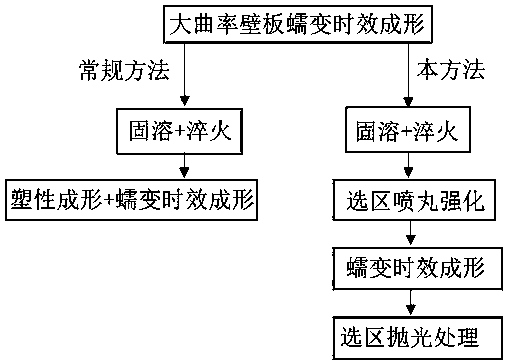

Creep aging forming method for large-curvature wallboard

A creep aging forming, large curvature technology, applied in furnace types, furnaces, heat treatment furnaces, etc., can solve the problem of reducing the corrosion resistance and fatigue resistance of wall panels, weakening the outstanding advantages of creep aging forming process, and creep aging forming. Low efficiency and other problems, to achieve the effect of increasing dislocation density and instability, eliminating stress concentration defects, and improving corrosion resistance and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

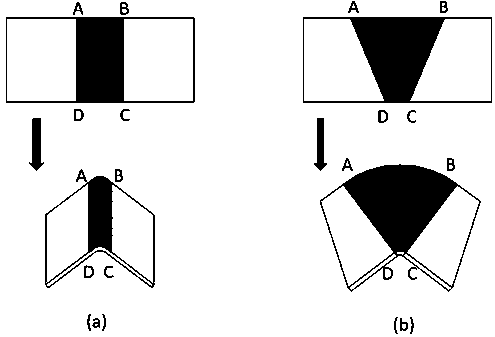

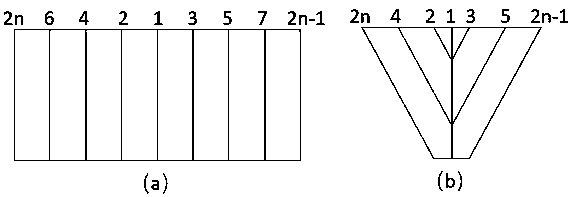

[0035] The wall plate material is 2024 aluminum alloy, the length of the wall plate blank is 1200mm, the width is 600mm, and the thickness is 5mm. Bending with a single curvature along the length of the wall plate, the bending radius is 300mm, and the bending angle is 45°. After calculation, the length of the siding selection area is 600mm and the width is 140mm. Using cast steel shot with a hardness of 500HV and a diameter of 400μm, with a spray speed of 500 m / s and a nozzle moving speed of 300 mm / min, press image 3 The shot peening trajectory shown in a performs shot peening on the selected area.

[0036] Put the panel in a mold with a radius of 235mm, apply a forming pressure of 300MPa in an autoclave, and keep it at a temperature of 175°C for 12h. Uninstall the pickup. Finally, use SiC sandpaper with a particle size of 400 and 600 to polish the selected area, and then use canvas to mechanically polish the selected area.

Embodiment 2

[0041] The wall plate material is 2024 aluminum alloy, the length of the wall plate blank is 1200mm, the width is 600mm, and the thickness is 5mm. Multi-curvature bending along the length of the wall plate, the bending radii along the width direction are 300mm, 400mm, 500mm respectively, and the bending angle is 45°. After calculation, the panel selection area is a trapezoid with a top edge of 140mm, a bottom edge of 240mm, and a height of 600mm. Using cast steel shot with a hardness of 500HV and a diameter of 400μm, with a spray speed of 500 m / s and a nozzle moving speed of 300 mm / min, press image 3 The shot peening trajectory shown in b performs shot peening on the selected area.

[0042] Put the wall panels in molds with radii of 235mm, 335mm, and 435mm, apply a forming pressure of 350MPa in an autoclave, and keep warm at a temperature of 175°C for 12h. Uninstall the pickup. Finally, use PH=2 sulfuric acid to etch and polish the selected area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com