Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Eliminate the extraction process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

River and lake bottom sludge pollutant flux test method and device based on diffusion theory

ActiveCN102590479AWide applicabilityThe concentration of pollutants does not need to be testedEarth material testingTesting waterSludgeSample water

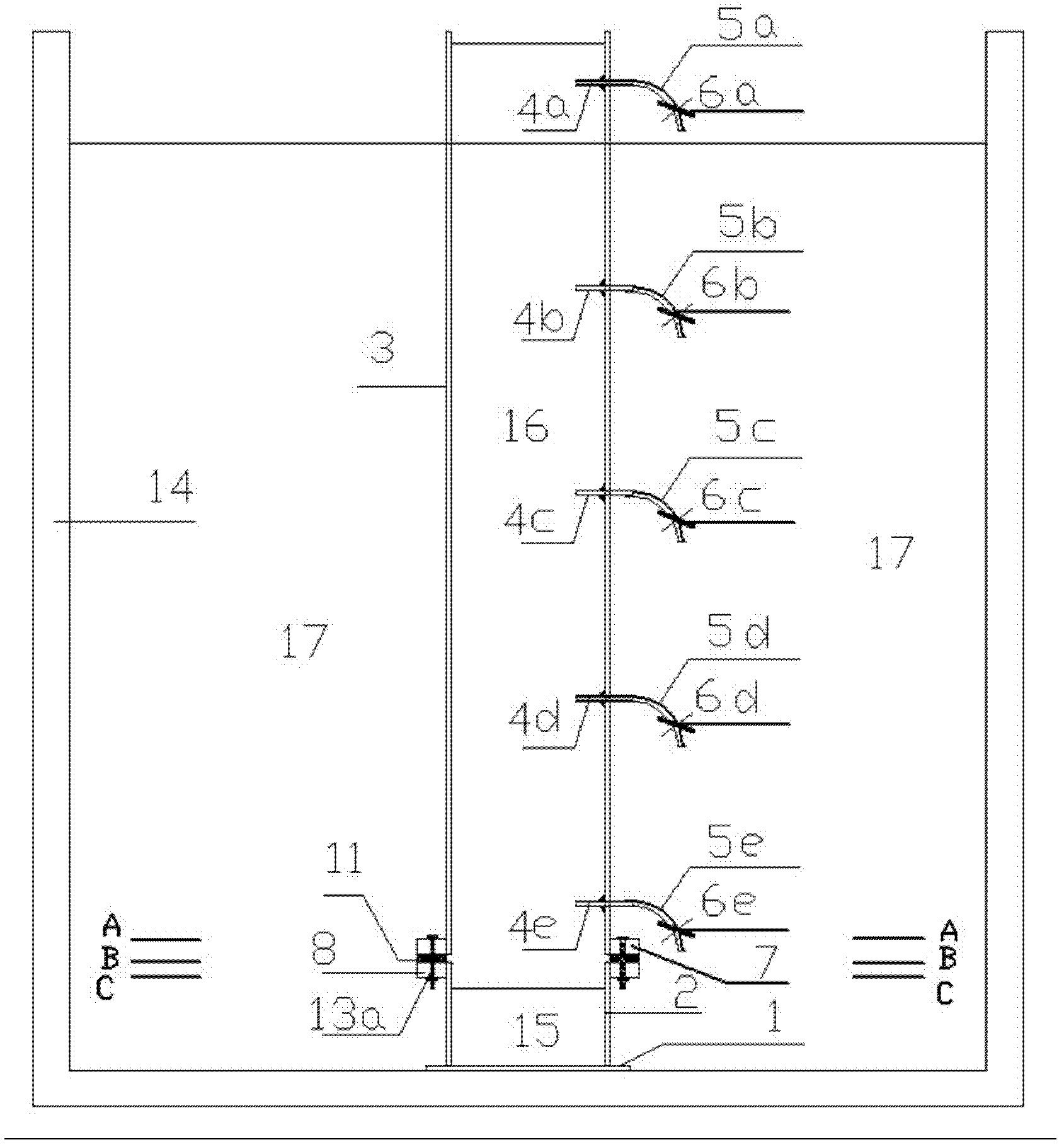

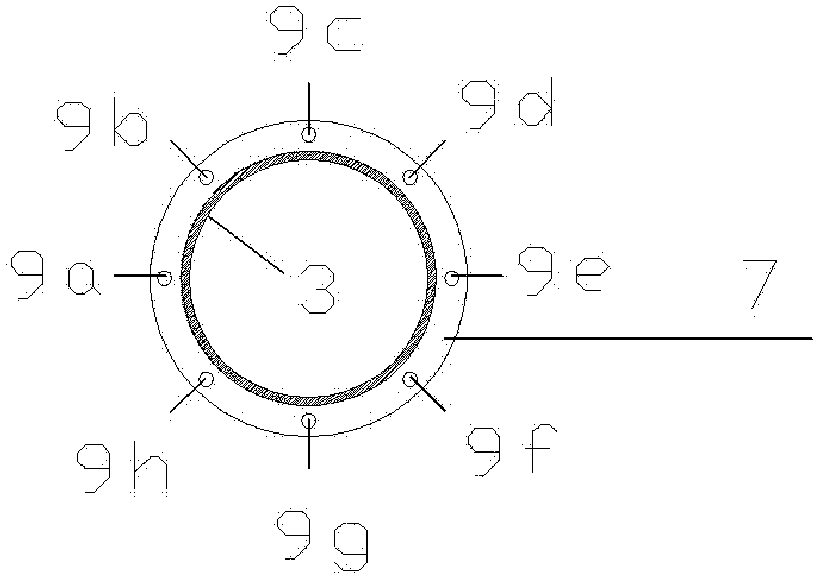

The invention discloses a river and lake bottom sludge pollutant flux test method and a river and a device based on a diffusion theory. The method comprises the following steps of: A, acquiring a bottom sludge sample; B, putting the bottom sludge into a base of an experimental device, and enabling the sludge surface to be horizontal; C, slowly injecting water to a column port along a column wall; D, injecting running water into the experimental device without the bottom sludge; E, standing for a certain time; F, measuring the pollutant concentration of the taken water sample; G, calculating a degrading coefficient of the pollutant in the water; H, calculating an initial concentration value of the bottom sludge water; and I, calculating a pollutant exchange flux of a water-sludge interface. A base plate is fixed at the bottom of a constant-temperature water tank; a base wall is arranged on the base plate; a lower flange disk is arranged on the upper part of the base wall; an upper flange disk is arranged at one end of a column body; and an upper flange disk fixing bolt flange hole is formed in the upper flange disk. The method is feasible, and is convenient to operate; the experimental device has a rational and simple structure; operations of accommodating deposits, sampling water samples and the like are extremely convenient; and outstanding economic benefit is achieved.

Owner:WUHAN UNIV

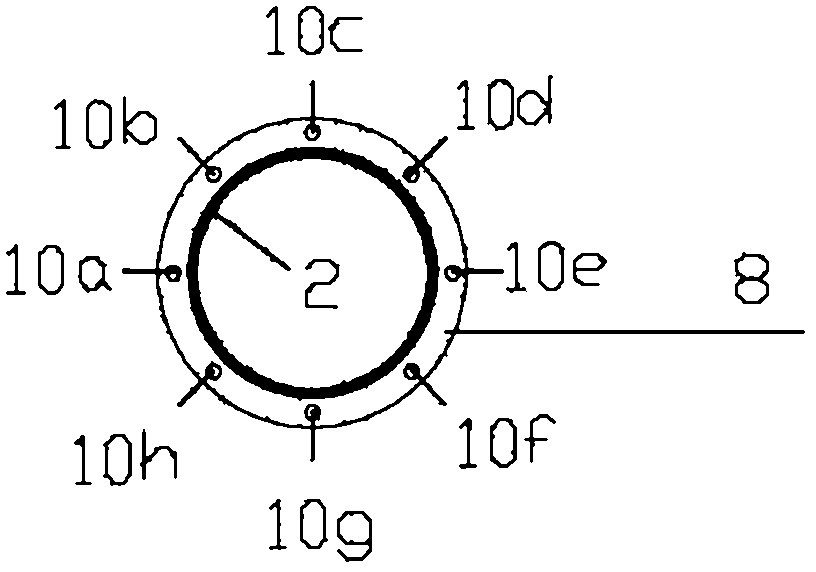

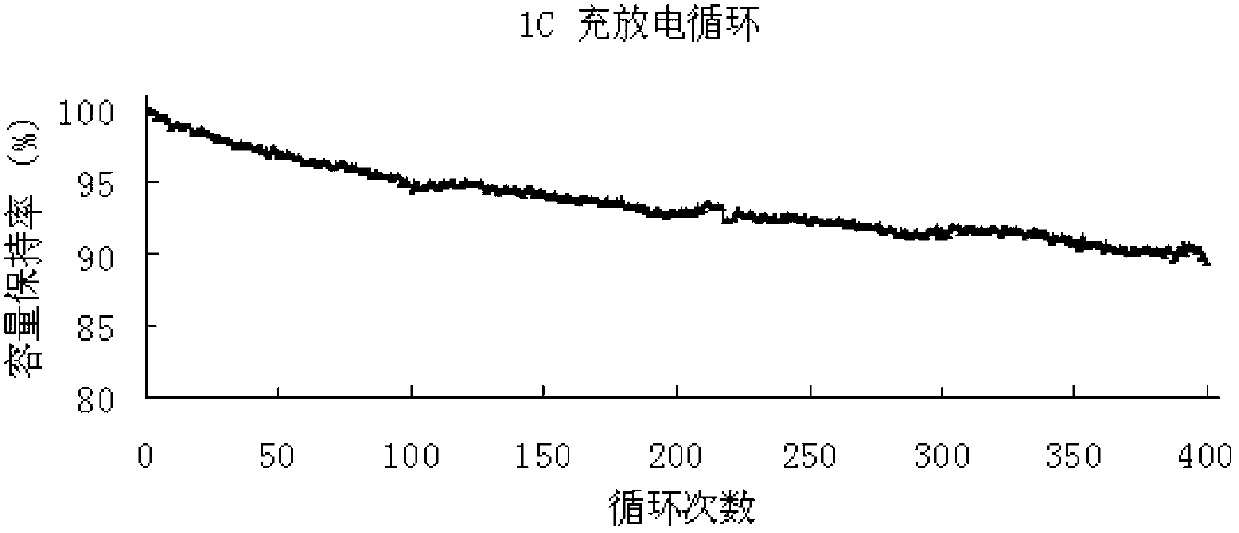

Polymer lithium ion battery and preparation method of diaphragm thereof

ActiveCN101662042AImprove performanceHigh liquid absorptionFinal product manufactureSecondary cellsPolyolefinPole piece

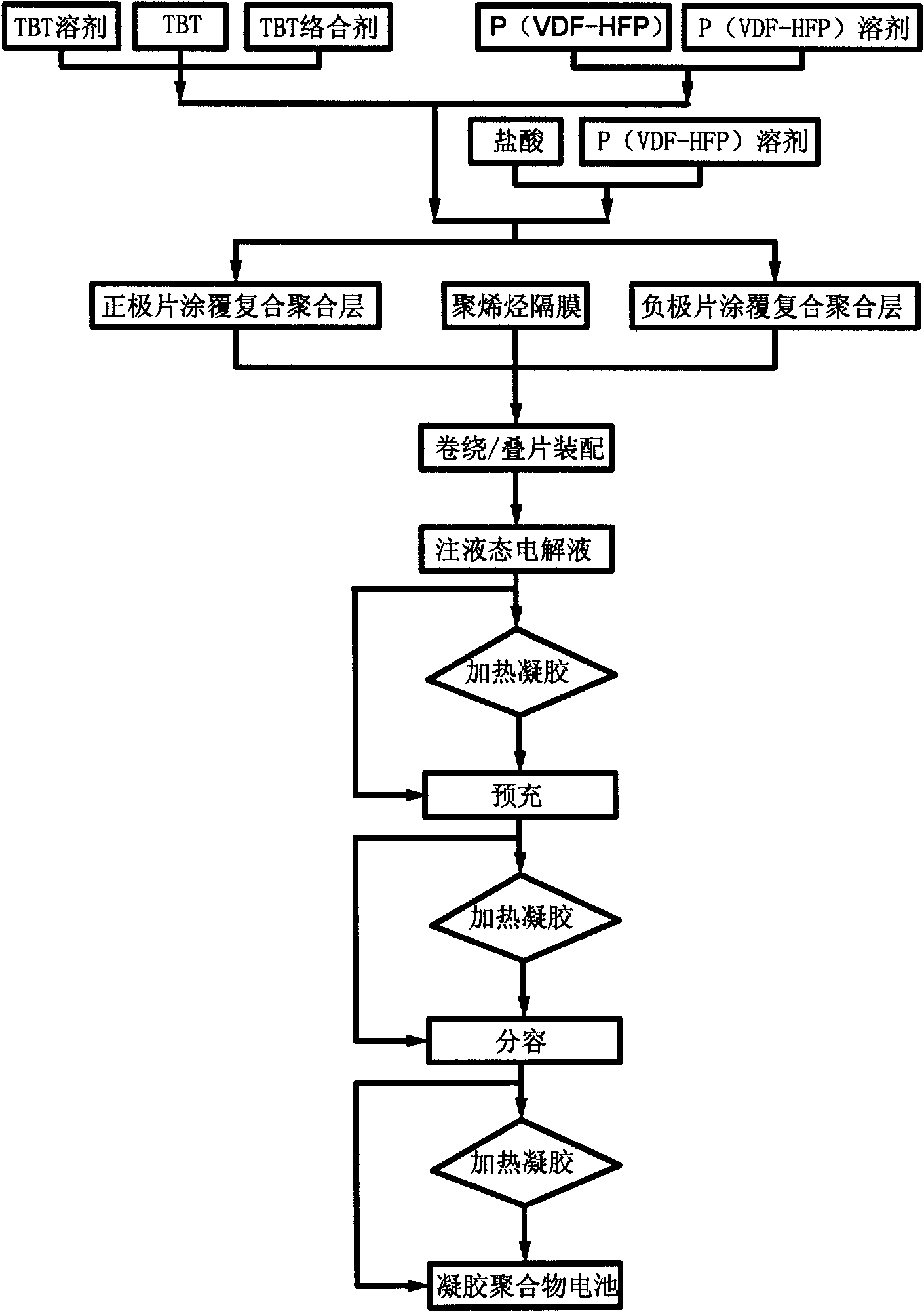

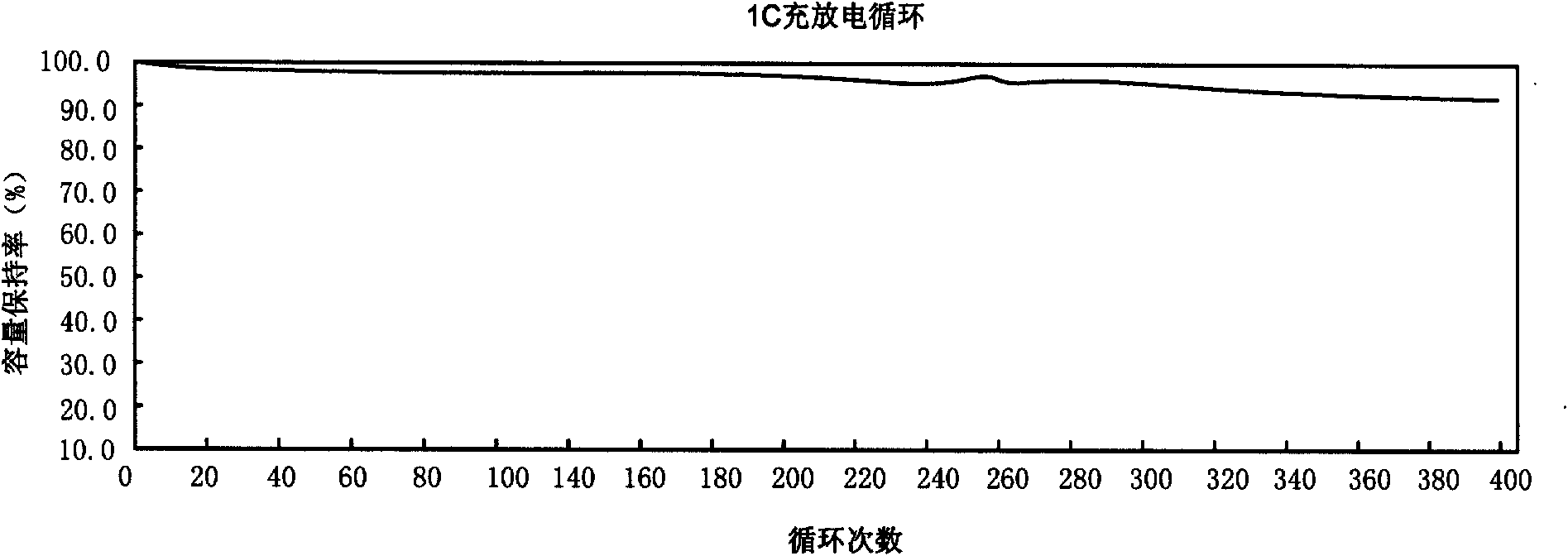

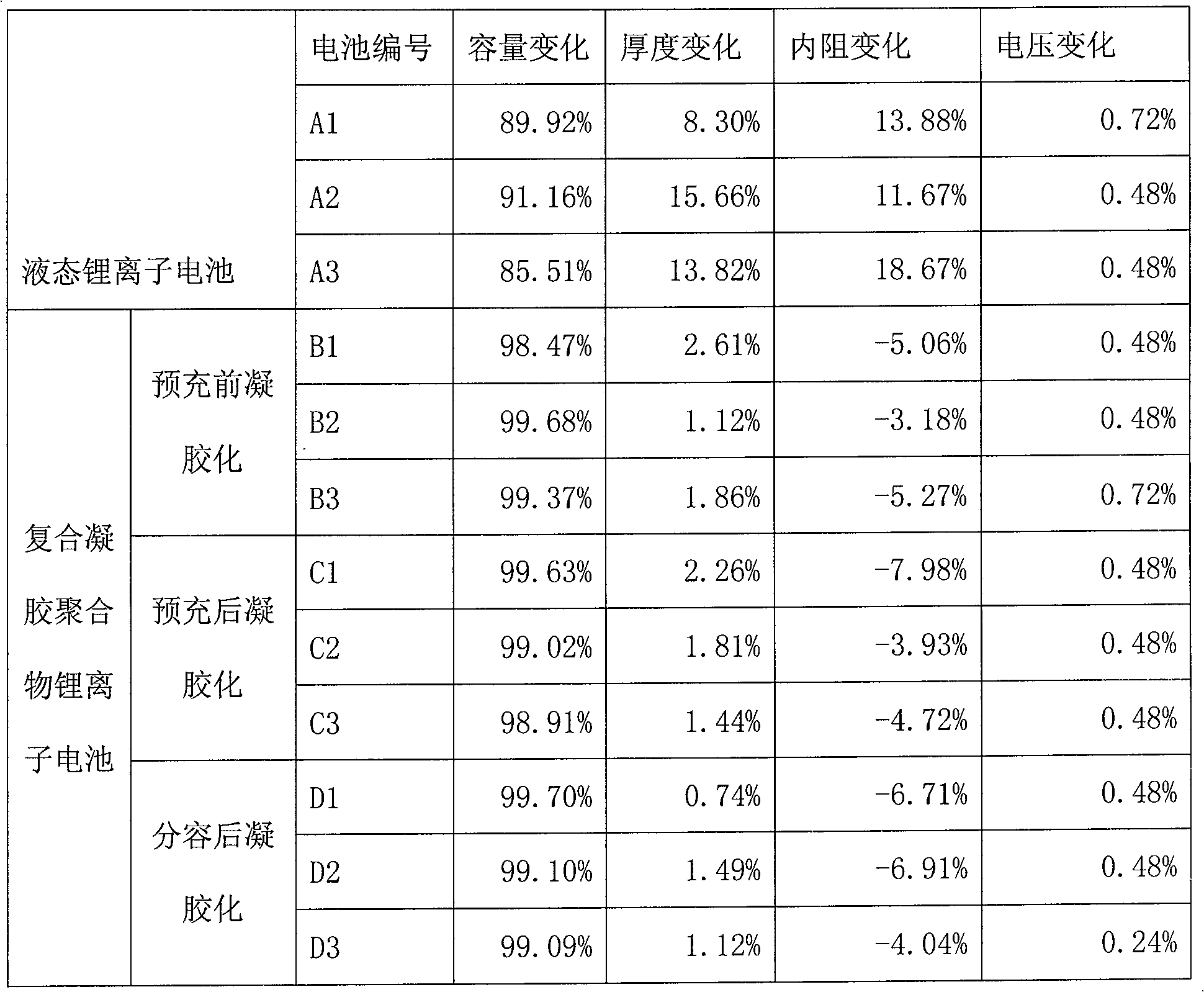

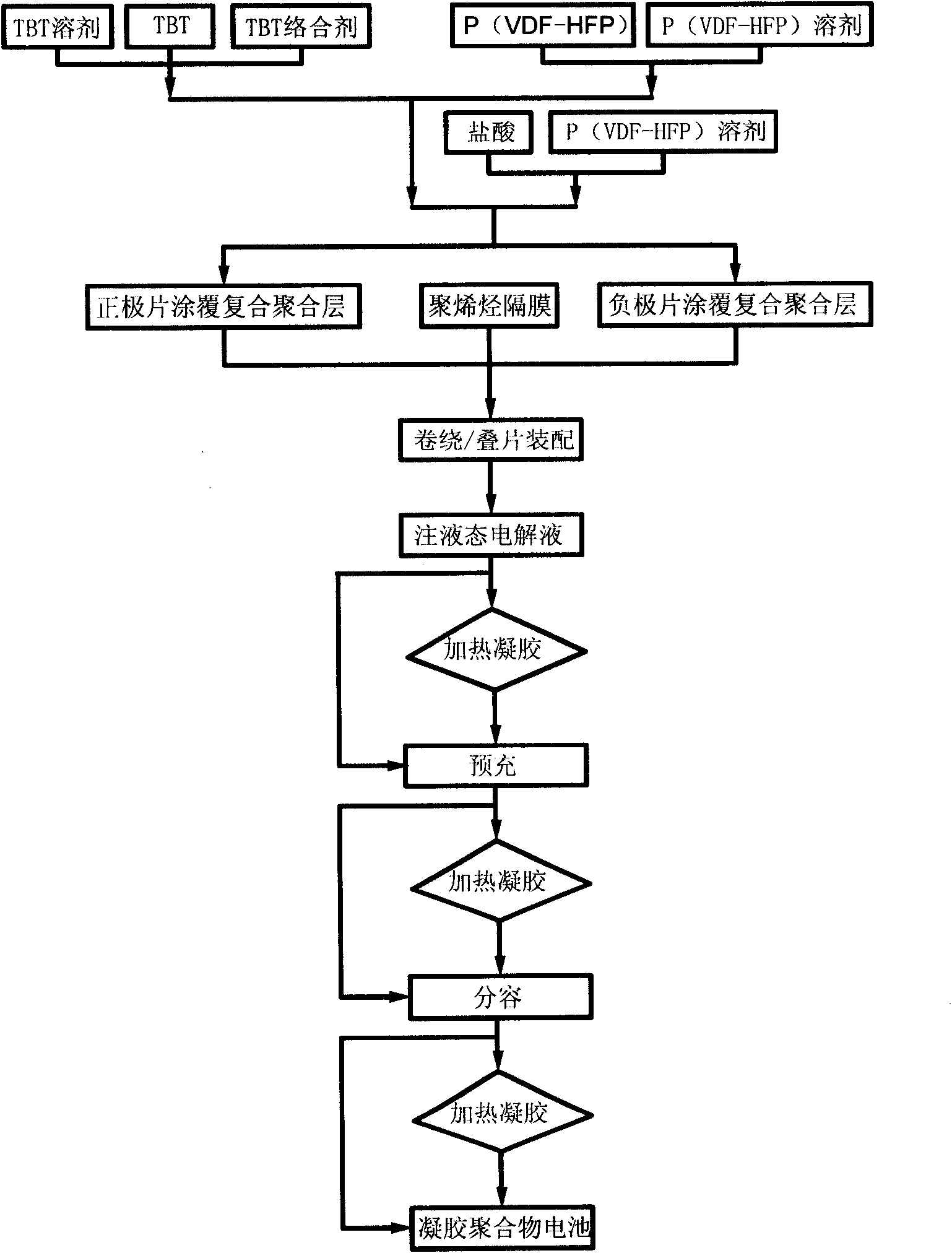

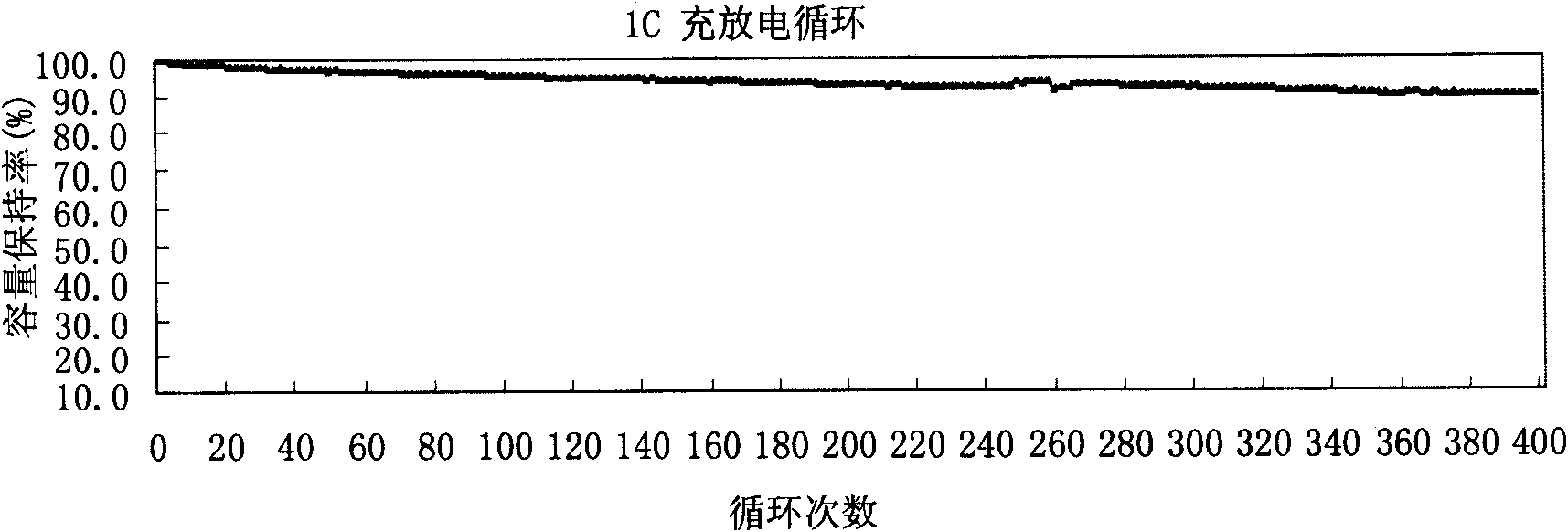

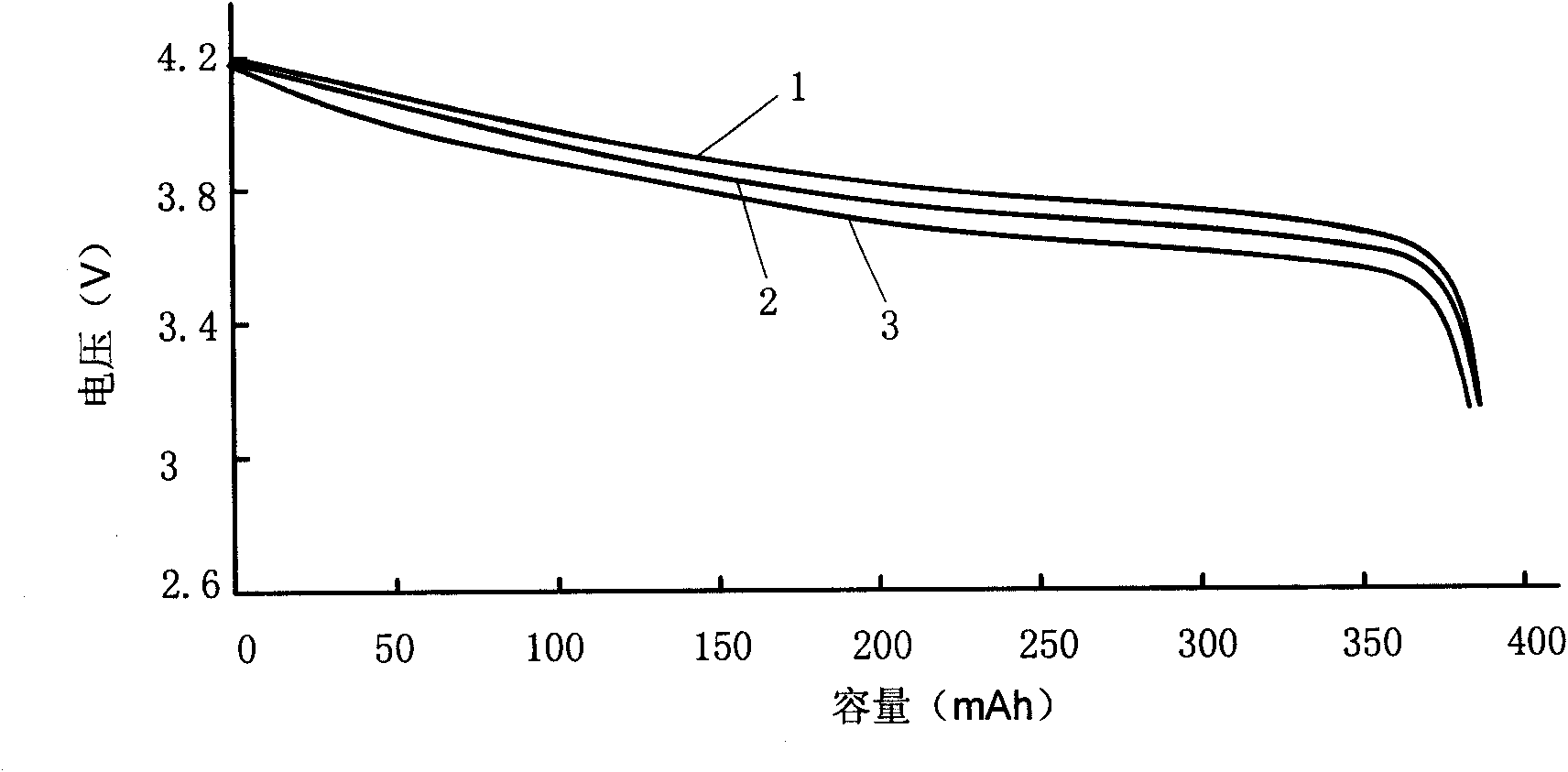

The invention discloses a polymer lithium ion battery and a preparation method of a diaphragm of the polymer lithium ion battery. The preparation method comprises the following steps: dissolving P(VDF-HFP) into an organic solvent, and adding inorganic ultra-fine powder into the mixture by adopting an in-situ hydrolysis method so as to prepare a mixed solution of P(VDF-HFP)-TiO2; coating the mixed solution on a polyolefin diaphragm so that the solvent is volatilized and a composite porous membrane is formed on the diaphragm; then assembling positive and negative pole pieces with the diaphragm; injecting liquid electrolyte into an electric core after assembling; and heating and baking the electric core so that the composite porous membrane and the electrolyte form a gel so as to prepare a gel polymer battery. The method has a simple technological process for preparing the polymer battery, low cost and wide application range of a production process; and the manufactured composite porous membrane has the advantages of high liquid absorption rate, high porosity and stable structure, and the battery has good cycling performance and electric conductivity.

Owner:ZHENGZHOU BAK BATTERY CO LTD

Method for eliminating sulfur compound contained in fuel oil by catalytic oxidation of phase transition

InactiveCN101050378AAvoid pollutionAbsorptiveOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsPhosphomolybdic acidQuaternary ammonium cation

This invention discloses a method for removing sulfur-containing compounds from fuel oil by phase-transfer catalytic oxidation. The method comprises: preparing six types of heteropolyacid quaternary ammonium salts as the phase-transfer catalysts from quaternary ammonium salts and phosphomolybdic acid / tungstophosphoric acid, mixing the phase-transfer catalysts, fuel oil, and peroxyformic acid oxidant (prepared from H2O2 and formic acid at a weight ratio of 3.5:(1-1.5)), reacting at 25-55 deg.C under ultrasonication for 1-2 h, and separating fuel oil and peroxyformic acid to obtain desulfurized fuel oil. The method avoids adsorption and extraction procedures due to the heteropolyacid quaternary ammonium salts phase-transfer catalysts, and has such advantages as simple process, and high reaction rate. The catalyst has such advantages as no toxicity and no pollution, and is recyclable and environmentally friendly.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing gel polymer lithium ion battery

ActiveCN101662041AImprove performanceHigh liquid absorptionFinal product manufactureSecondary cellsPolymer scienceOrganic solvent

The invention discloses a method for preparing a gel polymer lithium ion battery, which comprises the following steps: dissolving P(VDF-HFP) into an organic solvent, and adding inorganic ultra-fine powder into the mixture by adopting an in-situ hydrolysis method so as to prepare a mixed solution of P(VDF-HFP)-TiO2; coating the mixed solution on positive and negative pole pieces of the battery so that the solvent is volatilized, and composite porous membranes are formed on the positive and negative pole pieces; assembling the pole pieces containing the composite porous membranes with a diaphragm; injecting liquid electrolyte into an electric core after assembling; and heating and baking the electric core so that the composite porous membranes and the electrolyte form a gel so as to preparea gel polymer battery. The method has a simple technological process for preparing the polymer battery, low cost and wide application range of a production process; and the manufactured composite porous membranes have the advantages of high liquid absorption rate, high porosity and stable structure, and the battery has good cycling performance and electric conductivity.

Owner:ZHENGZHOU BAK BATTERY CO LTD

Method for preparing xylo-oligosaccharide and fermentable sugars through lignocelluloses-type biomass

The invention discloses a method for preparing xylo-oligosaccharide and fermentable sugars through lignocelluloses-type biomass. Firstly, oxidation pretreatment is conducted under the alkaline condition to selectively remove lignin in the lignocelluloses-type biomass; then endo-xylanase which does not have cellulase activity is adopted to conduct hydrolysis pretreatment on a substrate to obtain the xylo-oligosaccharide; and finally, cellulase is adopted to hydrolyze solid residues after the endo-xylanase is hydrolyzed to obtain the fermentable sugars. According to the method, the xylan separation and extraction processes where energy consumption is high, consequently the cost is high, the dosage of chemical reagents is large, and consequently, pollution is serious are omitted, the purity of the xylo-oligosaccharide is further improved, and the yield of the fermentable sugars is increased.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

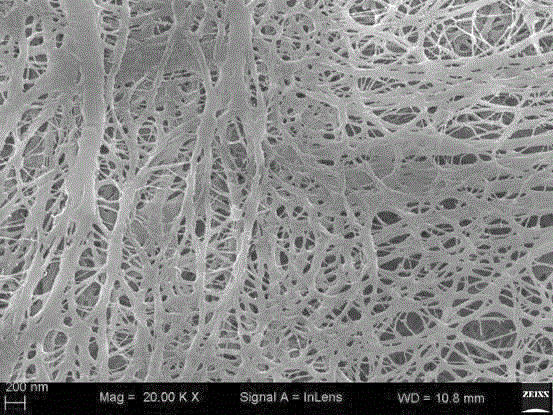

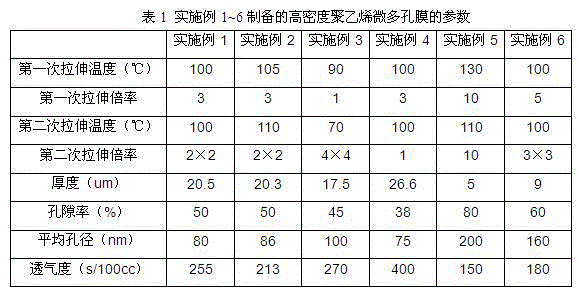

High-density polyethene micro porous membrane and preparation method therefor

The invention discloses a high-density polyethene micro porous membrane and a preparation method therefor, and belongs to the field of a film material. The method comprises the steps of: mixing raw materials, melting the mixed raw materials to form thick sheets, and then stretching the thick sheets twice: (1) stretching the thick sheets for the first time: preheating the thick sheets at the temperature of 40-130 DEG C, performing longitudinal stretching under the effect of thermal wind at 90-130 DEG C, wherein the stretching multiple rate is 1-10, and then performing heat shaping so as to obtain the films; (2) performing stretching for the second time: performing lateral uniaxial stretching or vertical and lateral bisynchronous stretching on the films prepared in the step (1) under the effect of thermal wind at 70-110 DEG C, maintaining stretching state for 2-4 minutes, wherein the multiple rate of lateral uniaxial stretching is 1-10, and the total multiple rate of vertical and lateral bisynchronous stretching is 4-16; and then, performing heat shaping so as to obtain finished products. According to the preparation method, in the stretching process, under the effect of thermal wind, a hole forming agent is rapidly volatilized from the films so as to form a micropore structure in mutual penetration, so that an extraction technology is omitted, the consumption of an extracting solvent is further reduced, the cost is reduced and the technological process is simplified.

Owner:XINXIANG ZHONGKE SCI&TECH

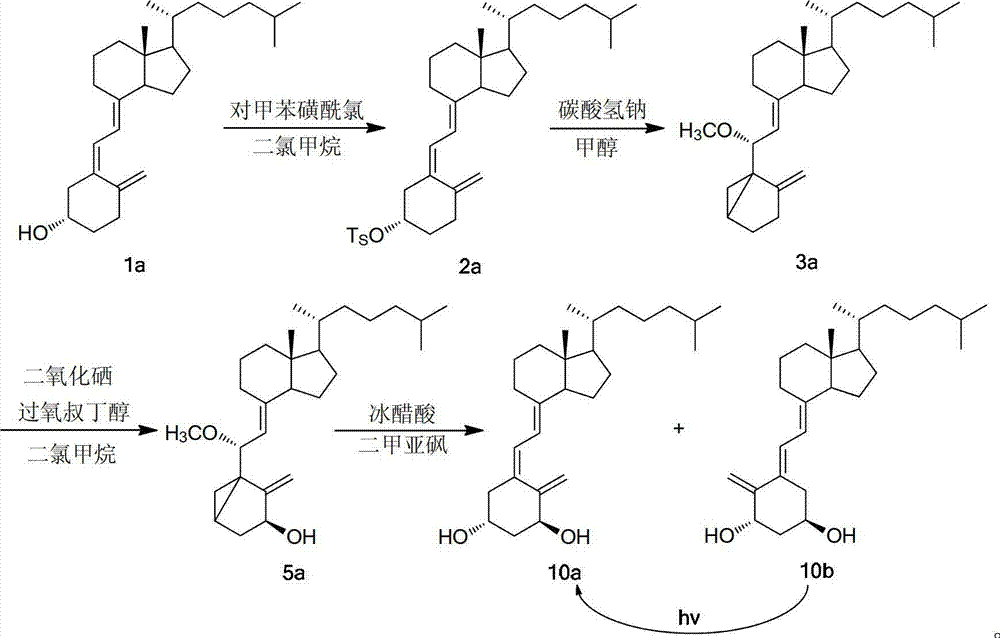

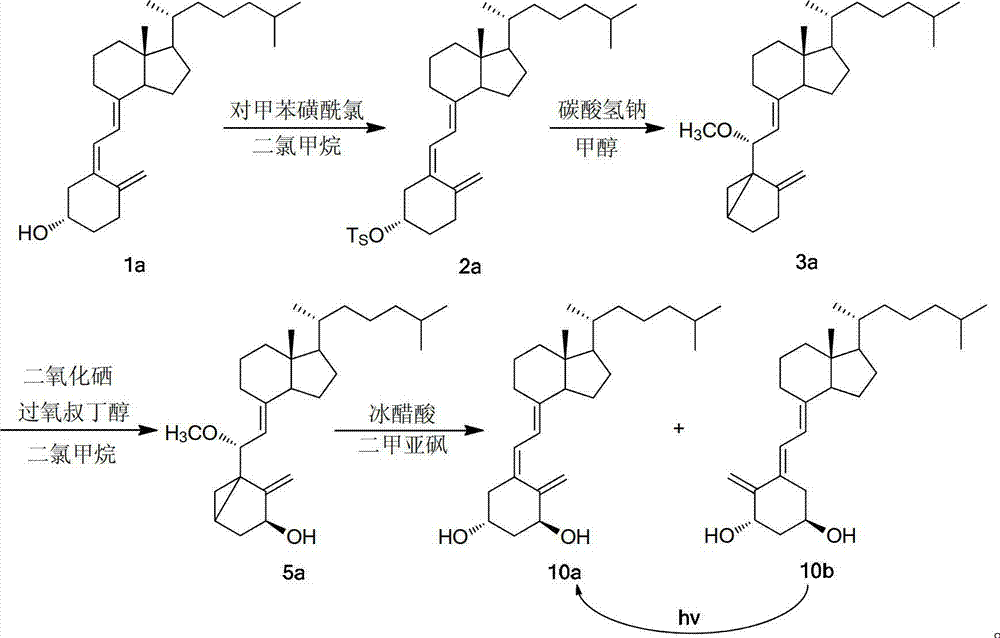

Synthetic method of osteoporosis treatment drug 1 alpha-hydroxyitamin D3

InactiveCN103073468AReduce usageShort reaction timeOrganic chemistrySkeletal disorderIsomerizationReaction temperature

The invention discloses a synthetic method of an osteoporosis treatment drug 1 alpha-hydroxyitamin D3, which comprises the following steps: 1) esterfying; 2) cyclizing; 3) oxidizing; 4) opening ring; and 5) performing photochemical isomerization: dissolving a mixture of 5,6-cis 1 alpha-hydroxyitamin D3 and 5,6-trans 1 alpha-hydroxyitamin D3 in methanol with 20-200 parts by weight, adding a photosensitizer, reacting for 0.5-10 hours under irradiation of ultraviolet light to obtain 5,6-cis 1 alpha-hydroxyitamin D3 which is 1 alpha-hydroxyitamin D3; and performing recrystallization to obtain the 1 alpha-hydroxyitamin D3 acicular crystal. According to the invention, a fat-soluble solvent substitutes pyridine, an organic alkalescence catalyst is used, under the analogous yield condition, the reaction temperature changes to normal temperature from low temperature, the reaction time is short, the energy consumption is low, toxic substance pyridine with mass usage can be avoided, the steps for extracting and cleaning pyridine can be omitted, and the technology economy is enhanced.

Owner:TIANJIN UNIV

Method for producing Sm-Fe-N permanent magnet alloy powder by reduction diffusion

The invention provides a method for manufacturing Sm-Fe-N permanent magnetic alloy powder by adopting a reduction diffusion method. The process flow is: selection of raw materials and pretreatment→ratio of reactants→mixing of reactants→metal thermal reduction and diffusion alloying→chemical separation of reaction products→dehydration and drying of metal powder→powder nitriding treatment→manufacture of anisotropic bonding Sm-Fe-N magnet; it is characterized in that: use rare earth chloride and selectively control the particle size of alloy element iron powder, and the reducing agent is metal Ca and CaH 2 , carry out reduction diffusion reaction in the lower temperature range of 760-860 ℃ to generate Sm-Fe alloy and by-products, and after chemical separation, Sm-Fe alloy is pulverized and nitrided to directly obtain Sm-Fe with required composition and particle size requirements -N magnetic alloy powder. The advantages are: low reaction temperature, small loss of Sm, easy control of composition, simplified process and good performance.

Owner:UNIV OF SCI & TECH BEIJING

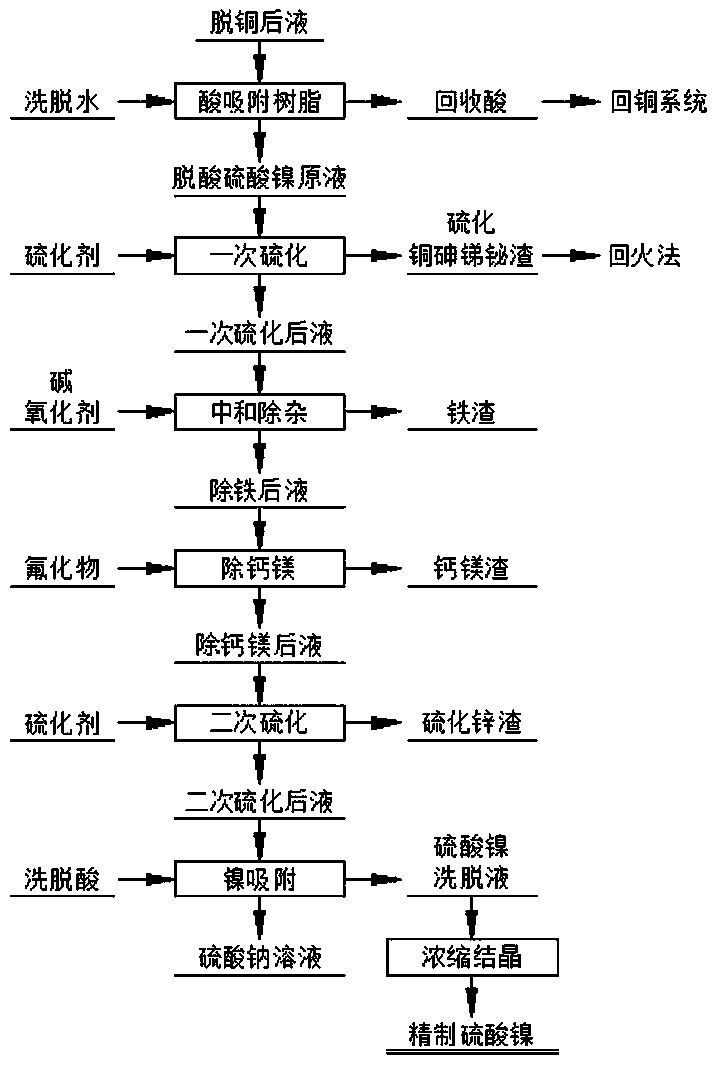

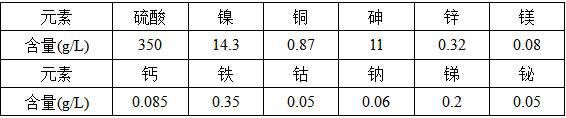

Method for preparing refined nickel sulfate from copper-removed solution of copper electrolyte

ActiveCN110983070AEliminate the extraction processThe process is simple and directProcess efficiency improvementElectrolytic agentSulfate

The invention discloses a method for preparing refined nickel sulfate from copper-removed solution of copper electrolyte. The method comprises the following steps that the copper-removed solution of the copper electrolyte is subjected to acid-salt separation for separating sulfuric acid and nickel sulfate, primary vulcanization, neutralization impurity removal, calcium and magnesium removal by fluoride, secondary vulcanization, nickel adsorption by an adsorbing material and concentration crystallization to obtain a refined nickel sulfate product. According to the method, the copper-removed solution of the copper electrolyte is directly purified, so that the primary concentration crystallization cost is saved; and the nickel yield is high, the purification process is simple, and a traditional extraction process is omitted, so that the investment cost and the operation cost are greatly reduced.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Preparation method of ultra-fine zirconium carbide particle dispersed and strengthened copper-based composite materials for spot-welding electrode

ActiveCN108531767AImprove mechanical propertiesSimple preparation processSelf-propagating high-temperature synthesisUltra fine

The invention belongs to the preparation field of copper-based composite materials for welding electrode, and discloses a preparation method of ultra-fine zirconium carbide particle dispersed and strengthened copper-based composite materials for spot-welding electrode. The preparation method comprises the following steps that cold press molding of uniformly mixed Cu-Zr-C powder is carried out, then powder compact is put into a self-propagating high temperature synthesis device to ignite to obtain ultra-fine ZrC powder body containing Cu, and a mixture of oxygen-free copper and the ultra-fine ZrC powder body containing Cu are smelted in a vacuum melting furnace and magnetic stirring is carried out, so that ultra-fine ZrC particle dispersed and strengthened copper-based composite materials are prepared. The preparation method has the characteristics of being low in cost, simple in techniques, high in production efficiency, tiny in ZrC size, uniform in distribution and the like.

Owner:温岭工联工量刃具科技服务有限公司

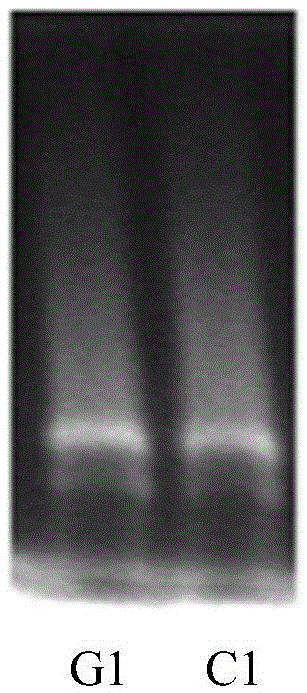

SNP (single nucleotide polymorphism) typing detecting method for utilizing locking-type probe for rolling ring amplification

ActiveCN105463108AEliminate the extraction processReduce the risk of cross-infectionMicrobiological testing/measurementEnzyme digestionPhosphorylation

The invention provides an SNP (single nucleotide polymorphism) typing detecting method for utilizing a locking-type probe for rolling ring amplification. At first, the locking-type probe and an amplification primer are designed, then the designed locking-type probe is phosphorylated, then a locking-type probe cyclization reaction is carried out, an enzyme digestion reaction is adopted for digesting an uncyclized locking-type probe and genomic DNA to obtain a cyclized locking-type probe, the cyclized locking-type probe is subjected to a rolling ring amplification reaction, a reactant obtained through the rolling ring amplification reaction is taken and subjected to 1% agarose gel electrophoresis detection, and the gene type of SNP can be judged through an electrophoresis detecting result. According to the method, SNP typing detection can be directly carried out on biological samples like peripheral blood, the genomic extraction process is omitted, the operation steps are greatly reduced, detecting time is greatly shortened, cost is saved, the risk of cross infection of operators is reduced, the detecting method has great popularization prospects, and the detecting result is accurate and sensitive.

Owner:华桥生物工程科技有限公司

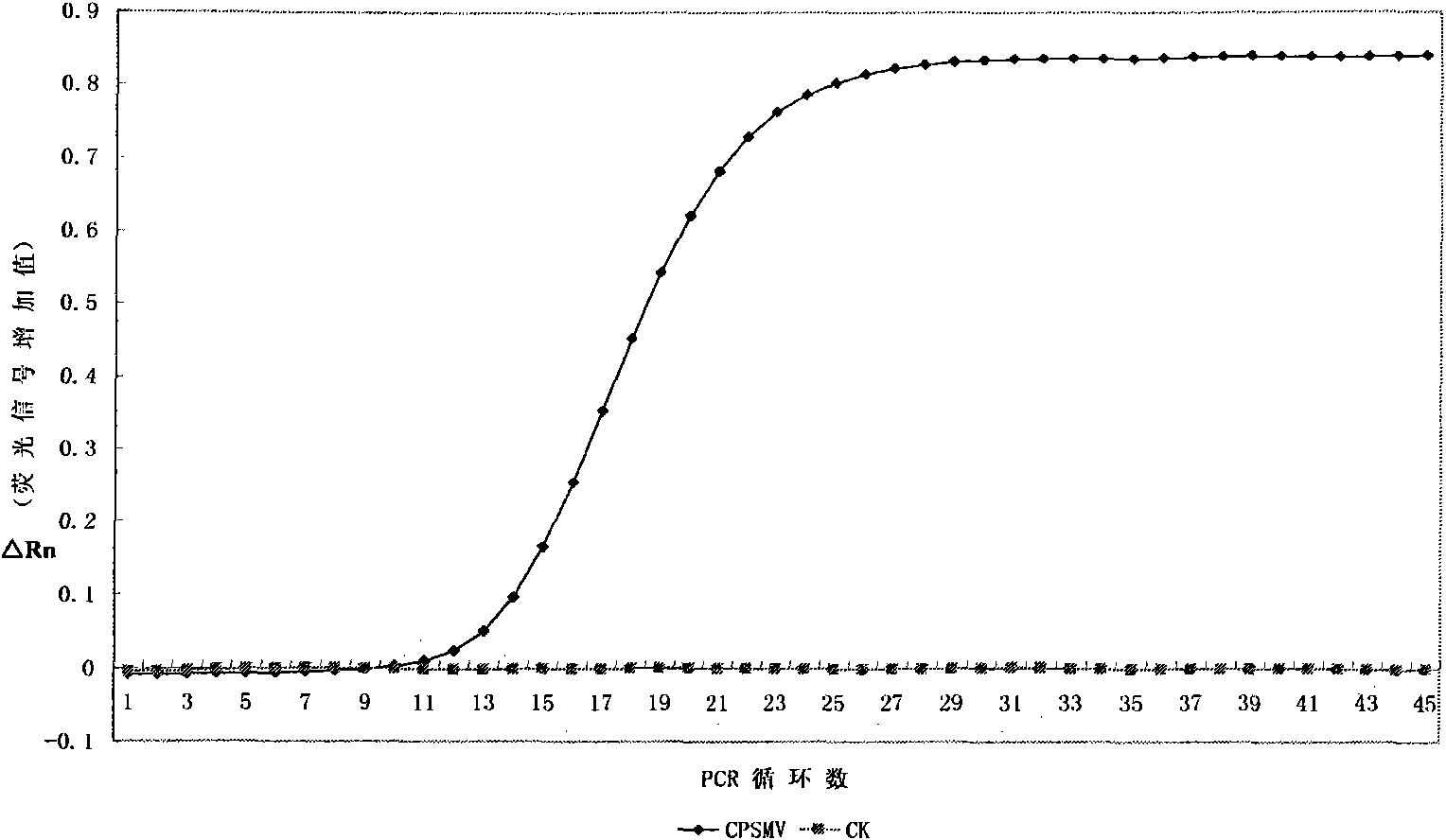

Molecule detection method for cowpea severe mosaic virus

InactiveCN101818211AStrong specificityGood repeatabilityMicrobiological testing/measurementFluorescence/phosphorescenceForward primerFluorescence

The invention relates to a molecule detection method for cowpea severe mosaic virus, which belongs to the technical field of biology. The method comprises the following steps of: obtaining coarse virus extract; preparing an immune capturing PCR tube; releasing cowpea severe mosaic virus RNA in the immune capturing PCR tube and taking the cowpea severe mosaic virus RNA as a template, and performing reverse transcription reaction by using CPSMVR of a sequence 5'-GGCTTCTGCAGGTGTTCCAA-3' as a primer to obtain a reverse transcription product; and performing real-time fluorescent PCR reaction by using the reverse transcription product as a template and using a forward primer 5'-GGTCAATCCCGGCATTATTG-3', a reverse primer CPSMVR and a Taq Man probe CPSMVPro 5'FAM-TGTAGCACAATCAGGGCAAACACAGCA-TAMRA 3', wherein when the initial cycle number is less than or equal to 35, a sample is infected with the cowpea severe mosaic virus.

Owner:ANIMAL AND PLANT & FOOD DETECTION CENTER JIANGSU ENTRY EXIT INSPECTION AND QUARANTINE BUREAU

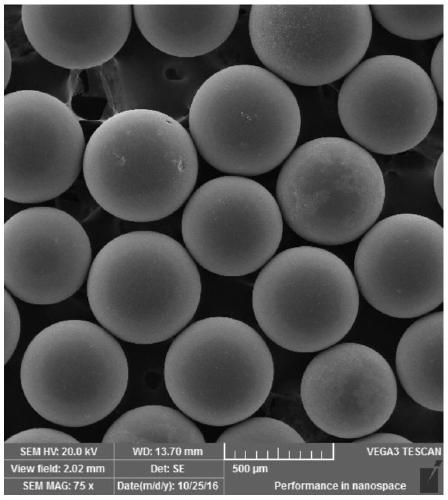

Method for controlling surface micro crack of pitch-based spherical activated carbon

ActiveCN109052398AImprove performancePromote the engineering processCarbon compoundsActivated carbonApplication areas

The invention relates to a method for controlling surface micro cracks of pitch-based spherical activated carbon. The method comprises the following steps: carrying out modification with high softening point coal tar pitch, improving pelletizing conditions of naphthalene-containing pitch granules, and changing a removal method for naphthalene in the naphthalene-containing pitch granules, thereby obtaining the pitch-based spherical activated carbon which is smooth in surface, free of surface micro crack and high in sphericity degree, wherein the pitch-based spherical activated carbon has a density of 0.5-0.85g / cm<3>, a specific surface area of 800-1300m<2> / g, vibration strength greater than 95% and a micro pore content greater than 83%. By adopting the method, while the pitch-based spherical activated carbon is prepared, the problem of micro cracks on the surface of the pitch-based spherical activated carbon can be effectively solved, the mechanical properties of the material are improved, and the method has great significances for promoting engineering progress of the material and widening the application range of the material.

Owner:湖南曦威新材料有限公司

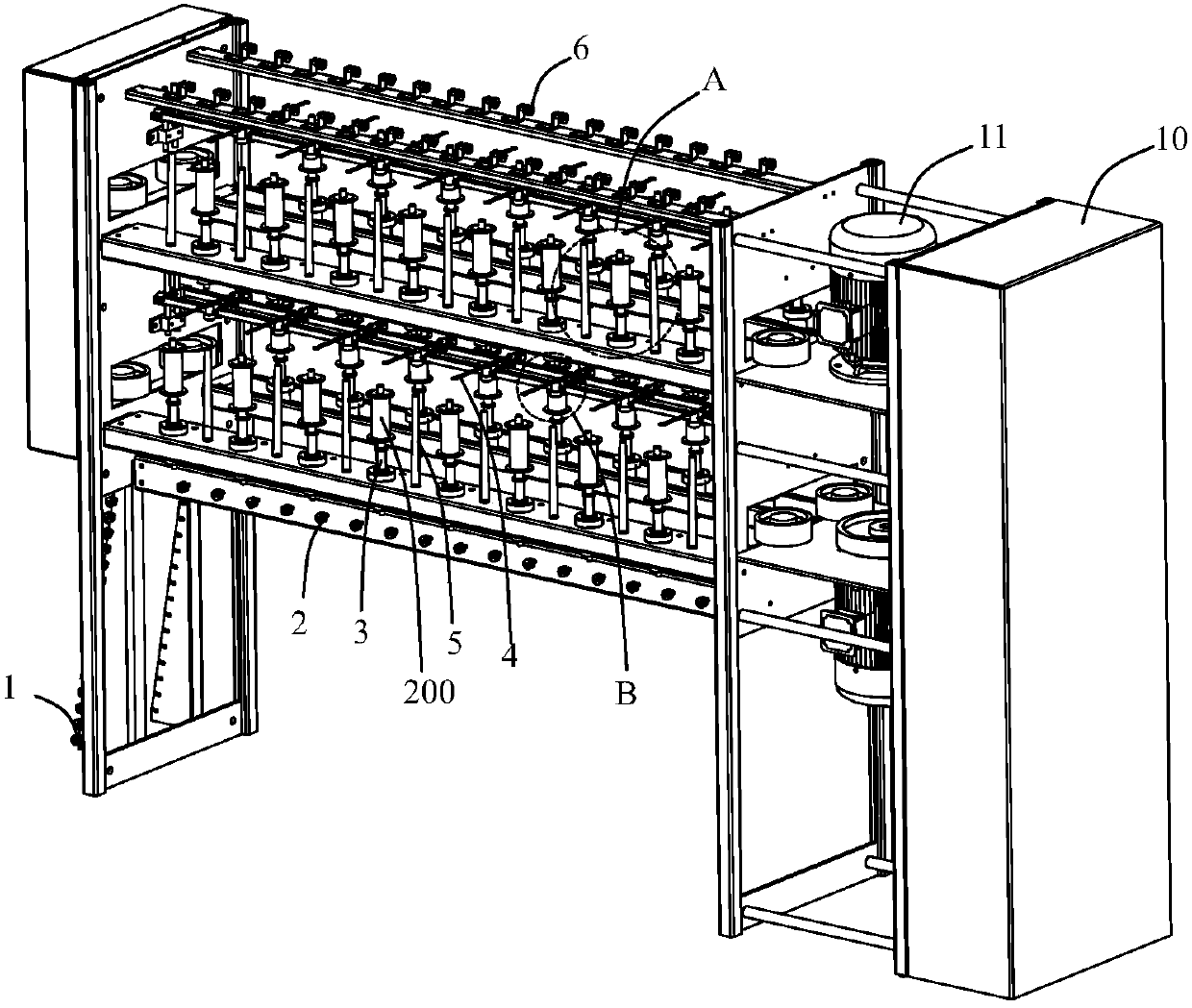

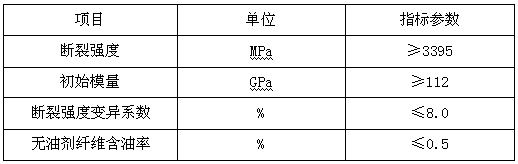

Artificial grass yarn wrapping machine

The invention discloses an artificial grass yarn wrapping machine. The wrapping machine comprises a rack, a dividing hook, a lower yarn guide wheel, a spindle with a center hole, a threading mechanismand an upper yarn guide wheel, and the dividing hook, the lower yarn guide wheel, the spindle with the center hole, the threading mechanism and the upper yarn guide wheel are installed on the rack; the dividing hook is used for dividing fiber spun by a spinning machine into multiple center yarns; the spindle is rotatably installed on the rack, and a coated yarn winding drum is arranged on the spindle; the threading mechanism is provided with a threading hole; each bunch of the center yarn passes through the lower yarn guide wheel, the center hole of the spindle and the threading hole of the threading mechanism in sequence, coated yarn penetrates through the threading hole, the center yarn is wrapped at the threading hole, and artificial grass yarn formed after wrapping passes through theyarn guide wheel and then is output. By means of the artificial grass yarn wrapping machine, the fiber spun by the spinning machine can be directly used as the center yarn for wrapping, the fiber coiling and extraction processes are omitted, the occupied space is effectively reduced, and the production efficiency is improved.

Owner:日照贝尔机械有限公司 +1

Preparation of high purity, 1,1,1-trifluoro-2,2,-dichloroethane

ActiveCN1273426CEfficient use ofImprove utilization efficiencyPreparation by halogen additionTrichloroethyleneMixed gas

Owner:中化蓝天氟材料有限公司 +2

Preparation method of methimazole

The invention relates to a preparation method of methimazole. The method specifically comprises the following step: enabling reaction of N-methylimidazole, N-butyllithium and powdered sulfur in an organic solvent to obtain methimazole. The preparation method disclosed by the invention is simple in process, mild in condition, simple to operate, easy for post treatment, applicable for industrialized production, and capable of greatly improving the reaction yield of methimazole.

Owner:WUHAN CONFORM PHARMA CO LTD

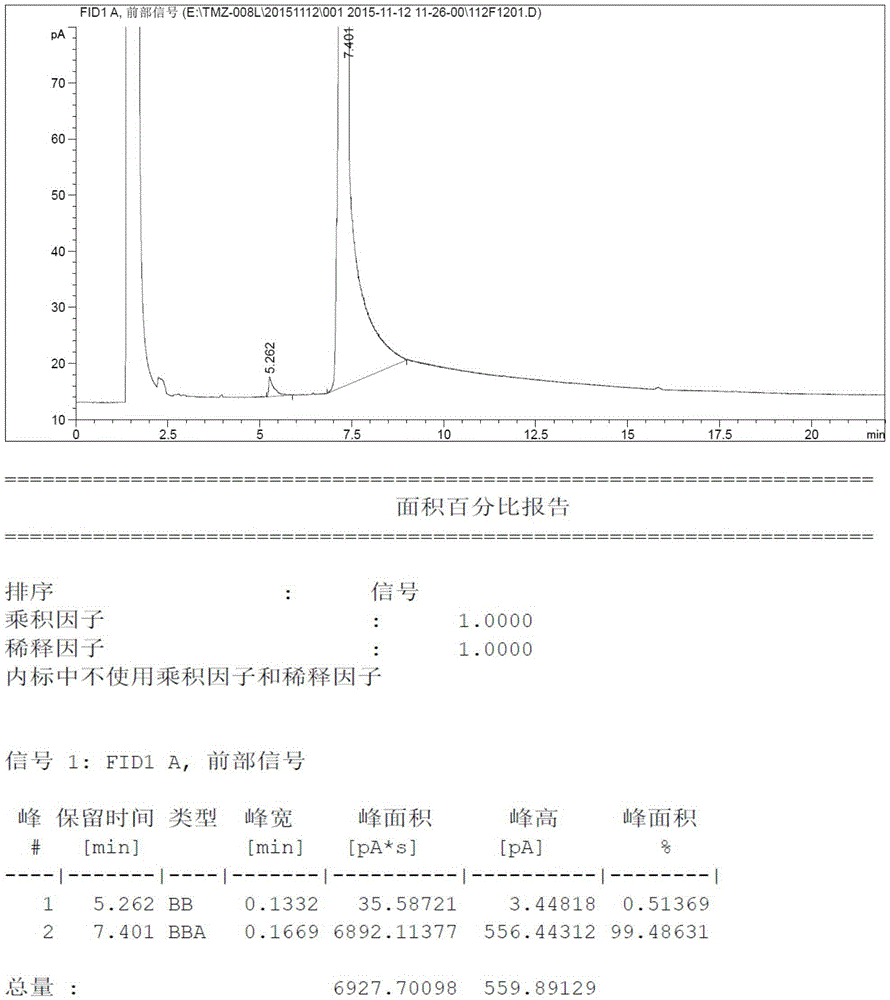

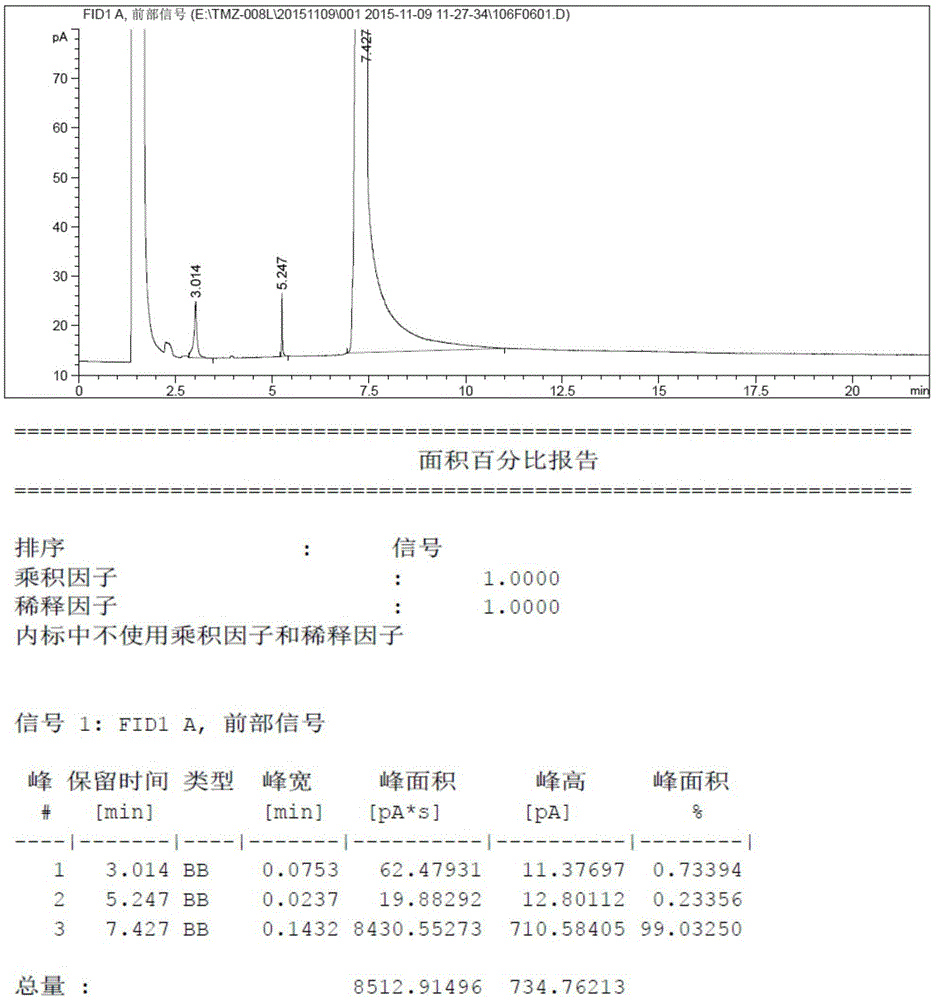

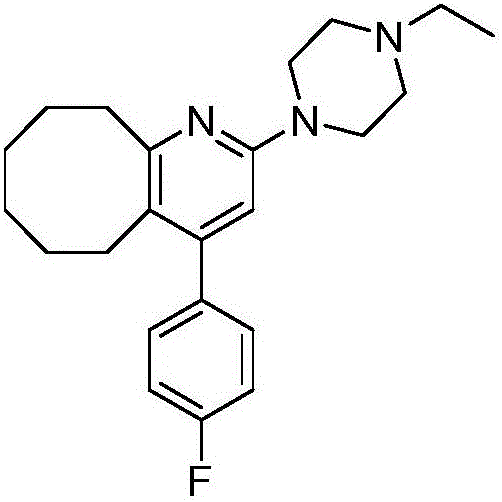

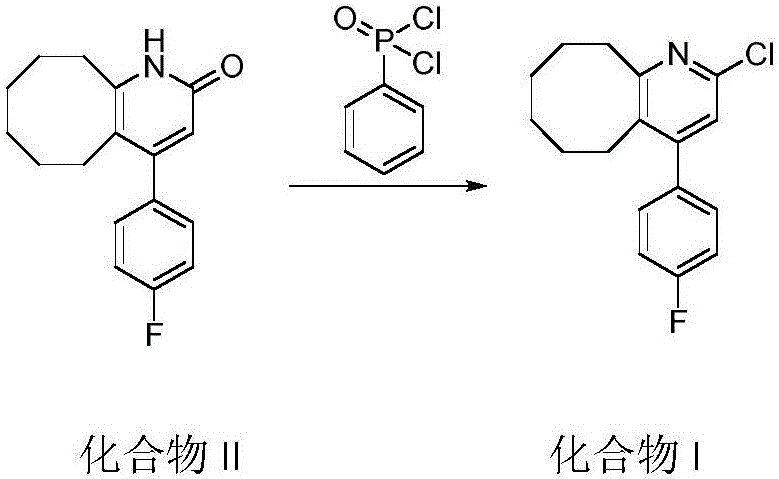

Preparation method of blonanserin intermediate

InactiveCN105837504AReduce lossEliminate the extraction processOrganic chemistryBlonanserinFiltration

Owner:HEBEI GUOLONG PHARMA CO LTD

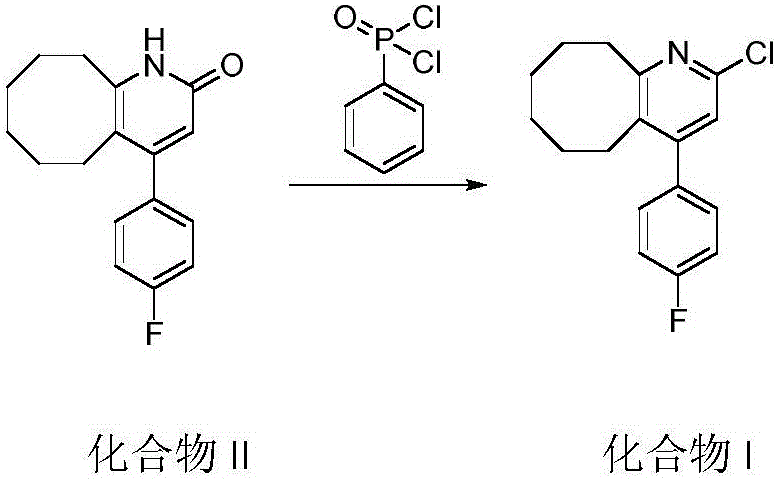

Melt spinning preparation method of high molecular weight polyethylene fiber

ActiveCN108588884ACompact structureIncrease stiffnessMelt spinning methodsMonocomponent polyolefin artificial filamentProduction ratePolymer science

The invention discloses a melt spinning preparation method of a high molecular weight polyethylene fiber. The preparation method comprises the following steps: purifying and modifying kaoline, grinding the purified and modified kaoline to 200 meshes, performing ion exchange on the micron-sized kaoline through a cationic monomer, namely methacryloyloxyethyl trimethyl ammonium chloride to form organic kaoline, blending with initiators, namely dibenzoyl peroxide and high molecular weight polyethylene, performing granulation in an auxiliary granulation machinery to form a modified high molecular weight polyethylene grain, performing melt extrusion on the modified high molecular weight polyethylene grain in a screw extruder to form a nascent fiber, performing hot stretching on the nascent fiberafter cooling and drying, and performing thermoforming, curling and false twisting after the stretching to form the high molecular weight polyethylene fiber. The method has the technical advantages that a melt flowing property is significantly improved, a production rate is significantly increased, and the recovery cost is lowered.

Owner:山东莱威新材料有限公司

Method for preparing 2-bromomethyl-2-phenyl-4-(4-chlorophenyl)-butyronitrile

The invention relates to a 2-bromomethyl-2-phenyl-4-(4-chlorophenyl)-butyronitrile preparation method, which takes 2-phenyl-4-(4-chlorophenyl)-butyronitrile and dibromomethane as raw materials and sodium hydroxide as an acid binding agent, and the invention is characterized in that the reaction is processed with the existing of catalyst until the 2-phenyl-4-(4-chlorophenyl)-butyronitrile is completely converted into 2-bromomethyl-2-phenyl-4-(4-chlorophenyl)-butyronitrile, and when the reaction finishes, the reactant obtained from the reaction is settled stationarily and layered, after the alkali liquid layer is separated, the acquired liquid is 2-bromomethyl-2- phenyl-4-(4-chlorophenyl)-butyronitrile which can be used as the intermediate of nitrile benzenezole which is an agricultural fungicide. Application of solvent of dimethyl sulfoxide and extraction solvent of 1, 2-dichloroethane are avoided in the method, thereby reducing the cost, decreasing pollution and discharge of sewage and shortening the process, and the preparation method is environmental friendly, with prominent economic benefit.

Owner:JIANGSU FENGDENG PESTICIDE

Extraction process of purple sweet potato pigment

The invention discloses an extraction process of purple sweet potato pigment. The extraction process is characterized by comprising the following steps: (1) preparing purple sweet potato pulp; (2) carrying out enzymolysis; (3) carrying out hydrolysis; (4) carrying out filtration treatment; and (5) carrying out ammonification. According to the extraction process, the purple sweet potato is used as a raw material, so that the extraction process of starch is saved and the technological process is simplified; and moreover, the purple sweet potato contains natural pigment and is acid-resistant, salt-tolerant and good in stability. By using the technologies such as enzymolysis and ultrafiltration, the produced pigment is high in color index and good in stability. And the extraction process has the effects of shortening the production period and saving the cost, and belongs to green chemical processes and technologies.

Owner:QINGDAO PENGYUAN KANGHUA NATURAL PROD

River and lake bottom sludge pollutant flux test method and device based on diffusion theory

ActiveCN102590479BWide applicabilityThe concentration of pollutants does not need to be testedEarth material testingTesting waterSample waterSludge

The invention discloses a river and lake bottom sludge pollutant flux test method and a river and a device based on a diffusion theory. The method comprises the following steps of: A, acquiring a bottom sludge sample; B, putting the bottom sludge into a base of an experimental device, and enabling the sludge surface to be horizontal; C, slowly injecting water to a column port along a column wall; D, injecting running water into the experimental device without the bottom sludge; E, standing for a certain time; F, measuring the pollutant concentration of the taken water sample; G, calculating a degrading coefficient of the pollutant in the water; H, calculating an initial concentration value of the bottom sludge water; and I, calculating a pollutant exchange flux of a water-sludge interface. A base plate is fixed at the bottom of a constant-temperature water tank; a base wall is arranged on the base plate; a lower flange disk is arranged on the upper part of the base wall; an upper flange disk is arranged at one end of a column body; and an upper flange disk fixing bolt flange hole is formed in the upper flange disk. The method is feasible, and is convenient to operate; the experimental device has a rational and simple structure; operations of accommodating deposits, sampling water samples and the like are extremely convenient; and outstanding economic benefit is achieved.

Owner:WUHAN UNIV

Buckwheat dried orange peel cakes and making method thereof

The invention discloses buckwheat dried orange peel cakes and a making method thereof. The buckwheat dried orange peel cakes are made from the following raw materials in parts by weight: 80-100 partsof buckwheat powder, 30-50 parts of dried orange peel, 20-40 parts of haws, 20-40 parts of rice flour, 20-40 parts of glutinous rice flour, 10-15 parts of soybean oil, 10-15 parts of Chinese yam powder and 4-8 parts of licorice roots. The making method comprises the following steps of crushing the dried orange peel, the haws and the licorice roots into fine powder, mixing the fine powder with thebuckwheat powder, the rice flour, the glutinous rice flour and the Chinese yam powder, adding the soybean oil which is refined to be cooked, to obtain a mixture, loading the mixture into molds in theneeded shapes, performing high-temperature steaming, performing vacuum sterilization and performing packaging so as to obtain finished products. The buckwheat dried orange peel cakes disclosed by theinvention are scientific in selection of raw materials, the making technology is simple, the dried orange peel, the haws and the licorice roots are directly crushed into the fine powder creatively, anextraction technology is omitted, industrialization is easy, the mouth feel of pastries is not bad, but the pastries are more palatable.

Owner:刘照明

Method of preparing gel polymer lithium ion battery

ActiveCN101677139BImprove performanceHigh liquid absorptionFinal product manufactureSecondary cellsOrganic solventPhysical chemistry

The invention discloses a method of preparing a gel polymer lithium ion battery, comprising the following steps: solving P(VDF-HFP) in organic solvent, and then adding P(VDF-HFP) nonsolvent to obtain mixed P(VDF-HFP) solution; spreading the mixed P(VDF-HFP) solution on the diaphragm or the positive electrode plate and the negative electrode plate of the lithium ion battery to volatilize the solvent of the mixed P(VDF-HFP) solution and form a composite porous film on the diaphragm or the positive electrode plate and the negative electrode plate of the lithium ion battery; assembling the positive electrode plate and the negative electrode plate with the diaphragm of the lithium ion battery, and injecting liquid electrolyte in to as assembled electrical core; and heating and baking the electrical core to make the composite porous film and the liquid electrolyte form gel to obtain the gel polymer lithium ion battery. The method of preparing the gel polymer lithium ion battery has simple process, low cost and wide application range and ensures that the produced composite porous film has high liquid absorption rate and stable structure and the gel polymer lithium ion battery has good cycling performance and conducting performance.

Owner:ZHENGZHOU BAK BATTERY CO LTD

Process for preparing erythricine from gentian

InactiveCN101941976AEliminate the extraction processSimple processOrganic chemistryChromatographic columnSolvent

The invention relates to a process for extracting erythricine from a gentianaceae plant acting as a gentian source, which comprises the following steps: making rhizome powder of raw gentian medicinal materials into coarse powder, carrying out reflux extraction in the environment of alkaline water bath of 60-100 DEG C for 2-4 hours with a hydrophilic organic solvent of which the amount is 2-20 times more than that of the coarse powder, carrying out vacuum filtration while hot, recovering the filtrate while depressurizing, processing the obtained solvent and reusing the processed solvent, and drying the extract while depressurizing to obtain a crude erythricine product 3; dissolving the crude erythricine product in a hydrophilic solvent, extracting with a lipophilic organic solvent according to a ratio of 2-4:1, recovering the hydrophilic organic solvent layer while depressurizing, and drying to obtain a crude erythricine product 2; and dissolving the crude erythricine product 2 in an acidic water solution, filtering to obtain a solution, enriching the solution with a resin column, and carrying out chromatography with a chromatographic column to obtain a refined erythricine product. The invention has the characteristics of simple process, low cost, low pollution, high product yield and purity and the like.

Owner:刘树民

Process for producing caramel pigment

InactiveCN101693903BIncrease concentrationHigh color ratioNatural dyesFermentationAlpha-amylaseHigh pressure

The invention discloses a process for producing caramel pigment, comprising the following procedures of a) gelatinization procedure, b) liquefaction and saccharification procedure, c) hydrolysis procedure and d) ammonification procedure, wherein the b) liquefaction and saccharification procedure comprises the following steps: adding alpha-amylase and saccharifying enzyme to the gelatinized purplesweet potato with the pH of 4.5-6.0 and the temperature of 70-95 DEG C, and reacting for 30-60min, wherein the weight proportion of the purple sweet potato, the alpha-amylase and saccharifying enzymeis 1:0.01-0.04:0.01-0.04. Compared with the prior art, in the invention, the purple sweet potato is taken as the raw material, therefore the extraction procedure of starch is saved and the process flow is simplified; furthermore, the purple sweet potato contains natural pigment and has good acid resistance, salt resistance and good stability; the caramel pigment produced by taking the sweet potato as the raw material has high color ratio and good stability, generates no pollutants during the hydrolysis process, shortens the production period and saves the cost; and the caramel pigment prepared by utilizing the sugar solution through a high-pressure ammonia method has good color ratio and good product quality.

Owner:ANHUI POLYTECHNIC UNIV

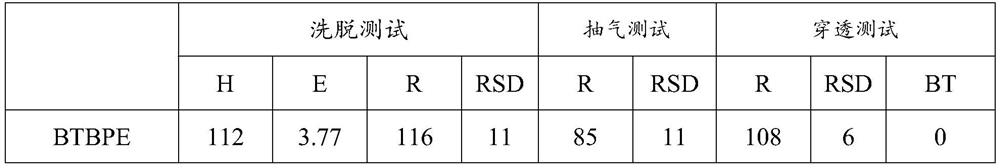

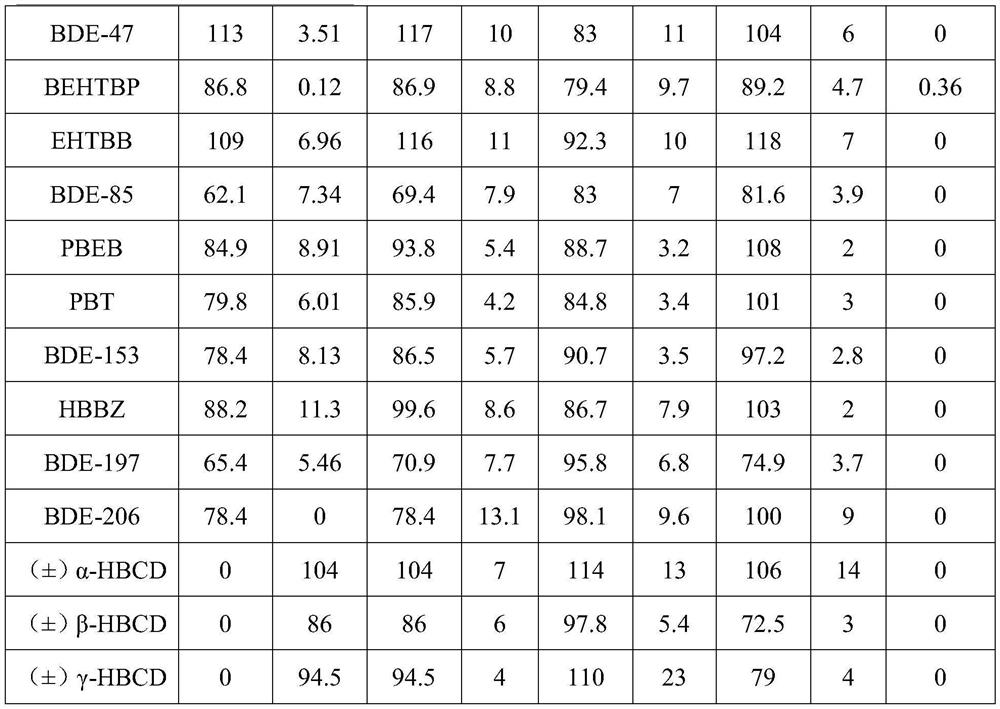

Sampler for brominated flame retardants in indoor air and sampling and measuring method thereof

ActiveCN111795874AHighly selective adsorptionEliminate the extraction processComponent separationWithdrawing sample devicesGlass fiberSolid phase extraction

The invention provides a sampler for brominated flame retardants in indoor air and a sampling and measuring method thereof, and relates to the technical field of analysis and detection. The sampler provided by the invention comprises a plurality of small solid-phase extraction columns connected in parallel, a flow meter connected with the outlets of the small solid-phase extraction columns, and adiaphragm vacuum pump connected with the outlet of the flow meter. The small solid-phase extraction columns are filled with filler, the filler comprises upper-layer CNWBOND HC-C18 filler and lower-layer CNWBOND NH2 filler, and the filler is separated by glass fiber sieve plates. According to the sampler disclosed by the invention, traditional and novel brominated flame retardants in air are directly enriched by the solid-phase extraction columns, the eluent can be directly subjected to nitrogen blowing concentration and then subjected to sample injection detection, the steps of solvent extraction and purification in a traditional sampling mode are omitted while the sampling requirements of different types of indoor environments are met, solvent consumption is remarkably reduced, the sampling process is simplified, and interference of uncertain factors on sampling measurement results is reduced.

Owner:NANKAI UNIV

A control method for microcracks on the surface of pitch-based spherical activated carbon

ActiveCN109052398BImprove performancePromote the engineering processCarbon compoundsActivated carbonCrazing

The invention relates to a method for controlling microcracks on the surface of asphalt-based spherical activated carbon. By modifying coal tar pitch with a high softening point, improving the pelleting conditions of naphthalene-containing pitch particles, and changing the removal method of naphthalene in the naphthalene-containing pitch pellets, the final A pitch-based spherical activated carbon with smooth surface, no microcracks and high sphericity was obtained. Among them, the prepared pitch-based spherical activated carbon has a density of 0.5-0.85g / cm 3 , The specific surface area is 800~1300m 2 / g, vibration strength higher than 95% and microporous content higher than 83%. The invention effectively solves the problem of microcracks on the surface of the pitch-based spherical activated carbon during the preparation process, not only improves the mechanical properties of the material, but also has great significance for promoting the engineering process of the material and expanding its application field.

Owner:湖南曦威新材料有限公司

A kind of method for preparing refined nickel sulfate from copper electrolytic solution after decoppering

ActiveCN110983070BEliminate the extraction processThe process is simple and directProcess efficiency improvementElectrolytic agentSulfidation

The invention discloses a method for preparing refined nickel sulfate from copper electrolyte decoppered liquid, which includes separating sulfuric acid and nickel sulfate through acid salt separation, primary sulfurization, neutralization and impurity removal, fluoride Removal of calcium and magnesium, secondary vulcanization, adsorption of nickel by adsorbent materials and concentrated crystallization to produce refined nickel sulfate products. The method of the present invention directly purifies the decoppered copper electrolyte, saving the cost of primary concentration and crystallization, and has a high nickel yield, a simple purification process, and eliminates the traditional extraction process, thereby significantly reducing investment costs and operating costs.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

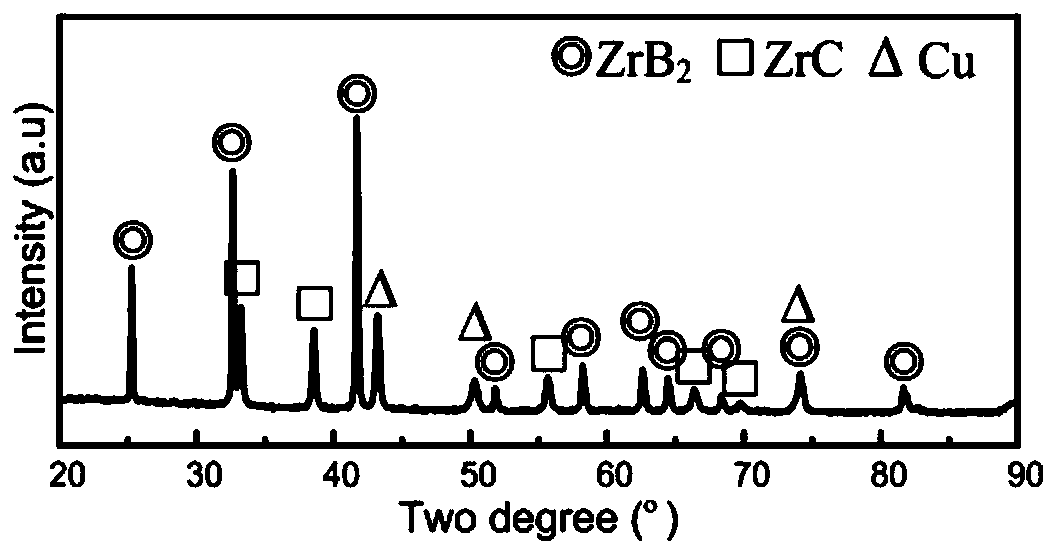

A kind of superfine zirconium carbide particles-zirconium boride rod crystal reinforced copper-based electrode material and its preparation method

The invention belongs to the field of preparation of copper-based composite materials for welding electrodes, and discloses an ultrafine zirconium carbide particle-zirconium boride rod crystal reinforced copper-based electrode material and a preparation method thereof: uniformly mixed Cu-Zr-B 4 C mixed powder was put into a high-temperature tubular atmosphere furnace and heated to 1250 °C to obtain Cu-containing ultrafine ZrC particles and ZrB 2 Rod crystal composite powder, followed by smelting oxygen-free copper and Cu-containing ultrafine ZrC‑ZrB in a vacuum melting furnace 2 Mixture of composite powders and applying magnetic stirring to prepare ultrafine ZrC particles‑ZrB 2 Rod grain reinforced copper-based electrode material. The method of the invention has the characteristics of low cost, simple process, high production efficiency, small reinforcement body, uniform distribution and the like.

Owner:JIUJIANG UNIV +1

A sampler for brominated flame retardants in indoor air and its sampling and determination method

ActiveCN111795874BHighly selective adsorptionEliminate the extraction processComponent separationWithdrawing sample devicesGlass fiberEnvironmental engineering

The invention provides a sampler for brominated flame retardants in indoor air and a sampling and measuring method thereof, and relates to the technical field of analysis and detection. The sampler provided by the present invention includes: several solid-phase extraction columns in parallel, all filled with fillers in the solid-phase extraction columns, and the fillers include the upper CNWBOND HC-C18 filler and the lower CNWBOND NH 2 Packing, the packing is separated by glass fiber sieve plates; a flow meter connected to the parallel outlet of the solid phase extraction column; a diaphragm vacuum pump connected to the outlet of the flow meter. The sampler of the present invention uses a solid phase extraction column to directly enrich traditional and new brominated flame retardants in the air, and the eluent can be directly concentrated by nitrogen blowing and then injected for detection, meeting the sampling requirements of different types of indoor environments At the same time, the solvent extraction and purification steps in the traditional sampling method are omitted, the solvent consumption is significantly reduced, the sampling process is simplified, and the interference of uncertain factors on the sampling and measurement results is reduced.

Owner:NANKAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com