Production method for manufacturing cold-rolled oriented silicon steel with high magnetic strength by using generally oriented steel raw material

A technology of grain-oriented silicon steel and a production method, which is applied in the production field of manufacturing high-magnetic-inductance cold-rolled grain-oriented silicon steel with general grain-oriented steel raw materials, can solve the problems of difficult production, high energy consumption, and large billet burning loss in the cold rolling process, and achieves perfection. The effect of secondary recrystallization, high yield of silicon steel, and enhanced suppression ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] 1. Use a 500 kg vacuum furnace to make steel according to the final composition of Table 1, and the hot rolling conditions are shown in Table 2:

[0084] Table 1. Steelmaking composition of experimental steel (wt%)

[0085] Element C Si mn P S als N sn Remark A 0.059 3.15 0.15 0.021 0.015 0.025 0.048 0.018 B 0.048 3.09 0.16 0.019 0.011 0.018 0.005 0.022

[0086] Table 2. Experimental steel hot rolling conditions (°C)

[0087] project heating temperature Finishing temperature coiling temperature Thickness (mm) Remark C 1190 900 510 2.20 D 1295 950 535 2.20 compared to

[0088] 2. The normalization conditions are: 1120°C×5s+900°C×60s+50°C / s cooling;

[0089] 3. The steel strip was cold-rolled to 0.30mm, decarburized and coated with MgO annealing separator, followed by high-temperature annealing and tensile leveling annealing (including coating insulation layer), and th...

Embodiment 2

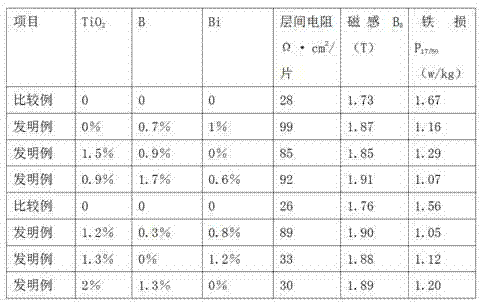

[0097] Use the A component in the middle of the above table 1 and the C hot-rolled condition steel in the table 2 to carry out the nitriding experiment in the early stage of the high temperature annealing stage. Table 4 shows the influence of the holding time of the step and the dew point of the atmosphere on the magnetic properties.

[0098] Table 4. Relationship between atmosphere, time and dew point and magnetism

[0099]

[0100] For a long time, the general production method of oriented silicon steel has been to use high-temperature heating of slabs. The heating temperature of slabs is as high as about 1400°C, so that the favorable inclusions can be fully dissolved, and the dispersion distribution and reasonable size of the favorable inclusions can be obtained during the hot rolling process. During high-temperature annealing, the primary recrystallization grains are suppressed to obtain a relatively good secondary recrystallization structure, and only 30Q120-30Q140, 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com