Method for preparing low-cost asphalt-based spherical activated carbon with hierarchical porouse structure

A technology of spherical activated carbon and structured asphalt, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of increasing fixed asset costs, inflammability and explosion, and shorten the production process, shorten the reaction time, improve The effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

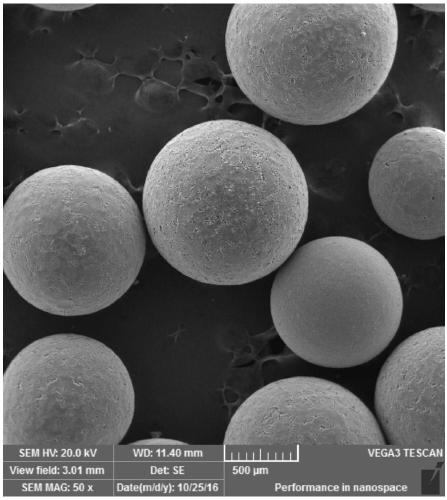

[0052] Using high-temperature coal tar pitch with a softening point of 130°C as raw material, 1000kg of medium-temperature coal tar pitch is crushed into coal tar pitch particles with a diameter of 0.6-0.8mm using a roller crusher. The asphalt particles were successively placed in a 5000L high pressure reactor, and 99.99% high-purity nitrogen was introduced to keep the pressure in the reactor at 0.5MPa. The reaction medium was heated to 140°C at a heating rate of 5°C / min, kept at a constant temperature for 30 minutes, and then cooled to 50°C naturally. Because the pelletizing temperature is 10°C higher than the softening point of high temperature coal tar pitch, and under the action of surface tension and polyvinyl alcohol surfactant, all high temperature coal tar pitch particles become spherical coal pitch balls. Then the pitch balls were placed in a rotary kiln and passed through for 20m 3 / h of air, and heated to 330°C at a heating rate of 0.5°C / min and kept at a constant ...

Embodiment 2

[0054] Taking heavy asphalt slag as raw material, the softening point of the raw material is 226° C., the coking value is 76.8%, and the content of quinoline insoluble matter is 43.9%. Using a twin-screw extruder, 1000 kg of heavy asphalt residue and 100 kg of coal tar were uniformly mixed to form coal tar / heavy asphalt residue bars with a diameter of 3 mm. Using a roller crusher, 1100kg of coal tar / heavy asphalt slag bars were crushed into coal tar / heavy asphalt slag particles with a diameter of 0.6-0.8 mm. 3000L of deionized water, 10kg of polyvinyl alcohol, and 500kg of coal tar / heavy asphalt slag particles were placed in a 5000L high-pressure reactor successively, and 99.99% high-purity nitrogen was introduced to keep the pressure in the reactor at 0.5MPa. Then, the reaction medium was heated to 93°C at a heating rate of 5°C / min, kept at a constant temperature for 30 minutes, and then cooled to 50°C naturally. The produced 1100kg product is coal tar / heavy asphalt slag bal...

Embodiment 3

[0056] Using heavy asphalt slag with a softening point of 226°C as raw material, 1000kg of heavy asphalt slag and 270kg of coal tar were uniformly mixed with a twin-screw extruder to produce coal tar / heavy asphalt slag with a diameter of 3mm. Using a roller crusher, 1270kg of coal tar / heavy asphalt slag bars were crushed into coal tar / heavy asphalt slag particles with a diameter of 0.6-0.8 mm. 3000L of deionized water, 10kg of polyvinyl alcohol, and 500kg of coal tar / heavy asphalt slag particles were placed in a 5000L high-pressure reactor successively, and 99.99% high-purity nitrogen was introduced to keep the pressure in the reactor at 0.5MPa. Then, the reaction medium was heated to 193°C at a heating rate of 5°C / min, kept at a constant temperature for 30 minutes, and then cooled to 50°C naturally. Due to the high spheroidizing temperature, coal tar / heavy asphalt slag particles dissolve and coalesce at this spheroidizing temperature, and only ellipsoidal coal tar / heavy aspha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com