Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "High voltage strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

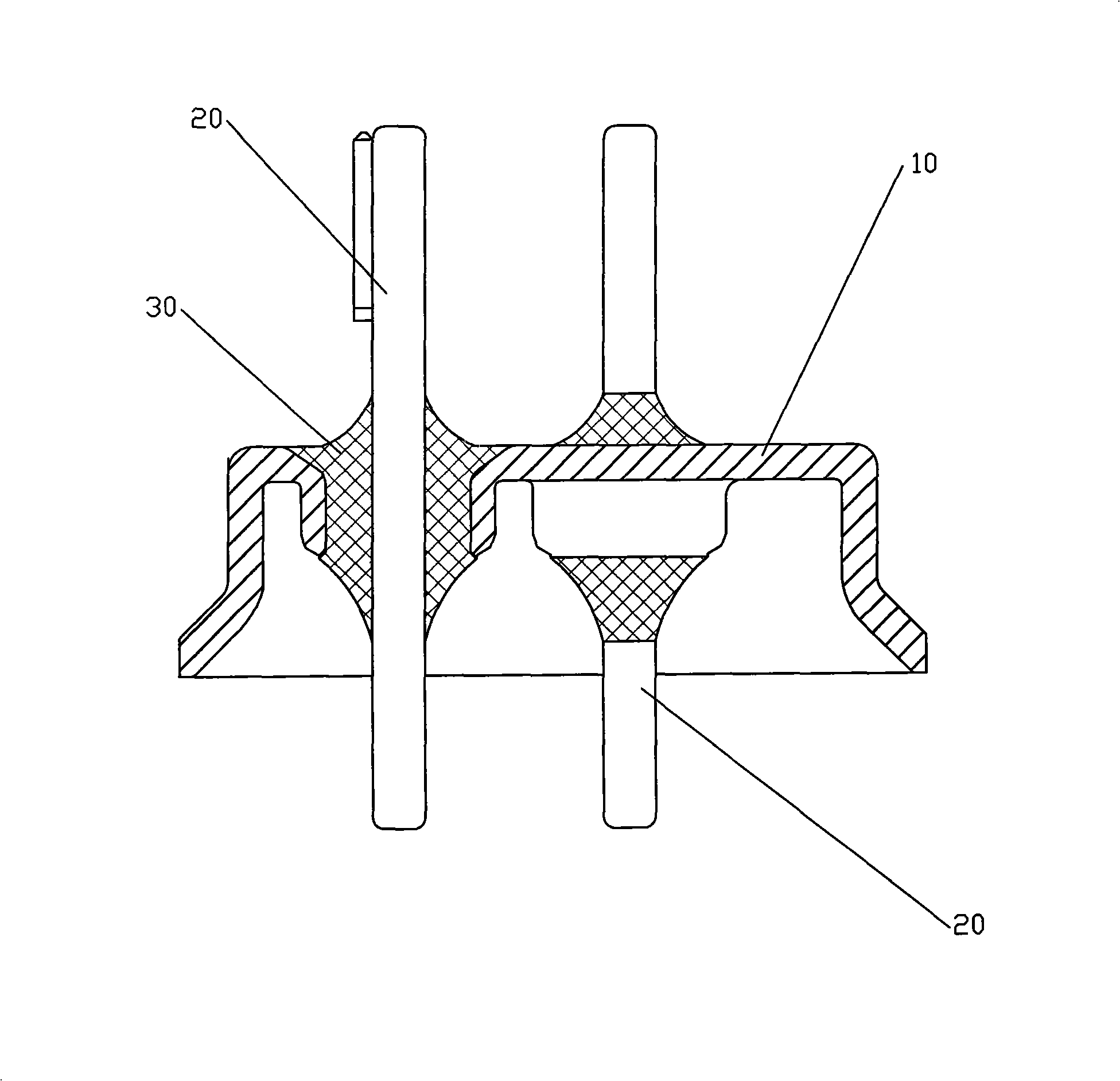

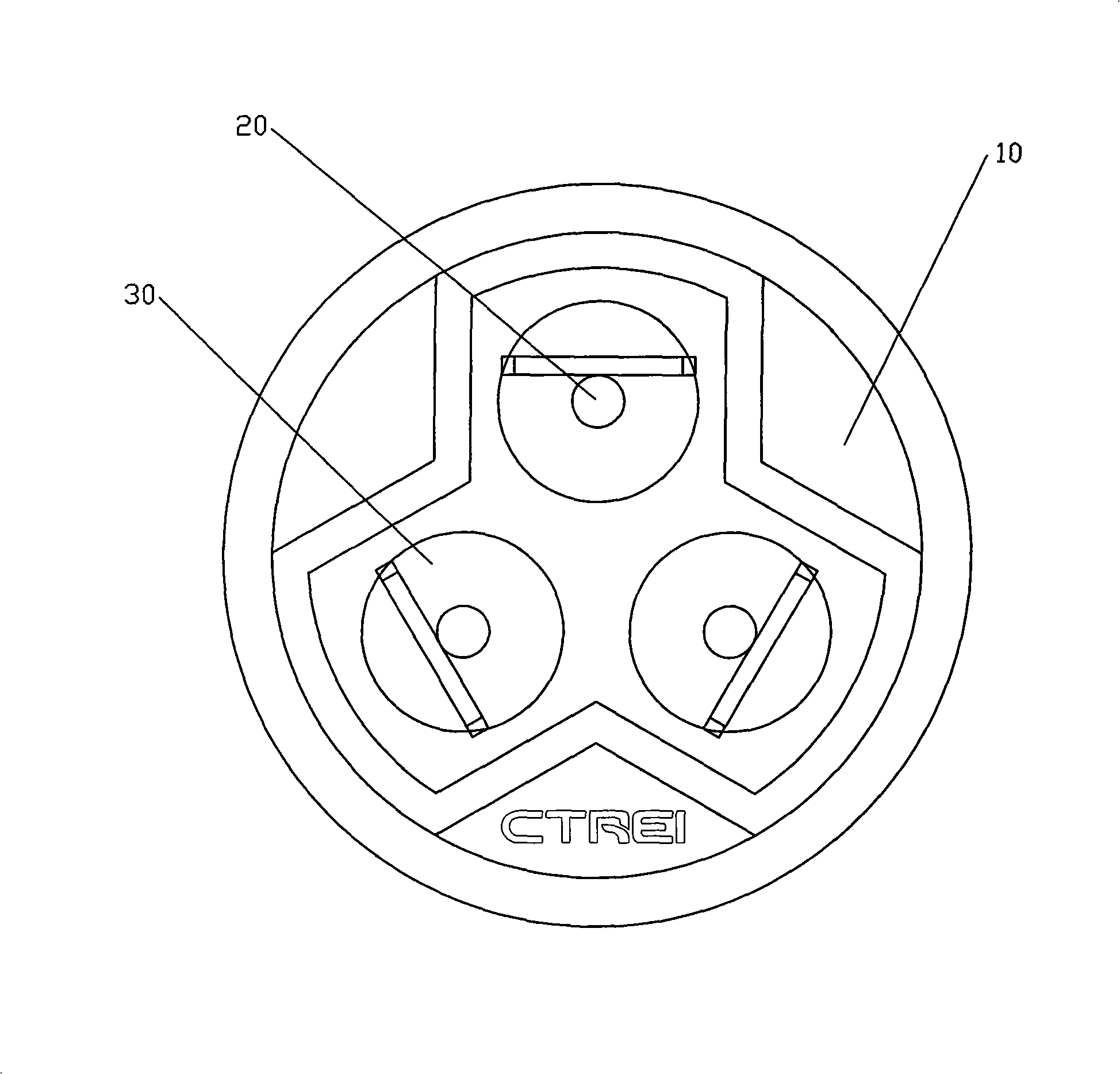

Connector post of refrigeration compressor

ActiveCN101404360AEasy to sinterPorcelain forming temperature rangeElectrically conductive connectionsCeramicsRefrigeration compressorSilicon oxide

The invention relates to a terminal part of a compressor, in particular to a binding post of a cold compressor of highly reliable ceramic insulation medium connection. The binding post comprises an end cover which is welded with a shell of the compressor, and a conductive pillar that is sealed and connected with the end cover by glass; wherein, the glass is used for playing the role of insulation and sealing, the conductive pillar is provided with an insulator separating the surface of the glass from the air, and the insulator is made of the following materials: 92-96% of aluminium oxide, 2-3% of silicon oxide, 1-3% of calcium oxide, 0.5-1.0% of bismuth oxide and 0.5-1.0% of antimony oxide. The binding post has the advantages that specially prepared aluminum oxide ceramics is adopted to replace steatite ceramics (or forsterite) to be taken as the insulator, so that the creep age distance is prolonged, and the phenomenon of overflash is avoided in the low vacuum environment, thereby effectively avoiding the serious result of compressor explosion. At the same time, the expansion of microcrack is prevented, and the probability of air leakage is effectively reduced, so that good connecting effect is formed.

Owner:CHAOZHOU THREE CIRCLE GRP

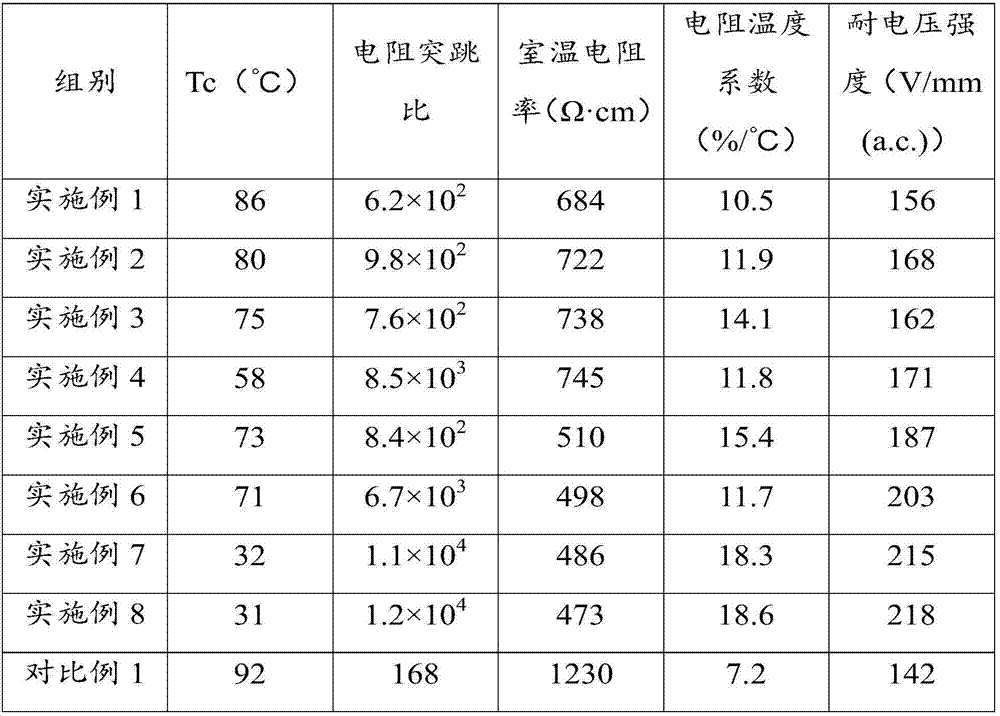

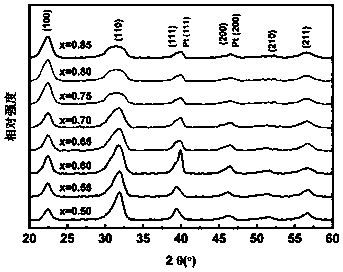

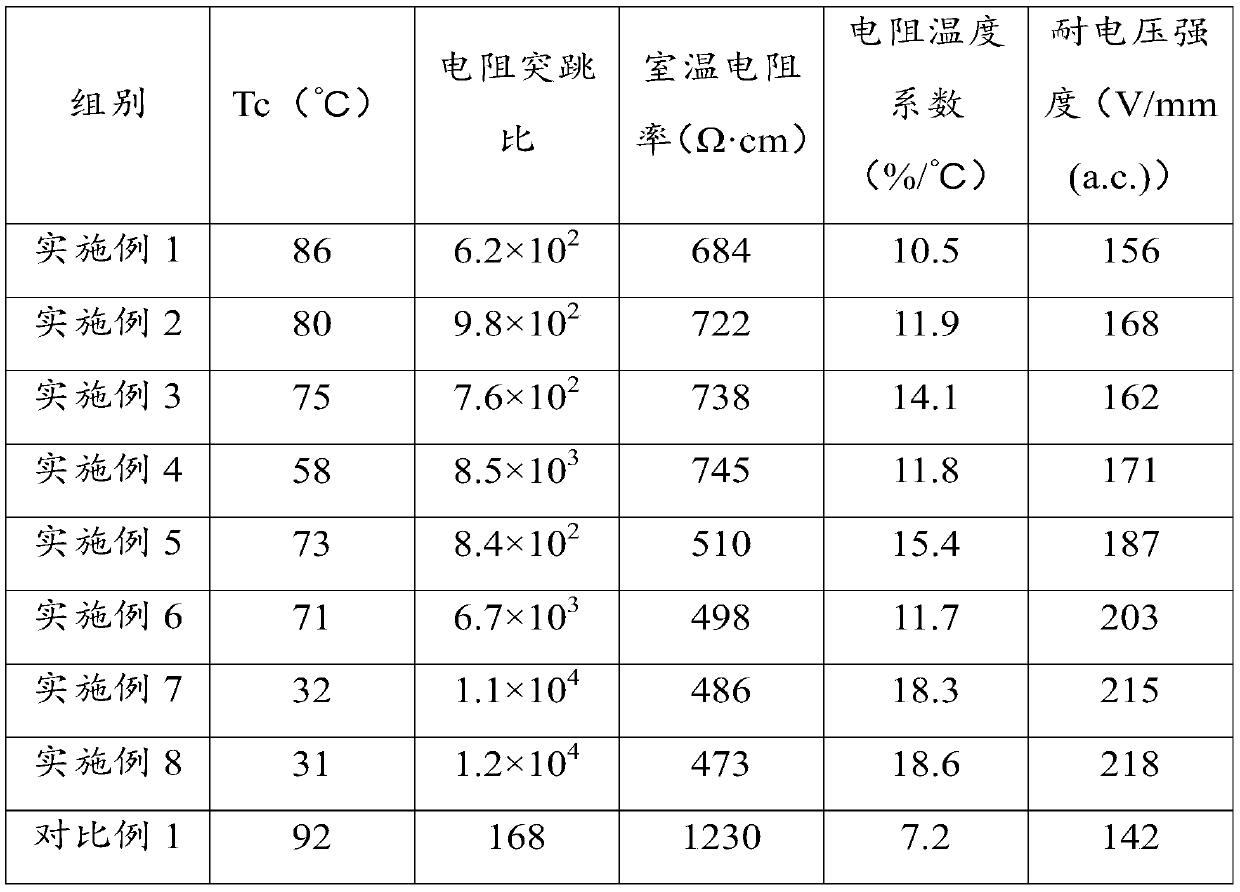

PTCR ceramic material and preparation method and application thereof

ActiveCN107226694AImprove microstructureUnique physical propertiesPositive temperature coefficient thermistorsHigh resistanceCurie temperature

The invention relates to the field of electronic ceramics and provides a PTCR ceramic material and a preparation method and application thereof. The PTCR ceramic material has a general formula x(BaTiO3)-y(SrTiO3)-(1-x-y)(CaTiO3)+a mol% M+b mol% N, x is greater than or equal to 0.6 and less than or equal to 0.9, y is greater than or equal to 0.1 and less than or equal to 0.4, a is greater than or equal to 0.1 and less than or equal to 1, b is greater than or equal to 0 and less than or equal to 3, the sum of x and y is less than or equal to 1, M represents any one or more of Y2O3, Bi2O3, La2O3, Sm2O3, Nb2O5, Ta2O5 and Sb2O5, and N represents any one or more of MnO2, CuO, Fe2O3, ZrO2, Al2O3, SiO2, TiO2, BN and B2O3. The PTCR ceramic material has the advantages of low Curie temperature, high resistance abrupt change ratio and high resistance temperature coefficient.

Owner:TONGREN UNIV

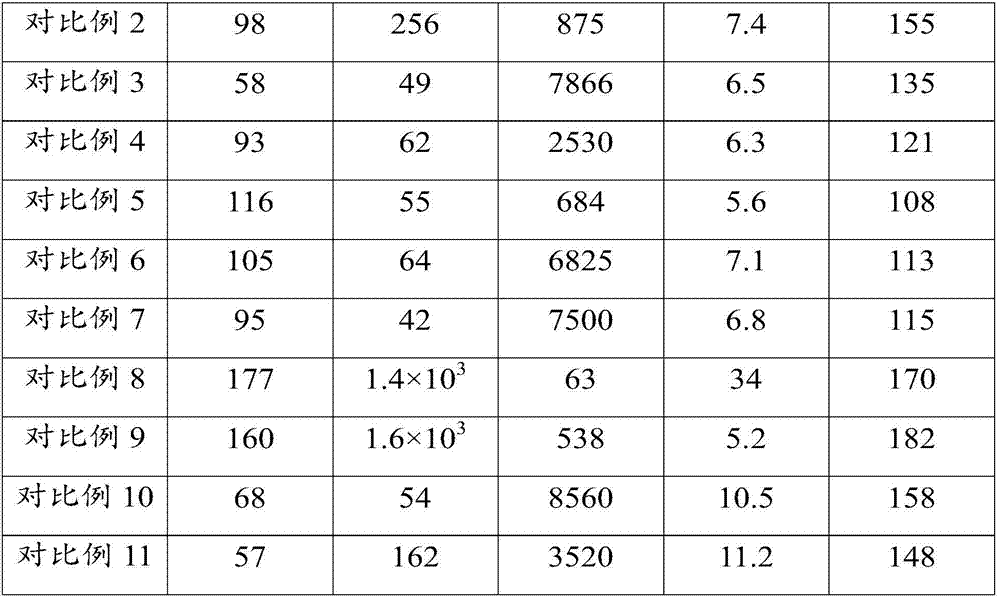

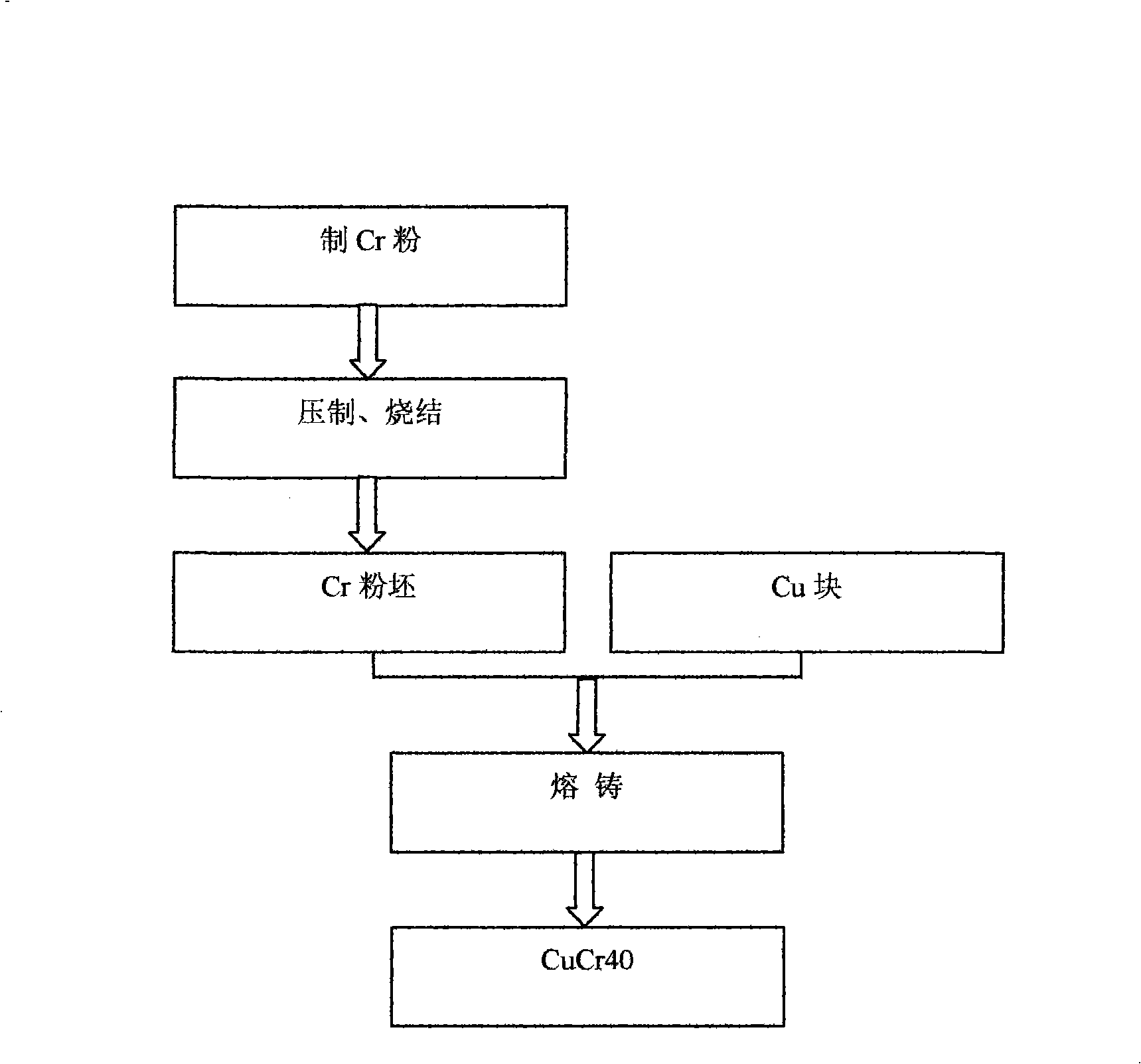

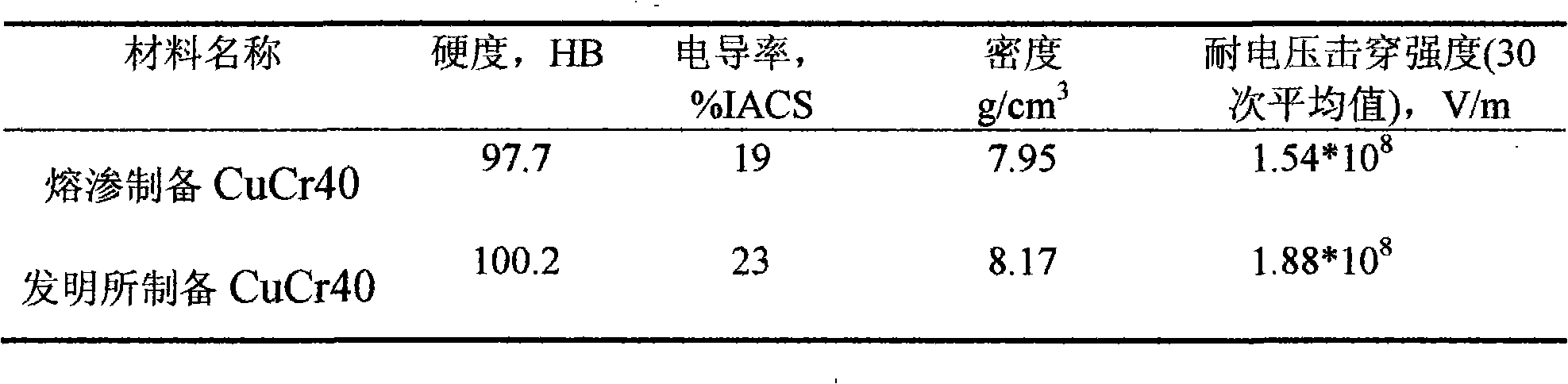

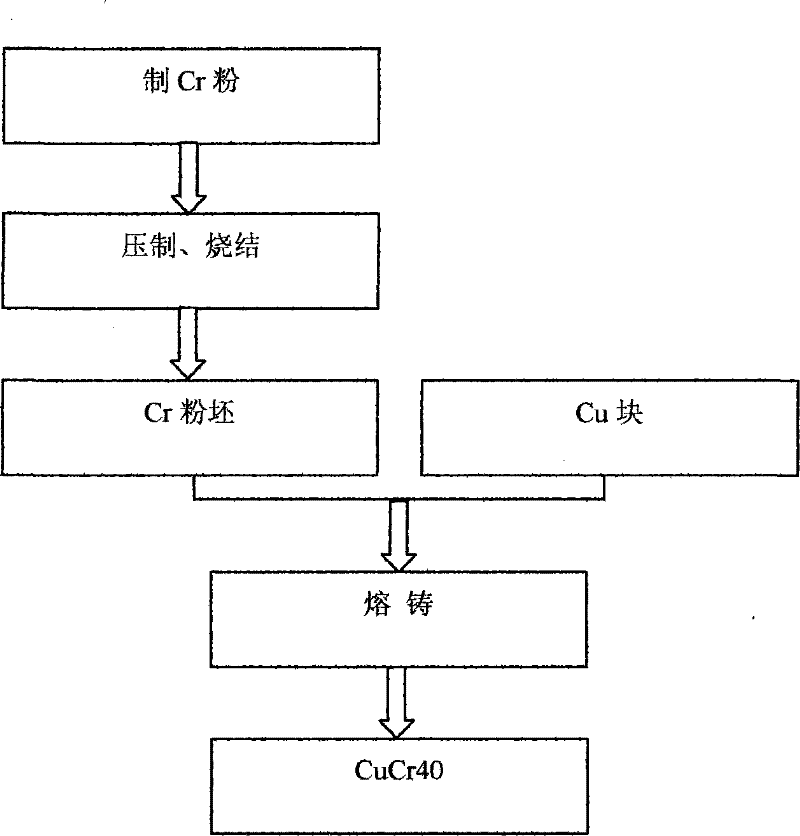

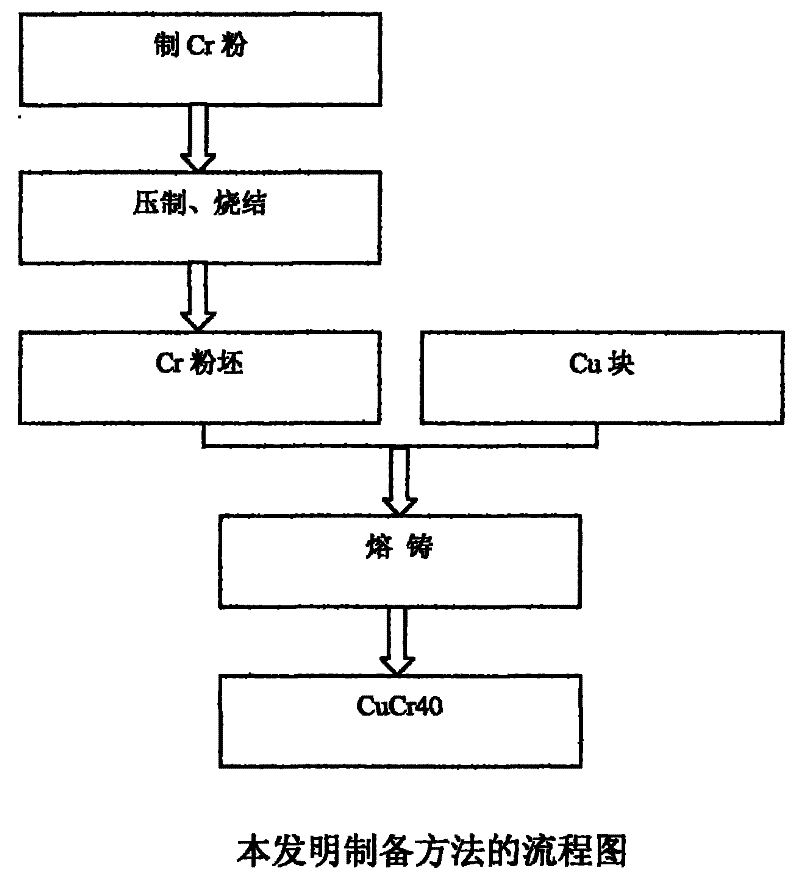

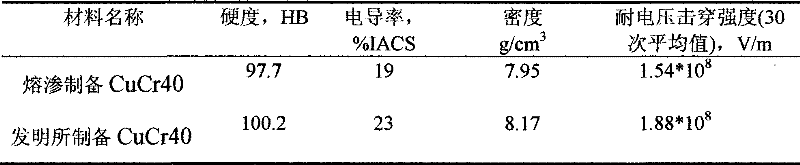

Method for producing CuCr40 contact material with vacuum fusion cast method

The invention discloses a method for preparing a CuCr40 electrical contact by adopting a vacuum fusion casting method, which belongs to the technical field of metal materials preparation. The CuCr40 electrical contact comprises the following compositions in percentage by weight: 40 percent of Cr, and the balance being Cu. The CuCr40 electrical contact is prepared by the following method: a Cr block is processed into Cr powder through a grinding crusher under the protection of low-temperature liquid; the Cr powder is pressed and then is sintered into a Cr powder billet; and then a Cu block and the Cr powder billet are placed into a vacuum furnace for heating, the casting is performed after the fusion, and a CuCr40 electrical contact material is obtained after cooling. The method has the advantages that the Cr block is crushed into the Cr powder, and the Cr powder is then pressed and sintered into the Cr powder billet, so as to reduce fusion temperature and shorten fusion time. The preparation method has simple process and low cost, and the prepared CuCr40 composite material has more excellent performance compared with a filtrated CuCr40 composite material prepared by infiltration.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Solid bus slot with high strength

InactiveCN101552441AThere will be no mutual "extended bite"Convenient thermal protectionBus-bar installationElectrical conductorHigh intensity

The invention discloses a solid bus slot with high strength which consists of a shell made of the composite materials, the composition of the composite materials and a preparation method thereof. By adopting the bus slot, as the shell of the bus slot made of the composite materials, the bus slot has good hydrolytic resistance and good anti-salt fog performance. The withstand voltage is as high as 5000V or more; and as the linear expansion coefficient of the composite materials are very close to the conductor, the situation of 'extended bite' with each other can not appear due to the mixed-assembled with a plurality of materials with different expansion coefficients, thus improving the insulation protection of the bus slot and having very high insulation performance. The mechanical strength of the bus slot made of the composite materials is high, which can withstand 15 Joules impact strength. The overload capability of the bus slot is strong, the anti inter-phase short circuit ability is good, the low temperature resistance is good, the protection grade can achieve IP68, and the use life is longer than that of the metal.

Owner:JIANGSU JIANGCHENG ELECTRIC

Glass reinforced plastic and preparation method thereof

The invention provides glass reinforced plastic and a preparation method thereof. The glass reinforced plastic comprises glass fiber cloth and a resin composition cured on the glass fiber cloth, wherein the resin composition comprises vinyl resin, silicon dioxide aerogel, styrene and a peroxide initiator; and the mass ratio of the silicon dioxide aerogel to the vinyl resin is (0.02-0.5):1. Under the effect of the peroxide initiator, the styrene, the silicon dioxide aerogel, the vinyl resin and the glass fiber cloth are cured to obtain the glass reinforced plastic. The glass reinforced plastic provided by the invention has high voltage resistance, mechanical property and corrosion resistance.

Owner:珠海正一复合材料制品有限公司

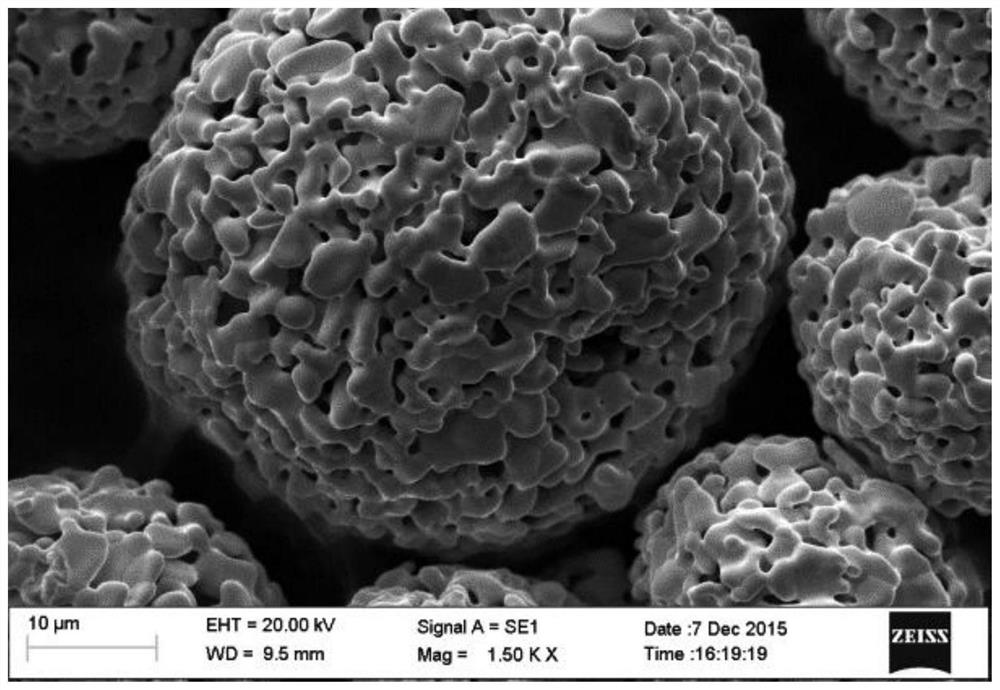

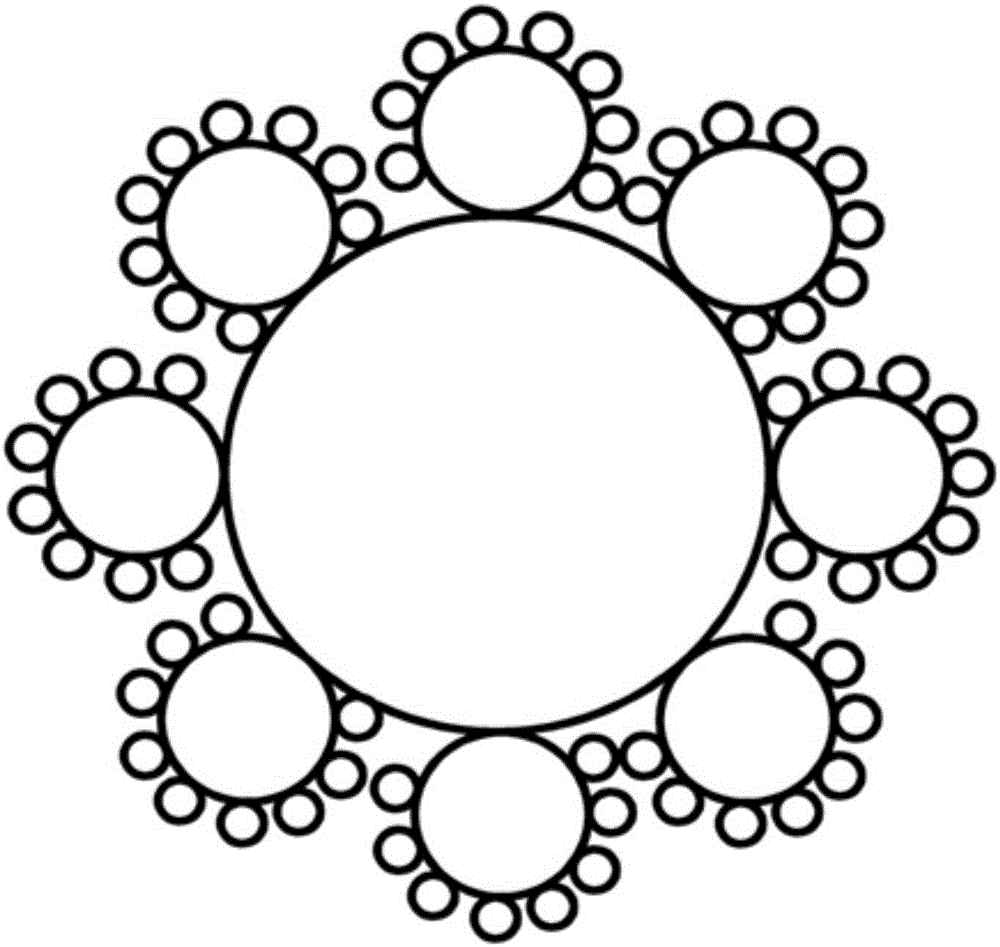

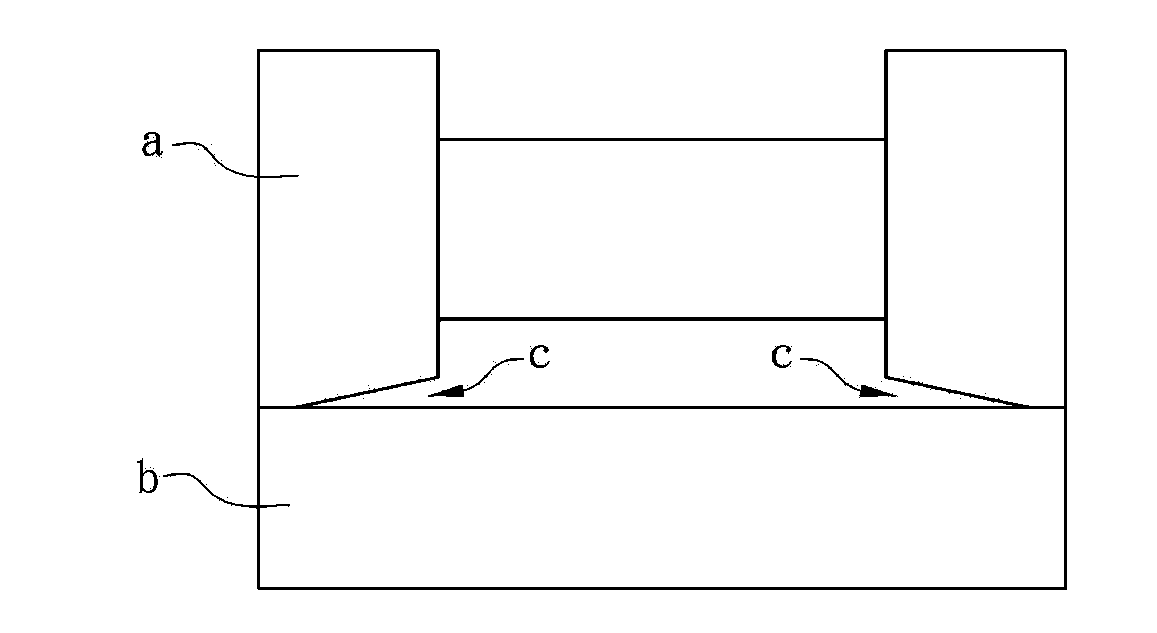

Effective and controllable preparation method of framework with multi-polar hole structure

PendingCN111778424ASolve the problem of residual air bubbles caused by seepageHigh voltage strengthTransportation and packagingMetal-working apparatusTungsten alloy

The invention discloses an effective and controllable preparation method of a framework with a multi-polar hole structure. The preparation method specifically comprises the following steps of S1, reducing initial tungsten powder by flame spraying to prepare spherical aggregate tungsten powder; and S2, preparing a tungsten framework of the multi-polar hole structure from the spherical aggregate tungsten powder prepared in the S1 by adopting a discharge plasma sintering technique. The preparation method provided by the invention solves the problem of preparing the tungsten framework of the multi-polar hole structure in a process of preparing a copper-tungsten alloy by an infiltration sintering method.

Owner:XIAN UNIV OF TECH

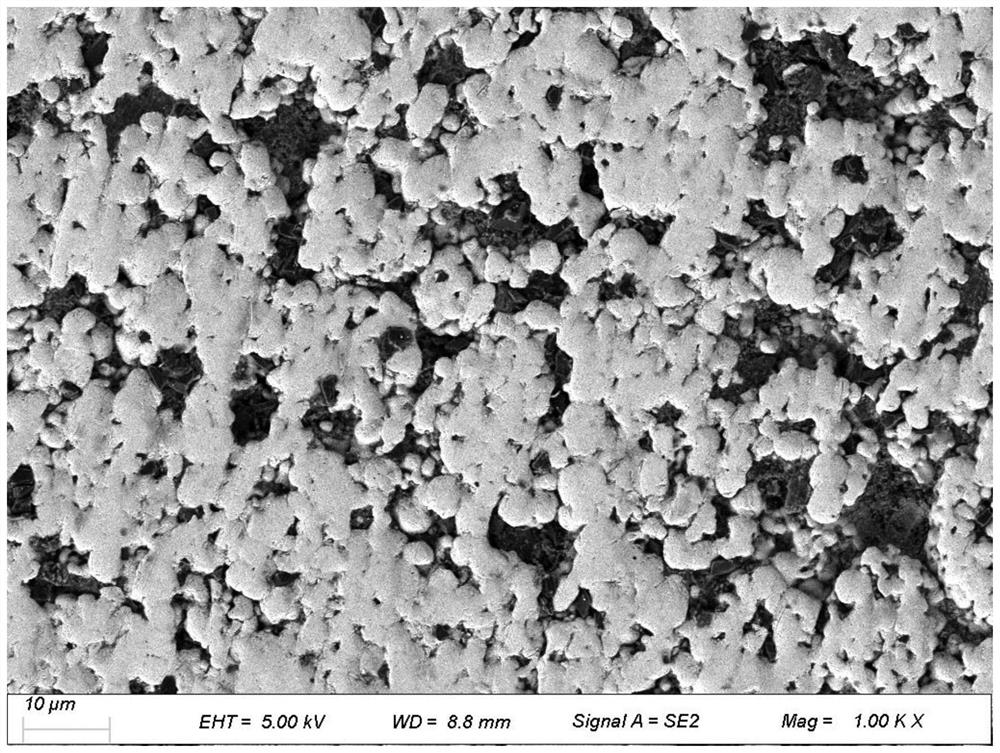

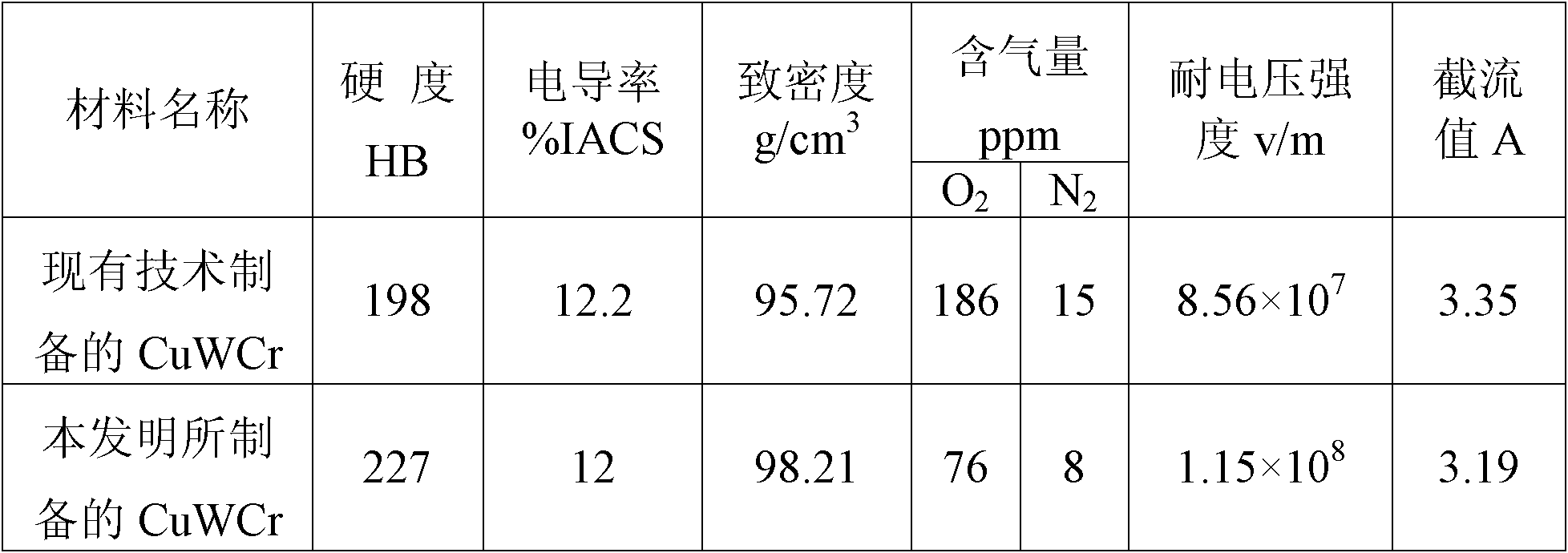

Method for preparing CuWCr composite material through electric arc melting and infiltration method

The present invention discloses a method for preparing a CuWCr composite material through electric arc melting and an infiltration method. The method comprises: adding Cu powder and Cr powder to a mixer to carry out mixing; carrying out mould pressing or cold isostatic pressing for the mixed material; placing the pressed blank in a vacuum sintering furnace to carry out sintering under a vacuum environment to obtain a CuCr infiltration blank; then carrying out mould pressing or cold isostatic pressing for W powder, and controlling the porosity of the W blank; placing the W blank in the vacuum sintering furnace to carry out sintering under a vacuum environment to obtain a W skeleton; finally, placing the W skeleton on the bottom of a water-cooled copper crucible of a consumable electrode arc melting furnace, placing the prepared CuCr infiltration blank on the W skeleton, carrying out melting for the CuCr infiltration blank under a vacuum environment, such that the CuCr infiltration blank is infiltrated in the W skeleton after the CuCr infiltration blank is molten at high arc temperature; carrying out cooling to obtain the CuWCr composite material. The prepared CuWCr composite material provided by the present invention has characteristics of high voltage strength resistance, high conductivity and low impurity content.

Owner:XIAN UNIV OF TECH

Method for preparing cucr 40 contact material by vacuum casting method

The invention discloses a CuCr40 electric contact prepared by adopting a vacuum melting casting method, which belongs to the technical field of metal material preparation. Its composition by weight percentage is: 40% Cr, and the rest is Cu. It is prepared by the following method: under the protection of low-temperature liquid, the Cr block is processed into Cr powder by grinding and crushing machine, the Cr powder is pressed and sintered into Cr powder, and then the Cu block and Cr powder are put into a vacuum furnace Heating, casting after melting, and then producing CuCr40 electrical contact material after cooling. The invention has the advantages of crushing Cr lumps into Cr powder, and then pressing and sintering to make Cr powder billets, which lowers the melting temperature and shortens the melting time. The preparation method of the invention has simple process and low cost, and the prepared CuCr40 composite material has superior performance compared with the infiltrated CuCr40 composite material.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Preparation method of copper-tungsten alloy and CuW-CrCu integrated material

InactiveCN106381411AImproved arc erosion resistanceHigh voltage strengthContact materialsTransportation and packagingHydrogenNational standard

The invention discloses a preparation method of a copper-tungsten alloy. The preparation method of the copper-tungsten alloy comprises the following steps: mixing submicron tungsten powder, micron tungsten powder, ultra-micron tungsten powder and induction Cu powder, bonding, drying and sieving to obtain mixed powder; pre-pressing the mixed powder to form a blank and then carrying out sintering infiltration on the blank to obtain the copper-tungsten alloy. A preparation method of a CuW-CrCu integrated material comprises the following steps: adding the prepared CuW alloy and a CrCu material in a high-purity graphite crucible, sintering under hydrogen protection atmosphere, then carrying out solid solution treatment and aging to obtain the CuW-CrCu integrated material. Through the preparation method of the copper-tungsten alloy, different contents of submicron tungsten powder and ultra-micron tungsten powder are added into conventional micro tungsten powder to prepare the multi-size CuW alloy; the conductivity of the prepared alloy is obviously improved and exceeds the national standard by 30%-50%; the arc erosion resistance of the prepared CuW alloy under the scheme is improved; the voltage resistance strength of the prepared CuW alloy is slightly improved; the bonding strength of the prepared CuW-CrCu integrated material is obviously improved.

Owner:XIAN UNIV OF TECH

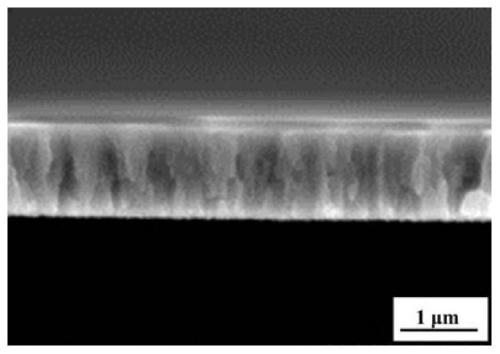

Vacuum arc-extinguishing chamber contact material surface coating and processing method thereof

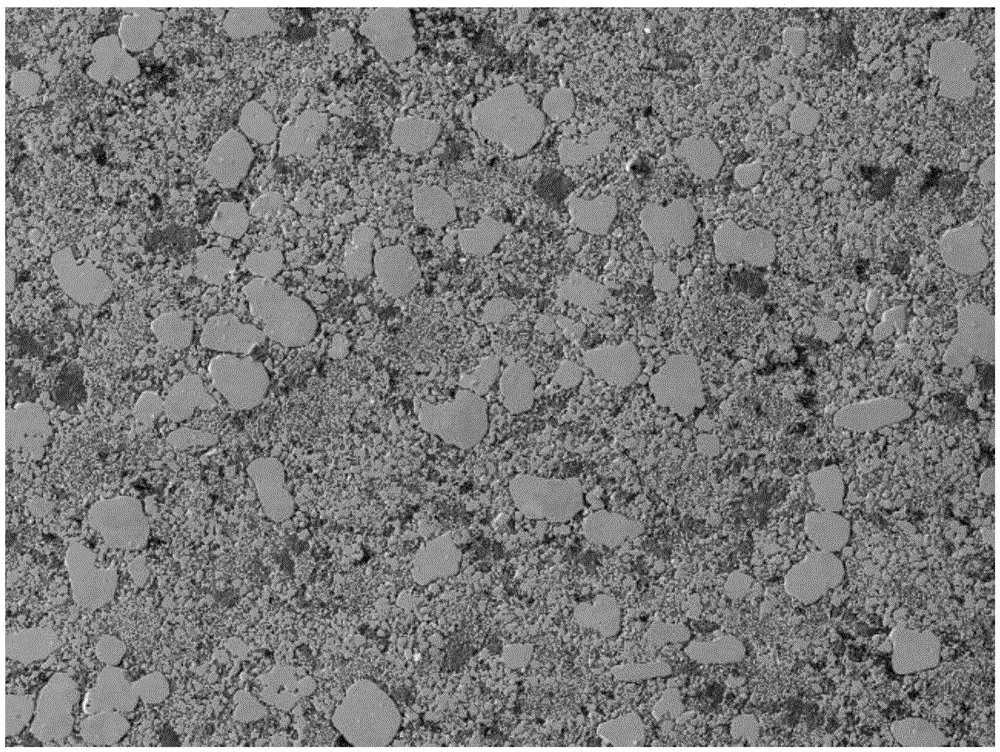

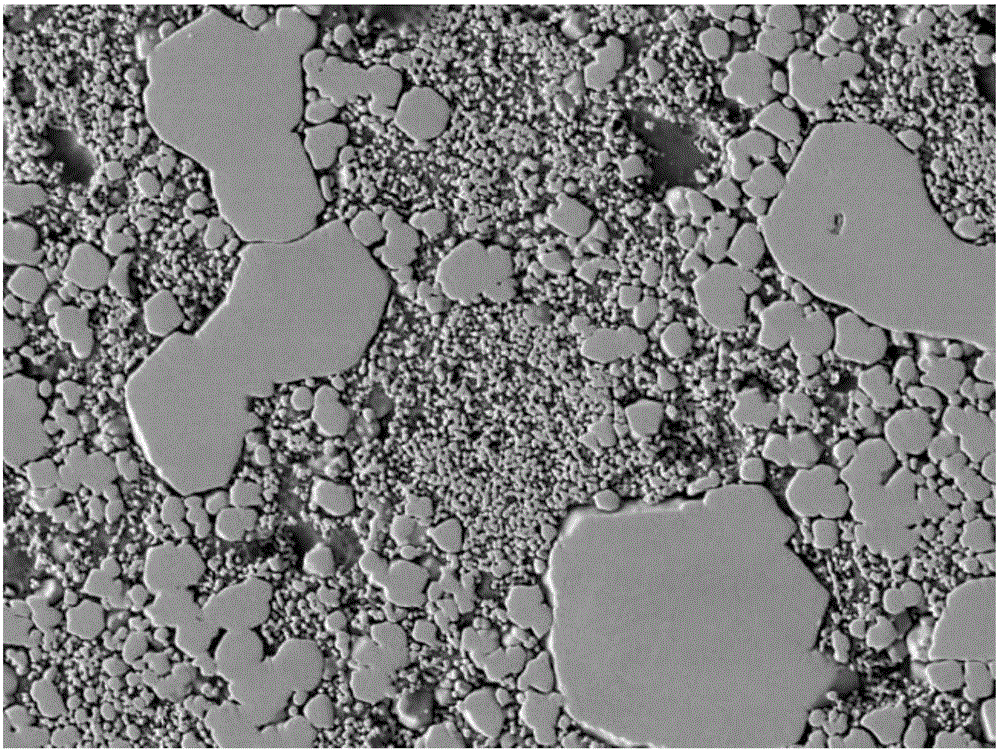

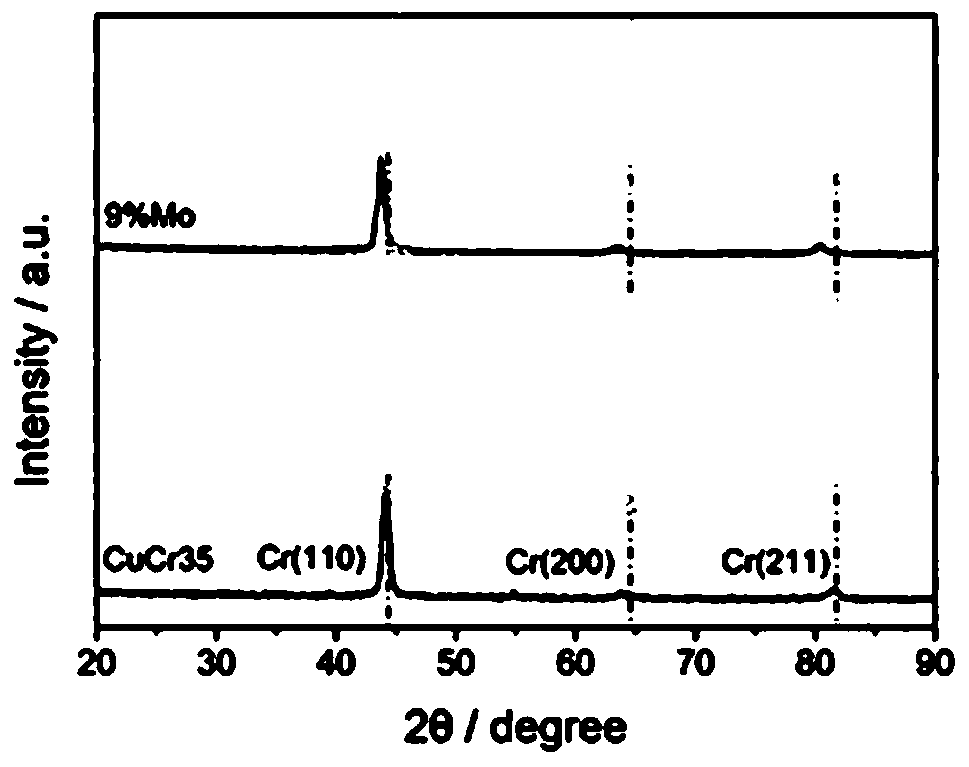

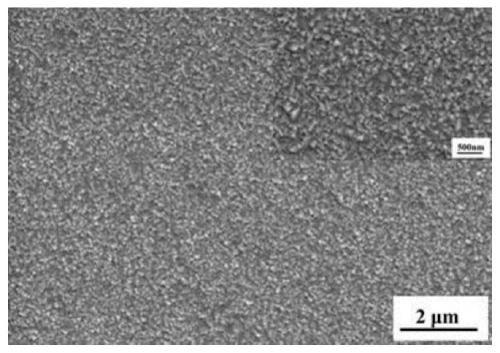

ActiveCN111074209AImprove compactnessThe composition is uniform and precisely controllableVacuum evaporation coatingSputtering coatingAlloyCopper

The invention discloses a vacuum arc-extinguishing chamber contact material surface coating and a processing method thereof. The method adopts a metal copper-chromium molybdenum target material for forming a CuCrMo alloy film on a CuCr alloy contact material substrate, wherein the CuCrMo alloy film comprises the following components of, by mass, 25%-55% of Cr, 5%-9% of Mo, and the balance Cu. Themethod specifically comprises the following steps that 1, the CuCr alloy contact material substrate is ground and polished; 2, the ground and polished CuCr alloy contact material substrate is cleanedand blow-dried; and 3, the surface of the CuCr alloy contact material substrate subjected to cleaning and blow-drying is coated with the CuCrMo alloy film by adopting a magnetron sputtering method, and finally the CuCr alloy contact material substrate with the CuCrMo alloy film grown is obtained. The coating prepared through the processing method has the thickness of 1-20 microns. Compared with the CuCr35, the CuCrMo alloy film prepared through the processing method has higher voltage resistance strength, lower chopping values and longer arcing time.

Owner:XI AN JIAOTONG UNIV

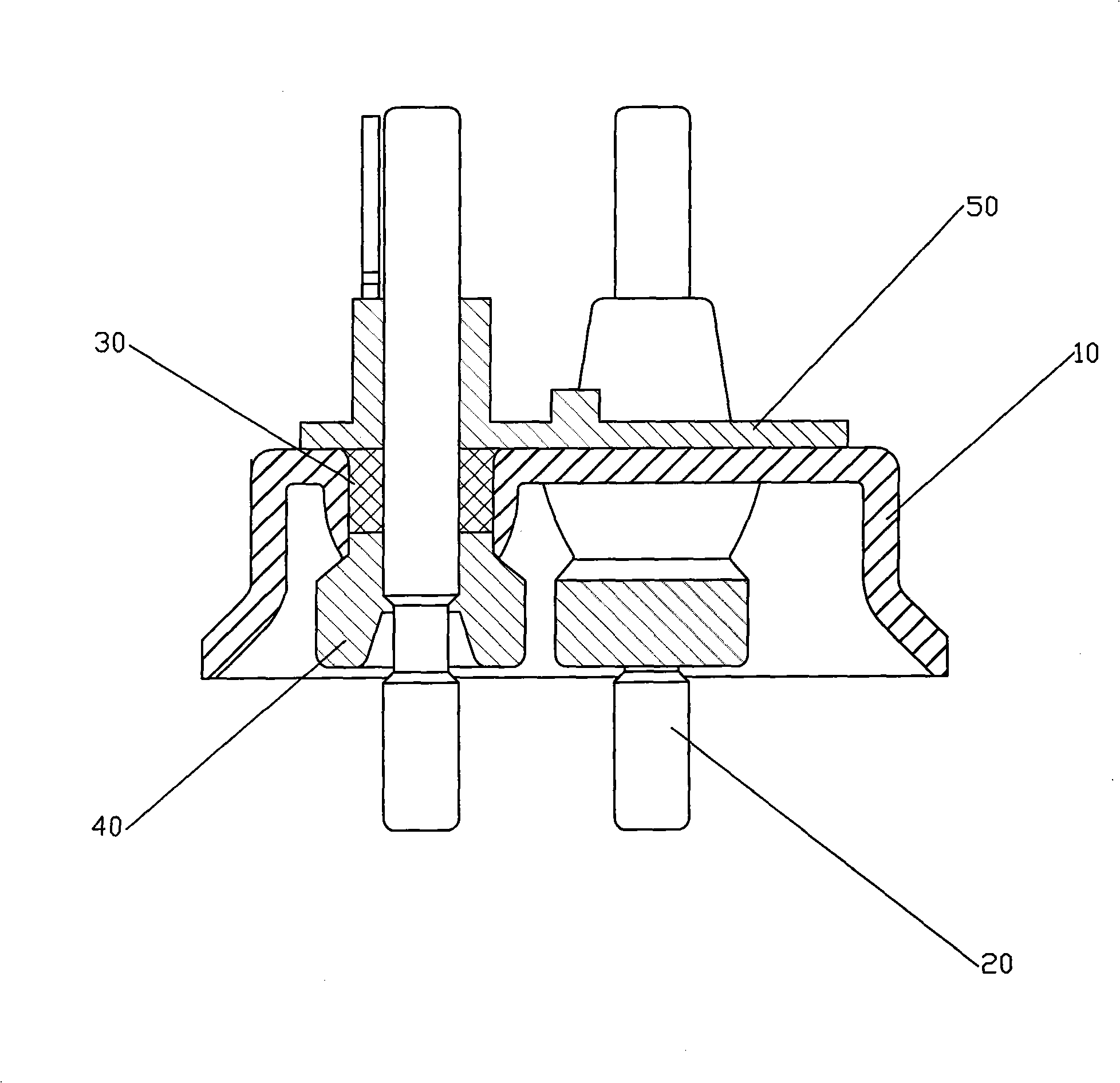

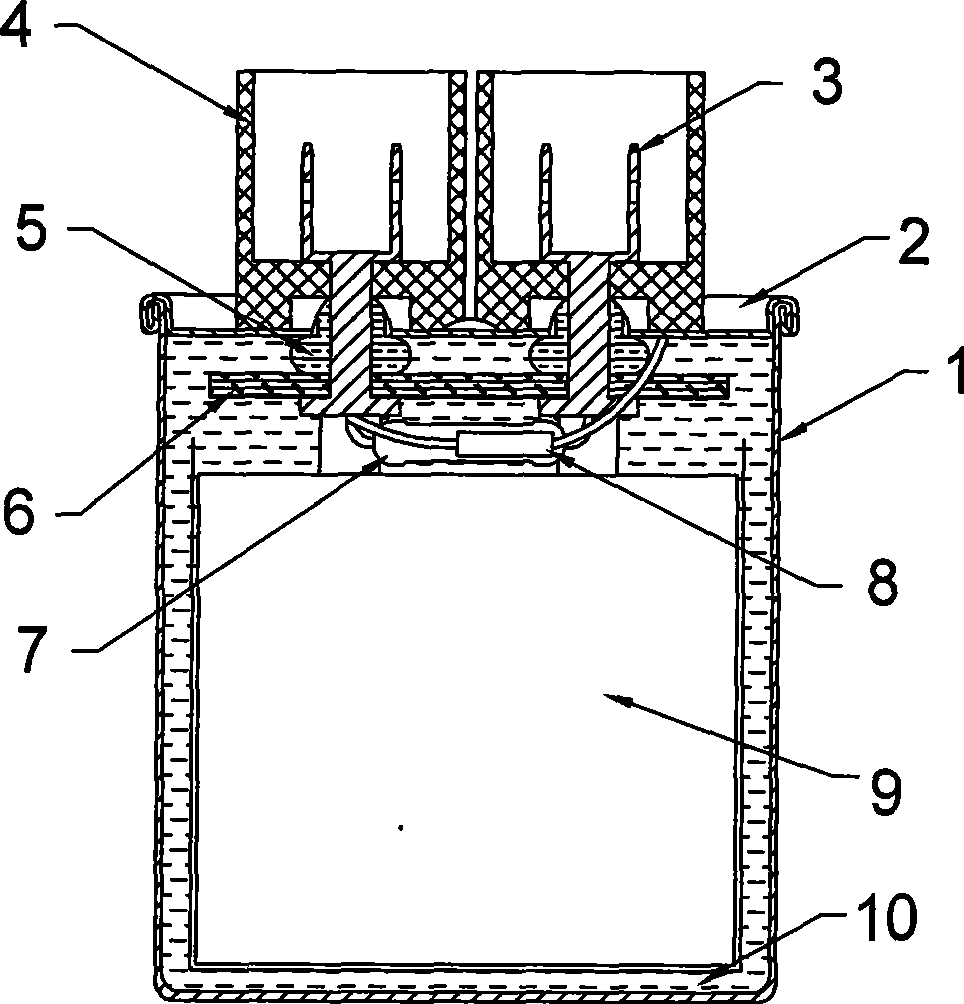

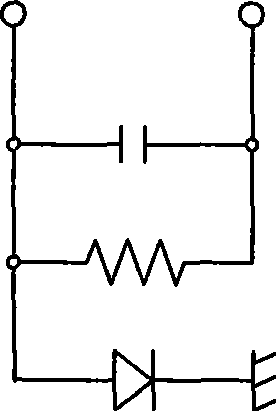

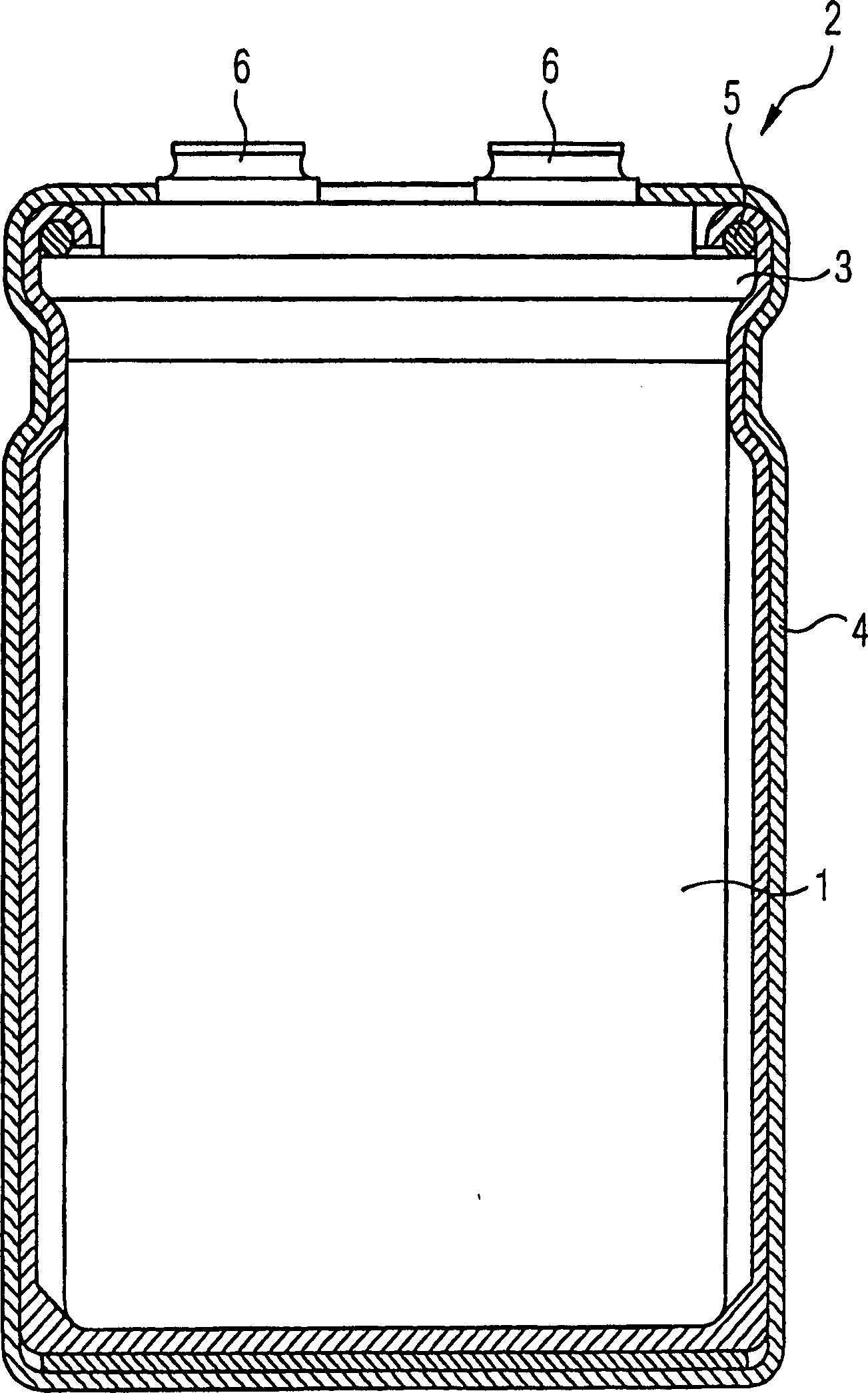

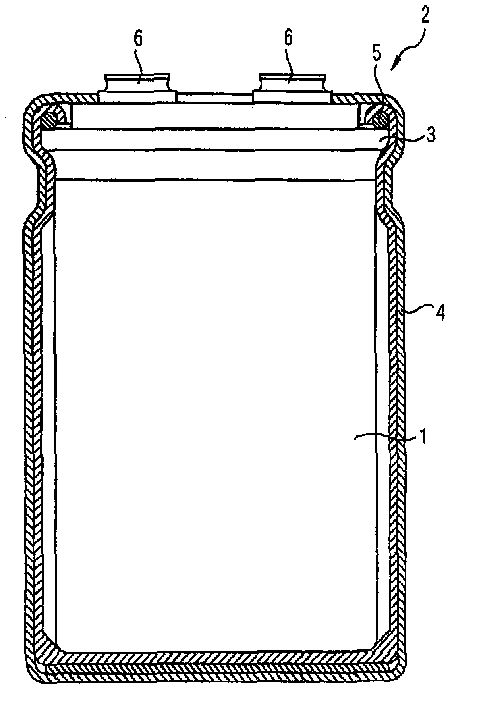

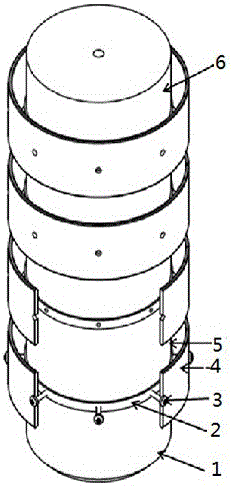

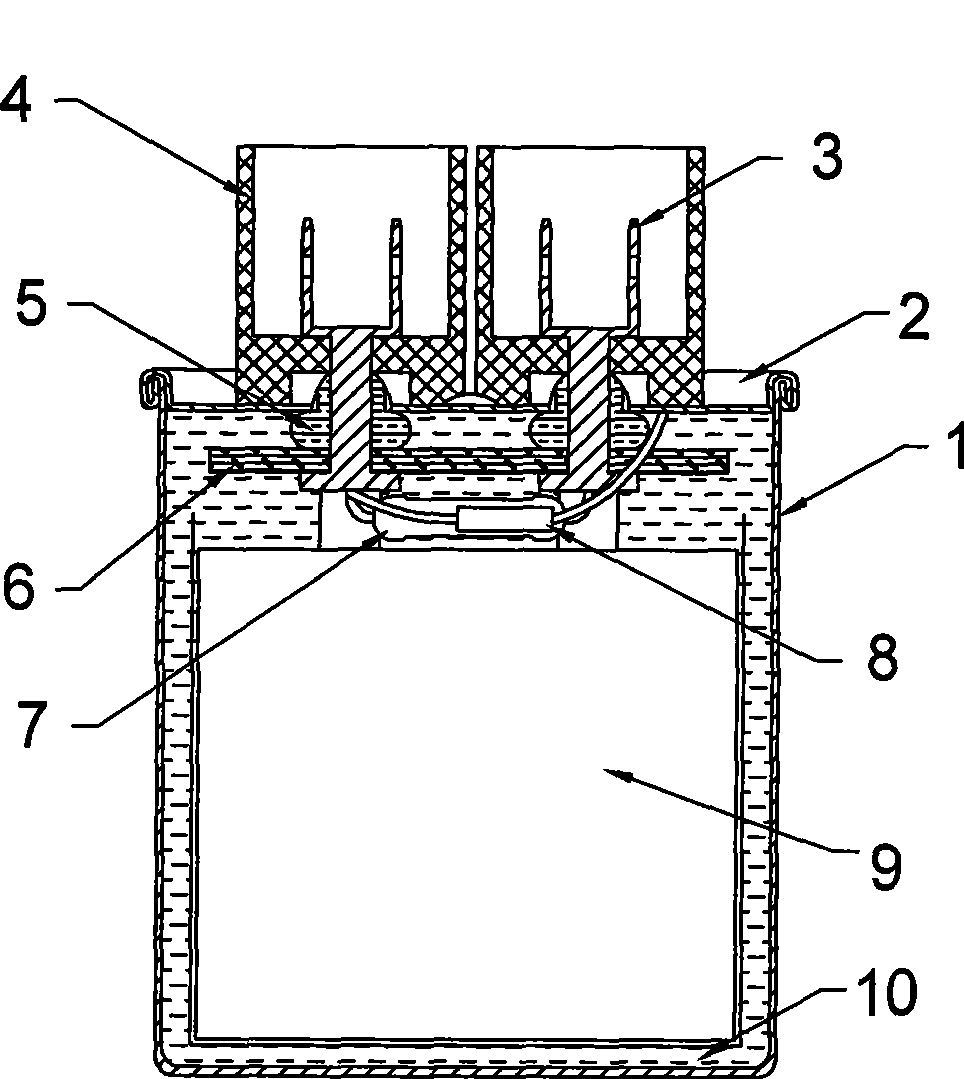

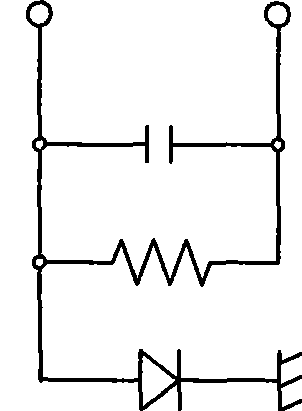

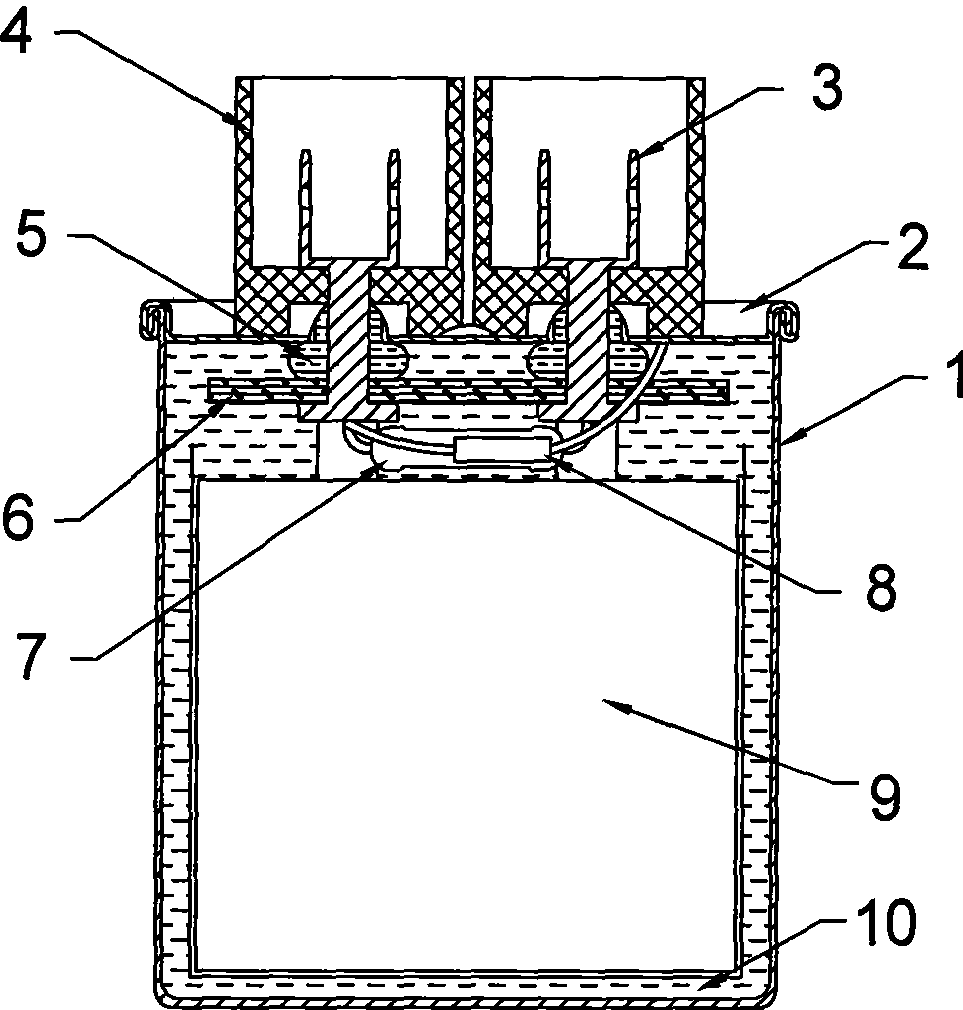

High-voltage capacitor having rectifying apparatus

InactiveCN101364481AHigh voltage strengthExtended service lifeStructural fixed capacitor combinationsCapacitanceHigh voltage capacitors

A high-voltage capacitor with a rectifying device comprises a casing (1) and two soldering terminals (3). A cover (2) is arranged at the opening end of the casing (1), a capacitor core (9) is arranged in the inner cavity of the casing (1), two electrodes of the capacitor core (9) are respectively soldered with one end of each soldering terminal (3) together, a resistor (7) is arranged between the two electrodes, the other ends of the soldering terminals (3) extend outside the cover (2), a silicon pad (5) is arranged between each soldering terminal (3) and the cover (2), and an insulating stool (4) is arranged around the end of each soldering terminal (3) extending outside the cover (2). The high-voltage capacitor also comprises a diode (8) which is arranged inside the inner cavity of the casing (1) and has one end thereof connected with the capacitor core (9) and the other end thereof connected with the cover (2), and insulating paper boards (6) are arranged between the diode (8) and the casing (1), between the diode (8) and the cover (2) and between the diode (8) and each soldering terminal (3). Compared with the prior art, the high-voltage capacitor is characterized by high withstand voltage strength of the diode, and long service life.

Owner:NINGBO BICAI IND

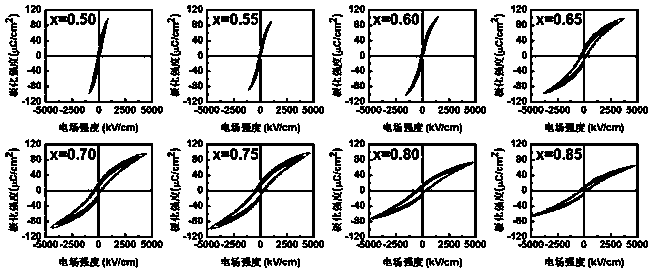

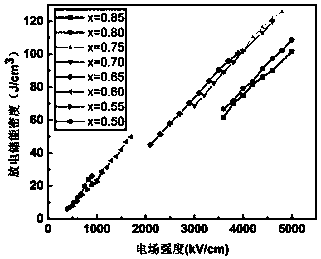

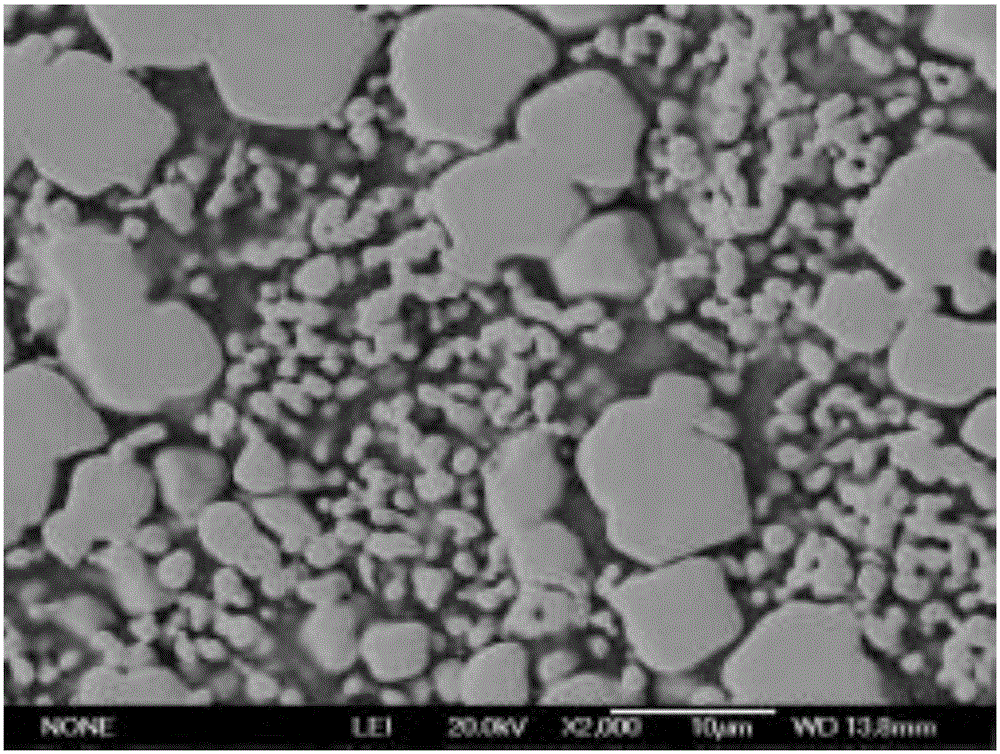

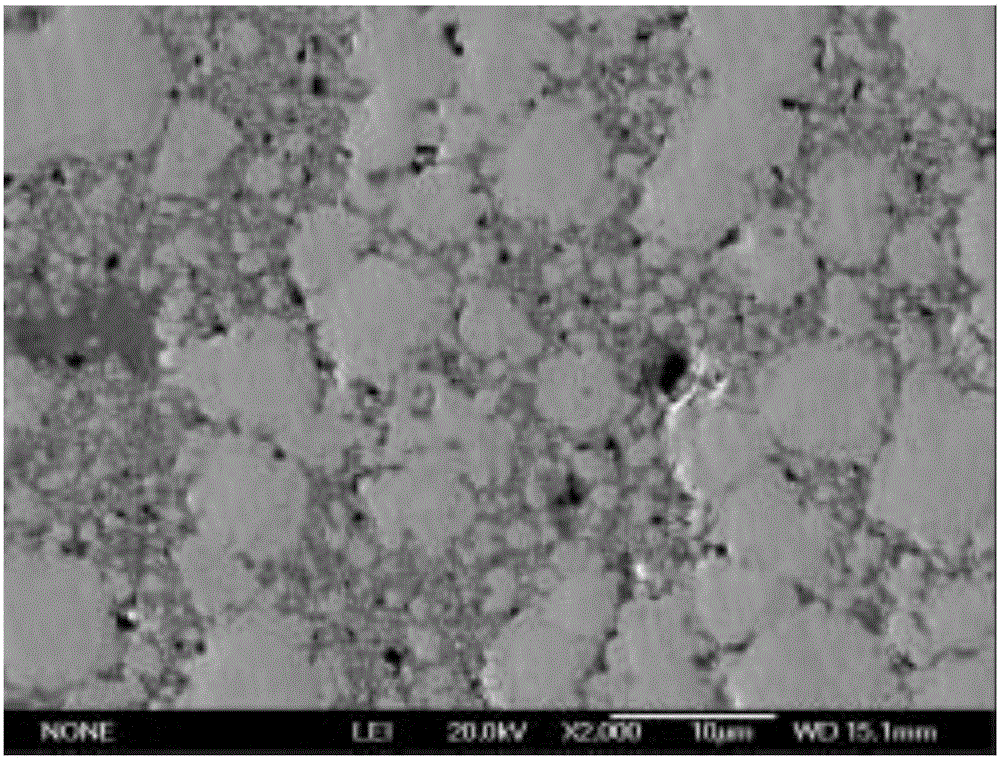

Dielectric film with ultrahigh discharge energy storage density and preparation method of dielectric film

ActiveCN108929111AGood discharge energy storage densityHigh voltage strengthFixed capacitor dielectricSolventPyrolysis

The invention provides a dielectric film with ultrahigh discharge energy storage density and a preparation method of the dielectric film. The dielectric film has a chemical formula: BiMg0.5TixO3, wherein x is equal to 0.50-0.85, the dielectric strength at room temperature reaches up to 5000 kV / cm, and the effective discharge energy storage density reaches up to 125.7 J / cm<3>. The preparation method of the dielectric film with ultrahigh discharge energy storage density comprises the steps as follows: (1) dissolving Bi(NO3)3, Mg(CH3COO)2 and Cl6H36O4Ti serving as raw materials into a mixed solution to obtain a stable precursor solution; (2) standing and ageing the prepared precursor solution to obtain uniformly-dispersed sol for spin coating; (3) coating a substrate with the sol by using a spin-coating method, and carrying out drying and pyrolysis to obtain a gel film; and (4) rapidly heating the obtained gel film in a rapid thermal treatment furnace to a required temperature, and carrying out crystallization treatment on a crystal form of the film to obtain the dielectric film with ultrahigh discharge energy storage density. The method is simple in preparation process, low in cost and pollution-free, and the prepared material has good energy storage properties.

Owner:WUHAN UNIV OF TECH

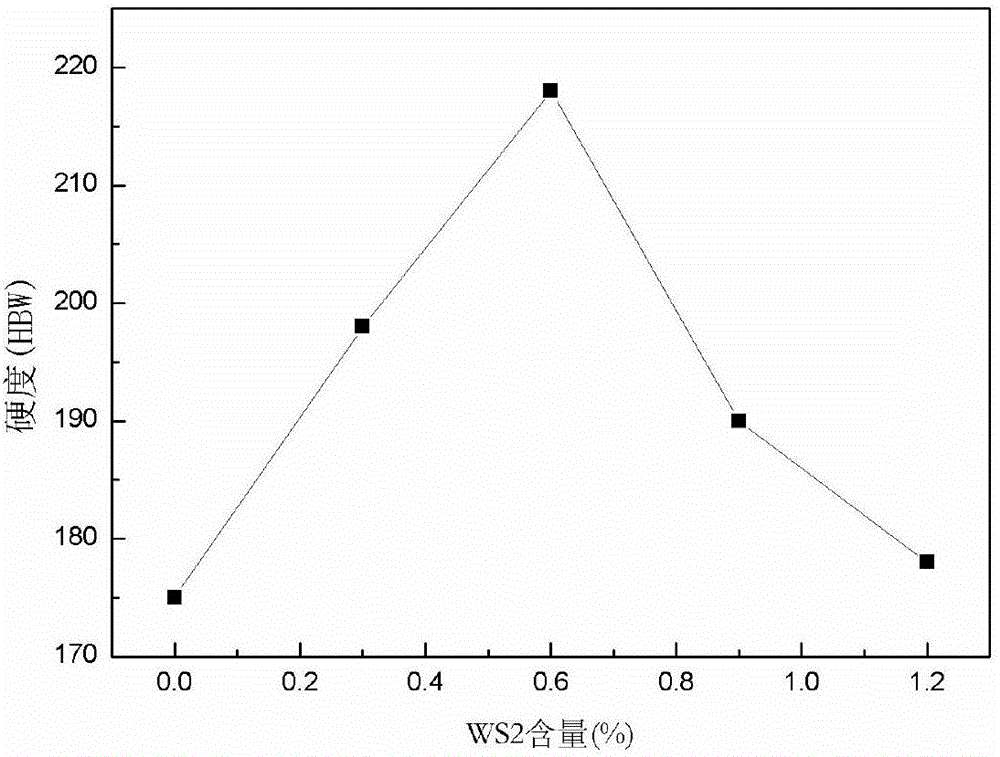

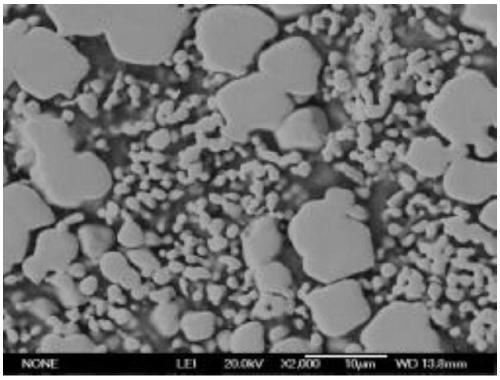

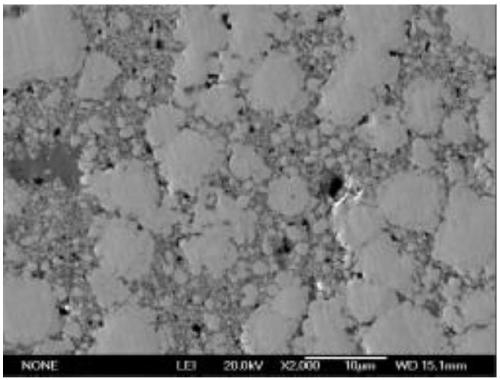

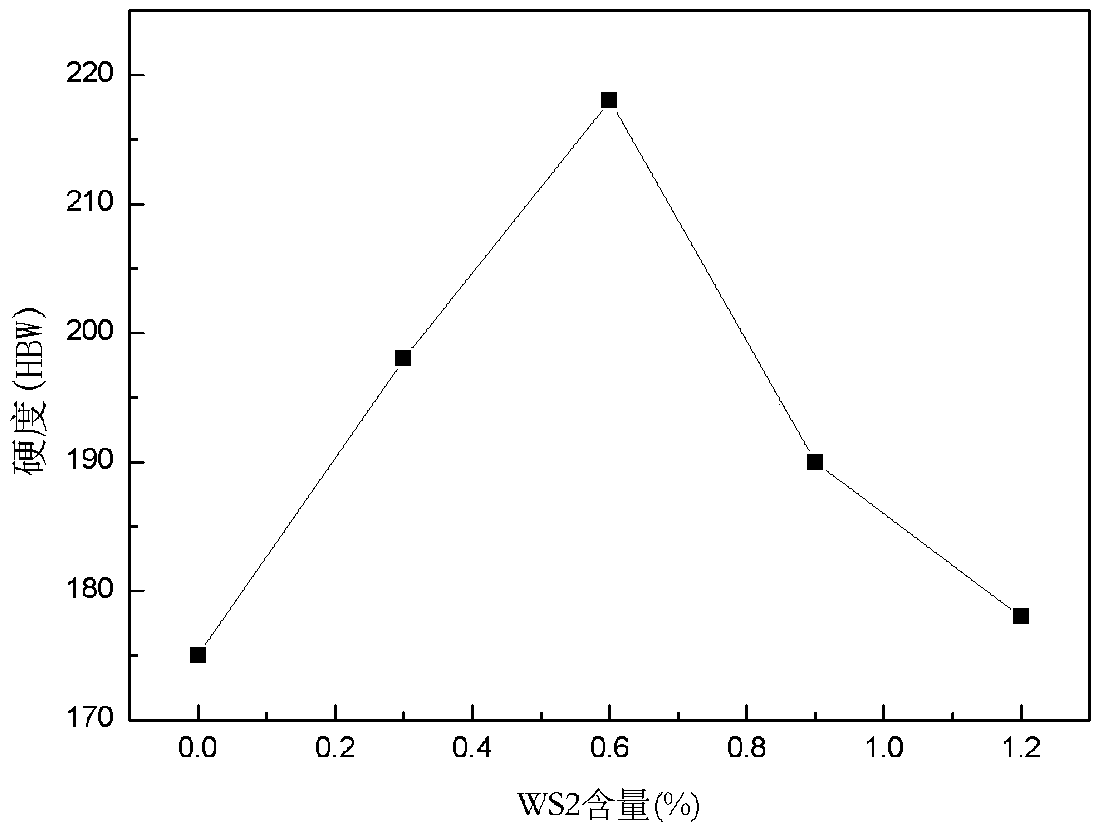

Method for improving hardness of CuW alloy

The invention discloses a method for improving the hardness of CuW alloy. After WS2, tungsten powder and Cu powder are mixed, bonding, airing and powder screening are carried out, and mixed powder is obtained; the mixed powder is pressed to form a blank through a cold pressing mold; a copper block is placed on the blank, the copper block and the blank are put in a high-purity graphite crucible together, sintering and infiltration are carried out in a hydrogen shielding atmosphere, and the CuW ally is obtained. According to the preparation method for improving the hardness of the CuW alloy, due to the fact that WS2 is added, a good W framework is formed in the alloy, the hardness of the CuW alloy is improved, and the highest hardness of the CuW alloy can reach 215 HB and is 23% higher than the national standard.

Owner:嘉兴如运建筑科技有限公司

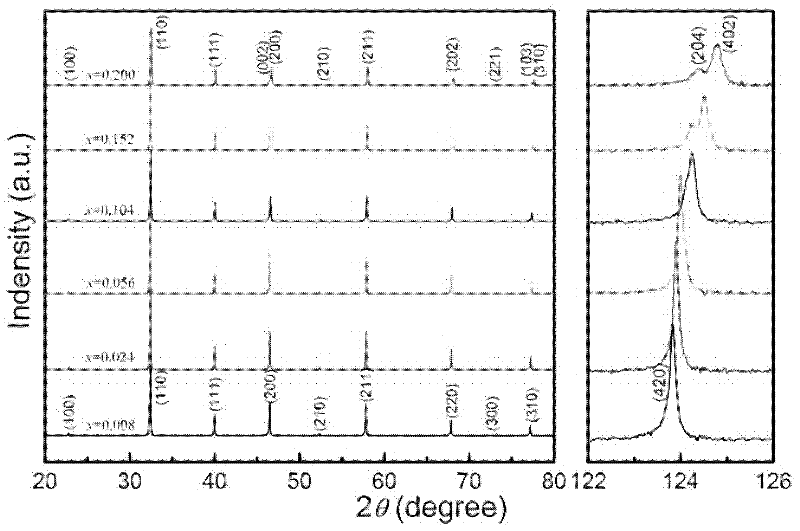

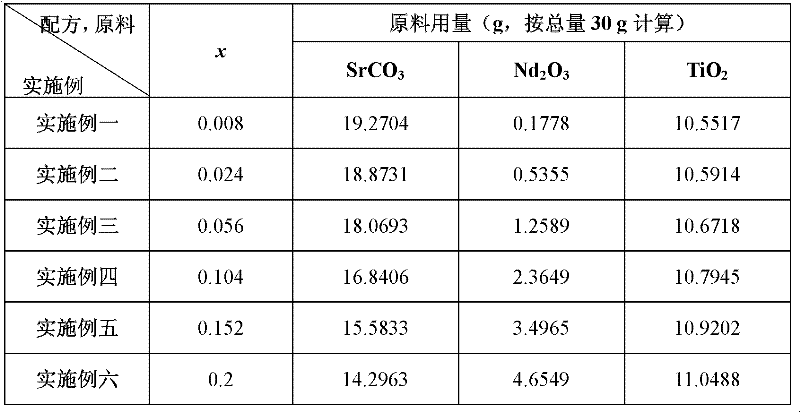

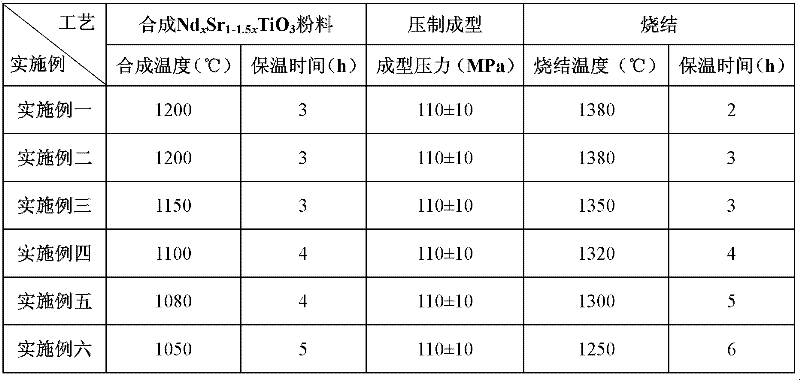

High-dielectric constant voltage-resistant rare earth-doped strontium titanate ceramic and preparation method thereof

The invention discloses high-dielectric constant voltage-resistant rare earth-doped strontium titanate ceramic. The high-dielectric constant voltage-resistant rare earth-doped strontium titanate ceramic has a general chemical formula of NdxSr1-1.5xTiO3, wherein x represents the mole number of Nd and is greater than 0 and less than or equal to 0.2. The invention also discloses a preparation method of the high-dielectric constant voltage-resistant rare earth-doped strontium titanate ceramic. The preparation method obviously improves a relative dielectric constant of a strontium titanate ceramic product, guarantees and improves dielectric strength of the strontium titanate ceramic product, realizes the technical breakthrough of a strontium titanate ceramic system material, effectively improves energy storage density and comprehensive performances of the strontium titanate ceramic product, develops an application range of the strontium titanate ceramic system material as a high-voltage energy-storage dielectric material, and greatly improves popularization and application of the strontium titanate ceramic system material.

Owner:JINGDEZHEN CERAMIC UNIV

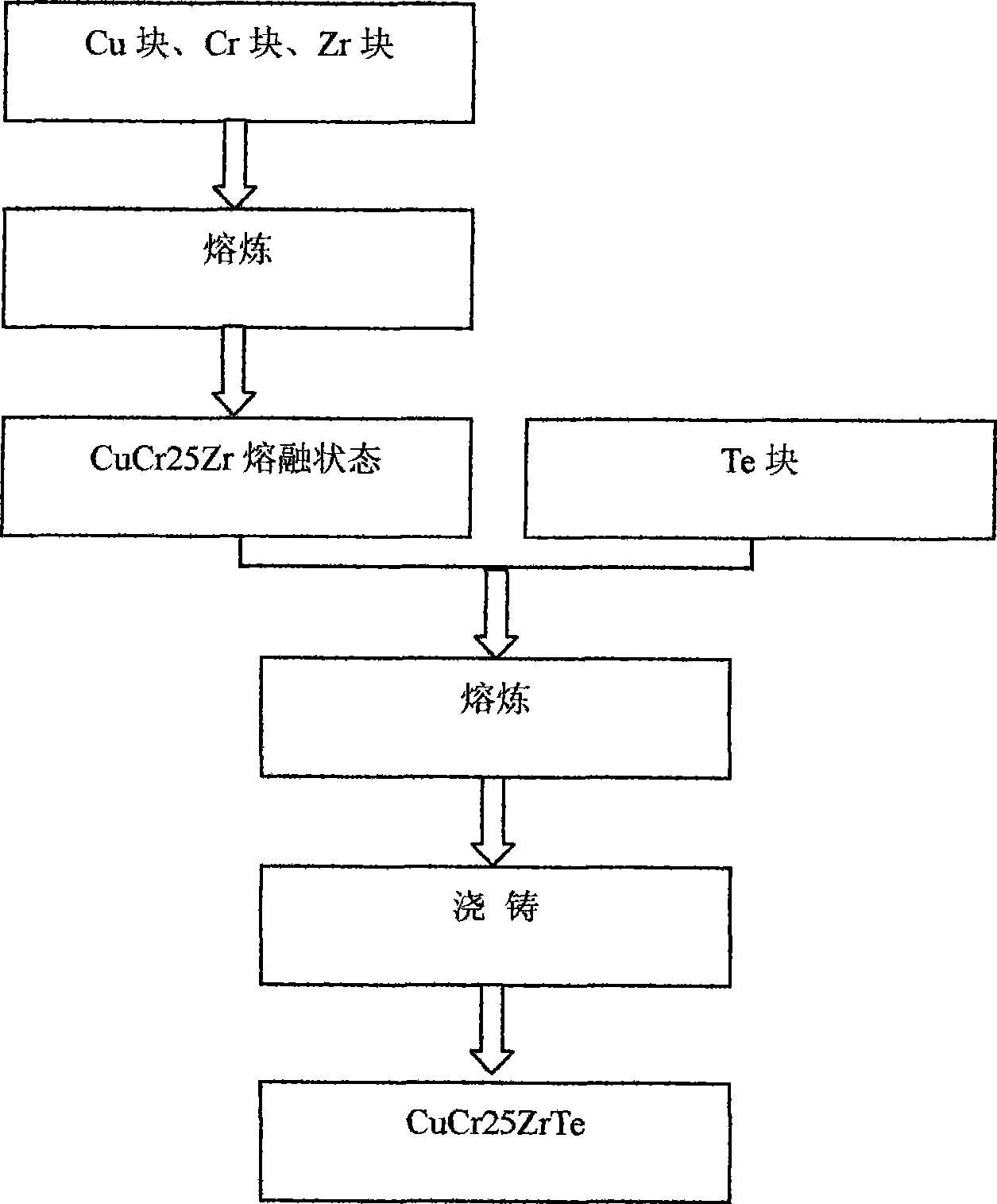

Method for preparing CuCr25ZrTe contact tip by vacuum casting process

ActiveCN101488406AReduce gas contentHigh voltage strengthElectric switchesVacuum fusionMetallic materials

The invention discloses a CuCr25ZrTe electrical contact prepared by using a vacuum fusion casting, belonging to the technical field of metallic material preparation. The components of the electrical contact are according to the percentage by weight: 25% of Cr, 0.01-0.3% of Te, 0.03-0.3% of Zr and the rest of Cu. The electrical contact is prepared by the following method: a Cu block, a Cr block and a Zr block are well mixed and put into a melting hearth; the melting is carried out in vacuum; after melting, the element Fe is added and casted after keeping a period of time; thereby CuCr25ZrTe electrical contact materials are obtained after cooling. The invention has the advantages that Zr is added into CuCr alloy, which reduces the gas content of the alloy and increases the wearing resistance of the alloy; the Te is added into CuCr alloy, which reduces the tensile strength of the alloy and increases the anti-melting welding performance. The preparation method of the invention has simple technique and low cost. Compared with CuCr25 composite materials, the prepared CuCr25ZrTe composite materials have more excellent performance.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

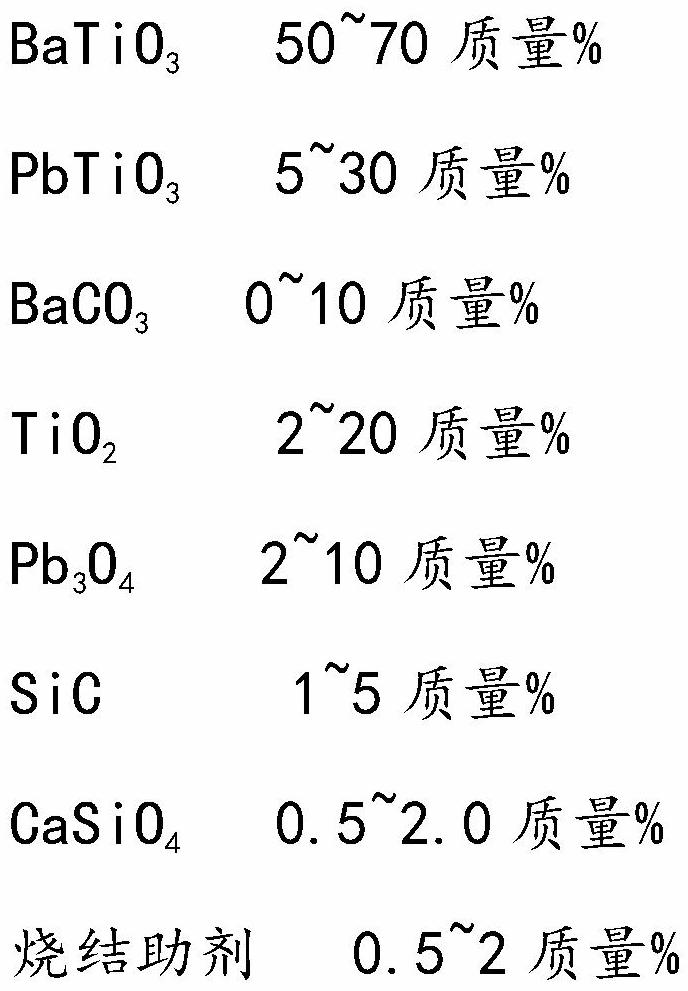

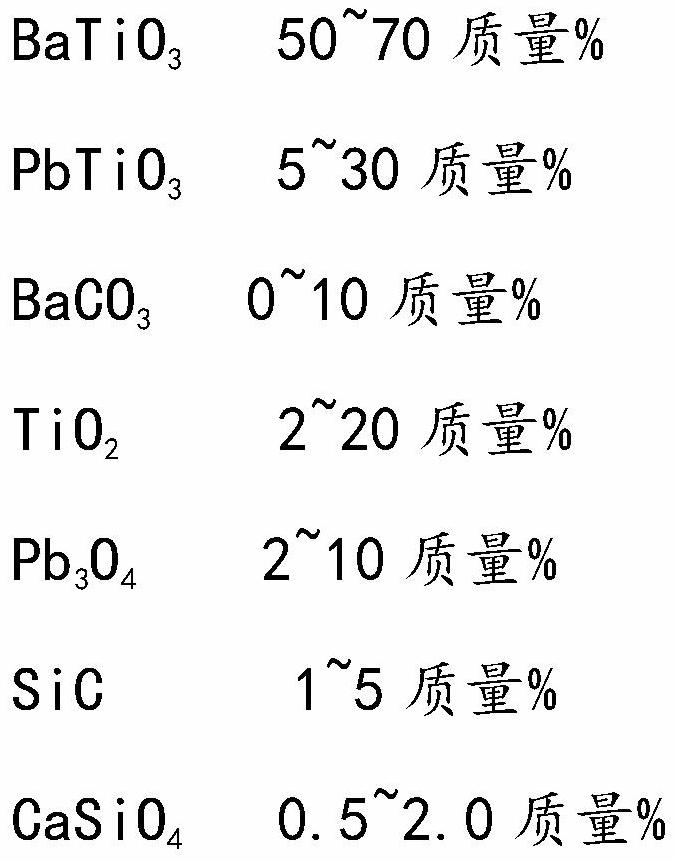

Method for manufacturing zero-power ceramic chip of PTC (Positive Temperature Coefficient) heater

PendingCN114133237ASafety and reliability guaranteedEasy to operateResistor manufacturePositive temperature coefficient thermistorsPelletizingCeramic

The invention discloses a method for manufacturing a zero-power ceramic chip of a PTC (Positive Temperature Coefficient) heater, which comprises the following steps of: grinding all components in the material of the zero-power ceramic chip of the PTC heater into powder through a ball mill, mixing to form mixed powder, and adding water as a medium; adding PVA particles or a PVA solvent as a binder, carrying out ball milling on the mixed powder, water and the binder for a preset time at the same time, and then carrying out granulation to obtain mixed powdery particles; the mixed powdery particles are pressed into a biscuit with a preset size, and the biscuit is placed in an air atmosphere with a preset temperature to be fully sintered into the compact ceramic. The zero-power ceramic chip of the PTC heater is made of waste recycled materials or sludge of PTC production enterprises. The waste treatment cost can be reduced, and the method is simple to operate, easy to control, low in cost and very suitable for industrial implementation.

Owner:江苏钧瓷科技有限公司

Ethylene glycol mixture, Al-electrolyte capacitor comprising ethylene glycol mixture and use of ethylene glycol mixture

InactiveCN1421042AReduce moisture contentWeak chemical corrosionCapacitor electrolytes/absorbentsDiethylene glycol monobutyl etherDiethylene glycol

The invention relates to an ethylene glycol mixture which is provided with diethylene glycol monobutyl ether and B2O3, in addition to ethylene glycol and sorbite. The ethylene glycol mixture is thus provided with high electric strength (up to 600 V), a low water content and self-extinguishing characteristics for the use as electrolyte in an Al electrolyte capacitor. The invention also relates to an Al electrolyte capacitor comprising the ethylene glycol mixture and to the use of the ethylene glycol mixture in Al electrolyte capacitors for voltages up to 600 V.

Owner:EPCOS AG

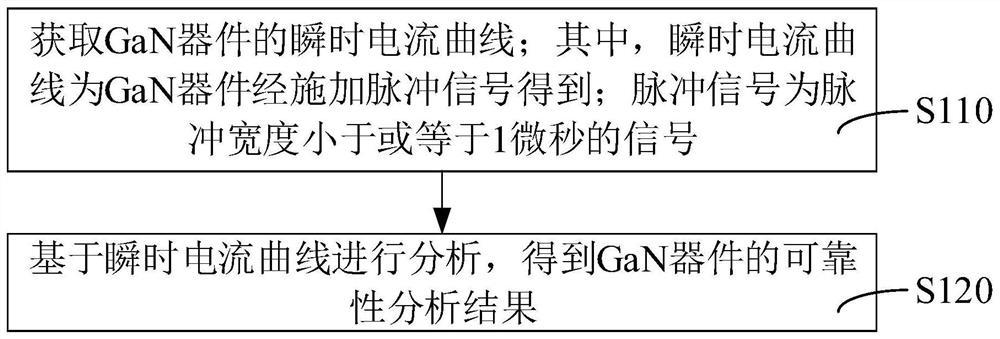

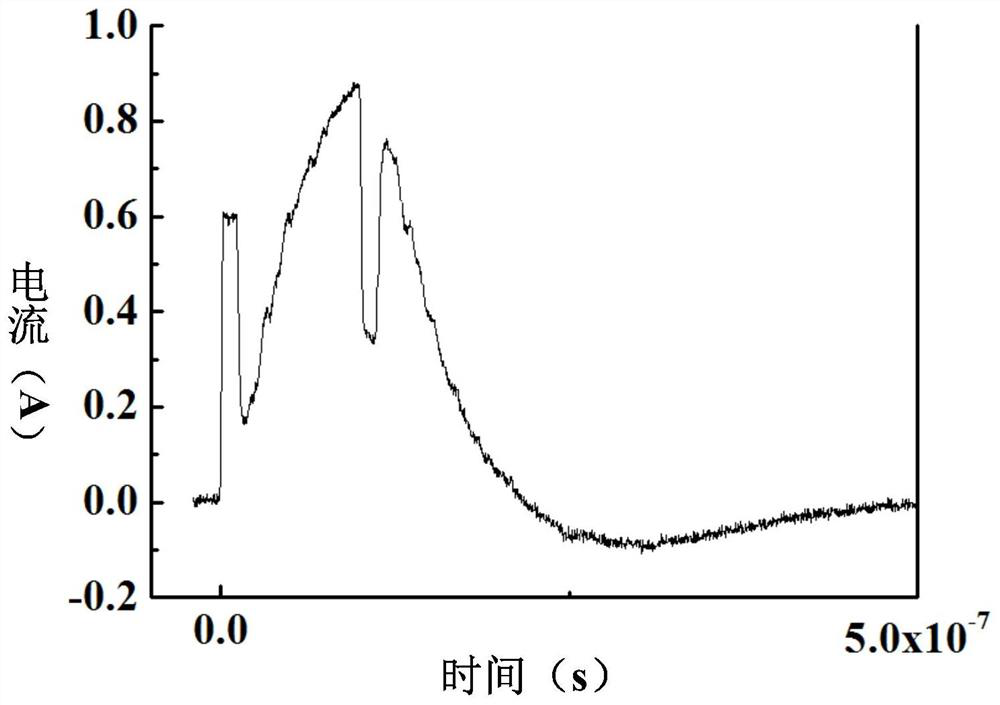

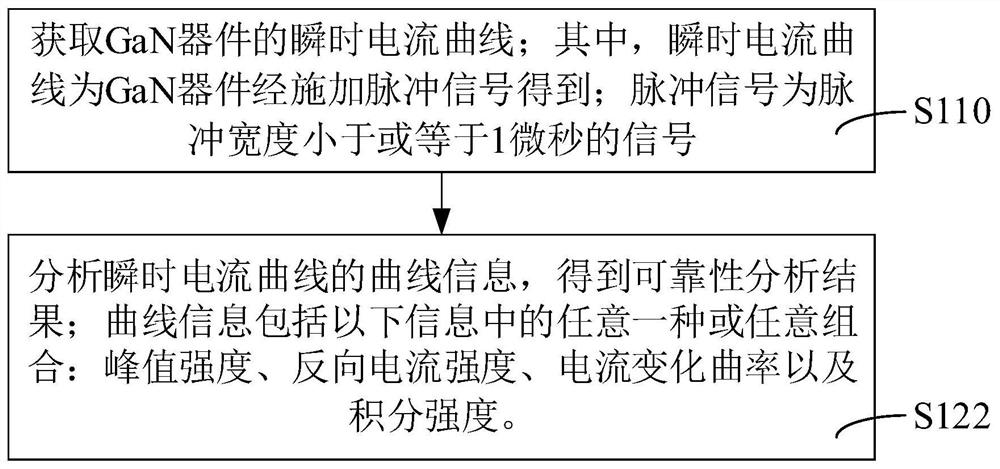

Reliability testing method, device and system of gan device

ActiveCN109596961BReliability AnalysisReal-time monitoring of current waveformIndividual semiconductor device testingComputational physicsElectric stress

The present application relates to a reliability testing method, device and system for GaN devices. The reliability testing method obtains the instantaneous current curve of the GaN device; wherein, the instantaneous current curve is obtained by applying a pulse signal to the GaN device; the pulse signal is a signal with a pulse width less than or equal to 1 microsecond. Based on the analysis of the instantaneous current curve, the reliability analysis results of the GaN device are obtained. A pulse signal with a small pulse width can apply short pulse electrical stress to the GaN device, and the gate region of the GaN device can apply a large transient cumulative voltage stress; at the same time, real-time monitoring and analysis of the current of the GaN device after each short pulse electrical stress Waveforms can obtain the dynamic whole-process behavior of device degradation and failure. The test method of the embodiment of the present application is simple and easy to operate. Under the condition of short pulse, a higher voltage intensity than the traditional test method can be applied, and the reliability of the device can be analyzed, and the advantages and disadvantages of different device structural parameters can be compared. .

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

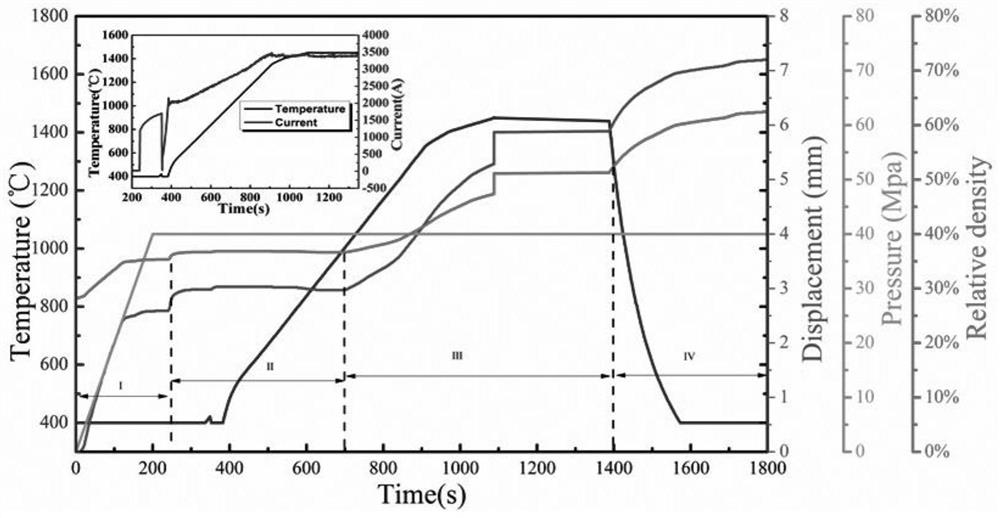

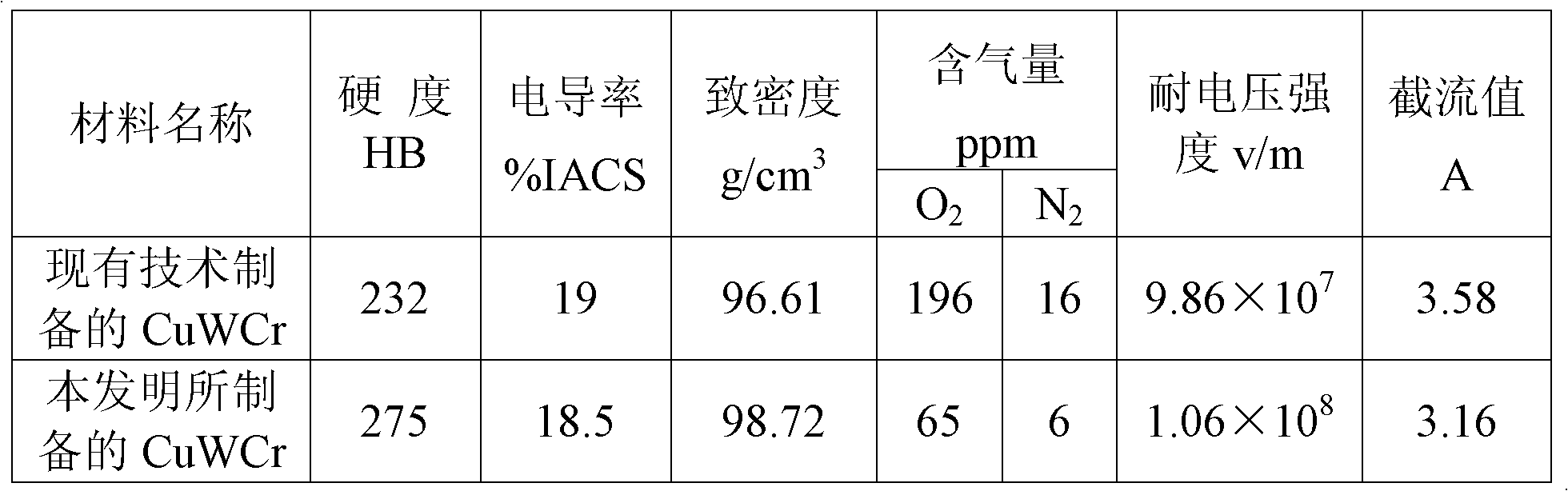

Method for preparing CuWCr composite material in consumable electrode arc-melting furnace

The invention discloses a method for preparing CuWCr composite material in a consumable electrode arc smelting furnace. First, Cu powder, W powder and Cr powder are mixed in a mixer according to the mass percentage, and then the mixed powder is molded or cold isostatic pressing; then place the pressed billet in a vacuum sintering furnace, and raise the temperature to 950°C to 1050°C for sintering in a vacuum environment with a vacuum degree greater than 10-2Pa to obtain a CuWCr sintered billet. Finally, the CuWCr sintered blank is placed in a vacuum consumable electrode arc melting furnace, and melted in a vacuum environment, so that the CuWCr blank is melted and dropped into a water-cooled copper crucible under the high temperature of the arc, and taken out after cooling to obtain a CuWCr composite material. . The invention combines smelting and directional solidification to prepare a CuWCr composite material with excellent comprehensive properties such as uniform and fine structure, high voltage resistance strength, high density, low gas content, and less impurities.

Owner:XIAN UNIV OF TECH

Solid bus slot with high strength

InactiveCN101552441BThere will be no mutual "extended bite"Convenient thermal protectionBus-bar installationElectrical conductorEngineering

The invention discloses a solid bus slot with high strength which consists of a shell made of the composite materials, the composition of the composite materials and a preparation method thereof. By adopting the bus slot, as the shell of the bus slot made of the composite materials, the bus slot has good hydrolytic resistance and good anti-salt fog performance. The withstand voltage is as high as5000V or more; and as the linear expansion coefficient of the composite materials are very close to the conductor, the situation of 'extended bite' with each other can not appear due to the mixed-assembled with a plurality of materials with different expansion coefficients, thus improving the insulation protection of the bus slot and having very high insulation performance. The mechanical strengthof the bus slot made of the composite materials is high, which can withstand 15 Joules impact strength. The overload capability of the bus slot is strong, the anti inter-phase short circuit ability is good, the low temperature resistance is good, the protection grade can achieve IP68, and the use life is longer than that of the metal.

Owner:JIANGSU JIANGCHENG ELECTRIC

Dielectric layer lead-less glasses material for plasma display screen

The present invention discloses a lead-free glass frit for the dielectric layer of a plasma display, and the glass frit comprises the following raw materials according to the weight percentage: 30%-50% of Bi2O3, 5%-40% of B2O3, 5%-30% of BaO, 0.1%-10% of Al2O3, 0.1%-10% of ZnO, 0.1%-10% of MgO and0.1%-5% of La2O3. The invention has the advantages that the glass frit belongs to environment-friendly materials; various performances are excellent; the cost performance is high; the glass frit has suitably and easily adjusted thermal expansion coefficient and proper sintering temperature, and also has good chemical stability and high dielectric strength; the competitive power is very strong in lead-free performance and cost performance; and the glass frit has wide market development prospect.

Owner:陈培

A kind of preparation method of copper tungsten alloy and cuw-crcu integral material

InactiveCN106381411BImproved arc erosion resistanceHigh voltage strengthContact materialsTransportation and packagingHydrogenNational standard

The invention discloses a preparation method of a copper-tungsten alloy. After mixing submicron tungsten powder, micron tungsten powder, supermicron tungsten powder and induced Cu powder, they are bonded, dried and sieved to obtain a mixed Powder; the mixed powder is pre-pressed to form a blank, and then the blank is sintered and infiltrated. The CuW alloy and CrCu material prepared above were placed in a high-purity graphite crucible for sintering under a hydrogen protective atmosphere, and then solid solution aging treatment was performed to obtain a CuW-CrCu monolithic material. The present invention prepares CuW alloys with multi-particle sizes by adding different contents of sub-micron and ultra-micron tungsten powders to conventional micron-sized tungsten powders, and the electrical conductivity of the prepared alloys is significantly improved, which is 30% to 50% higher than the national standard . The arc erosion resistance of the CuW alloy prepared under this scheme is enhanced, and its withstand voltage strength is improved; the bonding strength of the prepared CuW‑CrCu monolithic material is significantly improved.

Owner:XIAN UNIV OF TECH

Electrolyte for middle-high voltage aluminium electrolytic capacitor and preparation method thereof

InactiveCN107195461AImprove thermal stabilityReduce leakage currentLiquid electrolytic capacitorsHydrogenPhysical chemistry

The invention discloses electrolyte for a middle-high voltage aluminium electrolytic capacitor and a preparation method thereof. The electrolyte comprises the following components in percentage by mass: 79% to 80% of ethylene glycol, 1.0% to 1.5% of deionized water, 3.5% to 5% of nano TiO2, 8% to 9% of ammonium azelate, 4.0% to 4.5% of azelaic acid, 0.20% to 0.25% of hydrogen removal agent, 0.40% to 0.50% of stopping agent, 0.20% to 0.25% of sparking voltage agent, 0.20% to 0.25% of leakage current inhibitor and 0.20% to 0.25% of additive for improving forming characteristics. By adopting the technical scheme, a sparking voltage and cation repair oxidation capacity of the electrolyte can be improved, precipitation of hydrogen and generation of water in the working process are reduced, quality of the electrolyte is improved, and management and control of European Union REACH regulations on boric acid substances are met.

Owner:FOSHAN UNIVERSITY

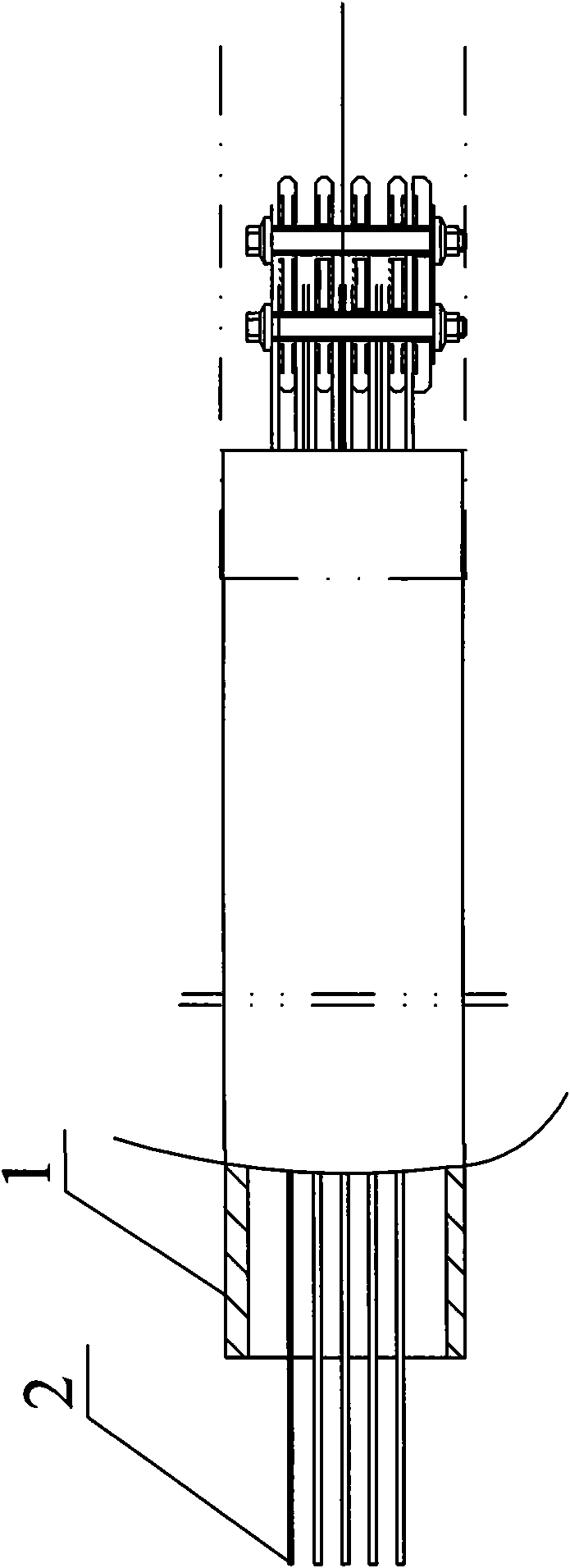

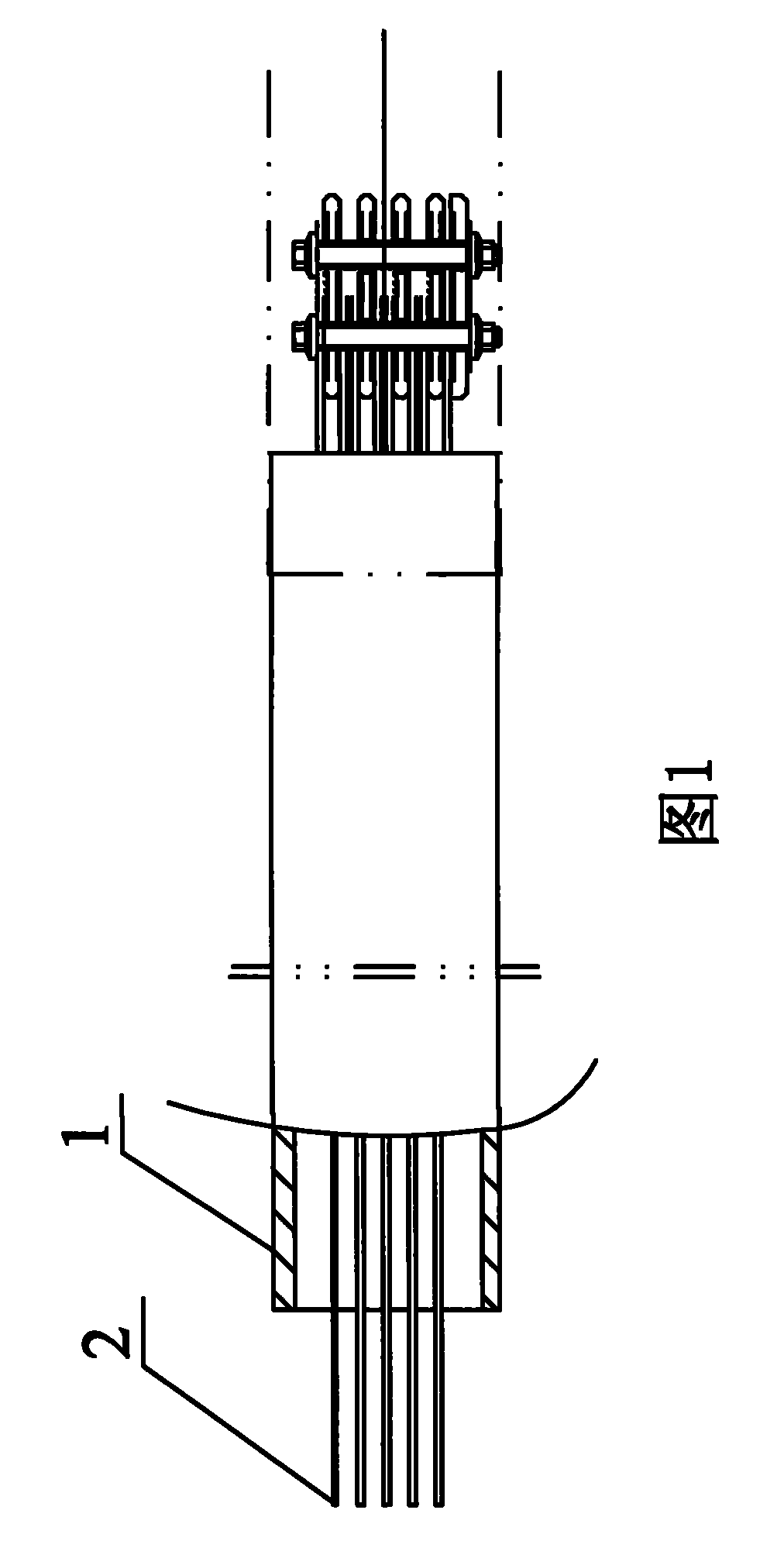

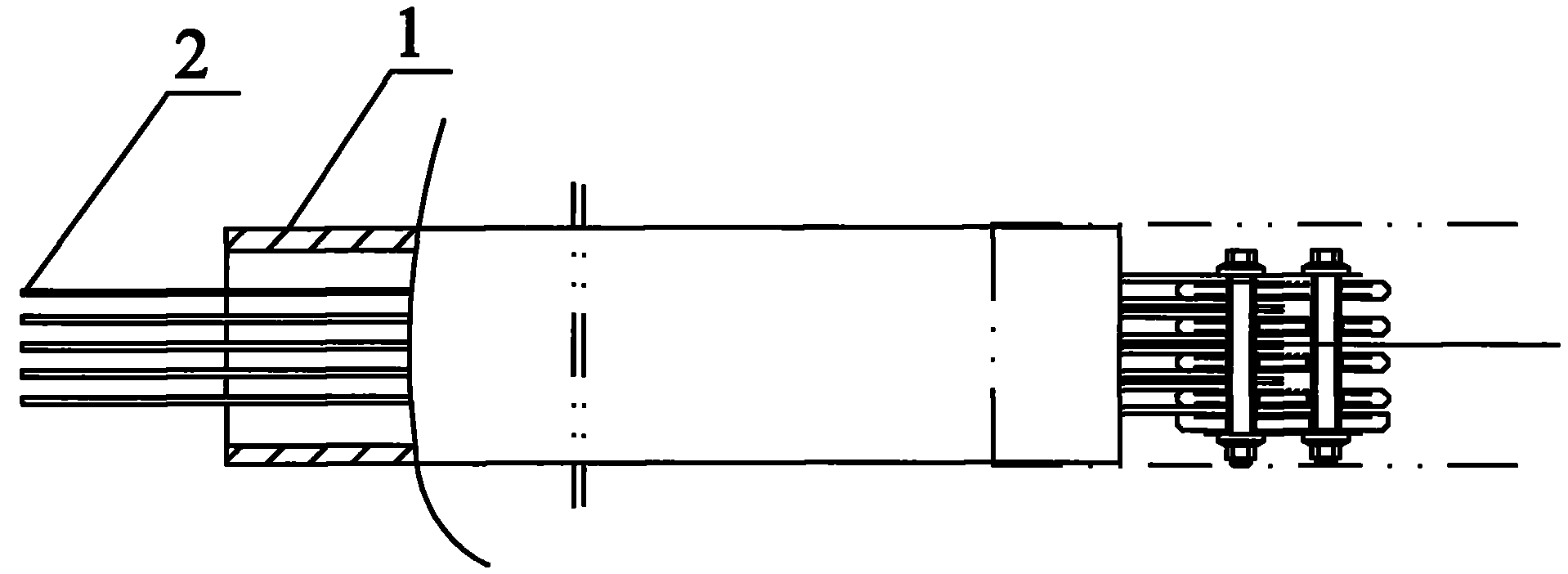

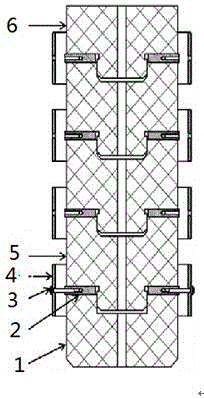

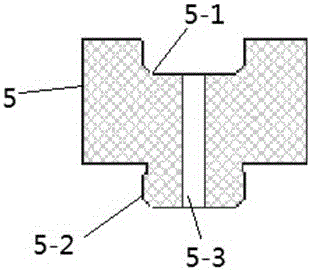

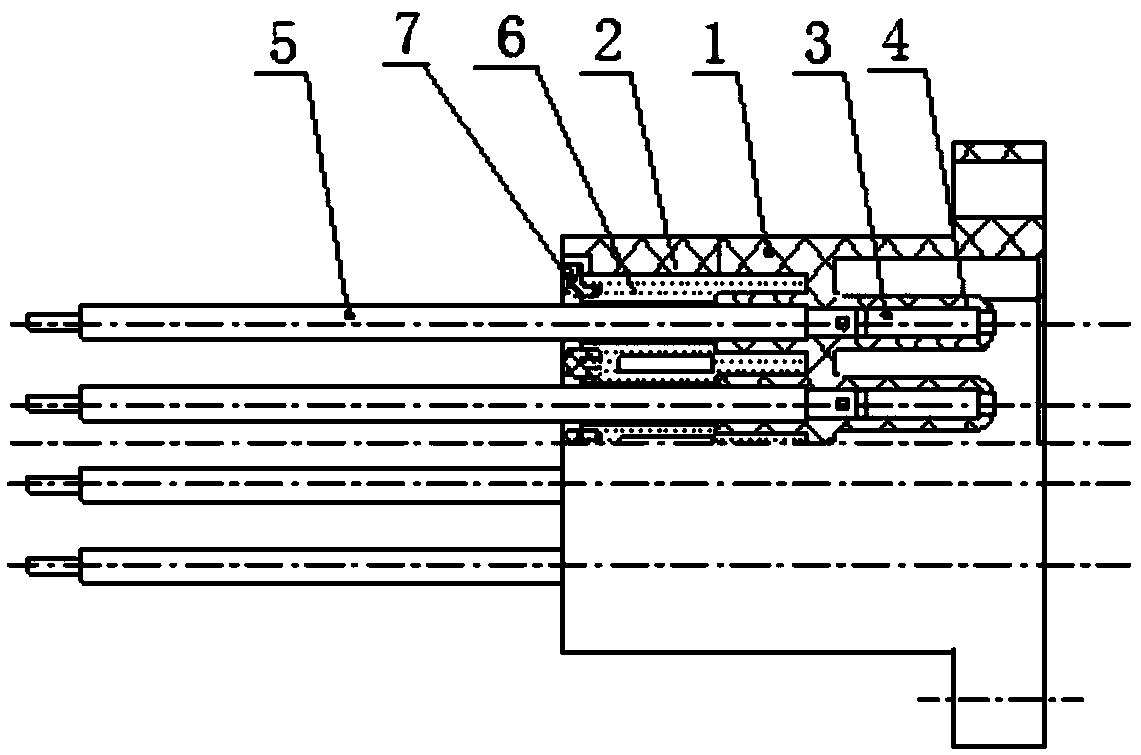

An integrated multi-stage high-voltage pulse isolation inductor

ActiveCN104376987BLower resistanceAvoid dissipationTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionElectrical resistance and conductanceHigh voltage pulse

The invention discloses an integrated multi-stage high-voltage pulse isolation inductor. The integrated multi-stage high-voltage pulse isolation inductor comprises a plurality of insulating connecting sections connected in sequence, a copper ring electrode is clamped between every two adjacent insulating connecting sections, each copper ring electrode is coaxially sleeved with a tubular voltage-sharing electrode, and each voltage-sharing electrode and the corresponding copper ring electrode are connected into a whole through bolts. The integrated multi-stage high-voltage pulse isolation inductor further comprises a wire, and the wire is evenly and spirally wound on the outer surface of the insulating connecting sections connected into a whole and is connected with each copper ring electrode in a pressing mode through bolts. The integrated multi-stage high-voltage pulse isolation inductor is higher in voltage resistance strength, small in contact resistance and compact in structure.

Owner:九源高能科技有限公司

High-voltage electric connector with integrated molding structure

PendingCN109546422AMeet the needs of useIncrease creepage distanceSecuring/insulating coupling contact membersCouplings bases/casesElectricityHigh tension leads

The invention discloses a high-voltage electric connector with an integrated molding structure. The high-voltage electric connector comprises a housing, a wire protecting sleeve connected to the front end of the housing, and a plurality of jack contact elements, a plurality of contact element positioning tubes are fixed in the housing, the plurality of jack contact elements are respectively inserted into the corresponding contact element positioning tubes, and a plurality of high-voltage wires pass through the wire protecting sleeve and are electrically connected with the jack contact elements in the housing. The shell, the wire protecting sleeve and the plurality of contact piece positioning pipes are of an integrated molding structure. The rear ends of the contact positioning tubes areof a closed structure, and the front ends of the contact positioning tubes are all adjacent to the front end of the shell. The shell and the wire protecting sleeve are of an integrated molding structure, so that the assembly process is reduced, the production cost of a product is reduced, the assembly efficiency of the product is improved, the supply period of the product is shortened, and the use requirements of users are met.

Owner:中国电子科技集团公司第四十研究所

High-voltage capacitor having rectifying apparatus

InactiveCN101364481BHigh voltage strengthExtended service lifeStructural fixed capacitor combinationsCapacitanceHigh voltage capacitors

A high-voltage capacitor with a rectifying device comprises a casing (1) and two soldering terminals (3). A cover (2) is arranged at the opening end of the casing (1), a capacitor core (9) is arranged in the inner cavity of the casing (1), two electrodes of the capacitor core (9) are respectively soldered with one end of each soldering terminal (3) together, a resistor (7) is arranged between thetwo electrodes, the other ends of the soldering terminals (3) extend outside the cover (2), a silicon pad (5) is arranged between each soldering terminal (3) and the cover (2), and an insulating stool (4) is arranged around the end of each soldering terminal (3) extending outside the cover (2). The high-voltage capacitor also comprises a diode (8) which is arranged inside the inner cavity of the casing (1) and has one end thereof connected with the capacitor core (9) and the other end thereof connected with the cover (2), and insulating paper boards (6) are arranged between the diode (8) and the casing (1), between the diode (8) and the cover (2) and between the diode (8) and each soldering terminal (3). Compared with the prior art, the high-voltage capacitor is characterized by high withstand voltage strength of the diode, and long service life.

Owner:NINGBO BICAI IND

ptcr ceramic material, preparation method and application

ActiveCN107226694BImprove microstructureUnique physical propertiesPositive temperature coefficient thermistorsElectronic ceramicsCeramic materials

The invention relates to the field of electronic ceramics and provides a PTCR ceramic material and a preparation method and application thereof. The PTCR ceramic material has a general formula x(BaTiO3)-y(SrTiO3)-(1-x-y)(CaTiO3)+a mol% M+b mol% N, x is greater than or equal to 0.6 and less than or equal to 0.9, y is greater than or equal to 0.1 and less than or equal to 0.4, a is greater than or equal to 0.1 and less than or equal to 1, b is greater than or equal to 0 and less than or equal to 3, the sum of x and y is less than or equal to 1, M represents any one or more of Y2O3, Bi2O3, La2O3, Sm2O3, Nb2O5, Ta2O5 and Sb2O5, and N represents any one or more of MnO2, CuO, Fe2O3, ZrO2, Al2O3, SiO2, TiO2, BN and B2O3. The PTCR ceramic material has the advantages of low Curie temperature, high resistance abrupt change ratio and high resistance temperature coefficient.

Owner:TONGREN UNIV

A method for improving the hardness of cuw alloy

The invention discloses a method for improving the hardness of CuW alloy. After WS2, tungsten powder and Cu powder are mixed, bonding, airing and powder screening are carried out, and mixed powder is obtained; the mixed powder is pressed to form a blank through a cold pressing mold; a copper block is placed on the blank, the copper block and the blank are put in a high-purity graphite crucible together, sintering and infiltration are carried out in a hydrogen shielding atmosphere, and the CuW ally is obtained. According to the preparation method for improving the hardness of the CuW alloy, due to the fact that WS2 is added, a good W framework is formed in the alloy, the hardness of the CuW alloy is improved, and the highest hardness of the CuW alloy can reach 215 HB and is 23% higher than the national standard.

Owner:嘉兴如运建筑科技有限公司

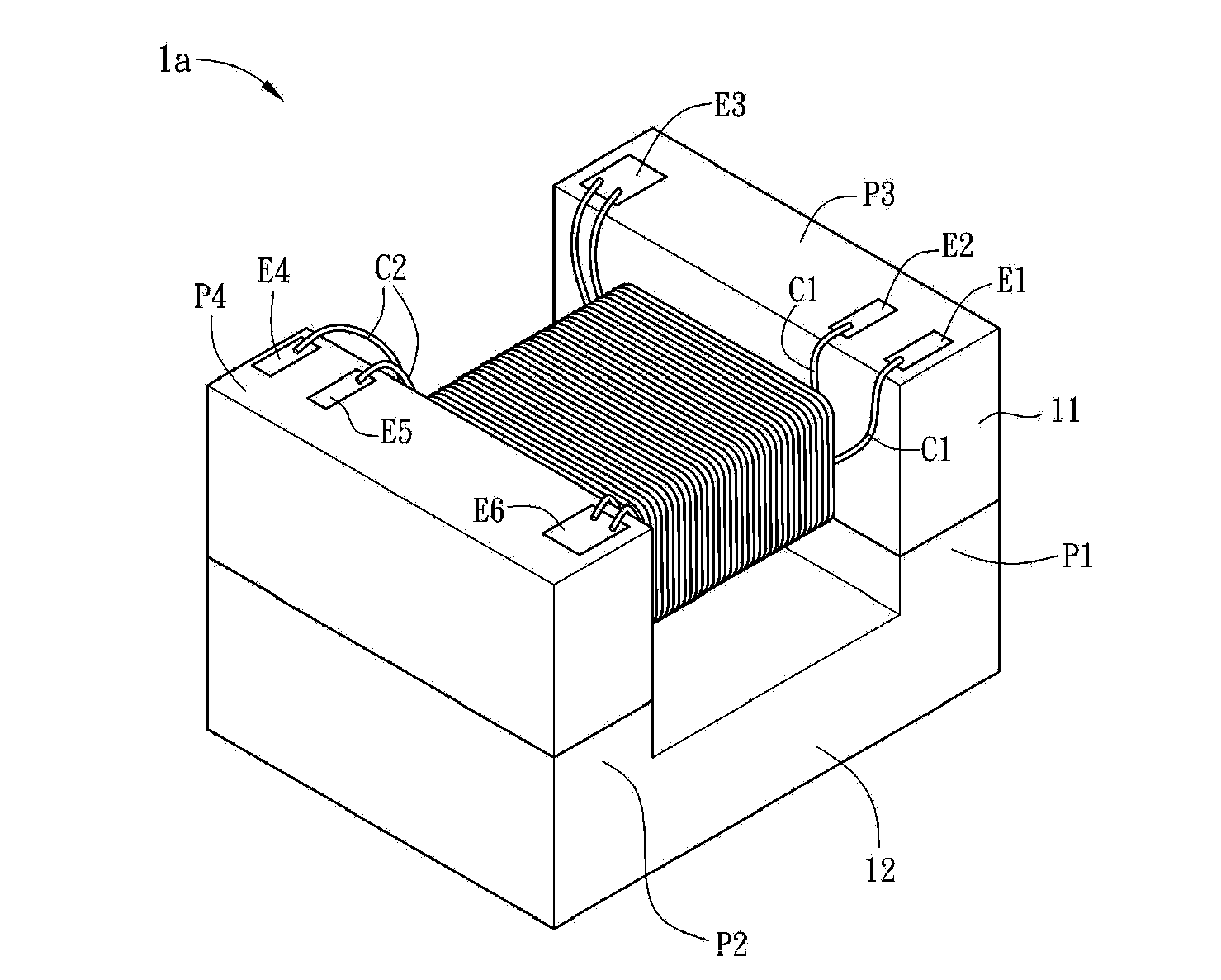

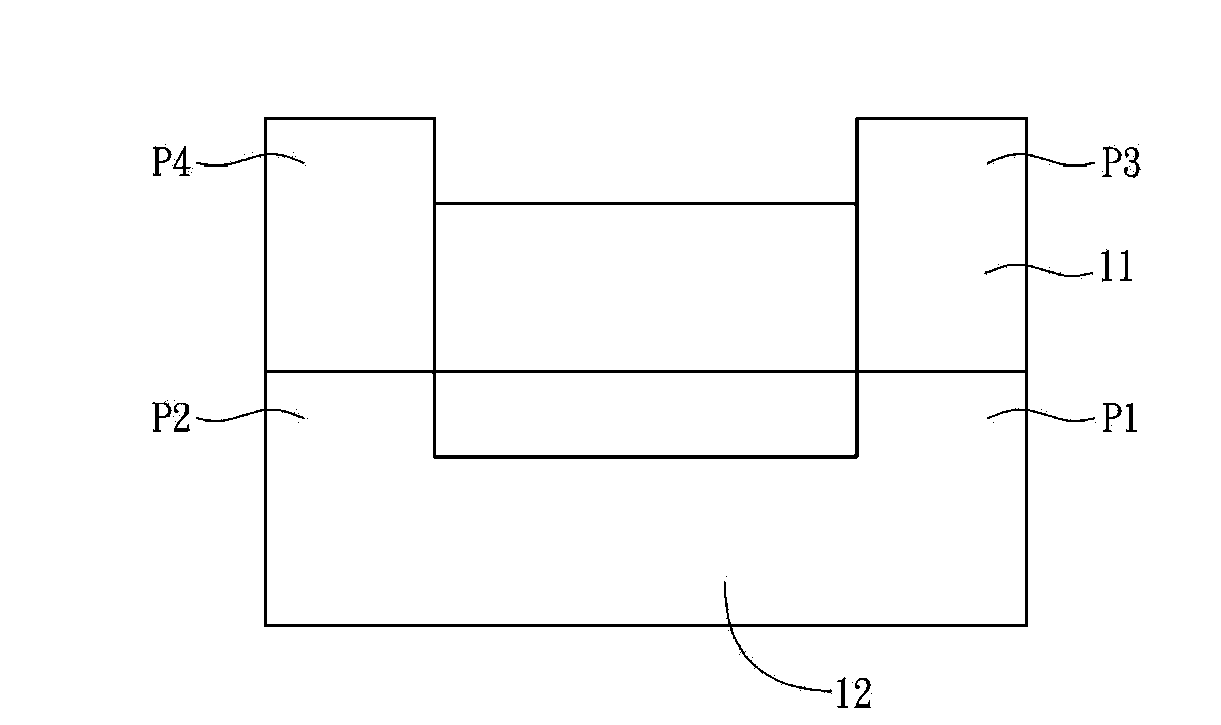

Transformer

InactiveCN104103401AImprove permeabilityHigh voltage strengthTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEngineeringConductor Coil

The invention discloses a transformer, which comprises a first magnetic conduction element, a primary winding and a second magnetic conduction element, wherein the primary winding is arranged around the first magnetic conduction element, a secondary winding is arranged around the first magnetic conduction element, the second magnetic conduction element comprises a first flange and a second flange, the first flange is arranged at one end of the second magnetic conduction element, the second flange is arranged at the other end of the second magnetic conduction element, the first flange and the second flange are connected with the first magnetic conduction element, and in addition, the magnetic conductivity of the second magnetic conduction element is greater than the magnetic conductivity of the first magnetic conduction element.

Owner:DELTA ELECTRONICS INC

High-voltage-resistant-strength glass fiber reinforced polyester material and preparing method thereof

The invention discloses a high-voltage-resistant-strength glass fiber reinforced polyester material. After glass fibers are pretreated at the ultralow temperature with a physical method, the bending resistance, the tensile performance and the wear resistance of the glass fibers are improved; original sizing materials on the surfaces of the glass fibers are oxidized and decomposed through high-temperature treatment, and water stored and adsorbed by the glass fibers is removed accordingly; then modification porosity carbon-nano-tube materials are grafted on the surfaces of the glass fibers with a chemical method, and a hole structure is formed; when the glass fibers and a matrix are compounded, some chain segments of high polymers enter holes to achieve the anchoring-similar effect. In this way, binding force between interfaces of the glass fibers and the polymers is increased, and the impact resistance of a product is improved; meanwhile, nylon 6 is creatively compounded into unsaturated polyester, the special performance of the nylon 6 and the special performance of the unsaturated polyester are achieved, and the prepared glass fiber reinforced polyester material has the advantages of being low in shrinkage rate and high in voltage-resistant strength, mechanical performance and anti-corrosion capability.

Owner:WUHU EDISON AUTOMATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com