Method for controlling surface micro crack of pitch-based spherical activated carbon

A technology of spherical activated carbon and control method, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of refined naphthalene escape, micro-cracks of naphthalene-containing pitch balls, micro-cracks of porous pitch balls, etc. The effect of improving mechanical properties, inhibiting surface micro-cracks, and avoiding micro-cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

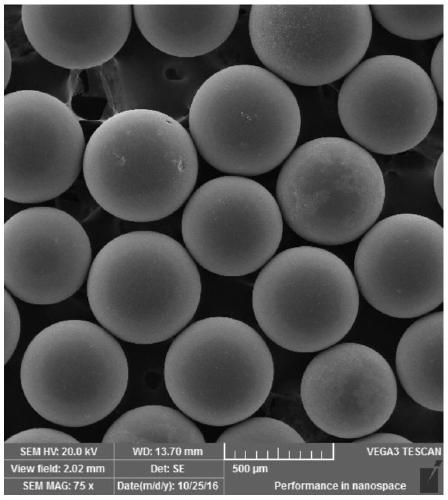

[0048] Using high softening point coal tar pitch with a softening point of 268°C as raw material, use a twin-screw extruder to uniformly mix 1000Kg of high softening point coal tar pitch and 250Kg of refined naphthalene to make naphthalene pitch strips with a diameter of 3mm. Using a roller crusher, crush 1250Kg of naphthalene pitch-containing strips into naphthalene pitch-containing particles with a diameter of 0.6-0.8 mm. 3000L of deionized water, 20Kg of polyvinyl alcohol, and 500Kg of naphthalene pitch-containing particles were successively placed in a 5000L high-pressure reactor, and 99.99% high-purity nitrogen gas was introduced to keep the pressure in the reactor at 0.5 MPa. Then the reaction medium was heated to 109°C at a heating rate of 5°C / min and kept at a constant temperature for 30 minutes, and then naturally cooled to 50°C. Although the obtained product is a naphthalene-pitch ball with a diameter of 0.6-0.8 mm, there are certain microcracks on the surface, such ...

Embodiment 2

[0050] Using high softening point coal tar pitch with a softening point of 268°C as raw material, use twin-screw extruder to uniformly mix 1000Kg high softening point coal tar pitch and 250Kg refined naphthalene to make naphthalene pitch strips with a diameter of 3mm. Using a roller crusher, crush 1250Kg of naphthalene pitch-containing strips into naphthalene pitch-containing particles with a diameter of 0.6-0.8 mm. 3000L of deionized water, 20Kg of polyvinyl alcohol, 5Kg of refined naphthalene, and 500Kg of naphthalene-containing pitch particles were successively placed in a 5000L high-pressure reactor, and 99.99% high-purity nitrogen gas was introduced to keep the pressure in the reactor at 0.5MPa. Then the reaction medium was heated to 109°C at a heating rate of 5°C / min and kept at a constant temperature for 30 minutes, and then naturally cooled to 50°C. The resulting product is a naphthalene pitch-containing ball with a diameter of 0.6 to 0.8 mm, but the surface of the nap...

Embodiment 3

[0052] Place the naphthalene pitch-containing balls prepared in [Example 2] in a blast oven and dry at 60°C for 2 hours. Before drying, the surface of naphthalene pitch-containing spheres was smooth, but after drying, although the macroscopic morphology of naphthalene pitch-containing spheres did not change, slight microcracks appeared on the surface, such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com