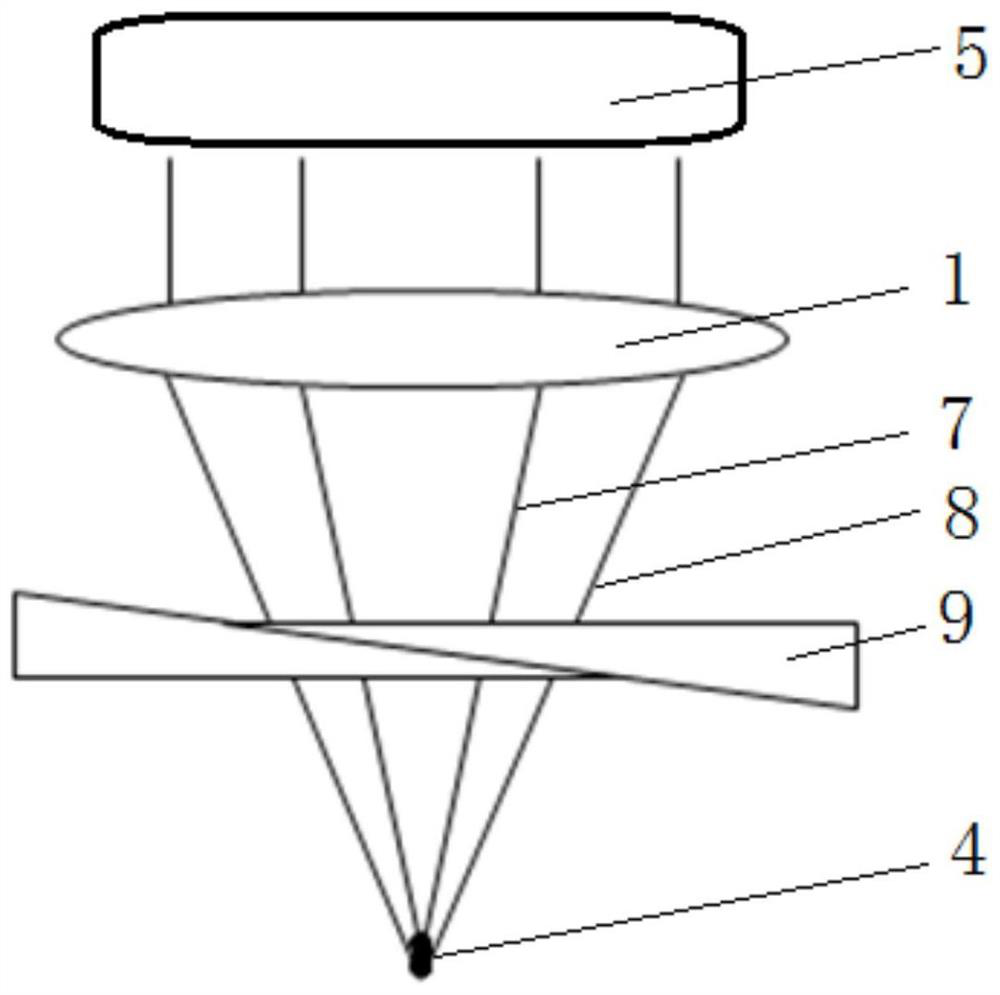

Femtosecond laser processing method and device for micro-nano structure of cladding on surface of optical fiber

ActiveCN113732511ASolve the problem of limited processing depthImprove positive correlationOptical waveguide light guideLaser beam welding apparatusMicro structureNano structuring

The invention discloses a femtosecond laser processing method and device for a micro-nano structure of a cladding on the surface of an optical fiber. According to the method, femtosecond laser passing through a focusing microscope objective passes through a spherical aberration introducer to generate spherical aberration, so that paraxial focuses and non-paraxial focuses of the femtosecond laser form a plurality of focuses separated along an optical axis, the focuses form a light filament structure, the light filament structure processes a micro structure on the surface of the optical fiber, and the size of the micro structure is between several microns and hundreds of microns. According to the method, the positive correlation between a laser focal spot and the focal depth and the nonlinear effect caused by energy distribution along the optical axis are greatly improved, so that a micro structure with a large depth-diameter ratio can be generated on the surface of the optical fiber.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Nitrogen-doped-polymerized porous nano deposition positive electrode material and preparation method and application thereof

PendingCN114256458AImprove Coulombic efficiencyShorten the migration pathSecondary cellsPositive electrodesPhysical chemistrySodium-ion battery

The invention belongs to the technical field of sodium ion batteries, and discloses a nitrogen-doped-polymerized porous nano-deposited positive electrode material and a preparation method and application thereof, the general formula of the nitrogen-doped-polymerized porous nano-deposited positive electrode material is NatLifNisZ1-sO2 (at) aNMC-Y, 0.8 < = tlt; 1, 0 < = flt; 0.3, 0.5 < = slt; 1, 0lt; a < lt >; z is at least one of Mn, Mo, Co, Mg and Al, and Y is at least one of Cu, Ga, Zn, Cr and Zr. According to the nitrogen-doped-polymerized porous nano deposited positive electrode material prepared by the invention, a plurality of layers of compact films are obtained on the surface of the NMC-Y deposited NatLifNisZ1-sO2 material, and after the nitrogen-doped-polymerized porous nano material is deposited, on one hand, the nitrogen-doped-polymerized porous nano material can contribute a considerable specific surface area; on the other hand, the migration path of ions in the material can be shortened, and the electrochemical performance is improved.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

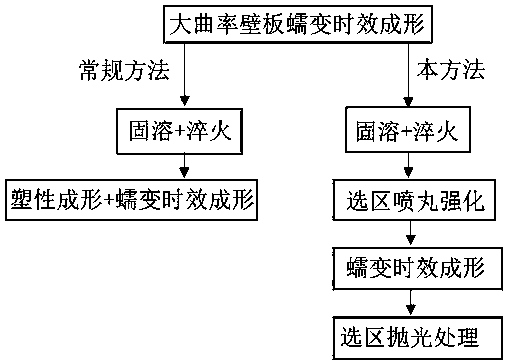

Creep aging forming method for large-curvature wallboard

ActiveCN110802220AIncrease the dislocation densityImprove instabilityFurnace typesProcess efficiency improvementPeeningMaterials science

The invention discloses a creep aging forming method for a large-curvature wallboard. The method is mainly used for increasing the creep aging forming curvature of the wallboard, improving the corrosion resistance and fatigue resistance of the large-curvature wallboard, and improving the creep aging forming efficiency. The method comprises the following steps of performing solid solution on an aluminum alloy wallboard blank at 420-520 DEG C for 1-3 hours, and performing quenching; then performing shot peening strengthening treatment on a selected area of the wallboard; then performing creep aging on the wallboard in a hot pressing tank; and finally, performing polishing treatment on the selected area of the wallboard. According to the method, the generation of microcracks during creep aging forming of the large-curvature wallboard can be effectively avoided, the precipitation efficiency of reinforced phases is promoted, the corrosion resistance and fatigue resistance of the wallboard are enhanced, the creep aging forming curvature of the wallboard is increased, and the application range of the creep aging forming process is improved.

Owner:SUZHOU UNIV OF SCI & TECH

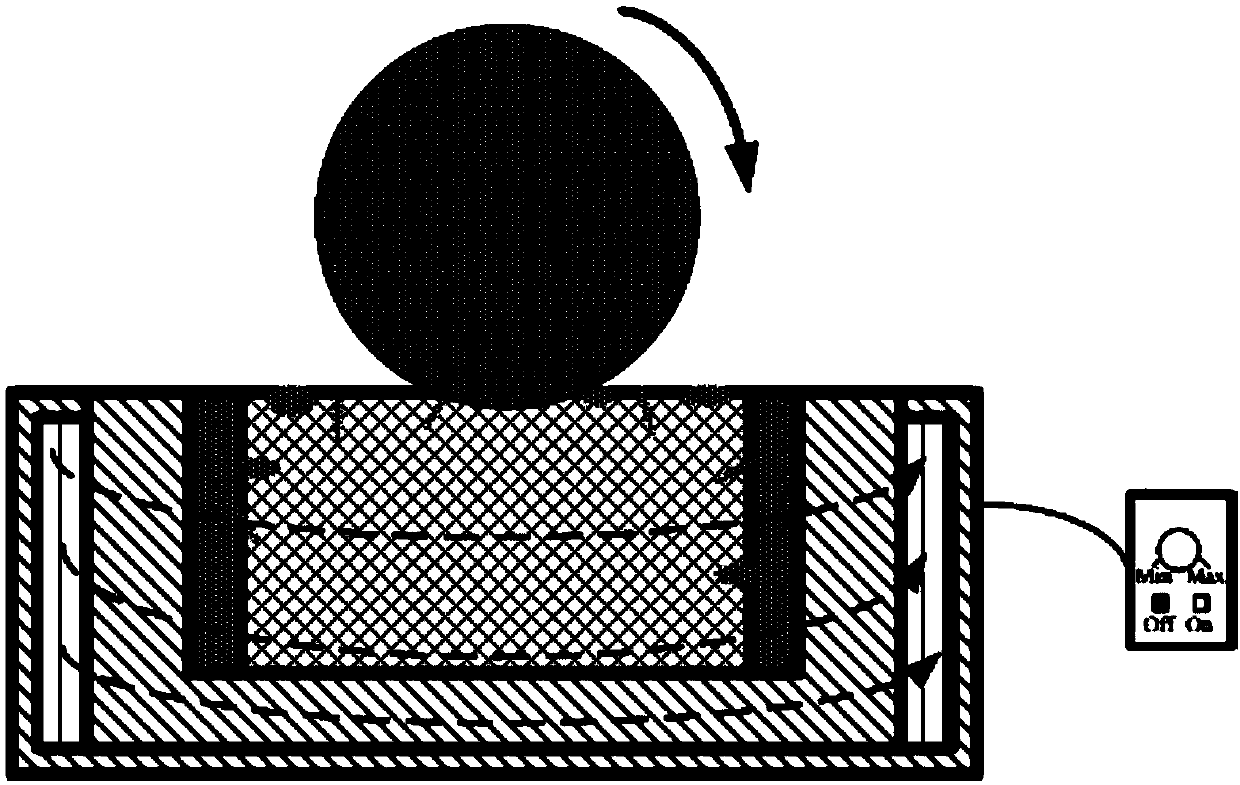

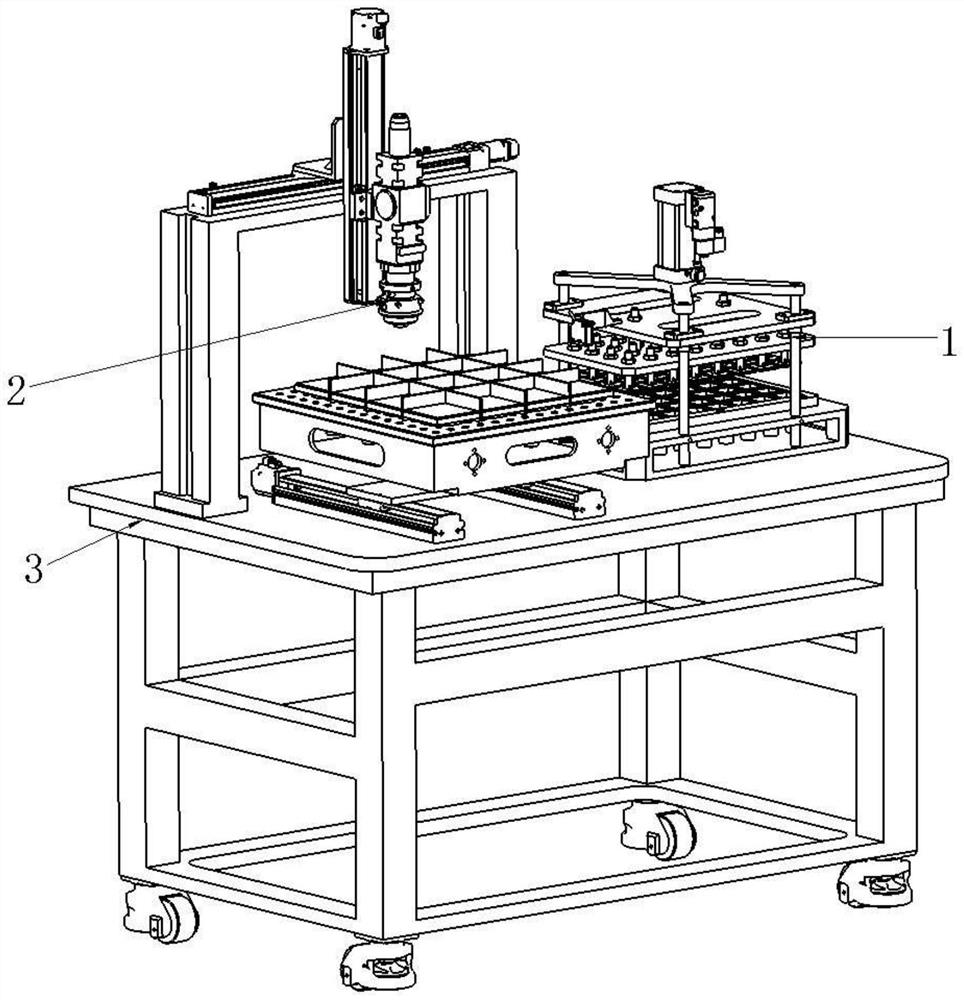

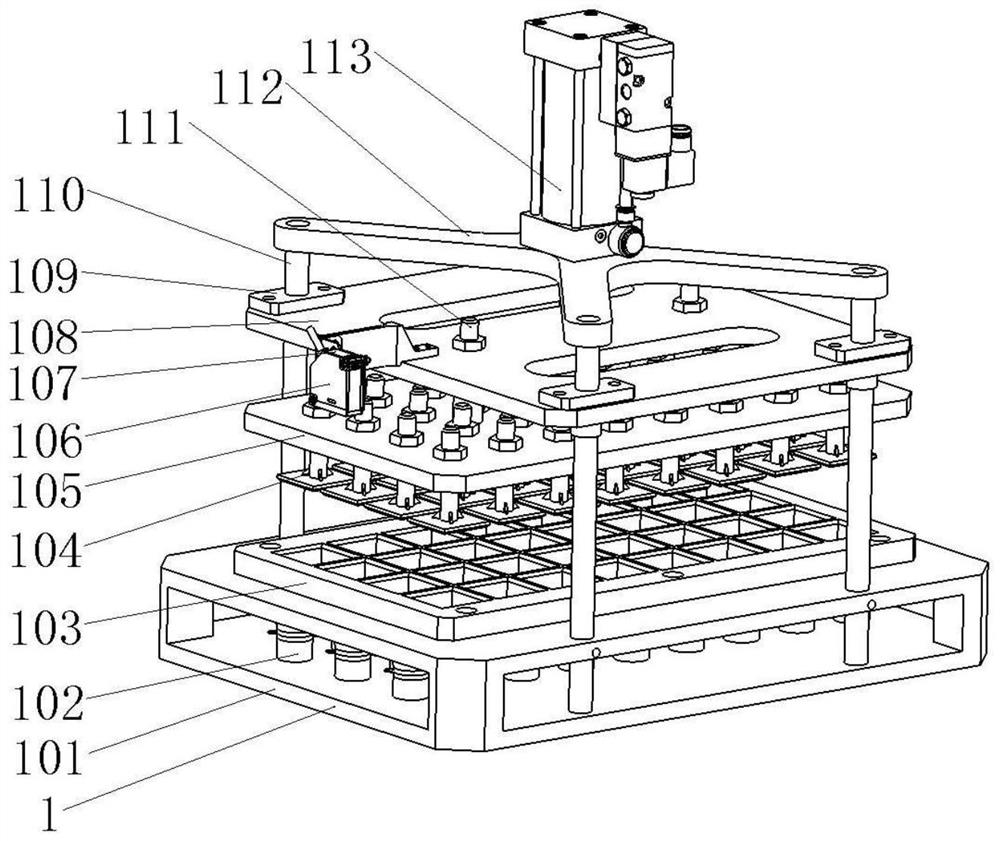

Ultrasonic-assisted laser micro-cladding method and device for gradient functional composite material

PendingCN114799182AImprove thermal conductivityFlat surfaceAdditive manufacturing apparatusMetallic material coating processesGradient materialGraphite

The invention provides an ultrasonic-assisted laser micro-cladding device for a gradient functional composite material. The ultrasonic-assisted laser micro-cladding device comprises a rack, a preset piece sample preparation assembly and an ultrasonic-assisted laser micro-cladding assembly, wherein the preset piece sample preparation assembly and the ultrasonic-assisted laser micro-cladding assembly are installed on the rack. The ultrasonic-assisted laser micro-cladding assembly comprises a laser micro-cladding head assembly and an ultrasonic-assisted workbench assembly. The invention also provides an ultrasonic-assisted laser micro-cladding method for the functional gradient composite material, which comprises the following steps: in the early stage of implementation, according to the gradient material theory, preparing a preset sheet sample through the procedures of controlling the component proportion of the copper-based composite material, performing a wet ball milling process, performing ultrasonic-assisted processing on the preset sheet, performing vacuum drying and demolding and the like; and then preparing the preset sheet sample into the graphene / copper-based gradient functional composite coating through a multi-channel and multi-layer processing mode under the action of a composite energy field based on an ultrasonic-assisted laser micro-cladding process. According to the method, the high-quality gradient functional composite coating can be formed in a metallurgical bonding mode through the laser micro-cladding technology.

Owner:WENZHOU POLYTECHNIC

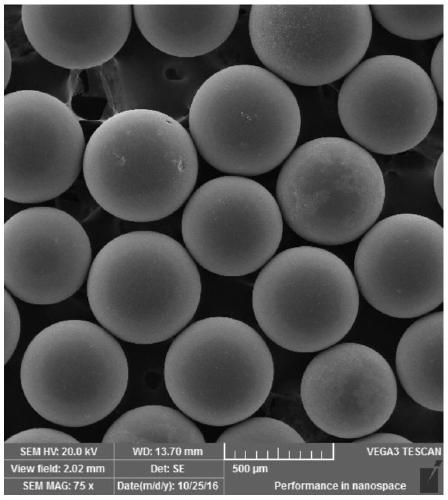

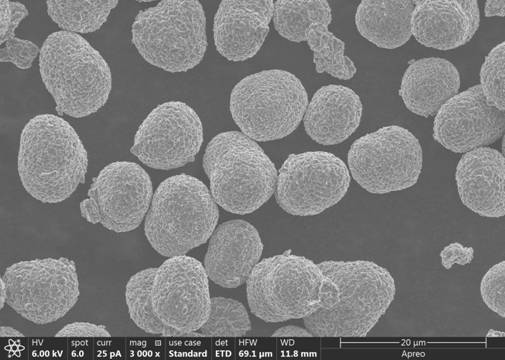

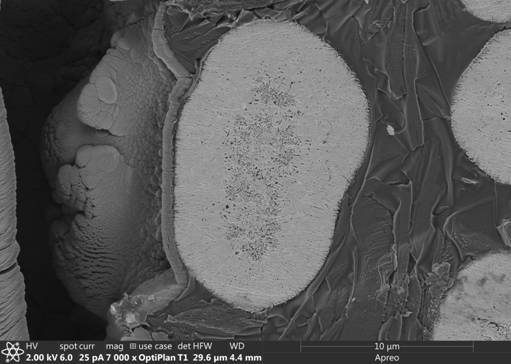

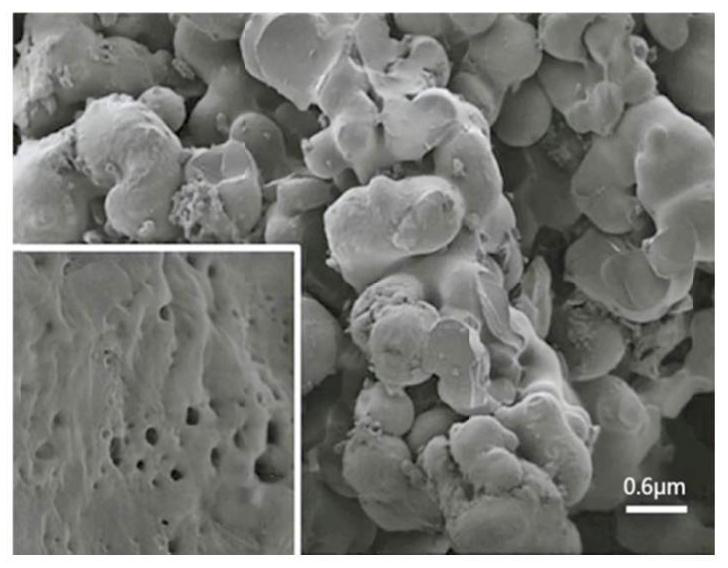

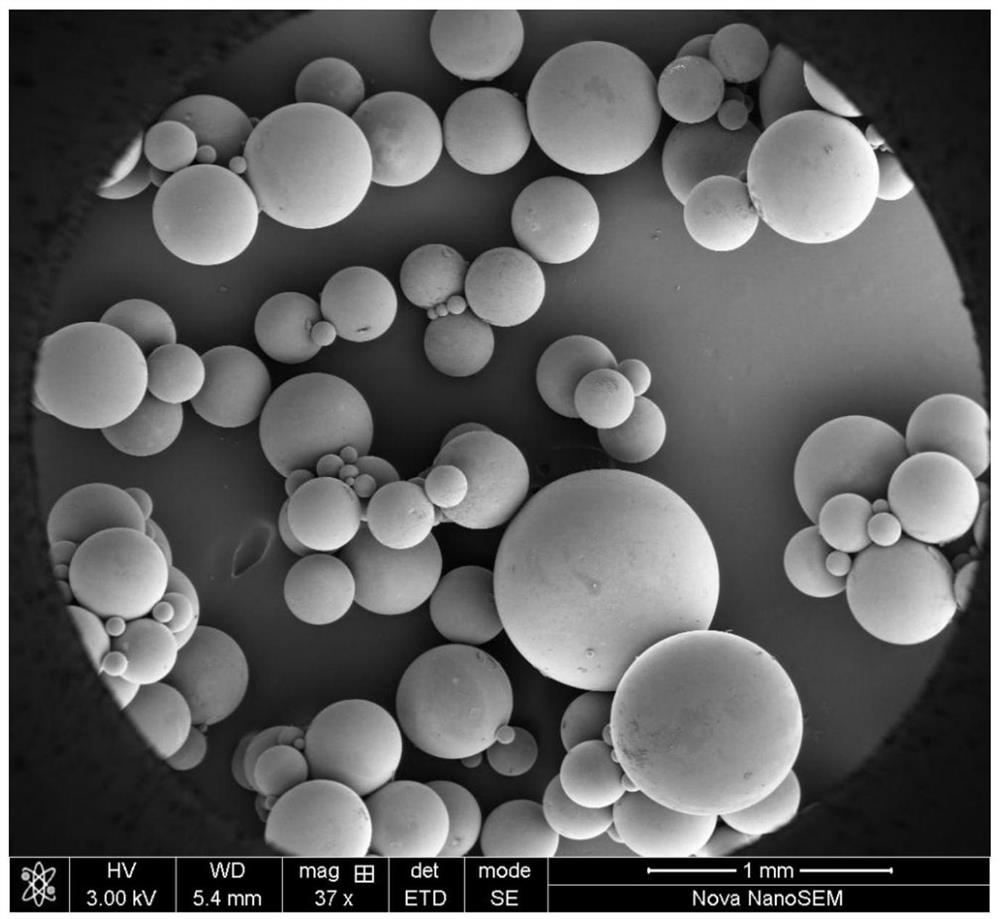

Preparation method of polystyrene resin-based spherical activated carbon

ActiveCN113443625AInhibition of microcracksReduce addCarbon compoundsActivated carbonPolymer science

The invention discloses a preparation method of high-strength spherical activated carbon, which is characterized by comprising the following steps: by taking styrene, a cross-linking agent, an initiator, a surfactant and deionized water as raw materials, carrying out copolymerization reaction to prepare polystyrene resin balls, wherein the mass ratio of the styrene to the cross-linking agent to the initiator to the surfactant is (20-30%):(10-20%):(0.05-0.5%):(0.5-1.5%), the balance is deionized water, and the total amount of the raw materials is 100%; and carrying out vacuum drying, oxidation non-melting treatment and carbonization treatment to obtain the polystyrene resin-based spherical activated carbon. The preparation process of the polystyrene resin ball activated carbon is an activation process without a pore-forming agent and without water vapor or carbon dioxide. The invention provides the novel preparation method for low-cost and high-strength spherical activated carbon, and also provides a novel way for application of styrene.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com