Method for preparing refined nickel sulfate from copper-removed solution of copper electrolyte

A technology for decoppering solution and copper electrolyte is applied in the field of preparing refined nickel sulfate and copper electrolyte solution after decoppering to prepare refined nickel sulfate, which can solve the problems of high operating cost and large investment, achieve good effect and simplify the process , the effect of eliminating the extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

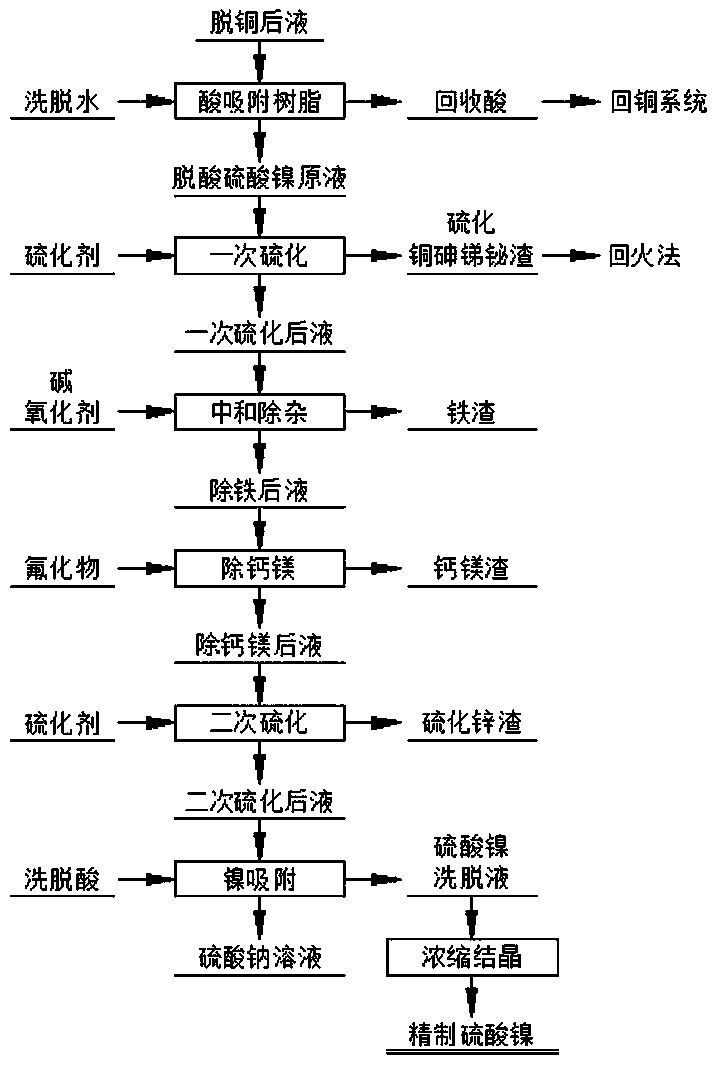

[0033] A method for preparing refined nickel sulfate from the copper electrolyte solution after decopper removal of the present invention, such as figure 1 shown, including the following steps:

[0034] The composition of the copper electrolyte after copper removal in a copper smelter is shown in Table 1.

[0035] Table 1 Composition of copper electrolyte after copper removal

[0036]

[0037] (1) Salt acid separation: After the copper electrolyte is decoppered and filtered through a 1μm filter membrane, the acid and metal ions are separated by a resin column equipped with 2.3L strong basic anion exchange resin (acid adsorption resin), so that The acid is adsorbed to obtain the deacidified nickel sulfate stock solution, and then the acid adsorption resin is washed with water, so that the acid is eluted, and the recovered acid solution is obtained, which is used to return to the copper system for acid supplementation.

[0038] Among them, the recovered acid solution contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com